Hydraulic elastic chuck and clamping method thereof

An elastic collet and hydraulic technology, which is applied in the field of mechanical processing, can solve the problem of not being able to determine that the starting processing position of the workpiece is the same, affecting the processing accuracy and production efficiency of the product, and poor self-centering accuracy of the mechanical three-jaw chuck. problems, to achieve the effect of simple structure, improved machining accuracy and production efficiency, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

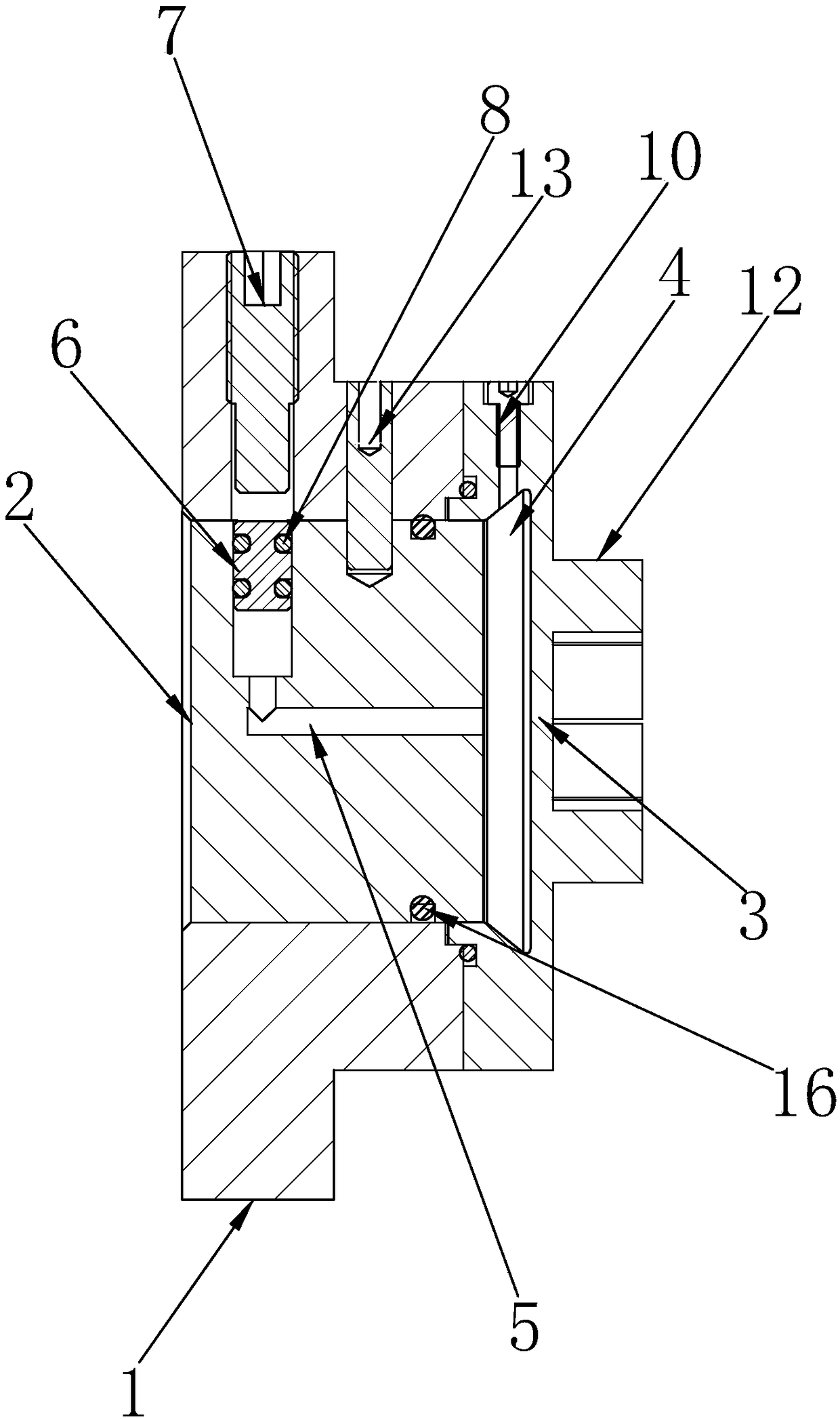

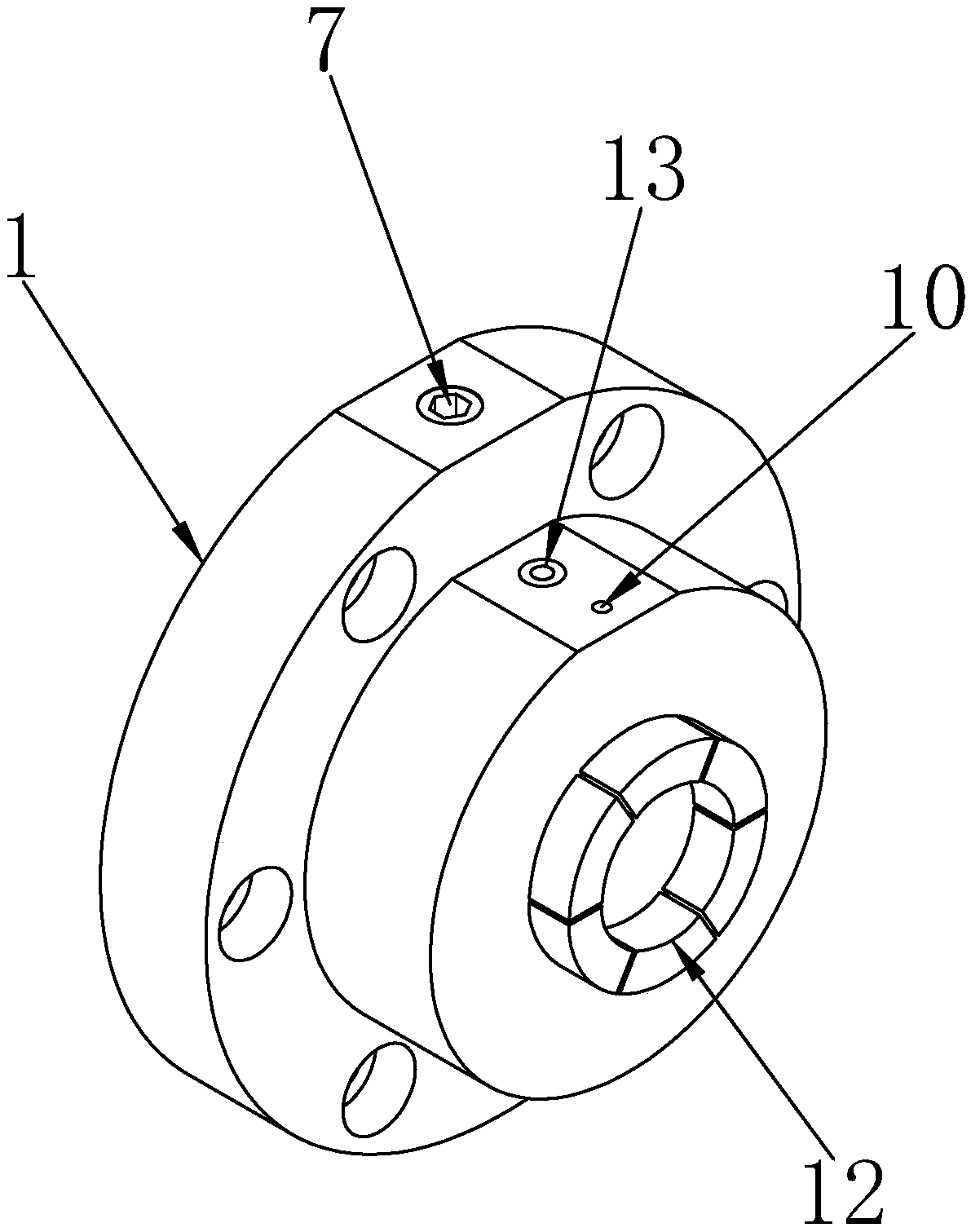

[0038] A hydraulic collet, such as figure 1 and figure 2 As shown, an overcoat 1 is included, and the front end of the overcoat 1 is provided with a chuck body. The rear end is provided with an inner cavity, and the inner cavity is sleeved with an inner core 2. In this embodiment, the chuck body includes a thin wall 3 and several claws 12 arranged at the front end of the thin wall 3 along the circumferential direction. In this embodiment, preferably Six claws 12 are used, and the six claws 12 form a ring along the circumference. The area between the front end of the inner core 2 and the rear end of the thin wall 3 forms an oil chamber 4, and an oil chamber 4 is provided between the inner core 2 and the inner chamber. The third sealing ring 16 ensures good sealing performance in the oil chamber through the third sealing ring 16. The inner core 2 is provided with an oil passage 5 communicating with the oil chamber 4, and the outlet of the oil passage 5 is provided with a movab...

Embodiment 2

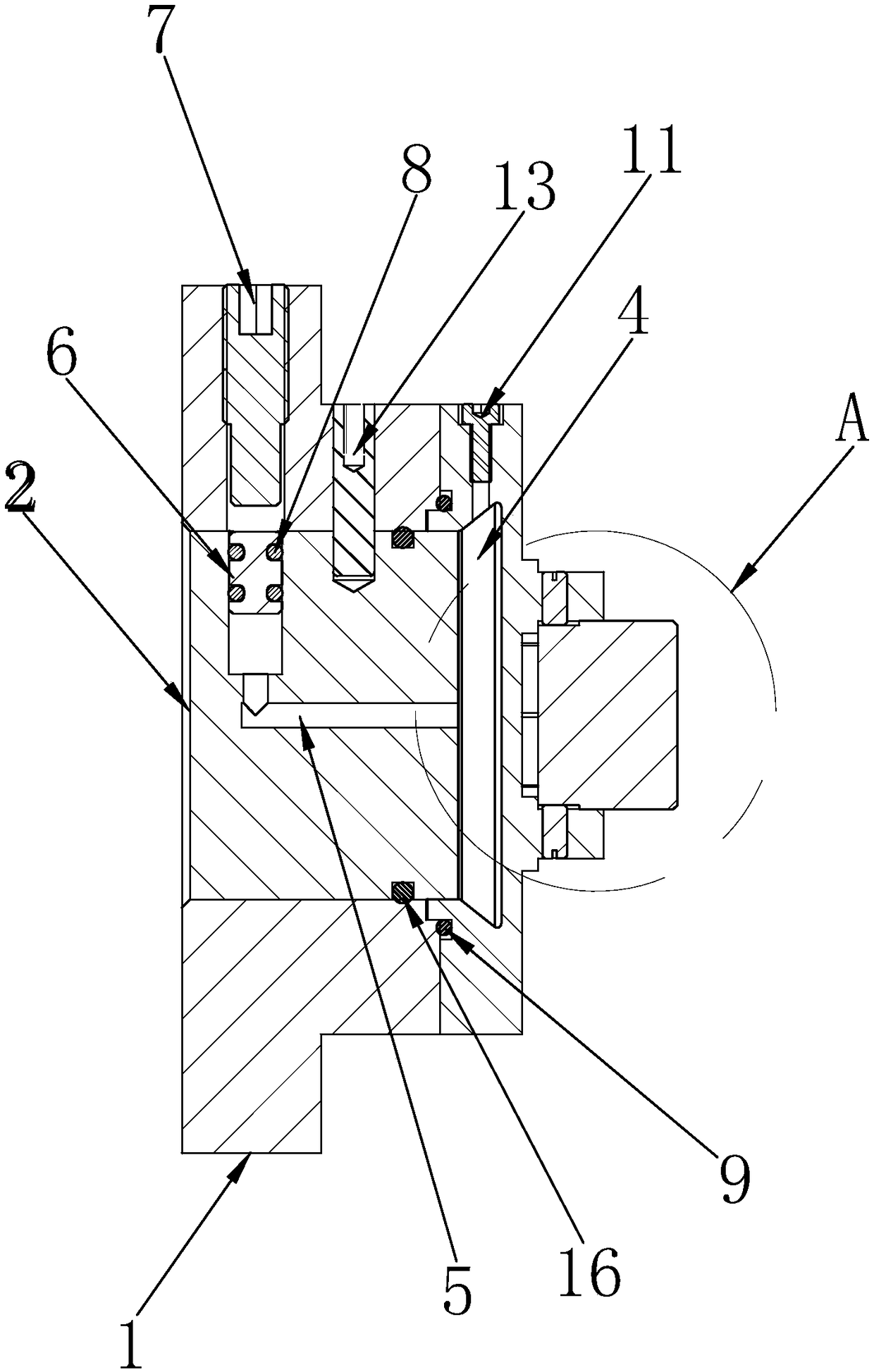

[0044] Such as Figure 3 to Figure 5As shown, the difference between this embodiment and the first embodiment above is that a stepped structure 15 is provided on the inner side and / or outer side of the jaw 12, and when the workpiece is clamped, one end of the workpiece is tightened under the action of continuous external thrust. Paste the step structure 15 to ensure the positioning accuracy of the workpiece in the axial direction. The same batch of workpieces can use the step structure 15 to ensure that the same batch of workpieces obtains the same machining accuracy and improve the machining accuracy of the workpiece; The inner side of the jaw 12 is provided with a stepped structure 15, which can process shaft parts, and the outer side of the jaw 12 is provided with a stepped structure 15, which can process hole parts, and the inner and outer sides of the jaw 12 are provided with a stepped structure 15, The purpose is to make the chuck body adaptable to two kinds of workpiece...

Embodiment 3

[0049] A clamping method realized by the above-mentioned embodiment 1 or embodiment 2 of the hydraulic elastic chuck. In this embodiment, the workpiece is a shaft part, which includes the following steps:

[0050] A. Fix the hydraulic elastic chuck on the machine tool spindle, which can be fixed on the machine tool spindle by bolt connection;

[0051] B. By screwing and tightening the compression bolt 7, the sealing plunger 6 is pushed to move along the oil passage to pressurize the hydraulic oil, and the thin wall 3 is slightly deformed and bulged outward by the pressing action of the hydraulic oil, thereby driving the jaws 12 open;

[0052] C. Load the workpiece into the jaw 12;

[0053] D. Reversely screw the compression bolt 7 to eliminate the pressure of the sealing plunger 6 on the hydraulic oil, so that the outwardly bulging thin wall 3 returns to its original shape, and the jaws 12 shrink, thereby clamping the workpiece and ensuring the radial positioning of the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com