Four-coordinate automatic loading-unloading robot

An automatic loading and unloading, robot technology, applied in manipulators, metal processing, manufacturing tools, etc., can solve the problems of low manual clamping accuracy, affecting processing quality, and high labor costs, shortening production cycles, improving efficiency, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

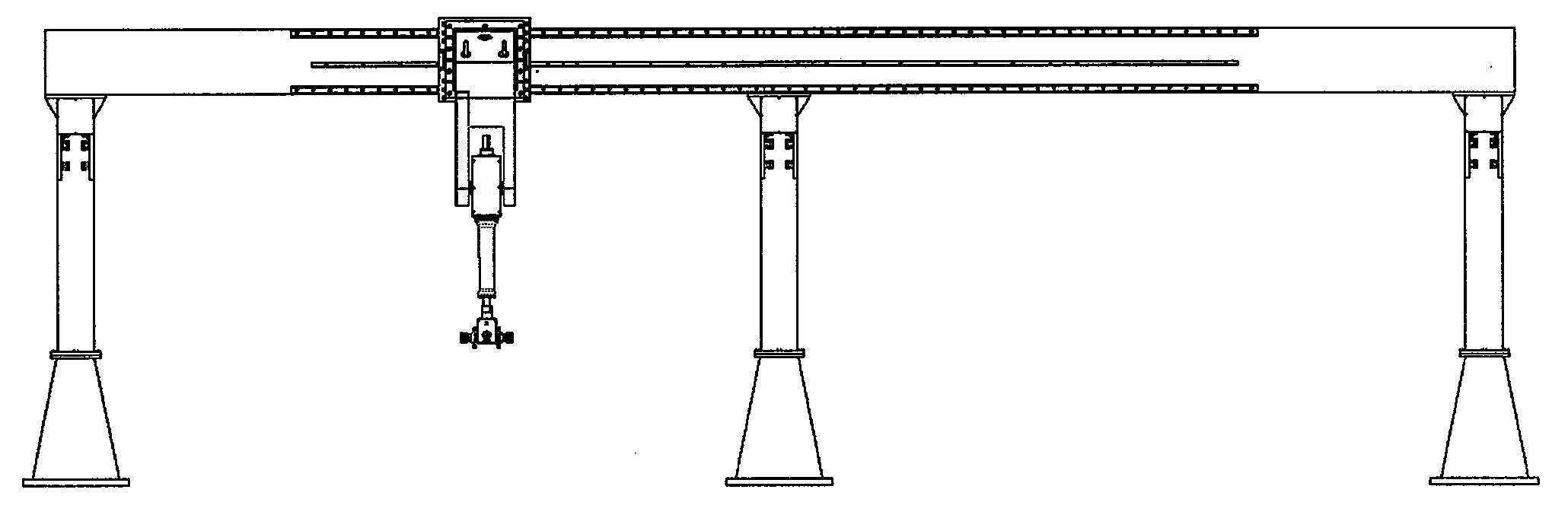

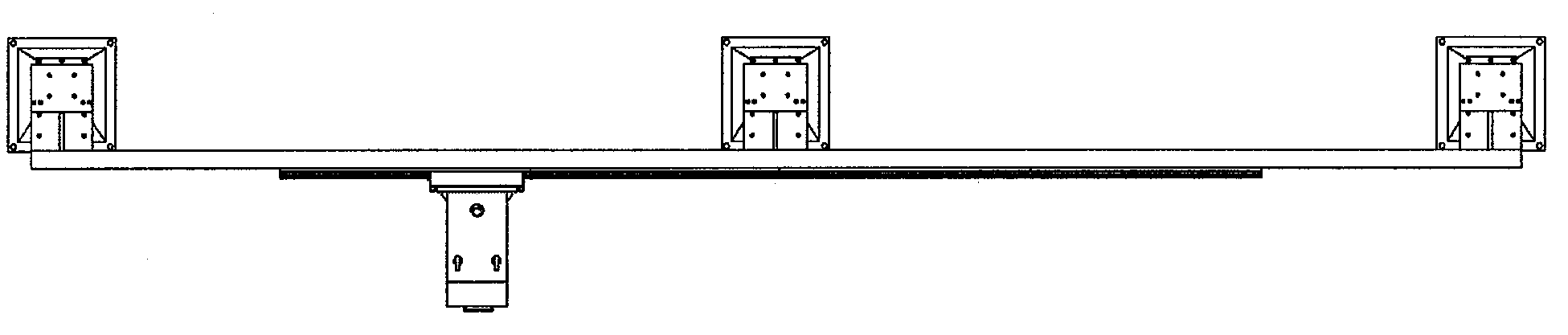

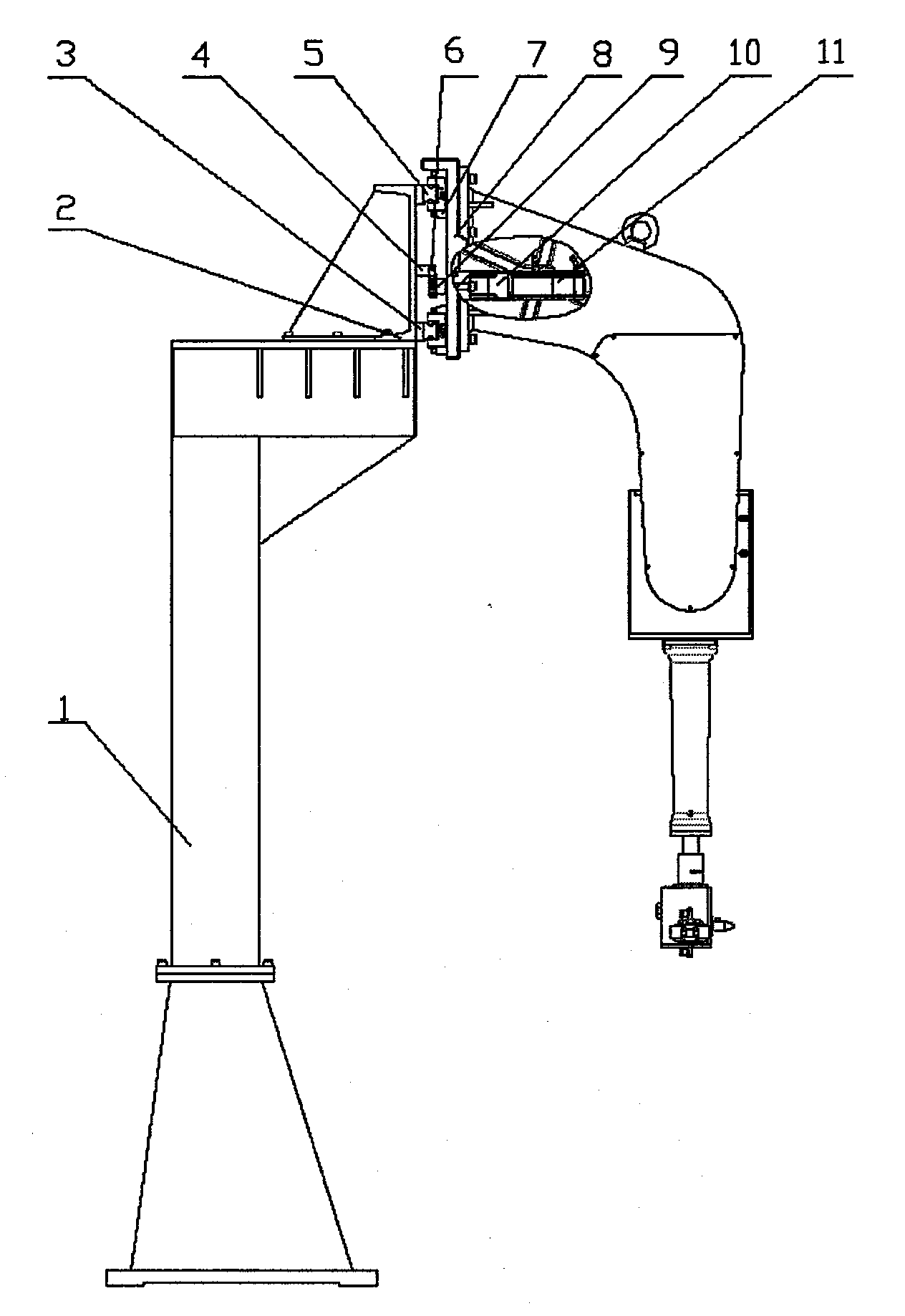

[0033] The four-coordinate automatic loading and unloading robot of the present invention includes a column and beam unit, a robot body unit and a swing unit, please refer to Figure 1a-8 As shown, it is the front view, left view and side view of the four-coordinate automatic loading and unloading robot of the present invention, the front view, left view and top view of the robot body unit, and the front view, left view and top view of the robot body unit.

[0034] Wherein, the shown column and beam unit includes a column 1, a beam 2, a guide rail spacer 3, a rack spacer 4, a guide rail 5, a first rack 6 and a slider 7;

[0035] The robot body unit includes a ram 8, a first gear 9, an X-direction reducer 10, an X-direction motor 11, a crank arm 12, a crank arm leg 15, a crank arm motor 19, a crank arm redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com