Method and equipment for processing polytetrafluoroethylene sealing ring

A polytetrafluoroethylene and processing method technology, which is applied in the field of polytetrafluoroethylene sealing ring processing methods and equipment, can solve the problems of large cost of equipment and molds, can not meet requirements, limited processing, etc. Molding accuracy and the effect of reducing the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The polytetrafluoroethylene sealing ring processing method that present embodiment provides, it comprises the steps:

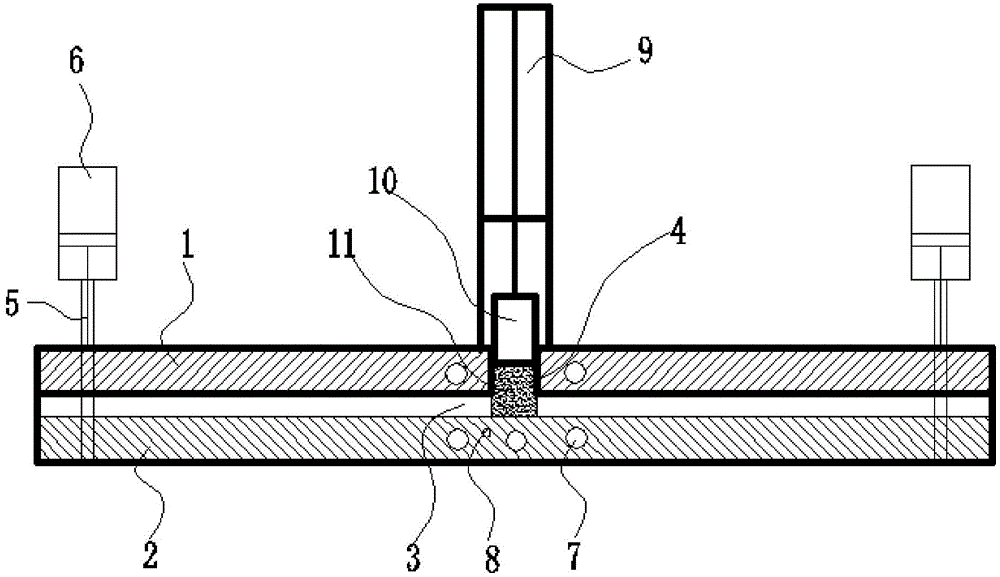

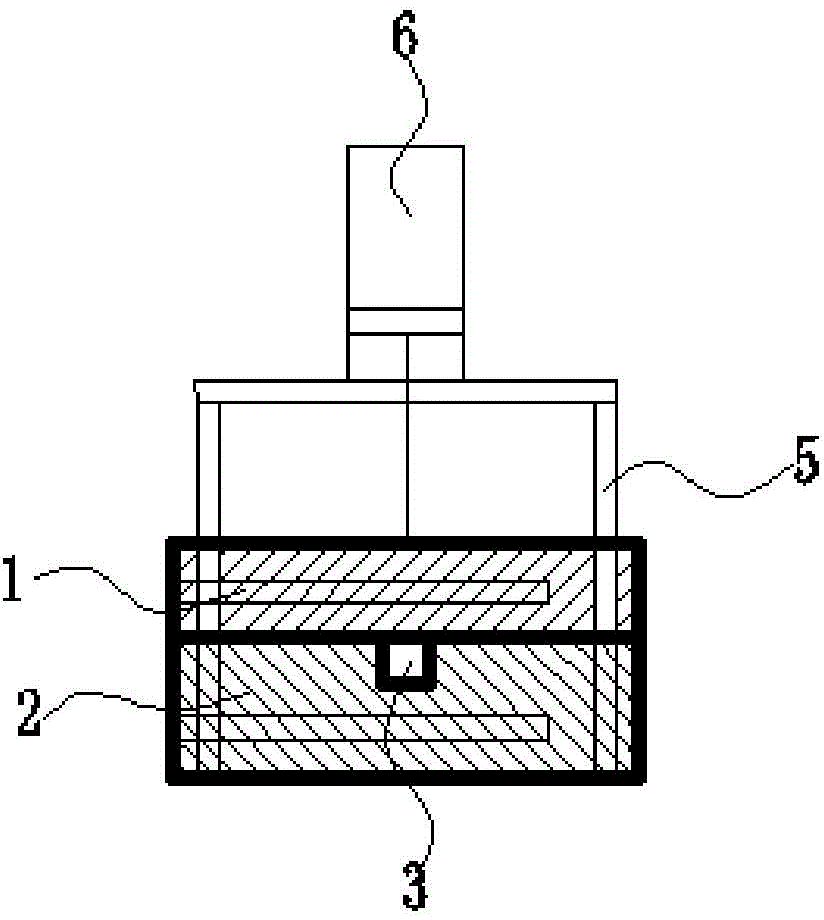

[0029] 1) A hot-melt mold is set. The hot-melt mold includes an upper mold 1 and a lower mold 2. A section of cavity 3 is formed between the upper and lower molds 1 and 2. The end face of the section cavity 3 and the sealing ring to be welded The end faces are matched (that is, the cross-section of the cavity is similar and identical to the cross-section of the sealing ring); a welding mechanism is set on the hot-melt mold, and the welding mechanism includes a heating device corresponding to the cavity 3, a filler Area 4 and pressing device; positioning grooves are set at both ends of the cavity 3 of the hot-melt mold, and the end faces of the positioning grooves are also adapted to the end faces of the sealing rings; a clamping mechanism is set on the hot-melt mold, The mold locking mechanism includes a guide post 5 arranged between the upper mold 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com