Hard point position stepless adjusting type test rig satisfying multiple suspension fork types

A stepless adjustment, test-bed technology, applied in the direction of vehicle suspension/shock absorption mechanism testing, etc., can solve the problems of difficult adjustment of the hard point position of the suspension, high price, stepwise adjustment, etc., to achieve convenient design and improvement, structure Simple, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

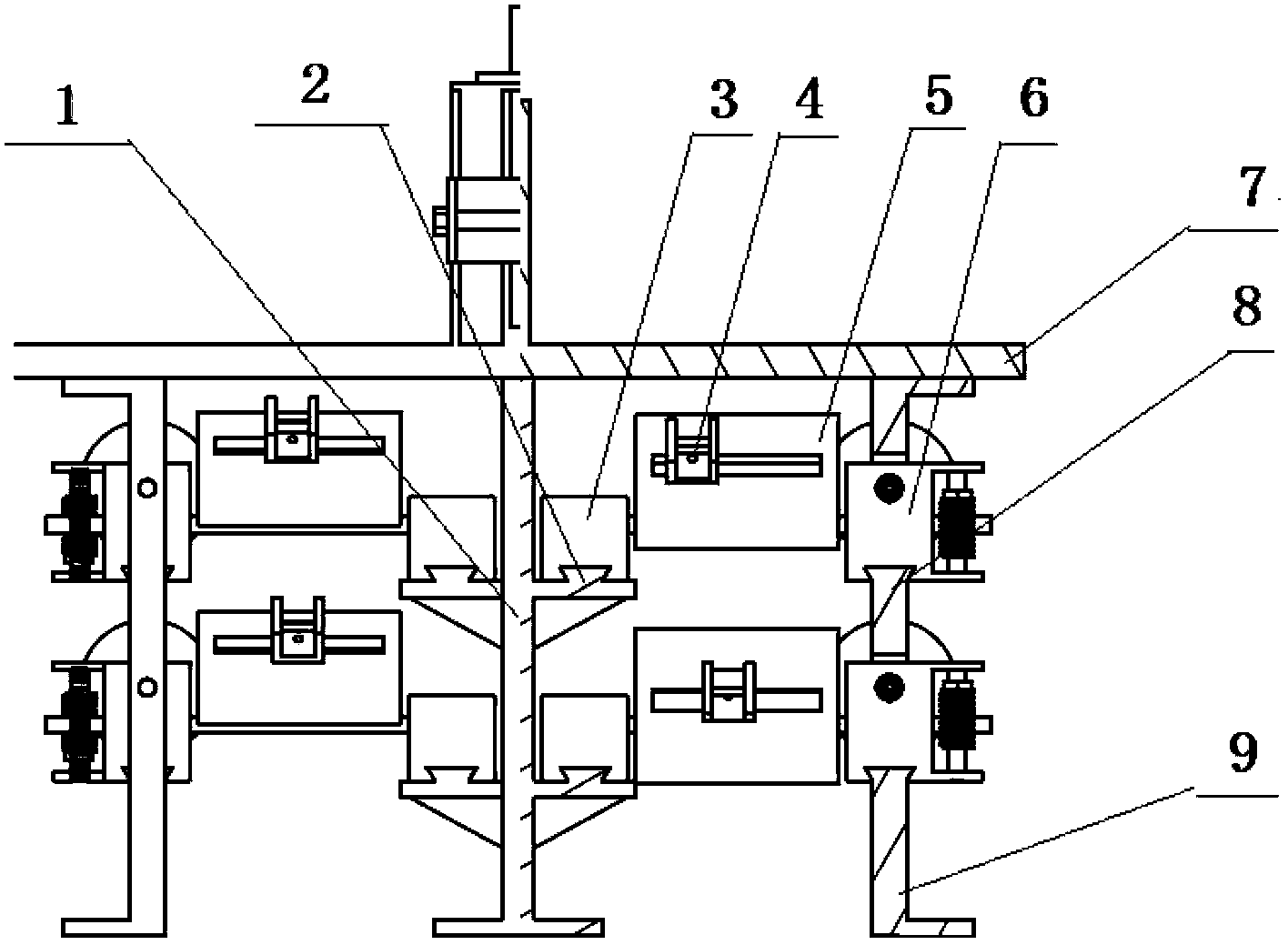

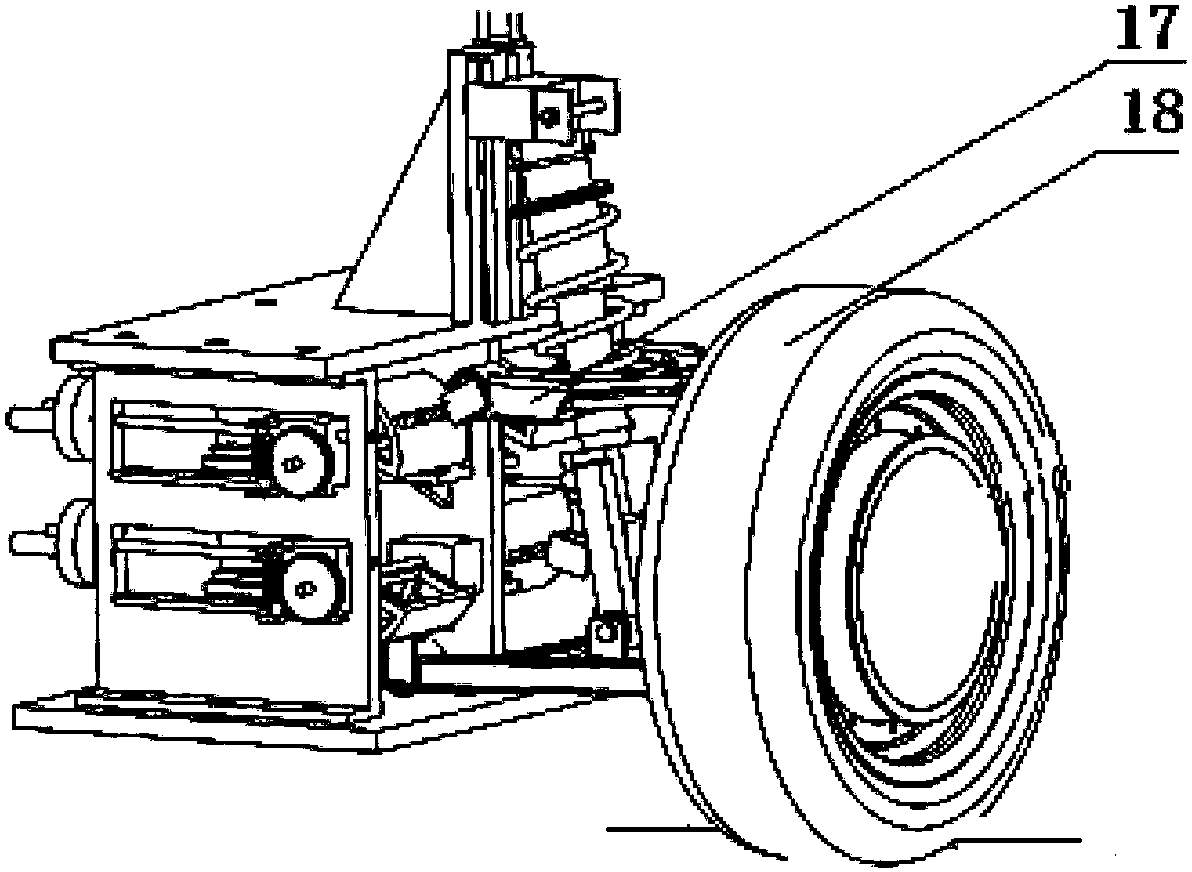

[0022] like Figure 1 to Figure 5 As shown, the hard point position stepless adjustment type test bench satisfying various suspension forms of the present invention includes a suspension hard point position adjustment mechanism, a support frame (9) and a tire suspension system loading mechanism, and the suspension The hard point position adjustment mechanism is arranged in the support frame, the support frame (9) is provided with a cover plate (7), and the tire suspension system loading mechanism is provided on the cover plate (7).

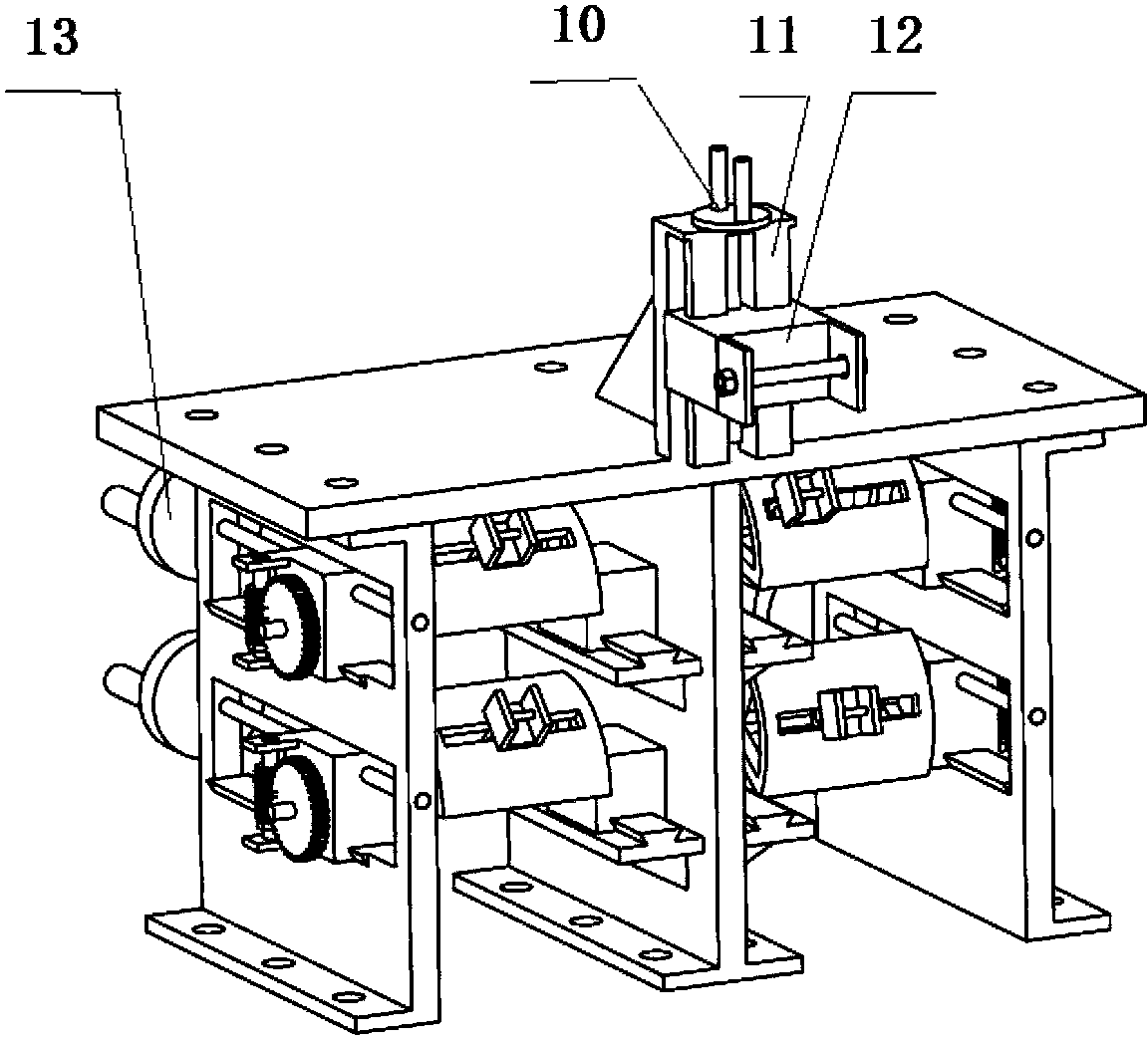

[0023] The suspension hard point position adjustment mechanism is composed of four identical adjustment mechanisms, and the adjustment mechanisms include a connected horizontal adjustment mechanism and a vertical adjustment mechanism. The horizontal adjustment mechanism includes a horizontal adjustment screw (13), a fan-shaped rotating mechanism (5), an outer support slider (6), an inner support slider (3), an inner dovetail guide rail (2) and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com