Liquid viscosity transmission tester with hydraulic load device

A load device, transmission test technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc., can solve the problems of increasing design and manufacturing cost, intricate system structure, complex structure, etc., to save design and manufacturing The effect of cost, saving experiment space, and expanding the scope of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

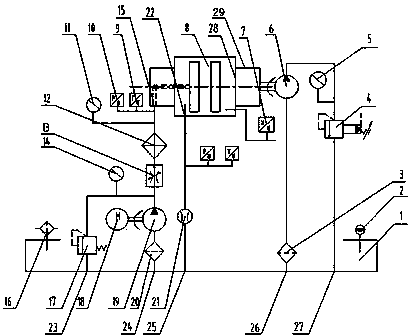

[0020] Attached below figure 1 The present invention is described in further detail.

[0021] A kind of hydroviscosity transmission test device with hydraulic load device of the present invention such as figure 1 As shown, it mainly includes: oil tank 1, liquid level and temperature gauge 2, coarse filter for load oil circuit 3, pilot relief valve 4, pressure gauge 5, vane pump 6, displacement sensor 7, liquid-viscous clutch 8, Temperature sensor 9, pressure sensor 10, pressure gauge 11, cooler 12, speed control valve 13, pressure gauge 14, oil inlet 15, air filter 16, overflow valve 17, motor 18, gear oil pump 19, oil supply Road coarse filter 20, flow meter 21, oil return port 22, first oil port 23, second oil port 24, third oil port 25, fourth oil port 26, fifth oil port 27, right support plate 28, output shaft 29.

[0022] On the oil inlet road of the oil supply system, the motor 18 is connected through a coupling to drive the gear oil pump 19 to work, absorbs oil from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com