Intelligent divider capable of conducting division with constant mass

A divider and divider technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problems of small (generally no more than 1:32, inability to realize automation, complex adjustment process, etc., to achieve simple and compact structure, adjustment Wide range and highly intelligent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

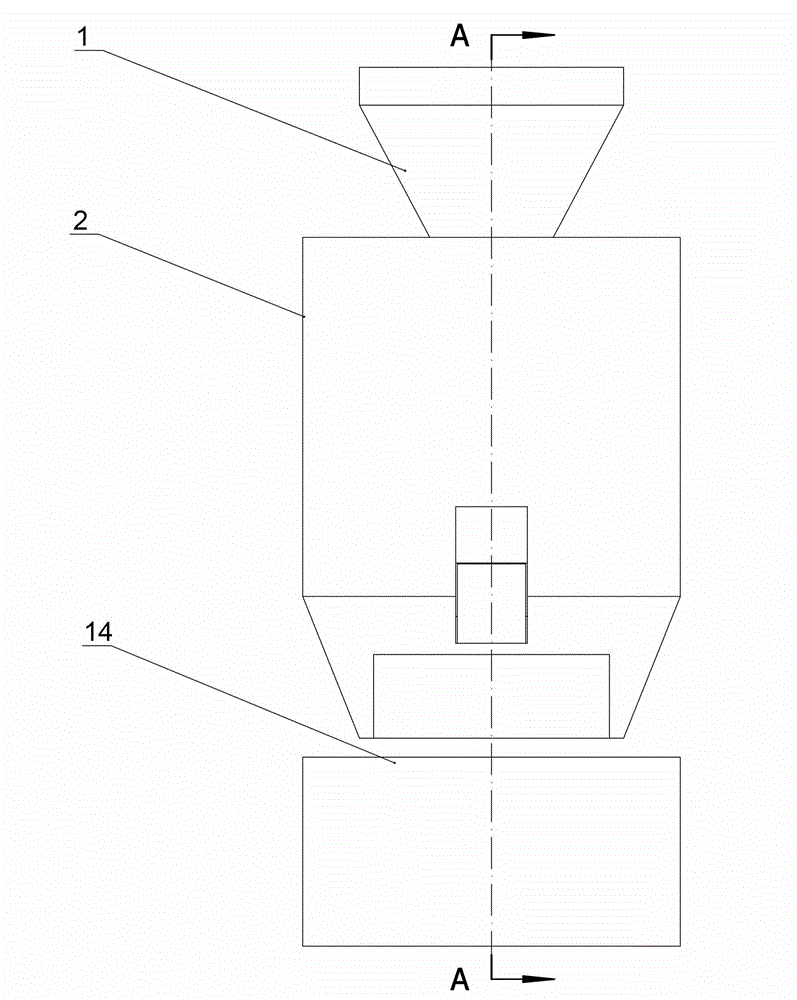

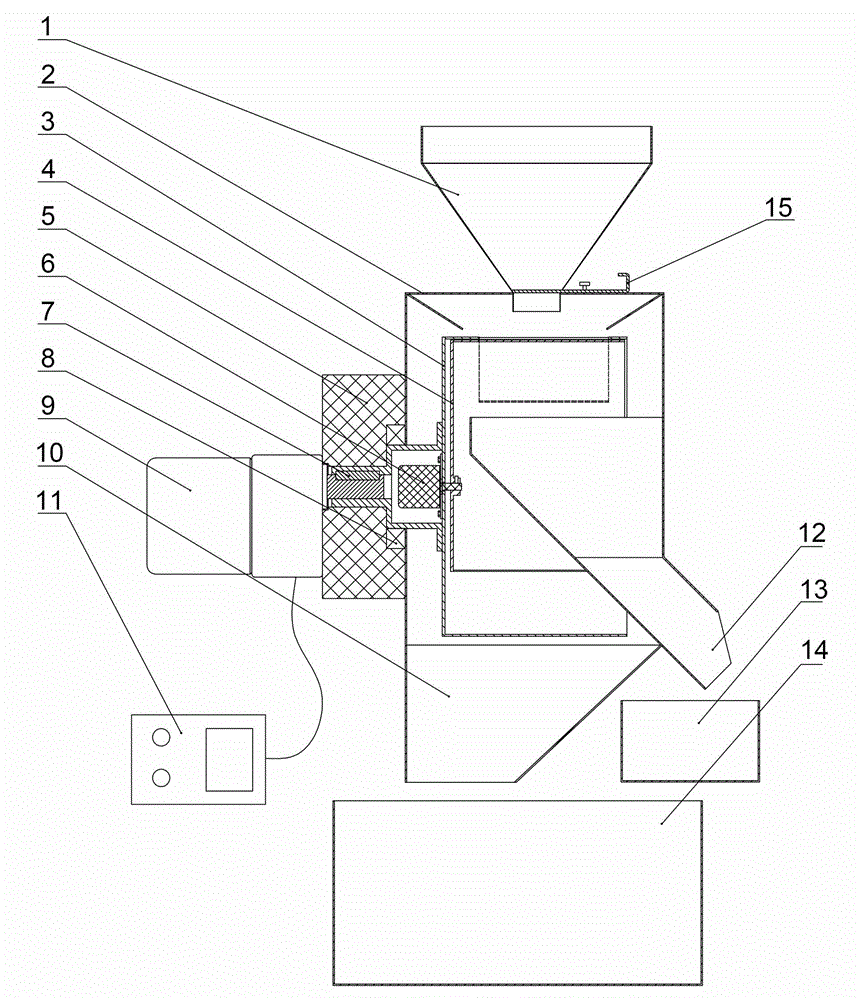

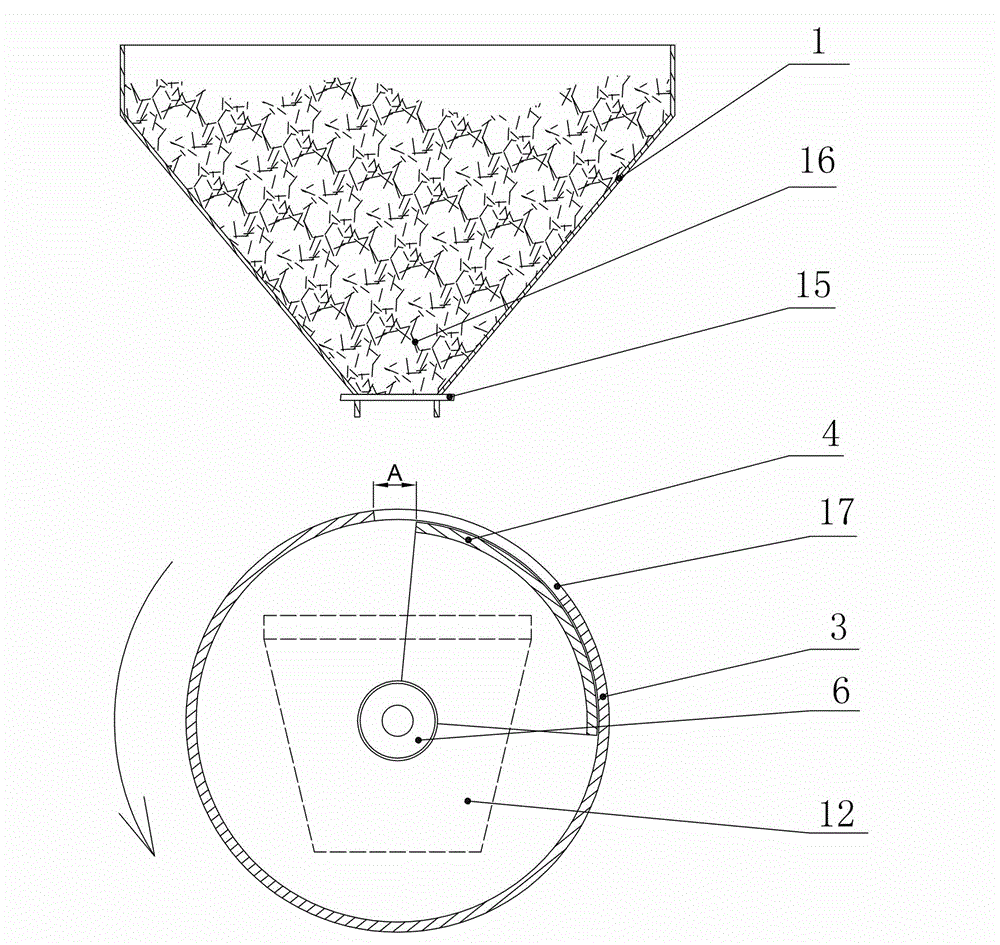

[0021] Such as figure 1 and figure 2 As shown, the intelligent splitter of the present invention, which can be fixed in quality, includes a control unit 11, a splitter housing 2, a hopper 1, and a splitter assembly. The splitter assembly is installed in the splitter housing 2, and the splitter The assembly is located at the discharge end of the hopper 1, that is, the hopper 1 can be located directly above the shrinking assembly. The shrinkage assembly includes a shrinkage drum 3 and a main drive member 9 for driving the rotation of the shrinkage drum 3. The outer circumference of the shrinkage drum 3 is provided with more than one cut-off opening 17, that is, the cut-off opening 17 is set on the On the outer wall of the drum 3; the inside of the shrinkage drum 3 is provided with more than one opening adjustment plate 4 for cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com