Braking moment stepless regulation permanent-magnet buffer

A technology of stepless adjustment and braking torque, applied in the direction of permanent magnet clutch/brake, etc., can solve the problems of unavailable, complex retarder structure, etc., and achieve the effect of wide range and fast working response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

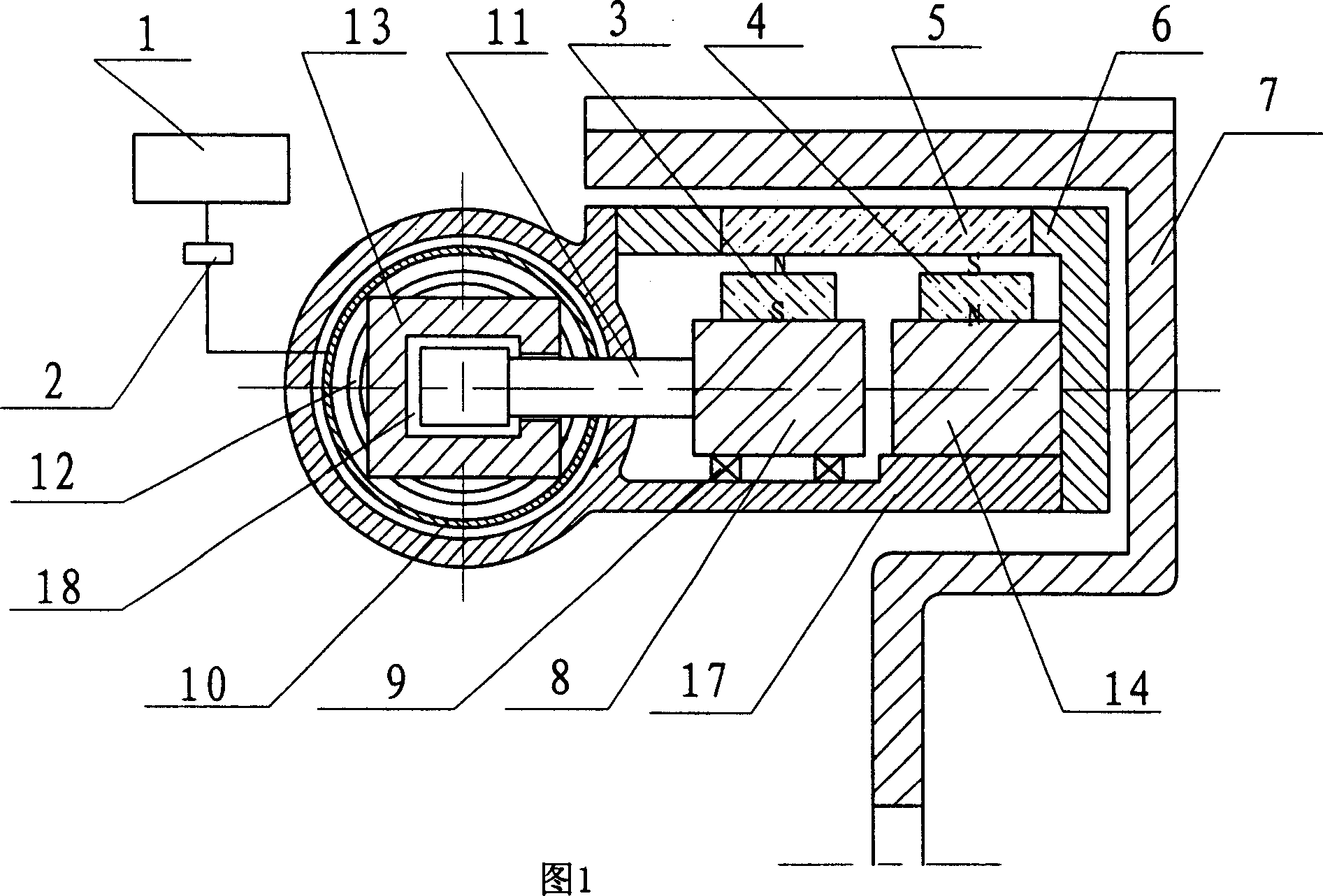

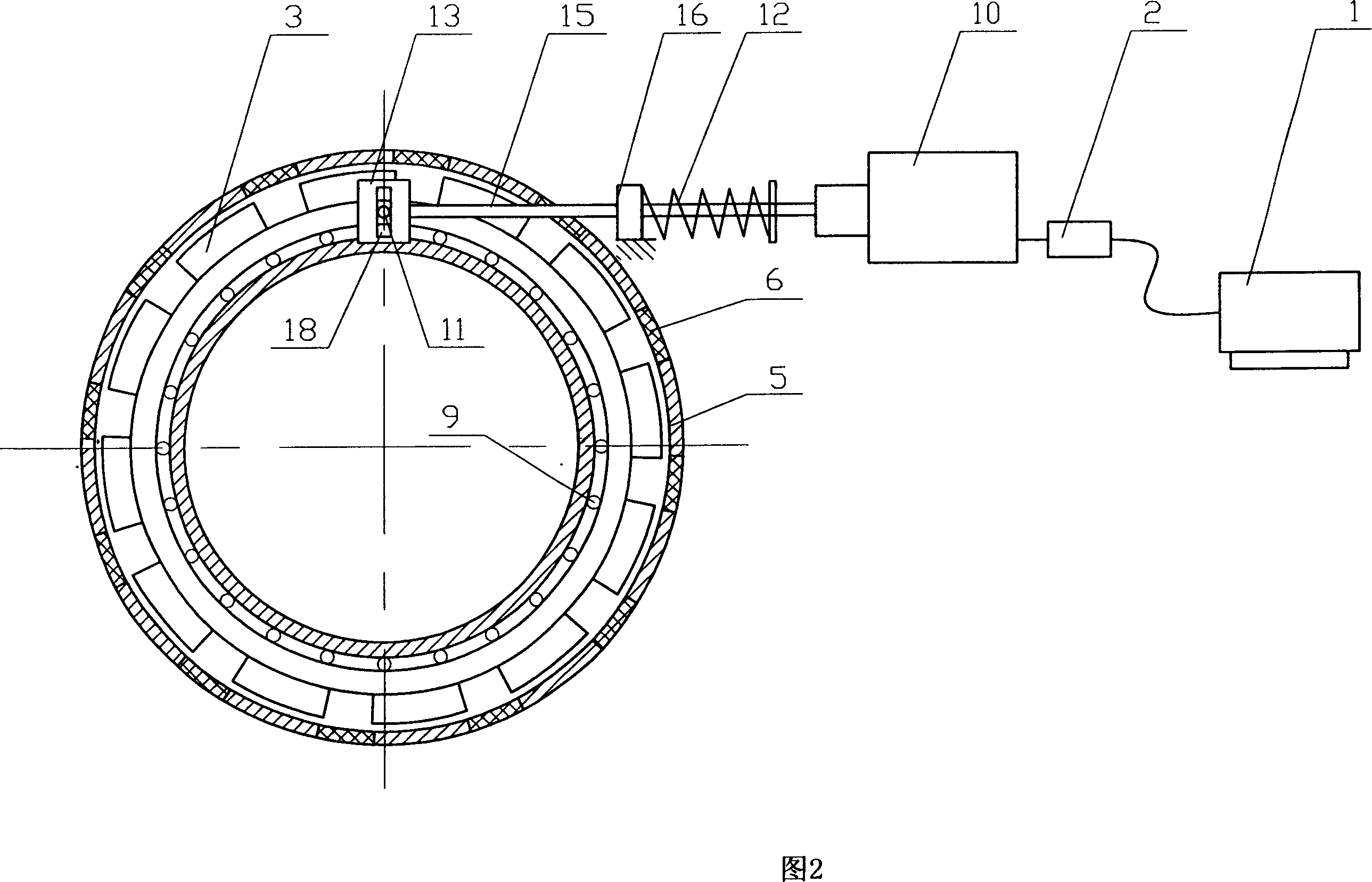

[0020] The present invention and its advantages will be further described below with reference to the accompanying drawings and embodiments.

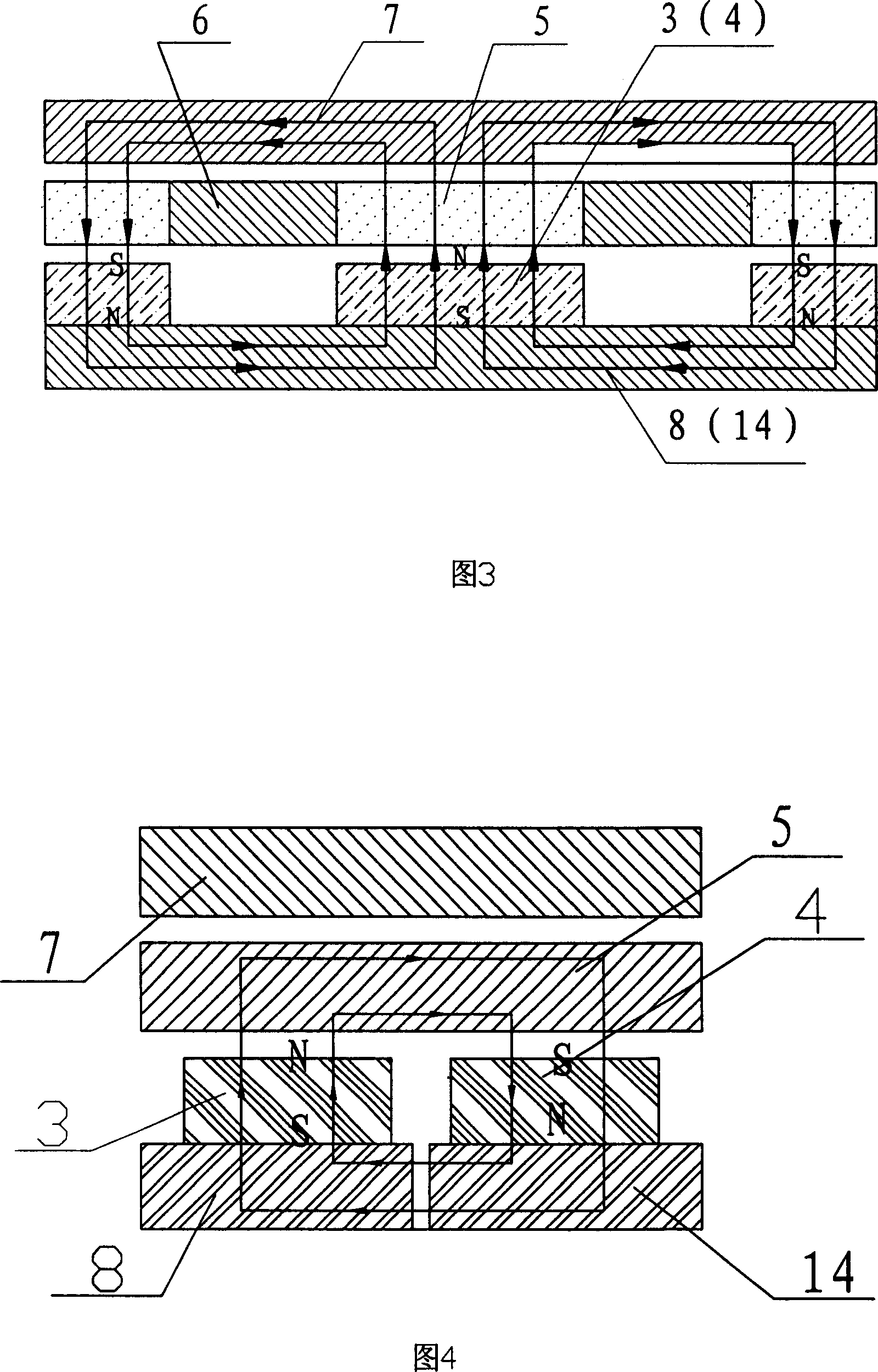

[0021] 1 , the fixed permanent magnets 4 are uniformly distributed on the fixed magnet support 14 along the circumferential direction, and are fixed to the inner side of the magnet holder 6 through the fixed magnet support to form an annular row of fixed permanent magnets 4 . The rotating permanent magnets 3 are evenly distributed on the movable magnet bracket 8 along the circumferential direction. The movable magnet bracket is installed on the stator casting body 17 through the sliding plate 9, placed inside the magnet holder, and can be rotated relative to the magnet holder at a certain angle, thus forming a rotating Annular row of permanent magnets 3 . The polarities of the permanent magnets on each row of permanent magnets are alternately arranged in opposite directions, that is, two adjacent permanent magnets in each row of permane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com