Modularized multi-level converter with auxiliary diode

A modular multi-level, auxiliary diode technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve problems such as large amount of calculation, current loop oscillation, and affecting response speed , to simplify the measurement and control circuit, reduce the number, and control the simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

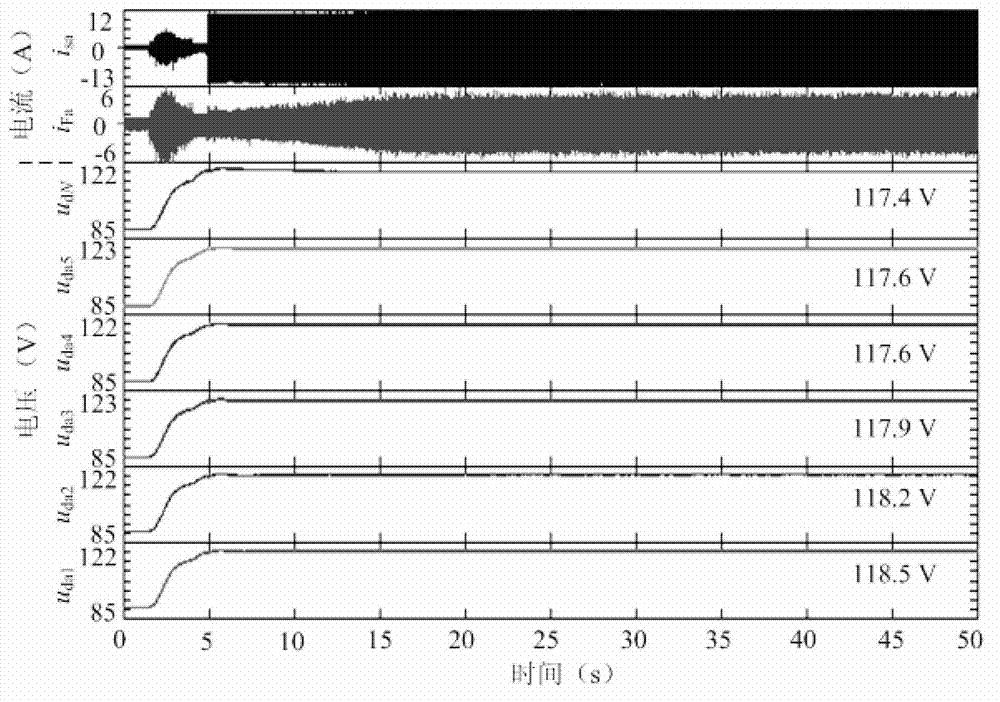

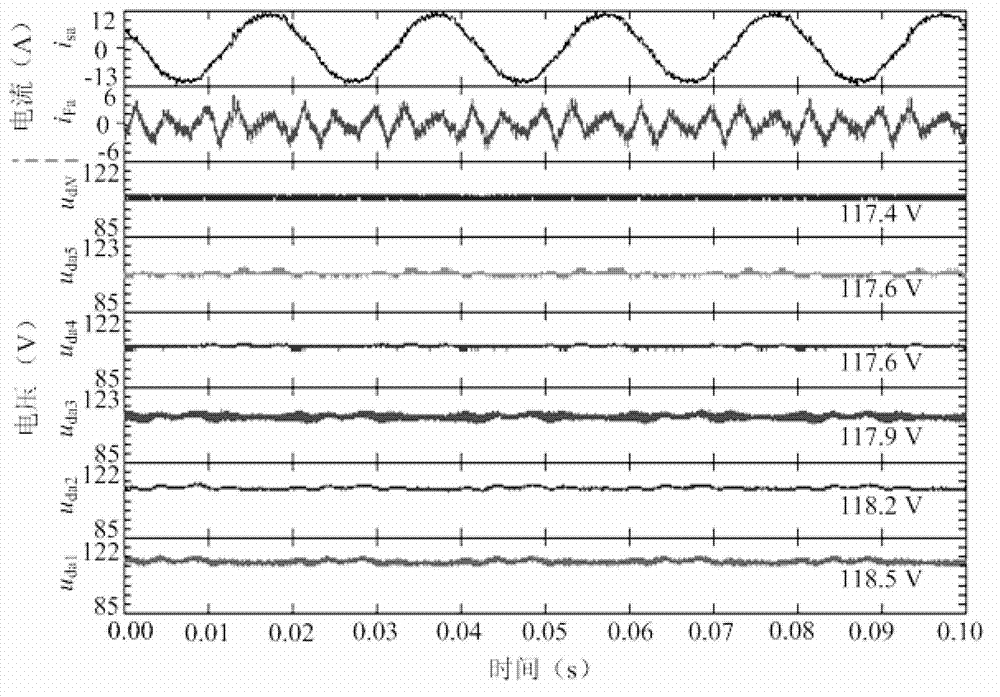

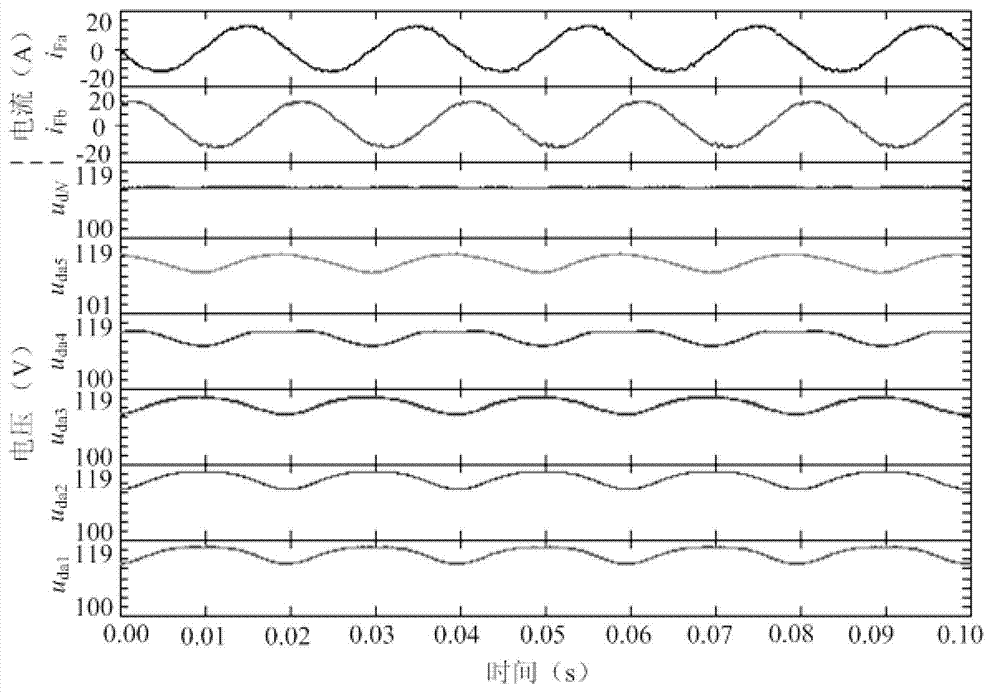

[0050] Embodiment: according to the principle of the present invention, a star-connected 7-level modular multilevel converter prototype with auxiliary diodes has been set up. When it works in the harmonic compensation state, the overall situation waveform of the experimental results can be obtained (such as Figure 7 , Figure 8 shown), in which, the order of the waveforms from top to bottom is: grid phase a current, phase a valve body current with auxiliary diode MMC, phase a valve body common unit capacitor voltage, a phase 5th stage unit capacitor voltage, a Phase 4 cell capacitor voltage, a phase 3 cell capacitor voltage, a phase 2 cell capacitor voltage, a phase 1 cell capacitor voltage. It can be seen from this that the voltage balance of capacitors at all levels in the steady-state valve body is good. When the prototype of the 7-level modular multilevel converter with auxiliary diodes works in the state of reactive power output (such as Figure 9 shown), the sequence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com