Aircraft oil tank inerting device based on catalytic oxidation technology

A technology of catalytic oxidation and fuel tank, which is applied in the direction of fuel tank safety measures, etc., can solve the problems of high price, narrow scope of application, low efficiency of OBIGGS, etc., and achieve the effect of fast start-up speed, high reliability, and low requirement for gas source purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

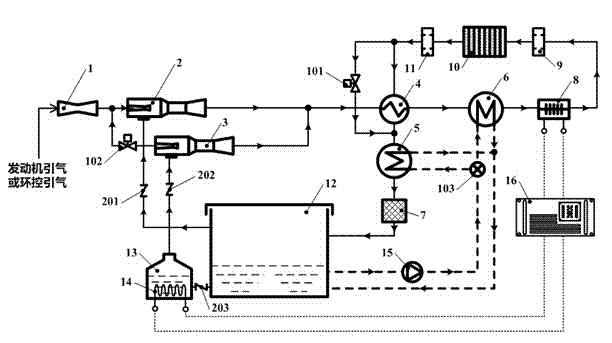

[0030] figure 1 It is an aircraft fuel tank inerting device based on catalytic oxidation technology of the present invention. The outlet of the voltage stabilizer 1 is connected to the primary inlet of the first gas injector 2 and the inlet of the second shut-off valve 102 through pipelines, and the outlet of the second shut-off valve 102 is connected through pipelines. It is connected with the secondary flow inlet of the second gas injector 2, the mixing outlet of the first gas injector 2 and the mixing outlet of the second gas injector 3 are connected with the inlet of the cold side channel of the regenerator 4 through pipelines, and the regenerator 4 is cooled Between the outlet of the side channel and the inlet of the second flame arrester 11, the hot side channel of the second cooler 6, the gas electric heater 8, the first flame arrester 9 and the catalytic reactor 10 are connected in sequence through pipelines, and the outlet of the second flame arrester 11 The pipelines...

Embodiment 2

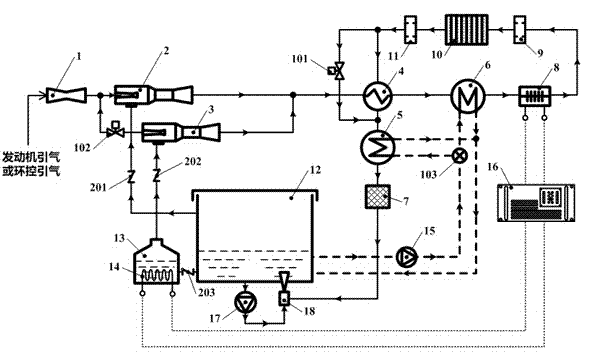

[0035] figure 2 It is a schematic flow diagram of the catalytic oxidation inerting device using injectors to wash fuel oil in this embodiment. In this implementation, the inlet of the voltage regulator (1) is connected to the air inlet of the environmental control, and the outlet of the water eliminator 7 is connected to the gas inlet of the washing injector 18 through a pipeline. Connection, the oil pump 17 is connected through a pipeline between the fuel outlet at the bottom of the fuel tank 12 and the fuel inlet of the washing injector 18, and the outlet of the washing injector 18 is below the lowest liquid level at the bottom of the fuel tank 12.

[0036] The working process difference of present embodiment and embodiment 1 is:

[0037] The inert gas leaving the water eliminator 7 no longer enters the upper inert gas inlet of the fuel tank 12, but flows into the gas inlet of the scrubber injector 18, and mixes with the fuel pumped in from the fuel tank 17 in the scrubber ...

Embodiment 3

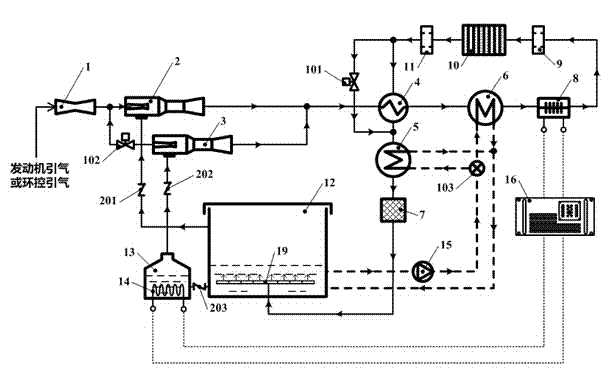

[0039] image 3 It is a schematic flow diagram of the catalytic oxidation inerting device using distributors to wash fuel oil in this embodiment. In this embodiment, the outlet of the water eliminator 7 is connected to the inlet of the gas distributor 19 through a pipeline, and the outlet of the gas distributor 19 is at the bottom of the fuel tank 12. face down.

[0040] The difference between this embodiment and Embodiment 2 is that the oil pump 12 and the scrubbing injector 18 in Embodiment 2 are replaced by a gas distributor 19, the inert gas flows into the inlet of the gas distributor 19, and flows into the inert gas main pipe through the inert gas inlet pipe 1001 1002, and then flow into the inert gas branch pipe 1003, a large number of inert gas small holes 1004 are opened on the inert gas branch pipe 1003, and finally the inert gas bubbles are formed and enter the fuel oil in the fuel tank 12. As the bubbles rise, the carbon dioxide and nitrogen in the inert gas and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com