Amorphous alloy and method for preparing same

A technology of amorphous alloys and amorphous phases, applied in the field of amorphous alloys and their preparation, can solve the problems of reducing the purity of raw materials and preparation conditions, demanding purity requirements, and deteriorating critical dimensions, so as to improve critical dimensions and mechanical properties , Purity requirements are reduced, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

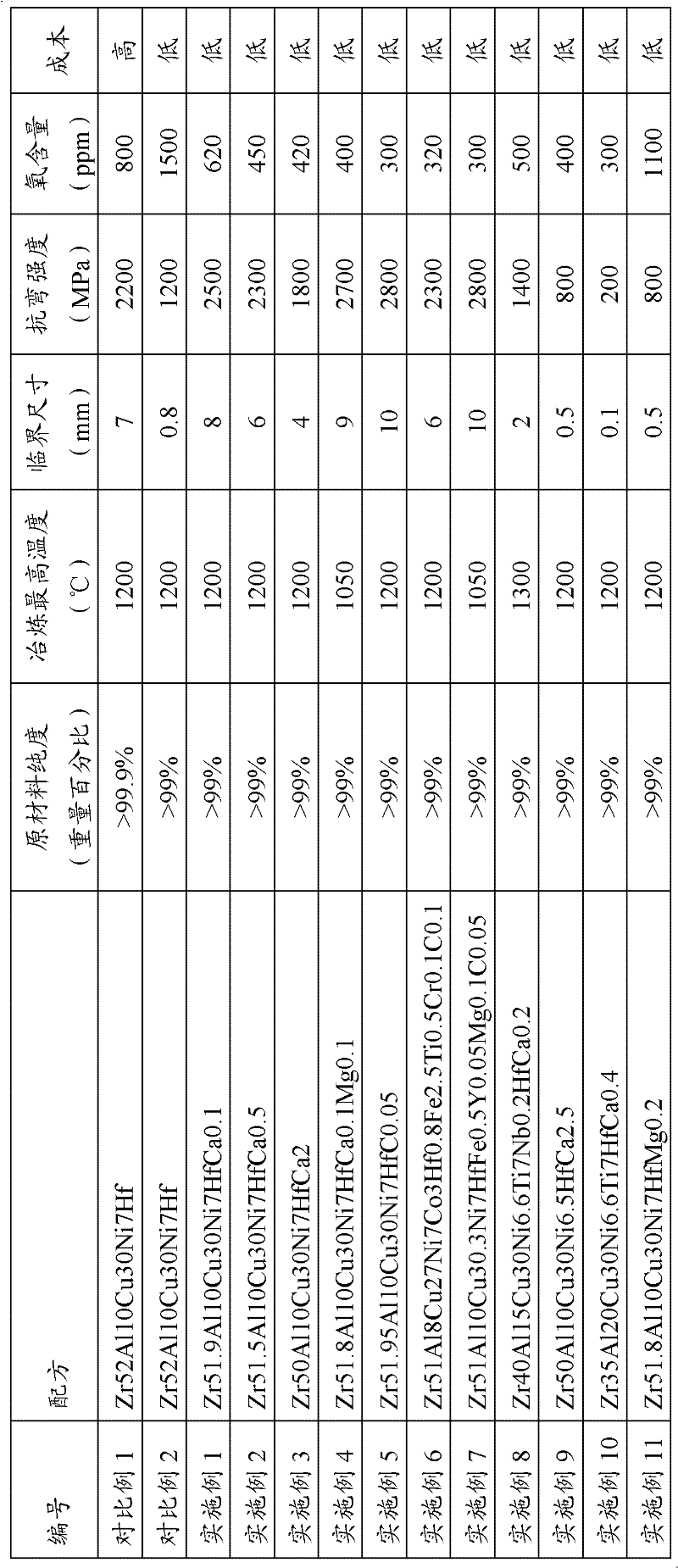

Examples

preparation example Construction

[0036] Specifically, the method for preparing an amorphous alloy according to an embodiment of the present invention includes the following steps:

[0037] First, the amorphous alloy matrix and additives are provided according to a predetermined ratio.

[0038] Then, the amorphous alloy and the additive are smelted under vacuum and inert gas conditions to obtain a mixed melt.

[0039] Finally, the melt is cast and cooled to obtain an amorphous alloy.

[0040] According to the preparation method of the amorphous alloy of the embodiment of the present invention, by mixing the amorphous alloy matrix with the additive, the amount of precious metals used is effectively reduced or eliminated, and the addition of the additive can effectively inhibit the The content of non-metallic elements such as oxygen and nitrogen can improve the critical size and mechanical properties of the amorphous alloy, so that it is more suitable for the promotion of industrial production. In addition, du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com