Quartz sand ore tailing or silica sand ore tailing based high-strength ceramic plate and preparation method thereof

A technology of ore tailings and silica sand, which is applied in the field of high-strength ceramic plates and its preparation, can solve problems such as high sintering temperature, difficult processing, and complex raw material components, and achieve low sintering temperature, reduced maintenance costs, and comprehensive performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

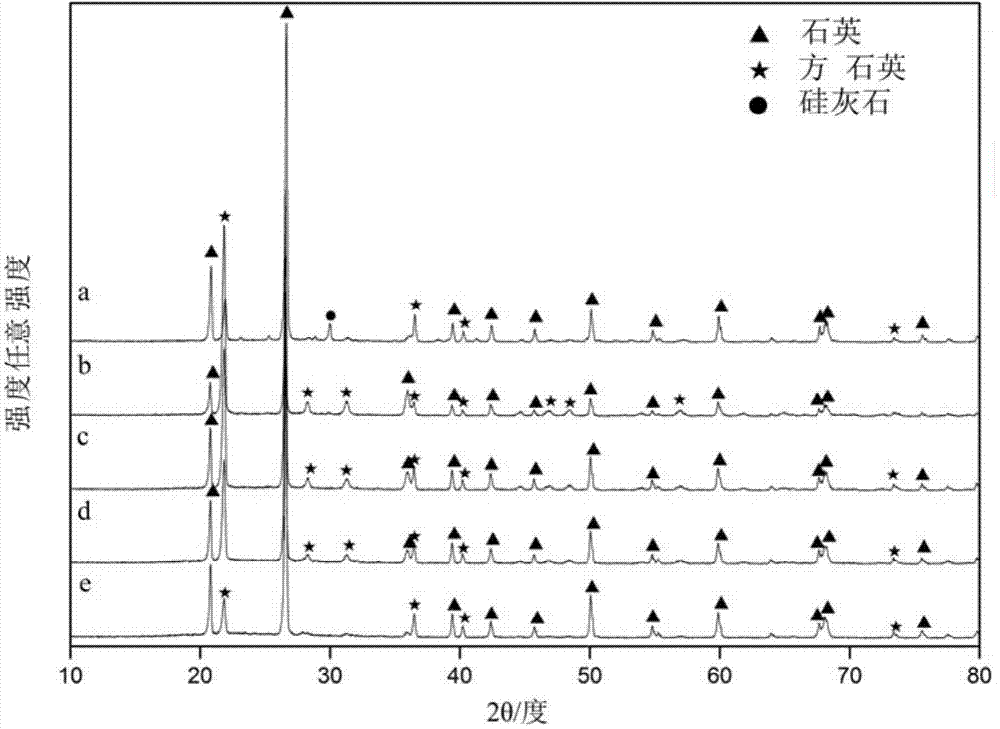

Method used

Image

Examples

Embodiment 1

[0031] Raw material ratio (mass percentage): 76% of quartz placer tailings or silica sand ore tailings, 11% of calcium carbonate, 10% of borax, and 3% of water glass.

[0032] Put the raw materials into a ball mill for ball milling, drying and sieving, take the powder between 200 and 300 mesh, mix it evenly, put it in a mold and press it into a mold, the molding pressure is 15MPa, fully dry the formed green body, put it into Sinter in a sintering furnace, the heating rate is 3°C / min, the sintering temperature is 900°C, and the temperature is kept for 0.5 hours.

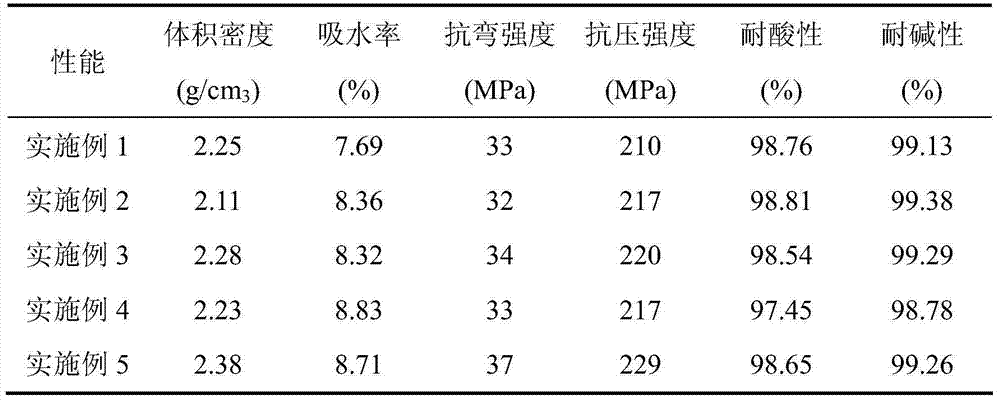

[0033] The bending strength of the prepared ceramic plate is 33MPa, and the compressive strength is 210MPa. Bulk density 2.25g / cm 3 , water absorption 7.69%, acid resistance 98.76%, alkali resistance 99.13%.

Embodiment 2

[0035] Raw material ratio (mass percentage): 80% of quartz placer tailings or silica sand ore tailings, 5% of calcium carbonate, 10% of borax, and 5% of water glass.

[0036] Put the raw materials into a ball mill for ball milling, drying and sieving, take the powder between 200 and 300 meshes, mix them evenly, put them in a mold and press them for molding, the molding pressure is 20MPa, fully dry the molded green bodies, put them into Sinter in a sintering furnace, the heating rate is 5°C / min, the sintering temperature is 950°C, and the temperature is kept for 2 hours.

[0037] The bending strength of the prepared ceramic plate is 32MPa, the compressive strength is 217MPa and the volume density is 2.11g / cm 3 , water absorption 8.36%, acid resistance 98.81%, alkali resistance 99.38%.

Embodiment 3

[0039] Raw material ratio (mass percentage): 80% of quartz placer tailings or silica sand ore tailings, 10% of feldspar, 5% of borax, and 5% of water glass.

[0040] Put the raw materials into a ball mill for 3 hours, dry, sieve, take the powder between 200 and 300 mesh, mix it evenly, put it in a mold and press it into a mold, the molding pressure is 20MPa, and fully dry the molded green body. Put it into a sintering furnace for sintering, the heating rate is 5°C / min, the sintering temperature is 950°C, and the temperature is kept for 2 hours.

[0041] The bending strength of the prepared ceramic plate is 34MPa, the compressive strength is 220MPa, and the bulk density is 2.28g / cm 3 , water absorption 8.32%, acid resistance 98.54%, alkali resistance 99.29%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| acid resistance | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com