Preparation method of multi-level structure magnesium borate hollow microspheres

A hollow microsphere, magnesium borate technology, applied in the direction of borates, boron oxides, nanotechnology, etc., to achieve the effect of complete crystal form, easy operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

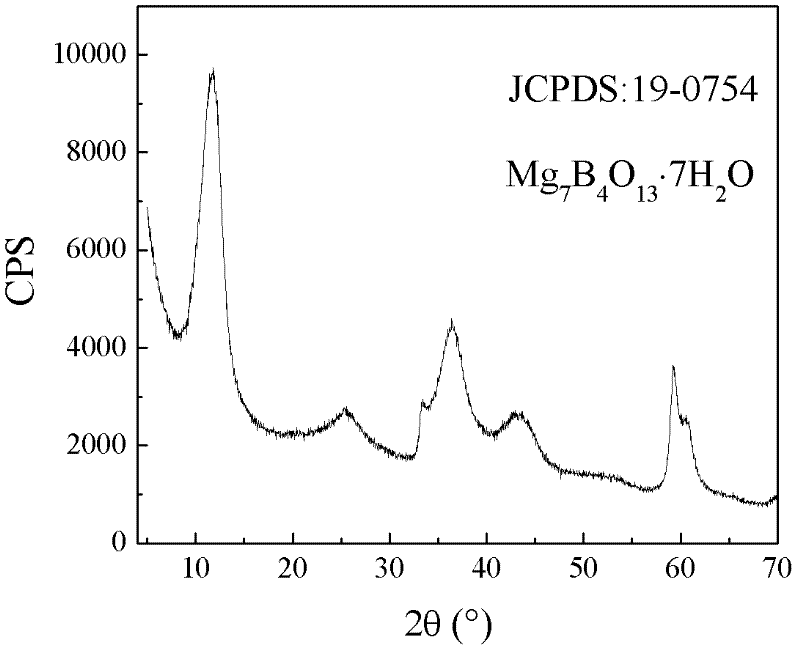

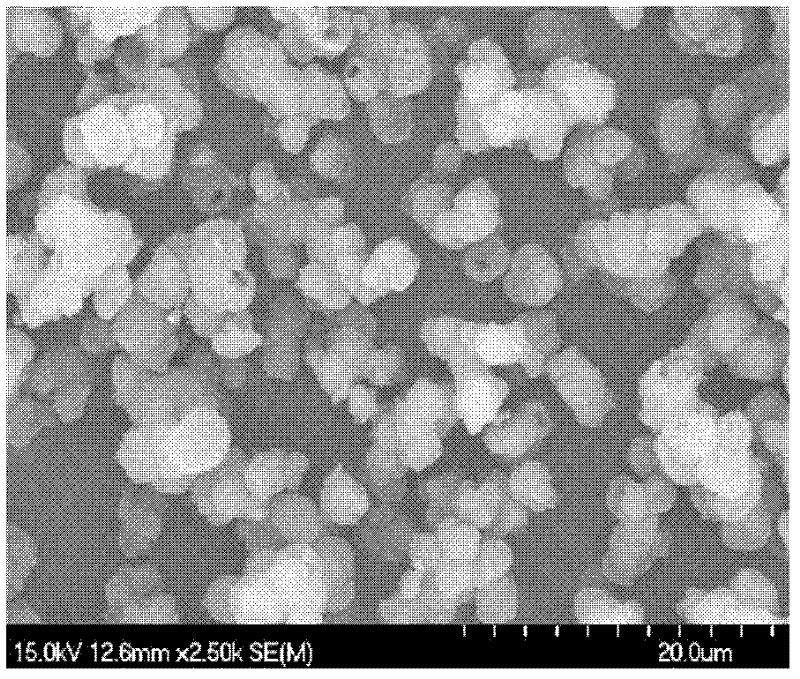

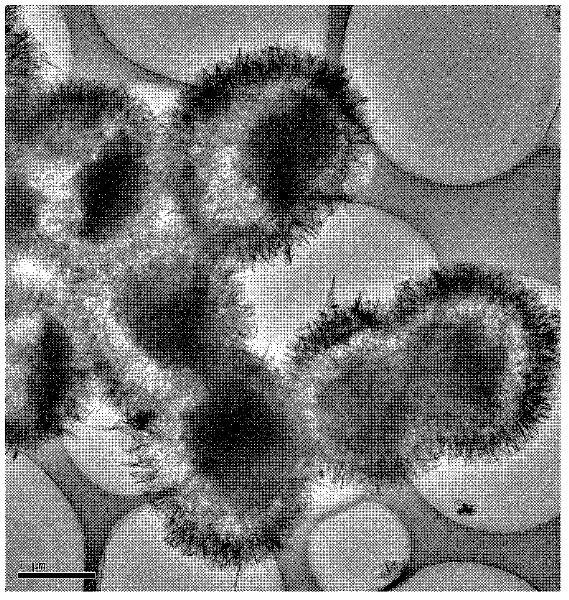

[0029] At room temperature (25°C), weigh 1.0 mmol of magnesium nitrate and dissolve it in 10 ml of distilled water to prepare 10 ml of 0.1 mol / L magnesium nitrate aqueous solution, add 0.5 ml of 1-ethyl-3-methylimidazole ethyl sulfate salt, and stir magnetically for 0.5 h, then add 10ml 0.1mol / L borax aqueous solution dropwise, continue to stir for 2h to obtain a white turbid solution, and age the white turbid solution at a constant temperature of 80°C for 48h. After the aging is completed, a precipitated mixture is obtained, and the precipitated mixture is filtered to obtain a white filter cake, and the white filter cake was washed successively with distilled water and absolute ethanol for 3 times, and the filter cake was dried at 120° C. for 24 h to obtain a white product, i.e., hollow microspheres of magnesium borate with a hierarchical structure. XRD (X-ray diffraction, figure 1 Shown) to detect the composition of magnesium borate as Mg 7 B 4 o 13 ·7H 2 O, its diffracti...

Embodiment 2

[0031]At room temperature, weigh 1.0mmol of magnesium sulfate and dissolve it in 100ml of distilled water to prepare 100ml of 0.01mol / L magnesium sulfate aqueous solution, add 1ml of 1-ethyl-3-methylimidazolium tetrafluoroborate, stir magnetically for 0.5h, and then Add 100ml of 0.10mol / L borax aqueous solution dropwise, continue stirring for 3 hours to obtain a white turbid solution, and age the white turbid solution at a constant temperature of 100°C for 12 hours. After the aging is completed, a precipitated mixture is obtained, and the precipitated mixture is filtered to obtain a white filter cake, and After washing the white filter cake with distilled water and absolute ethanol three times in sequence, the filter cake was dried at 80°C for 24 hours to obtain a white product, which is a hollow microsphere of magnesium borate with a hierarchical structure. The magnesium borate has a microcrystalline structure as detected by XRD. for Mg 7 B 4 o 13 ·7H 2 O, its diffraction ...

Embodiment 3

[0033] At room temperature, weigh 1.0mmol of magnesium chloride and dissolve it in 10ml of distilled water to prepare 10ml of 0.1mol / L magnesium nitrate aqueous solution, add 6ml of 1-ethyl-3-methylimidazole acetate, stir magnetically for 0.5h, and then add dropwise 10ml 0.01mol / L borax aqueous solution, continue to stir for 3 hours to obtain a white turbid solution, age the white turbid solution at a constant temperature of 120°C for 2 hours, after the aging is completed, obtain a precipitated mixture, filter the precipitated mixture to obtain a white filter cake, and remove the white After the filter cake was washed with distilled water and absolute ethanol for 3 times in sequence, the filter cake was dried at 80°C for 24 hours to obtain a white product, that is, hollow microspheres of magnesium borate with a hierarchical structure. The magnesium borate has a microcrystalline structure as detected by XRD, and the composition is Mg 7 B 4 o 13 ·7H 2 O, its diffraction peak ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com