Energy-saving and environment-friendly building material and preparation method thereof

A building material, energy saving and environmental protection technology, applied in the field of building materials, can solve the problems of fire prevention and energy saving and environmental protection, and achieve the effect of good adhesion, high rigidity and air purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

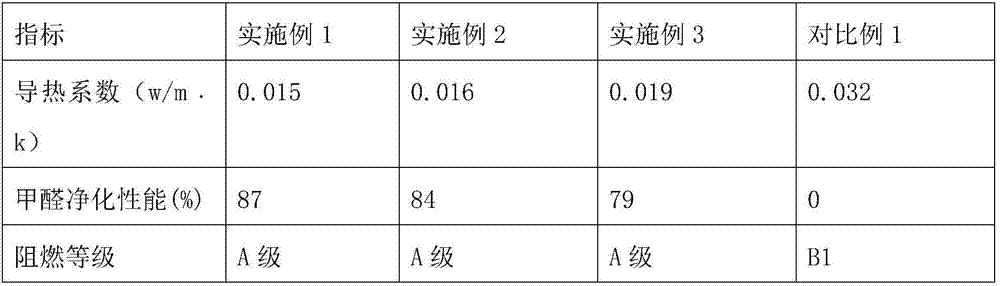

Examples

Embodiment 1

[0042] An energy-saving and environment-friendly building material, comprising the following raw materials in parts by weight: 10 parts of expanded perlite powder, 13 parts of pottery clay, 6 parts of magnesium borate whiskers, 5 parts of floating beads, 4 parts of calcium sulfate, 6 parts of barium phosphate, methoxy 7.5 parts of polyethylene glycol, 10 parts of polyacrylate emulsion, 8 parts of urea-formaldehyde resin, 5.5 parts of chlorosulfonated polyethylene, 8 parts of phenolic resin, 17 parts of waste polyethylene foam, 15 parts of diatomaceous earth, aluminum silicate 16 parts, 12 parts of activated carbon, 13 parts of bamboo charcoal, 13 parts of glass wool, 0.7 parts of foaming agent, 0.5 parts of flame retardant, 0.6 parts of heat stabilizer, 0.3 parts of light stabilizer and 0.6 parts of compatibilizer.

[0043] Phenolic resin is added to the raw material, and phenolic resin is a thermosetting resin, which has the advantages of high rigidity, high hardness, good adh...

Embodiment 2

[0063] An energy-saving and environment-friendly building material, comprising the following raw materials in parts by weight: 6 parts of expanded perlite powder, 10 parts of pottery clay, 5 parts of magnesium borate whiskers, 4 parts of floating beads, 3 parts of calcium sulfate, 5 parts of barium phosphate, methoxy 6 parts of polyethylene glycol, 7 parts of polyacrylate emulsion, 5 parts of urea-formaldehyde resin, 4 parts of chlorosulfonated polyethylene, 6 parts of phenolic resin, 13 parts of waste polyethylene foam, 13 parts of diatomaceous earth, aluminum silicate 11 parts, 9 parts of activated carbon, 11 parts of bamboo charcoal, 7 parts of glass wool, 0.5 parts of foaming agent, 0.3 parts of flame retardant, 0.4 parts of heat stabilizer, 0.1 part of light stabilizer and 0.4 parts of compatibilizer.

[0064] Phenolic resin is added to the raw material, and phenolic resin is a thermosetting resin, which has the advantages of high rigidity, high hardness, good adhesion, hi...

Embodiment 3

[0084] An energy-saving and environment-friendly building material, comprising the following raw materials in parts by weight: 14 parts of expanded perlite powder, 16 parts of pottery clay, 7 parts of magnesium borate whiskers, 6 parts of floating beads, 5 parts of calcium sulfate, 7 parts of barium phosphate, methoxy 9 parts of base polyethylene glycol, 13 parts of polyacrylate emulsion, 9 parts of urea-formaldehyde resin, 7 parts of chlorosulfonated polyethylene, 10 parts of phenolic resin, 21 parts of waste polyethylene foam, 17 parts of diatomaceous earth, aluminum silicate 21 parts, 15 parts of activated carbon, 15 parts of bamboo charcoal, 19 parts of glass wool, 0.9 parts of foaming agent, 0.7 parts of flame retardant, 0.8 parts of heat stabilizer, 0.5 parts of light stabilizer and 0.8 parts of compatibilizer.

[0085] Phenolic resin is added to the raw material, and phenolic resin is a thermosetting resin, which has the advantages of high rigidity, high hardness, good a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com