Superconducting material and method of synthesis

a superconducting material and compound technology, applied in the direction of superconductor details, superconductor devices, magnetic bodies, etc., can solve the problems of hsub>irr /sub>for the doped samples not as good as the undoped ones, and remain controversial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of (Mg+2B)1−x(SiC)x through nanoparticle SiC doping into MgB2

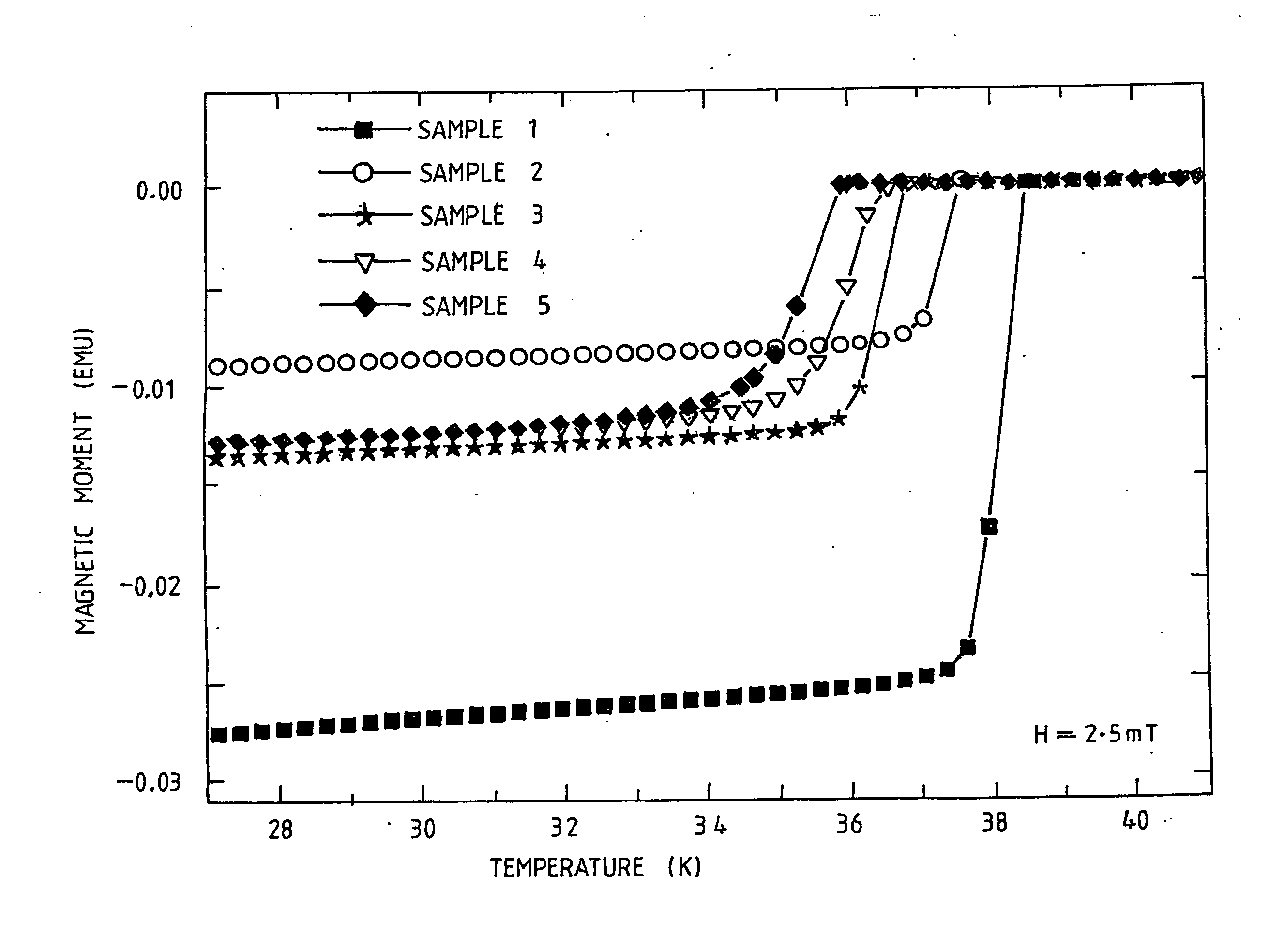

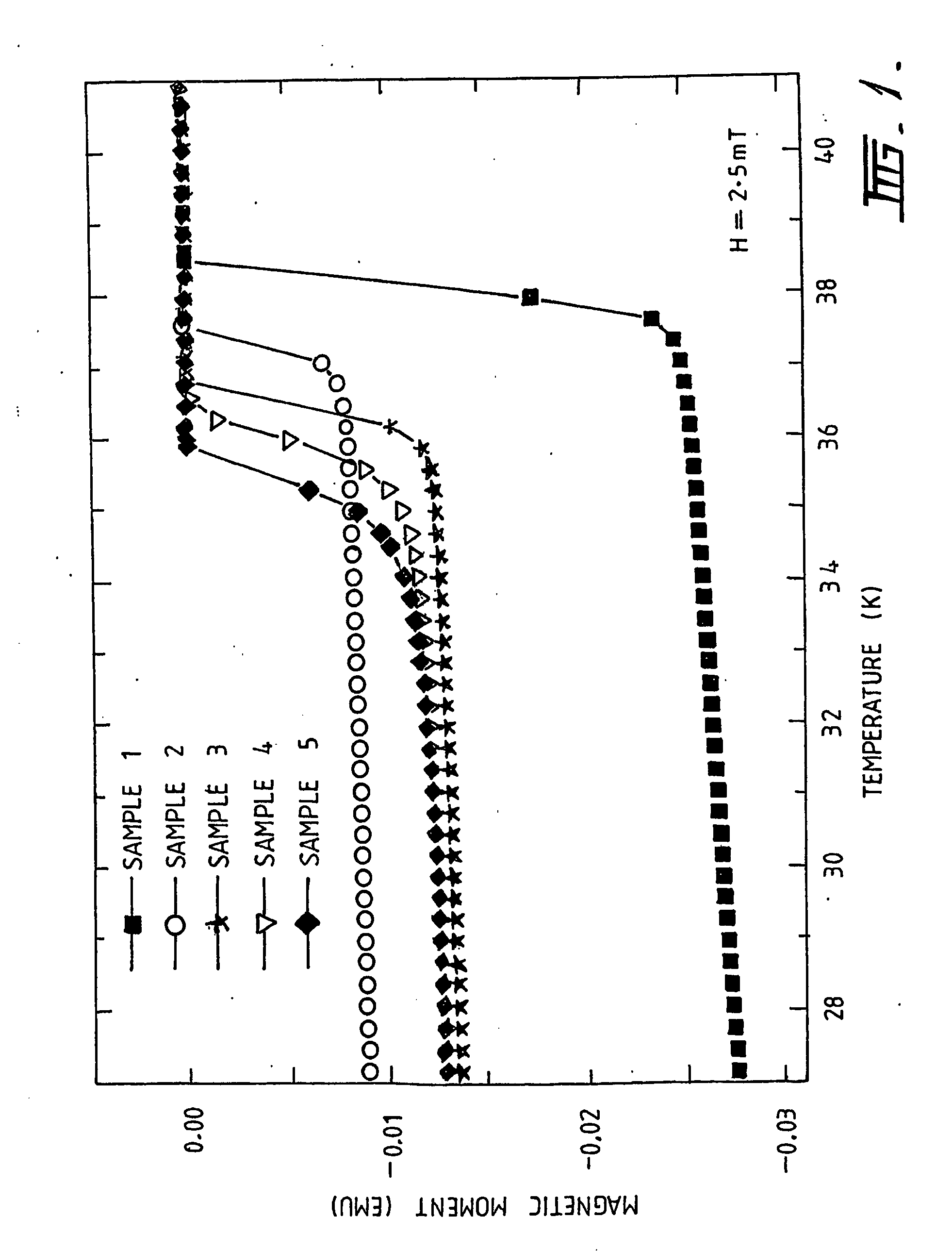

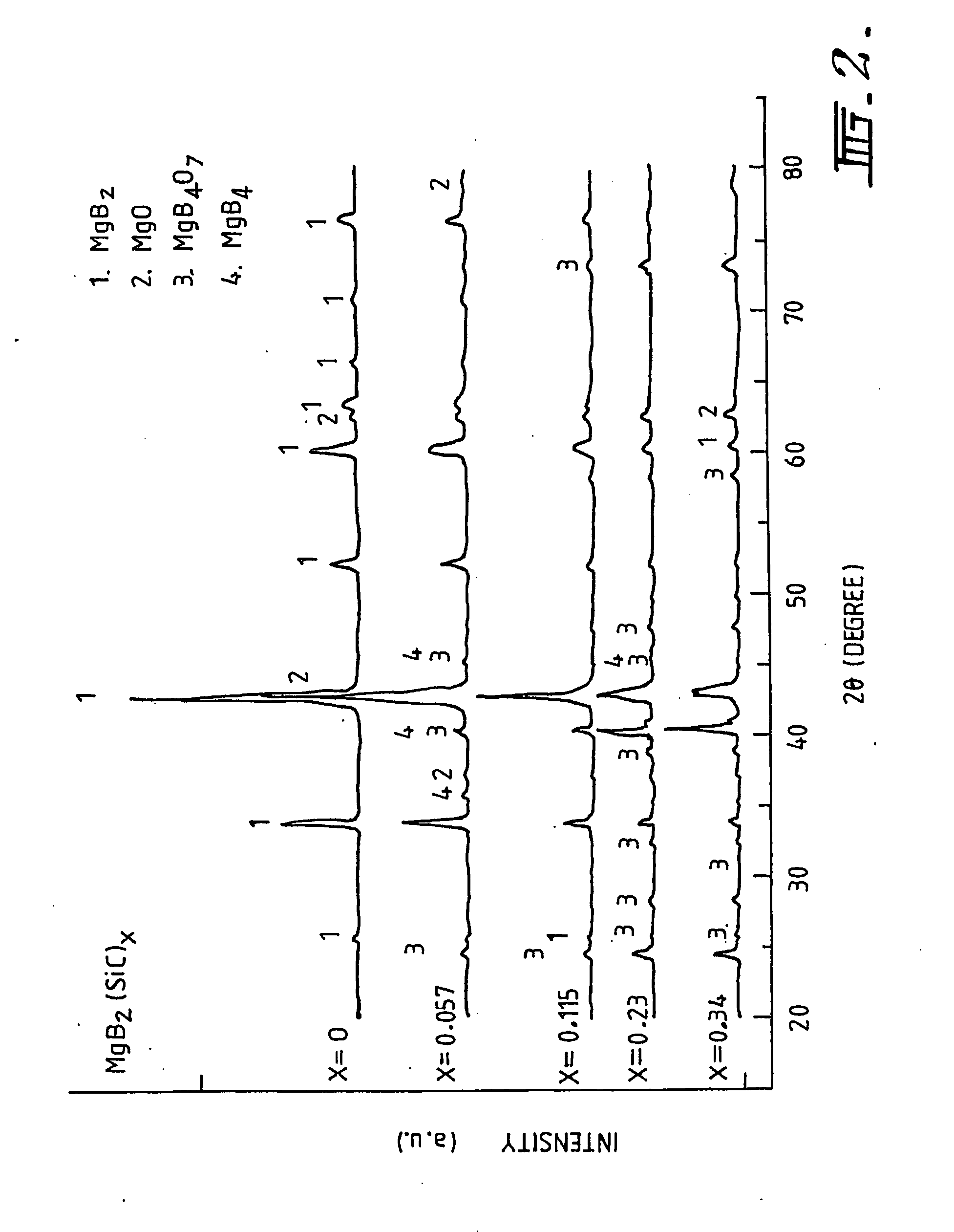

[0054] (Mg+2B)1−x(SiC)x samples were prepared by a reaction in-situ method. Powders of magnesium (99% purity) and amorphous boron (99% purity) were well mixed with SiC additive with the atomic ratio of (Mg+2B)1−x(SiC)x where x=0, 0.057, 0.117, 0.23 and 0.34 for samples 1 to 5 respectively (Table 1). The mixed powders were loaded into Fe tubes. The composite tubes were groove-rolled, sealed in a Fe tube and then directly heated at preset temperatures to 950° C. for 3 hours, in the presence of flowing high purity Ar. This was followed by quenching to liquid nitrogen temperature. Table 1 provides information, with samples 1, 2, and 3 being the undoped and doped with 5 wt % and 10 wt % MgO respectively.

[0055] The magnetization of 1.0×1.0×0.8 mm3 samples was measured over a temperature range of 5 to 30 K-using a Physical Property Measurement System (PPMS, Quantum Design) in a time-varying magnetic field of sweep rat...

example 2

Synthesis of MgB2−x(SiC)x using nanoparticle SiC to react with Mg and B

[0056] MgB2−x(SiC)x samples were prepared by a reaction in-situ method. Powders of magnesium (99% purity) and amorphous boron (99% purity) were thoroughlymixed with SiC additive, to prepare various samples with the following ratios of MgB2−x(SiC)x: X=0, 0.02, 0.05, 0.1, 0.15, 0.2, 0.5, 1.0, 1.5 and 2.0. The mixed powders were loaded into Fe tubes. The composite tubes were groove-rolled, sealed in a Fe tube and then directly heated at preset temperatures to 900° C., for 3 hours in the presence of flowing high purity Ar. This was followed by quenching to liquid nitrogen temperature.

example 3

Synthesis of MgB2−x−ySixCy using Mg, B, Si and C powders

[0057] MgB2 pellet samples were prepared by a reaction in-situ method. Powders of magnesium (99% purity) and amorphous boron (99% purity) were well mixed with SiC additive with the ratio of Mg+B2−x(SiC)x where x=0, 0.02, 0.05, 0.1, 0.15, 0.2, 0.5, 1.0, 1.5 and 2.0. The mixed powders were loaded into Fe tubes. The composite tubes were groove-rolled, sealed in a Fe tube and then directly heated at preset temperatures to 900° C., for 3 hours in flowing high purity Ar. This was followed by quenching to liquid nitrogen temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com