Preparation method of modified magnesium borate whisker/PP (propene polymer) composite material

A technology of magnesium borate whiskers and composite materials, which is applied in the field of polymer composite materials and the preparation of modified magnesium borate whiskers/PP composite materials, can solve the problems of limited wide application, large PP molding shrinkage rate, and high low temperature brittleness. To achieve the effect of broad application prospects, low cost and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The magnesium borate whisker sample that this example adopts is provided by Liaoning Yingkou Brother Boron Magnesium Chemical Co., Ltd. The surface modification treatment method of magnesium borate whiskers is as follows: put a 250ml flask containing 0.5g of coupling agent in an ultrasonic oscillator with a water temperature of 30-50°C, dissolve it in 100ml of absolute ethanol and add 25g of 120-140 The whiskers were dried at ℃ for 4 hours, electrically stirred and ultrasonically oscillated for 0.5-1 hour, filtered and washed, and then dried at 90-120 degrees Celsius for 4-6 hours to obtain surface-modified whiskers.

[0020] In this example, the modified magnesium borate whisker / PP composite material is prepared by the melt blending method, and the process is as follows:

[0021] (1) After the mixer is preheated to 185°C, add 100 parts of PP base material to melt for 5 minutes, add 2 parts of modified magnesium borate whiskers and mix for 8 minutes to obtain a semi-fin...

Embodiment 2

[0025] The surface modification treatment method of magnesium borate whisker is the same as example 1.

[0026] In this example, the modified magnesium borate whisker / PP composite material is prepared by the melt blending method, and the process is as follows:

[0027] (1) After the mixer is preheated to 185°C, add 100 parts of PP base material to melt for 5 minutes, add 5 parts of modified magnesium borate whiskers and mix for 8 minutes to obtain a semi-finished product;

[0028] (2) The semi-finished product obtained in step (1) is molded in a molding machine at a pressure of 10 MPa and a temperature of 185° C. for 6 minutes to obtain the modified magnesium borate whisker / PP composite material.

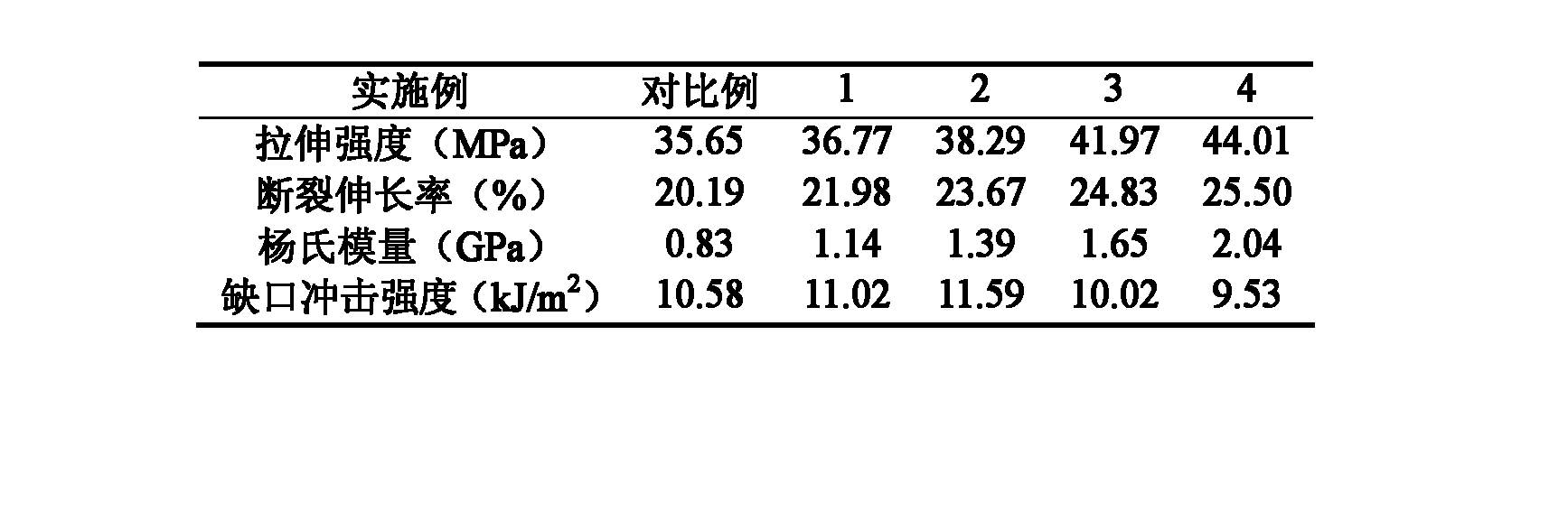

[0029] Composite material in embodiment 2 is made into standard tension and impact sample, carries out tension and impact performance test according to GB / T 1040-2006, GB / T 1843-1996 respectively, its result sees figure 1 .

Embodiment 3

[0031] The surface modification treatment method of magnesium borate whisker is the same as example 1.

[0032] In this example, the modified magnesium borate whisker / PP composite material is prepared by the melt blending method, and the process is as follows:

[0033] (1) After the mixer is preheated to 185°C, add 100 parts of PP base material to melt for 5 minutes, add 10 parts of modified magnesium borate whiskers and mix for 8 minutes to obtain a semi-finished product;

[0034] (2) Mold the semi-finished product obtained in step (1) in a molding machine at a pressure of 10 MPa and a temperature of 185°C for 6 minutes to obtain the modified magnesium borate whisker / PP composite material.

[0035] Composite material in embodiment 3 is made standard tension and impact sample, carries out tension and impact property test by GB / T 1040-2006, GB / T 1843-1996 respectively, and its result sees figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com