Method for preparing polyurethane loomage water proof and moisture permeable dressing agent

A waterproof and moisture-permeable polyurethane technology, which is applied in the preparation of polyurethane fabric waterproof and moisture-permeable finishing agents, in the field of polyurethane fabric waterproof and moisture-permeable finishing agents, can solve the problem of low response accuracy and response sensitivity of polyurethane waterproof and moisture-permeable coating materials, and waterproof Problems such as one-way moisture permeability and poor physical and mechanical properties, to achieve good physical and mechanical properties, improve response accuracy and response sensitivity, and high degree of microphase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

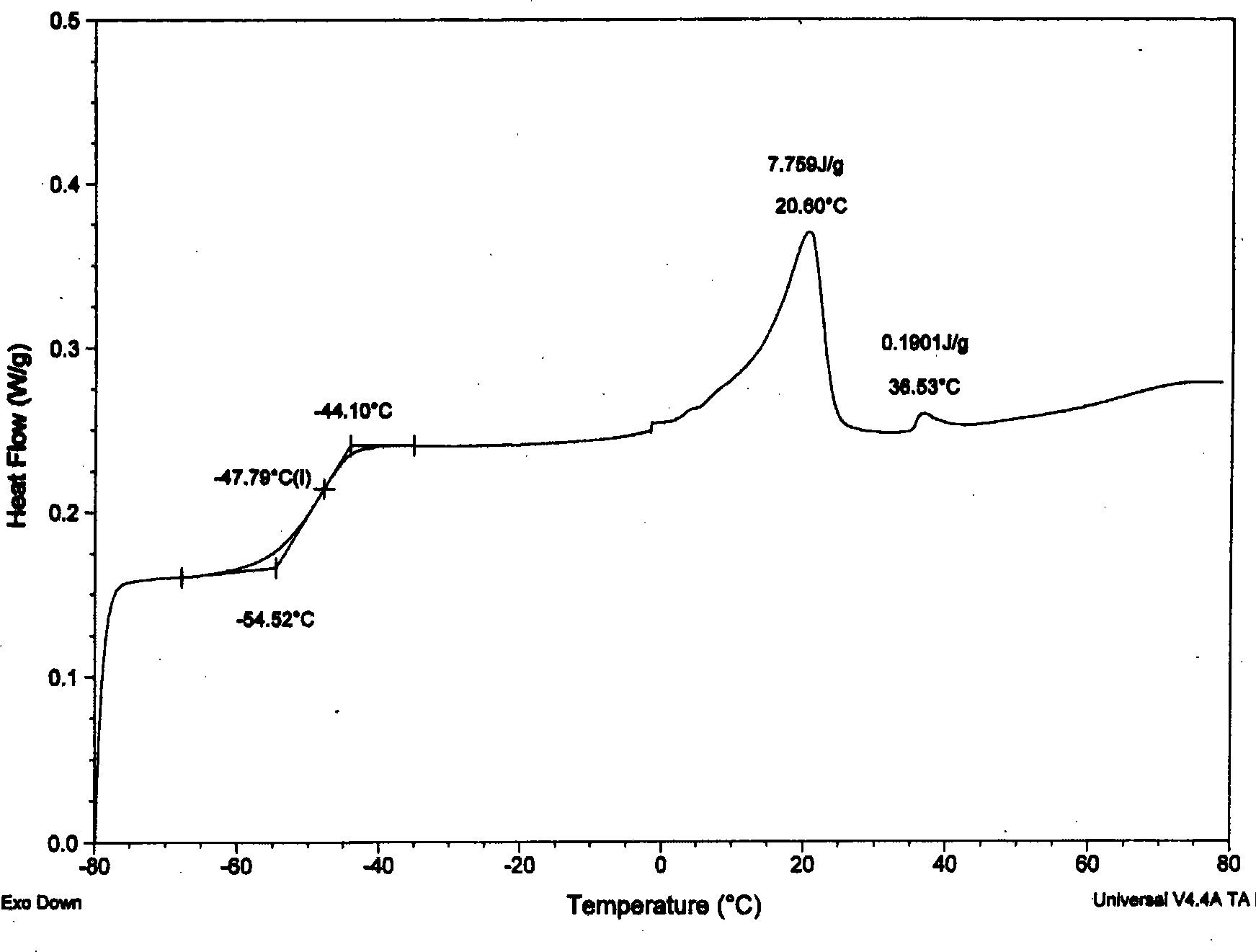

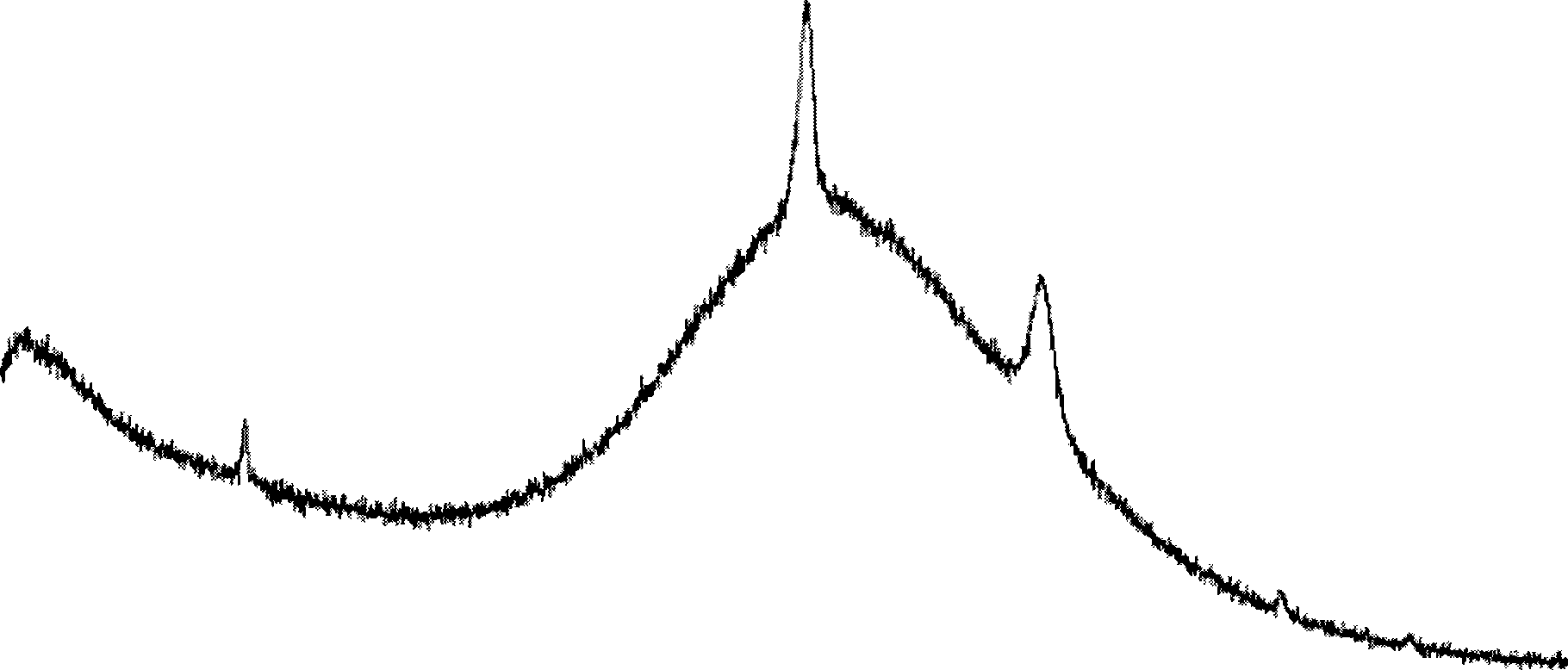

Image

Examples

Embodiment 1

[0054] The raw material of this preparation method comprises:

[0055] 1. Polyether polyol

[0056] 0.40 mol of polyethylene glycol with a molecular weight of 3000, 0.60 mol of polypropylene glycol with a molecular weight of 2000, and 0.15 mol of polyglycerol with a molecular weight of 4000.

[0057] 2. Diisocyanate

[0058] 3.00 mol of 4,4'-diphenylmethane diisocyanate.

[0059] 3. Chain extender

[0060] Dimethylolpropionic acid 1.775mol.

[0061] 4. Neutralizer

[0062] Triethylamine is used to control and adjust the pH of the emulsion to be about 7-9.

[0063] 5. Additives

[0064] Acetone (appropriate amount, used to adjust the viscosity of the reaction system); methanol (appropriate amount, used to terminate the reaction); deionized water (adjust the solid content of the product to 15-20%)

[0065] Conditions and equipment of the preparation method:

[0066] Reaction pressure: minus one atmosphere ~ one atmosphere;

[0067] Reaction temperature: 30~90℃;

[0068...

Embodiment 2

[0085] The raw material of this preparation method comprises:

[0086] 1. Polyether polyol

[0087] 0.60 mol of polyethylene glycol with a molecular weight of 2000, 0.40 mol of polytetrahydrofuran diol with a molecular weight of 2000, and 0.15 mol of ethylene oxide / propylene oxide random block copolyol with a molecular weight of 4000.

[0088] 2. Diisocyanate

[0089] Toluene diisocyanate 3.60mol.

[0090] 3. Chain extender

[0091] 0.500 mol of 1,4-butanediol and 1.875 mol of N-methyldiethanolamine.

[0092] 4. Neutralizer

[0093] The amount of formic acid is controlled to adjust the pH of the finished emulsion to about 4-6.

[0094] 5. Additives

[0095] Acetone (appropriate amount, used to adjust the viscosity of the reaction system); ethanol (appropriate amount, used to terminate the reaction); deionized water (adjust the solid content of the product to 20-25%).

[0096] Preparation conditions and equipment of the preparation method:

[0097] Reaction pressure: on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com