Preparation method for precious metal powder with high tap density

A technology of tap density and precious metal, applied in the field of preparation of precious metal powder, can solve the problems of insufficient dense film layer, particle agglomeration, large slurry sintering shrinkage, etc., and achieve the effect of simple and easy reaction steps and taking into account the dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

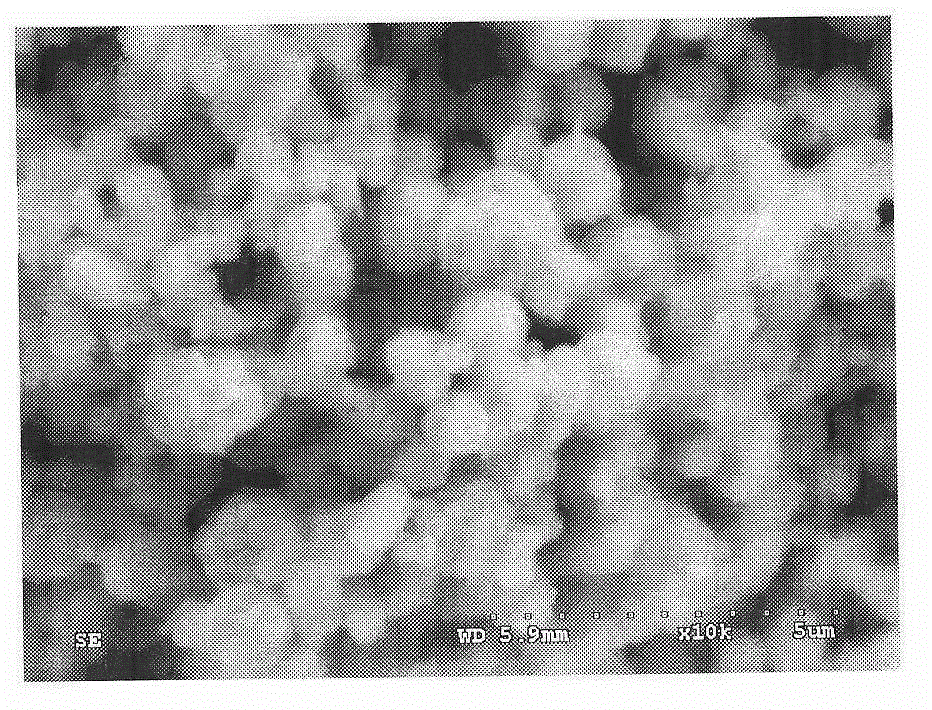

[0029] Prepare 1L of silver nitrate solution with a concentration of 200g / L and 1L of vitamin C reduction solution with a concentration of 200g / L, respectively, and add 500mL of a gelatin dispersant solution with a concentration of 200g / L and 5mL of polyethylene with a concentration of 1g / mL to the reduction solution. Alcohol butyral solution, take the reducing agent solution after adding the dispersant as the mother liquor, add the silver nitrate solution drop by drop into the reducing mother liquor while stirring, continue stirring for 5-10min after the addition is completed, and pour the powder after the color of the powder no longer changes. Add 1g of ethyl octanoate to the reaction system, and then let it settle; wash the precipitate with deionized water for 3-5 times, and dry the powder at 60°C. The obtained silver powder is as follows: figure 1 As shown, it has a good spherical shape, and its particle size distribution is as follows figure 2 As shown, the D50 is 2.3 μm...

Embodiment 2

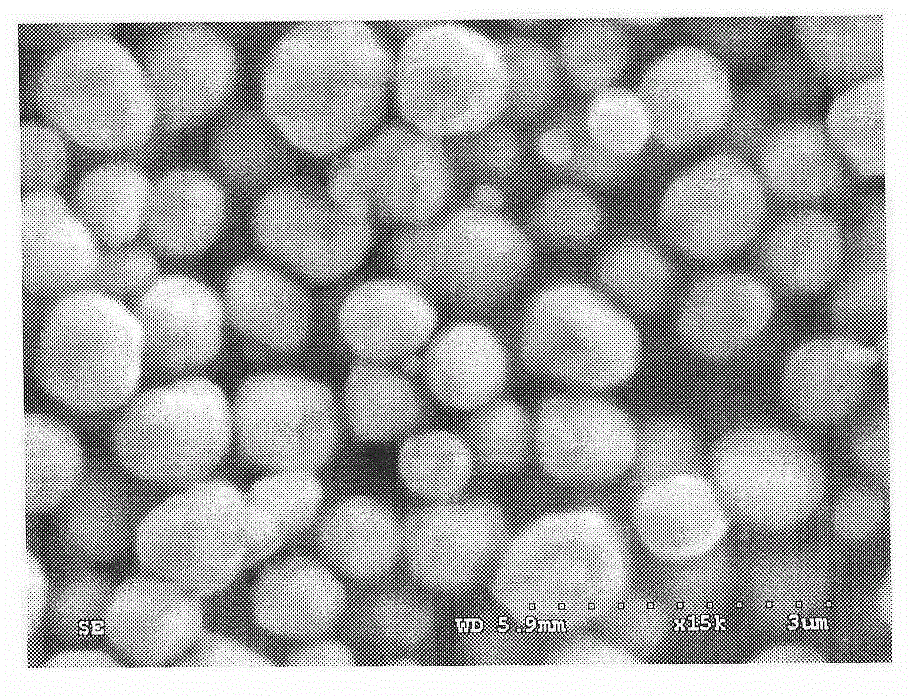

[0031] Preparation concentration is 1L of chloroauric acid solution 1L of 100g / L and 1L of vitamin C reducing solution of 100g / L respectively, and in reducing solution, add 500mL concentration and be the polyvinyl alcohol dispersant solution of 20g / L, to add the dispersant after The reducing agent solution is the mother liquor. Add the chloroauric acid solution to the reducing mother liquor within 5 seconds under stirring. After the addition, continue to stir for 5-10 minutes. After the powder color no longer changes, add 0.5g stearic acid to the reaction system, and then Set aside to settle; after washing the precipitate with deionized water for 3-5 times, dry the powder at 60°C, the obtained gold powder is as follows image 3 As shown, it has good spherical shape, D50 is 1.7μm, good dispersion, narrow particle size distribution, and tap density is 8.1g / mL.

Embodiment 3

[0033] Preparation concentration is 1L of palladium nitrate solution 1L of 200g / L and 1L of sodium hypophosphite reducing solution of 200g / L respectively, and in reducing solution, add 160mL concentration and be 200g / L polyvinylpyrrolidone dispersant solution and 3mL concentration be 1g / L mL of acrylic resin solution, take the reducing agent solution after adding the dispersant as the mother liquor, add the palladium nitrate solution dropwise into the reducing mother liquor under stirring, continue stirring for 5-10min after the addition is completed, and pour the powder after the color of the powder no longer changes. Add 1g of cetyl alcohol to the reaction system, and then let it settle; wash the precipitate with deionized water for 3-5 times, and dry the powder at 60°C. The particle size distribution of the obtained palladium powder is as follows: Figure 4 As shown, the D50 is 1.4 μm, the dispersion is good, the particle size distribution is narrow, and the tap density is 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com