A kind of preparation method of high tap density silver powder

A technology of tap density and silver powder, which is applied in the field of preparation of high tap density silver powder, can solve the problems of expensive chloroplatinic acid reagent, limited application, complicated process flow, etc., and achieves the effects of low price, reduced production cost, and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

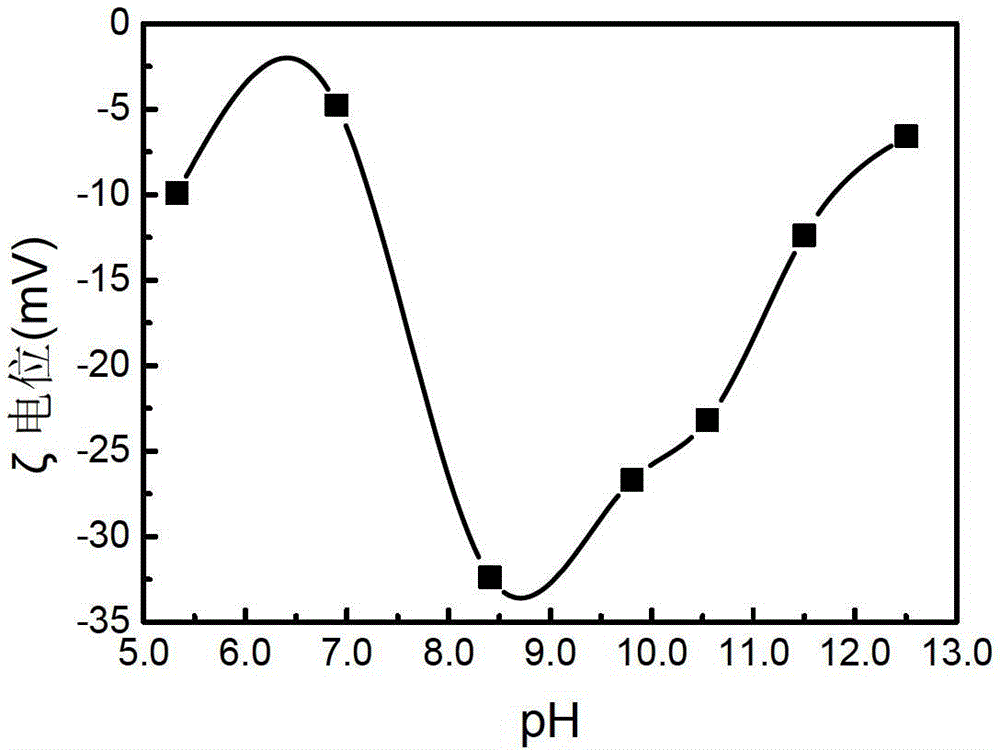

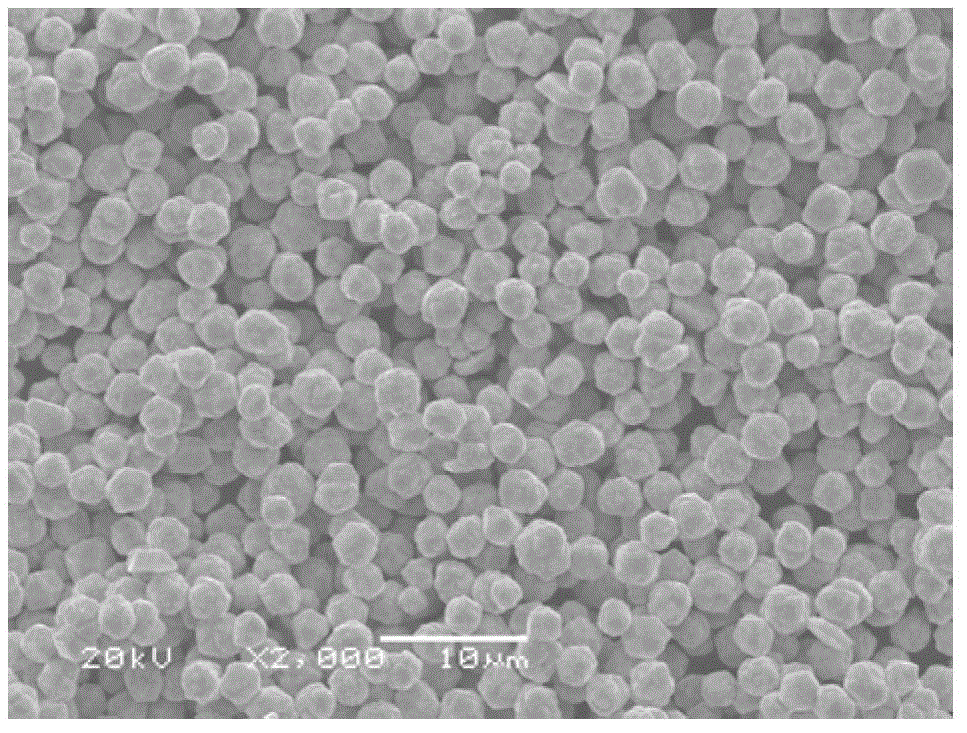

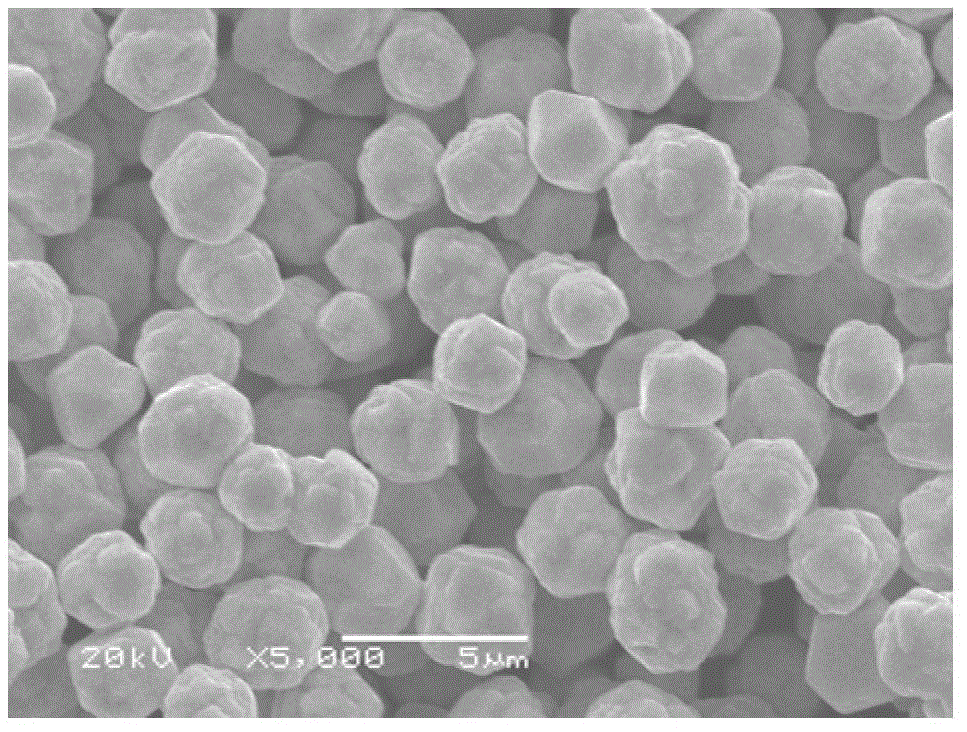

[0030] Prepare 1000mL of 50g / L silver nitrate solution, add concentrated ammonia water with a mass percentage concentration of 25-28% to it to obtain a silver ammonia solution with a pH=11.0; then measure 100mL of a 30% mass percentage concentration of hydrogen peroxide solution, And add water to it to dilute the hydrogen peroxide to 1000mL;

[0031] Use 200ml of deionized water as the bottom solution, heat the deionized water bath to 30°C; within 20s, add the silver ammonia solution and hydrogen peroxide solution into the bottom solution in parallel while fully stirring, react for 30min, and pass the concentration of 1mol / L NaOH solution to maintain the pH value in the reaction system throughout the process at 8.0-9.5. Then filter the reacted solution to obtain silver powder, wash the obtained silver powder 3 times with deionized water, and then wash 3 times with absolute ethanol; finally put the silver powder in a vacuum drying oven at 40°C and -0.08MPa Let dry for 10 hour...

Embodiment 2

[0034] Prepare 1000mL of 40g / L silver nitrate solution, add concentrated ammonia water with a mass percentage concentration of 25-28% to it to obtain a silver ammonia solution with a pH=10.5; measure 120mL of a 30% mass percentage concentration of hydrogen peroxide solution, and add Add water to dilute the hydrogen peroxide to 700mL;

[0035] Use 100mL deionized water as the bottom solution, heat the deionized water bath to 20°C, within 15s, add the silver ammonia solution and hydrogen peroxide solution into the bottom solution in parallel flow while fully stirring, react for 20min, and pass the concentration The 1.5 mol / L NaOH solution keeps the pH value of the reaction system in the whole process in the range of 8.0-9.5. Then the solution after the reaction is filtered to obtain silver powder, the silver powder obtained is cleaned 4 times with deionized water, and then cleaned 3 times with absolute ethanol, and finally the obtained silver powder is dried in a vacuum oven at ...

Embodiment 3

[0038] Prepare 1000mL of 30g / L silver nitrate solution, add concentrated ammonia water with a mass percentage concentration of 25-28% to it to obtain a silver ammonia solution with a pH=11.5; measure 40mL of a 30% mass percentage concentration of hydrogen peroxide solution, and Add water to it to dilute the hydrogen peroxide to 400mL;

[0039] Take 100mL deionized water as the bottom solution, heat the deionized water bath to 50°C, and within 30s, add the silver ammonia solution and hydrogen peroxide solution into the bottom solution while fully stirring, and react for 15 minutes, and by adding the concentration of 2mol / L NaOH keeps the pH value of the reaction system in the whole process in the range of 8.0-9.5. Then the solution after the reaction is filtered to obtain silver powder, the silver powder obtained is cleaned 3 times with deionized water, and then cleaned 2 times with absolute ethanol, and finally the cleaned silver powder is dried in a vacuum drying oven at 75°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com