Method for constructing large raft foundation under high temperature

A construction method and technology of high temperature environment, applied in the field of "cabin separation, can solve the problems of construction arrangement impact, temperature generation, shrinkage cracks, simultaneous parallel operation impact and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

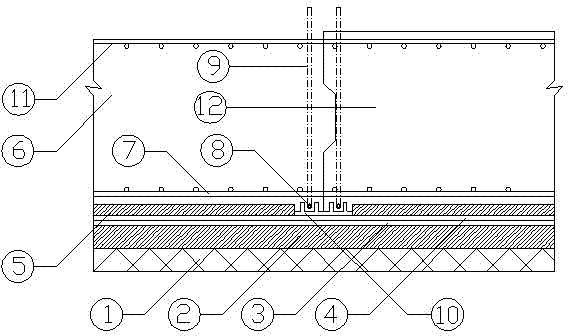

[0025] From figure 1 Visible, construction method of the present invention is specifically as follows:

[0026] 1) "Cabin partition" design:

[0027] On the basis of focusing on the local high temperature environment factors, the length of the raft foundation concrete without construction cracks is determined by calculation, and the raft foundation is divided into small pieces to form a "cabin separation". The construction joints of the raft foundation meet the design requirements and considerations the elements of:

[0028] Concrete is generally controlled at 1500-2500 square meters per block;

[0029] Stagger the positions of tower crane foundation and column foundation;

[0030] Avoid the position involved in the overlapping of the bent reinforcement of the independent column foundation and the reinforcement of the foundation pit of another adjacent column;

[0031] Avoid underground pipelines, kitchens, toilets, pool wells and other pipeline locations;

[0032] Compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com