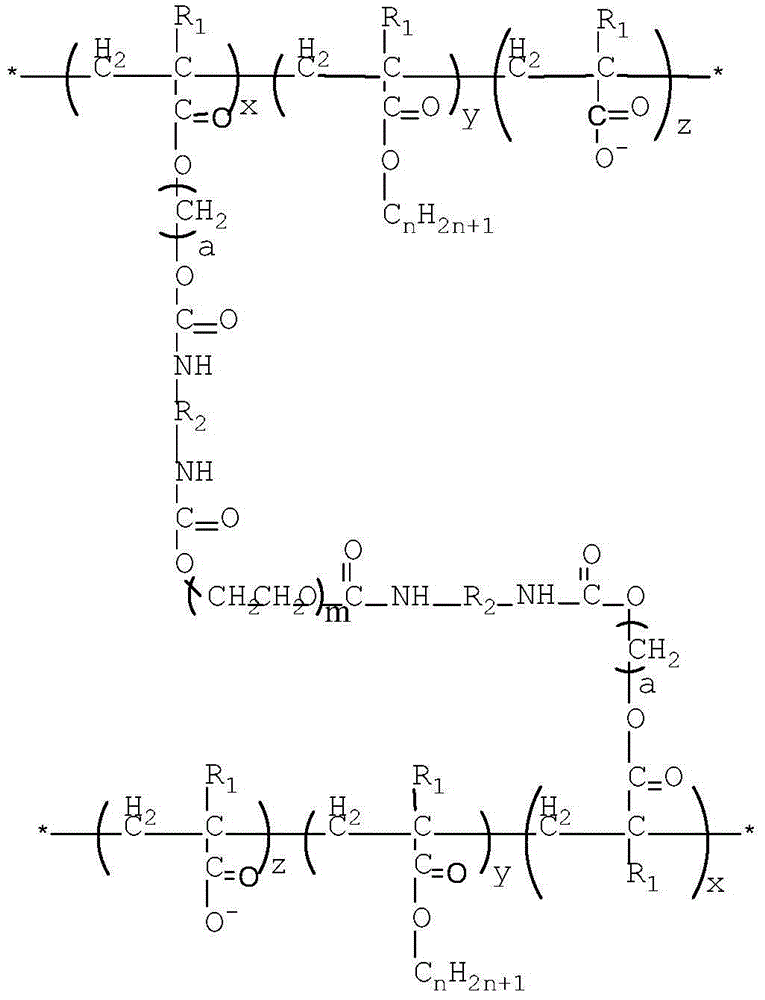

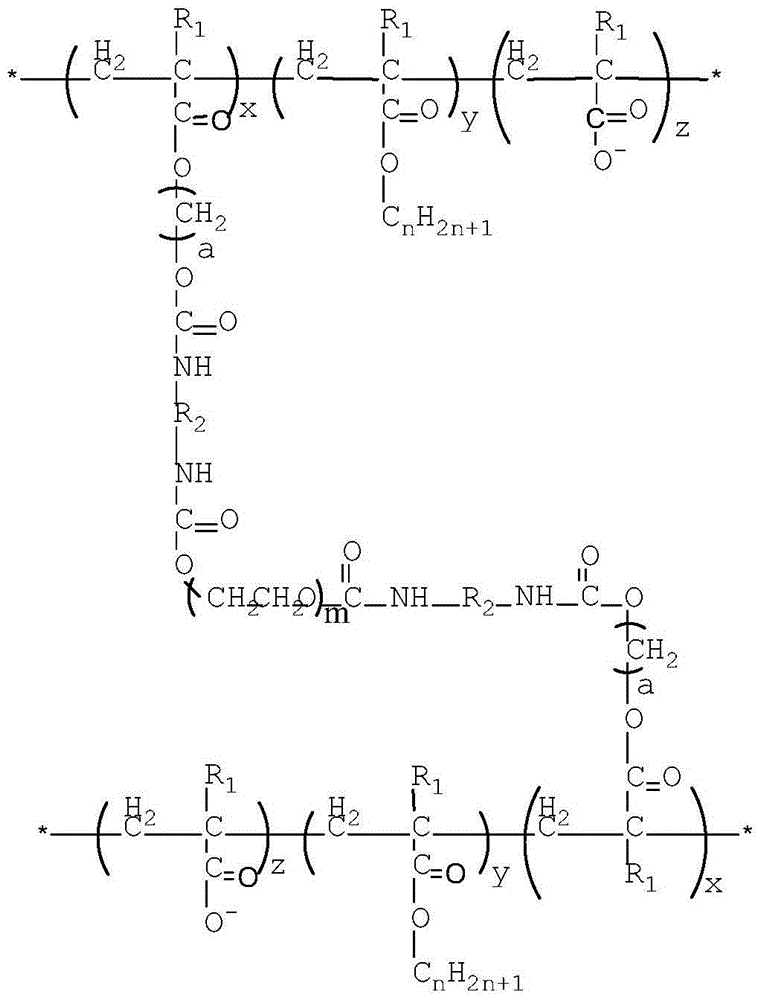

Self-dispersing UV photo-curing urethane acrylate aqueous copolymer, preparation method of aqueous copolymer and aqueous emulsion prepared from aqueous copolymer

A polyurethane acrylate, acrylate technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as reducing the performance of water emulsions, and achieve high cohesion, improved cohesion, oxidation resistance and high elongation at break. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of polyurethane prepolymer: vacuum-dry polyether PEG300 (molecular weight: 300) in a vacuum oven at 120°C to remove water for 4 hours; add 100 parts of dehydrated Polyether PEG300, heat up to 60°C, add 25 parts of toluene diisocyanate, mix evenly under stirring condition, heat up to 70°C, react for 6 hours to obtain polyurethane prepolymer PU1.

[0042]Preparation of acrylate prepolymer solution: by weight, add 75 parts of isobutyl methacrylate, 5 parts of hydroxypropyl acrylate, 20 parts of acrylic acid, 100 parts of 3 parts of xylene, 3 parts of azobisisovaleronitrile, stirred and mixed uniformly, after heating up to 100°C for 10 hours, adding 1.2 parts by weight of benzyldiethylammonium chloride and 8 parts by weight of glycidyl methacrylate, The temperature was raised to 102° C. for 3 hours to react to prepare an acrylate prepolymer PA1 solution.

[0043] Preparation of self-dispersing UV photocurable polyurethane acrylate water-based copolymer: 25 part...

Embodiment 2

[0047] Preparation of polyurethane prepolymer: vacuum-dry polyether PEG10000 (molecular weight: 10000) in a vacuum oven at 120°C to remove water for 4 hours; add 100 parts of dehydrated Polyether PEG10000, heat up to 58°C, add 20 parts of diphenylmethane diisocyanate, mix evenly under stirring condition, heat up to 75°C, react for 5 hours to obtain polyurethane prepolymer PU2.

[0048] Preparation of acrylate prepolymer solution: by weight, add 65 parts of isooctyl methacrylate, 10 parts of hydroxyethyl acrylate, 25 parts of methacrylic acid in the reactor equipped with stirrer, thermometer and reflux condenser , 100 parts of ethylene glycol monomethyl ether, 2.5 parts of azobisisobutyronitrile, stir and mix evenly, heat up to 85 ° C and react for 14 hours, add 1.5 parts by weight of tetrabutylammonium bromide and 15 parts by weight of glycidyl acrylate ester, heated to 102°C and reacted for 6 hours to prepare acrylate prepolymer PA2 solution.

[0049] Preparation of self-dis...

Embodiment 3

[0053] Preparation of polyurethane prepolymer: vacuum dry polyether N220 (molecular weight: 2000) in a vacuum oven at 120°C to remove water for 4 hours; add 100 parts of dehydrated Polyether N220, heat up to 65°C, add 25 parts of isophorone diisocyanate, mix evenly under stirring, heat up to 70°C, react for 6 hours to obtain polyurethane prepolymer PU3.

[0054] Preparation of acrylate prepolymer solution: by weight ratio, add 80 parts of isopropyl methacrylate, 5 parts of hydroxyethyl acrylate, 15 parts of methacrylic acid in the reactor equipped with stirrer, thermometer and reflux condenser , 100 parts of dioxane, 2 parts of azobisisoheptanonitrile, stirred and mixed uniformly, heated to 90 ° C for 15 hours, then added 1.8 parts by weight of tetrabutylammonium chloride and 18 parts by weight of glycidyl acrylate, Raise the temperature to 102°C and react for 7 hours to prepare an acrylate prepolymer PA3 solution.

[0055] Preparation of self-dispersing UV photocurable polyu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com