Semi-prefabricated comprehensive pipe rack and construction method thereof

A technology of integrated pipe gallery and construction method, which is applied in artificial islands, water conservancy projects, protection devices, etc., can solve the problems of large wet work workload, long construction period, and high construction cost on site, so as to overcome the long construction period and meet the waterproof requirements Requirements, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

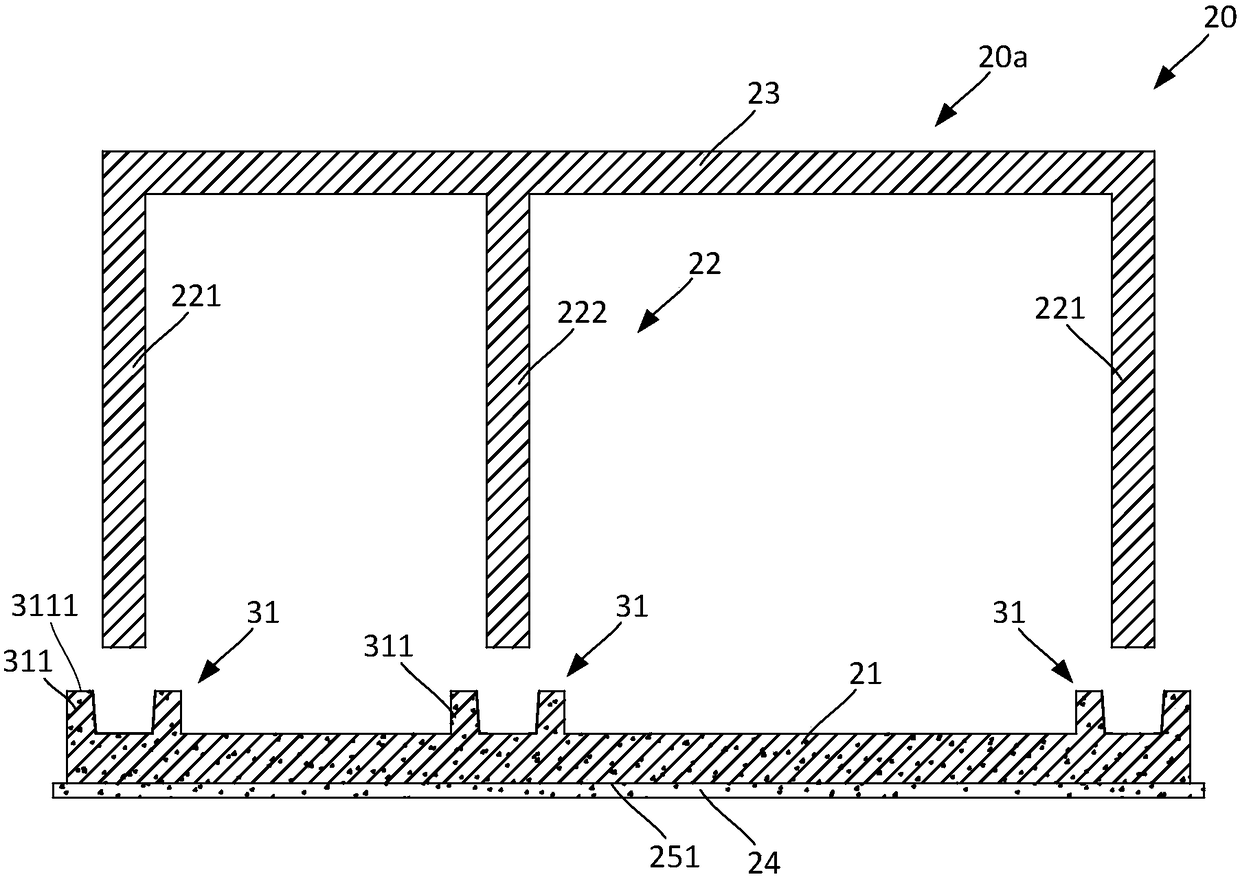

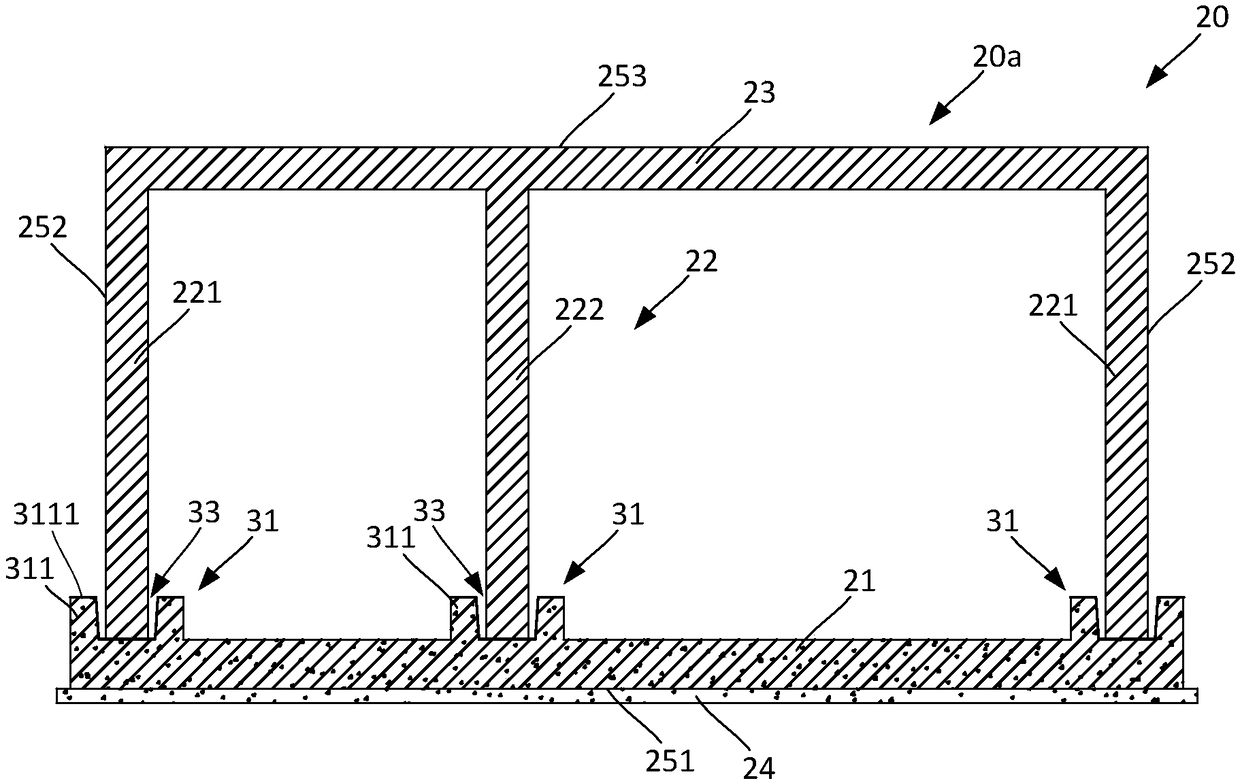

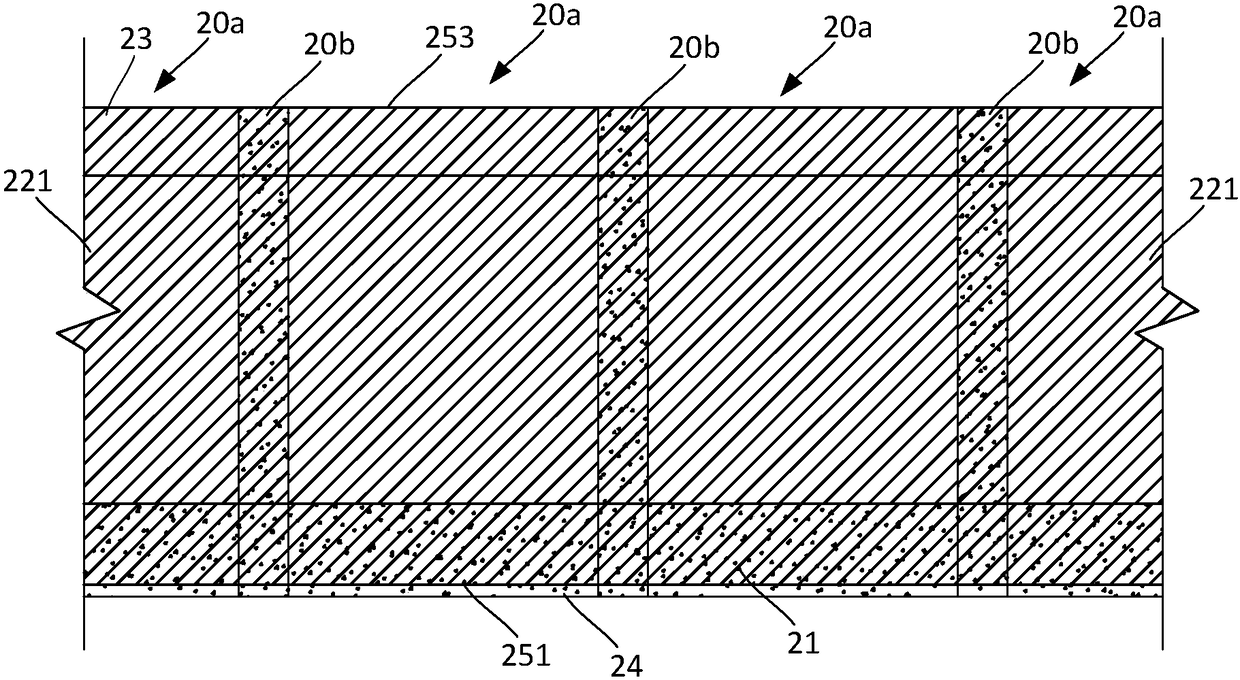

[0040] refer to figure 1 , the present invention provides a semi-prefabricated integrated pipe gallery and its construction method. The use of cup groove joints avoids the overlapping and binding construction of steel bars between prefabricated components and cast-in-place components, and fully utilizes the cast-in-place pipe gallery and fully prefabricated The advantages of both pipe galleries overcome the disadvantages of long construction time of cast-in-place pipe galleries, heavy wet work workload, low production efficiency and small transportation volume of fully prefabricated pipe galleries, environmental protection, energy saving, high construction efficiency, and excellent waterproof performance. The integral prefabricated form of the wallboard and the roof of the present invention can save the time for the formwork and support of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com