Optical fiber F-P pressure sensor and pressure liquid level sensing device thereof

A technology of a pressure sensor and a sensing device, applied in the direction of displaying a liquid level indicator through pressure measurement, fluid pressure measurement using an optical method, fluid pressure measurement of an elastic deformation gauge, etc., which can solve the problem of small linear elastic range of silicon wafers, Insufficient measurement accuracy, limited range and other problems, to achieve the effect of small size, mature technology and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and embodiment describe in detail:

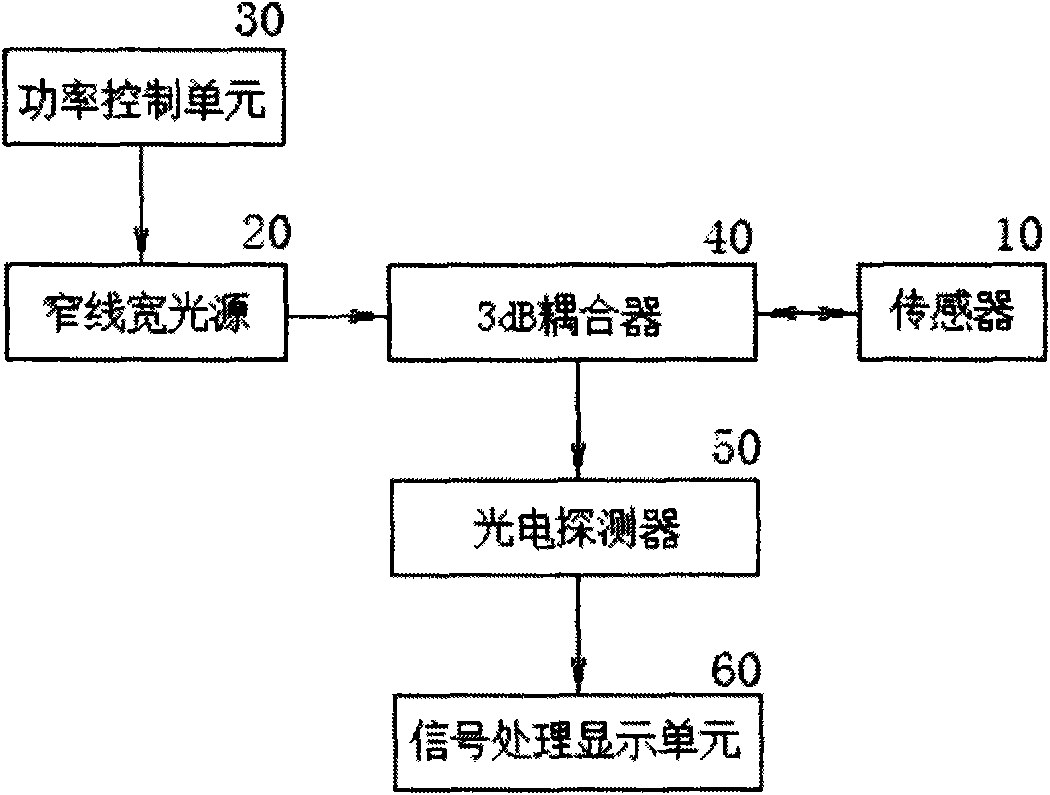

[0049] 1. Optical fiber F-P pressure sensor (referred to as sensor) 10

[0050] 1. Overall

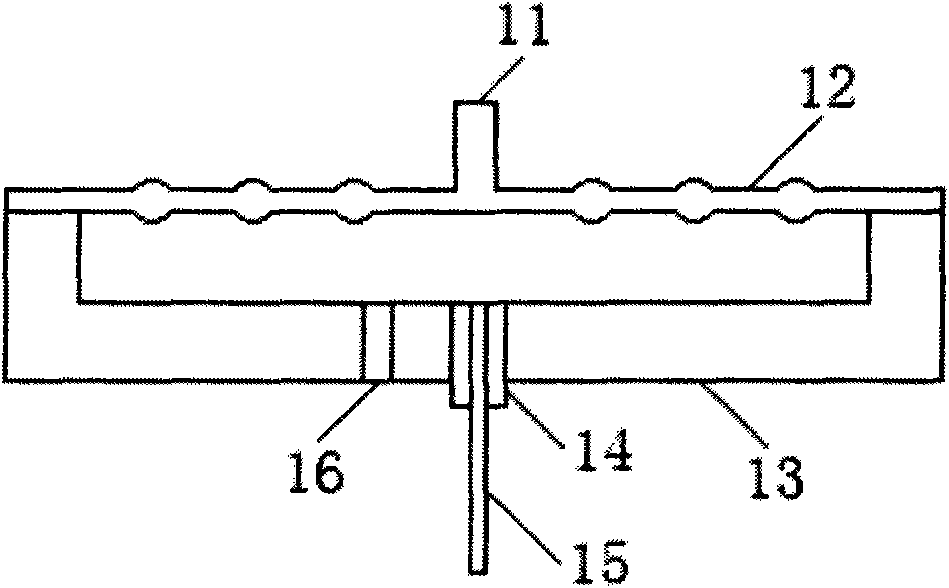

[0051] Such as figure 1 , the sensor 10 includes a pressure injection hole 11, a pressure capsule / sheet 12, a support 13, an optical fiber fixing hole 14, a conductive optical fiber 15 and an air pressure balance hole 16;

[0052] The pressure membrane box / sheet 12 with the pressure injection hole 11 in the center is sealed and connected with the periphery of the opening of the support 13; the center of the bottom surface of the support 13 is provided with an optical fiber fixing hole 14 and an air pressure balance hole 16, and the optical fiber fixing hole 14 is connected with a conductive Fiber 15;

[0053] An extrinsic F-P cavity is formed between the end face of the conducting fiber 15 and the center plane of the pressure bellows / sheet 12.

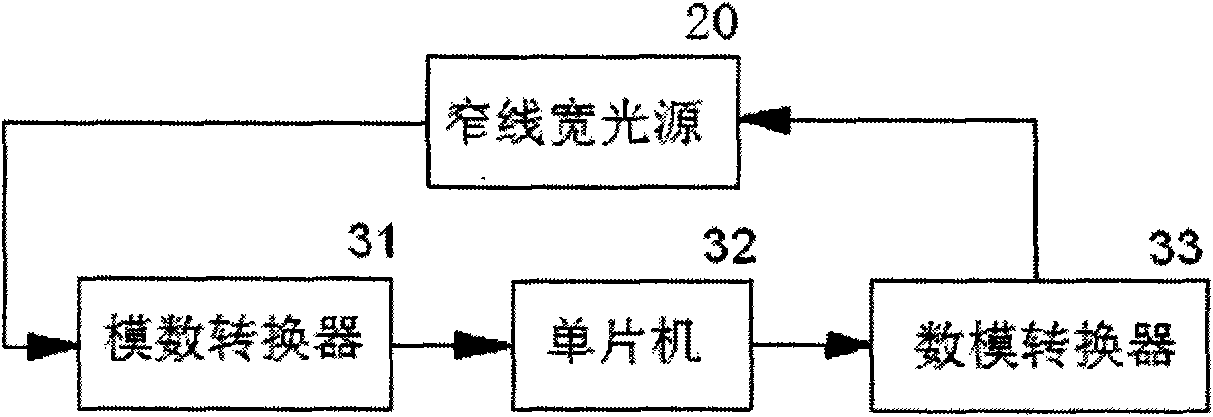

[0054] 2. Function block

[0055] 1. Pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com