Construction process for filling joints between door and window and universal auxiliary frame and side frame of buildings by pressure injection

A technology for building doors, windows and construction technology, applied in the direction of joint tightening/covering, frame fixing, etc., can solve problems such as water leakage, and achieve the effect of improving compactness, improving quality and safety, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

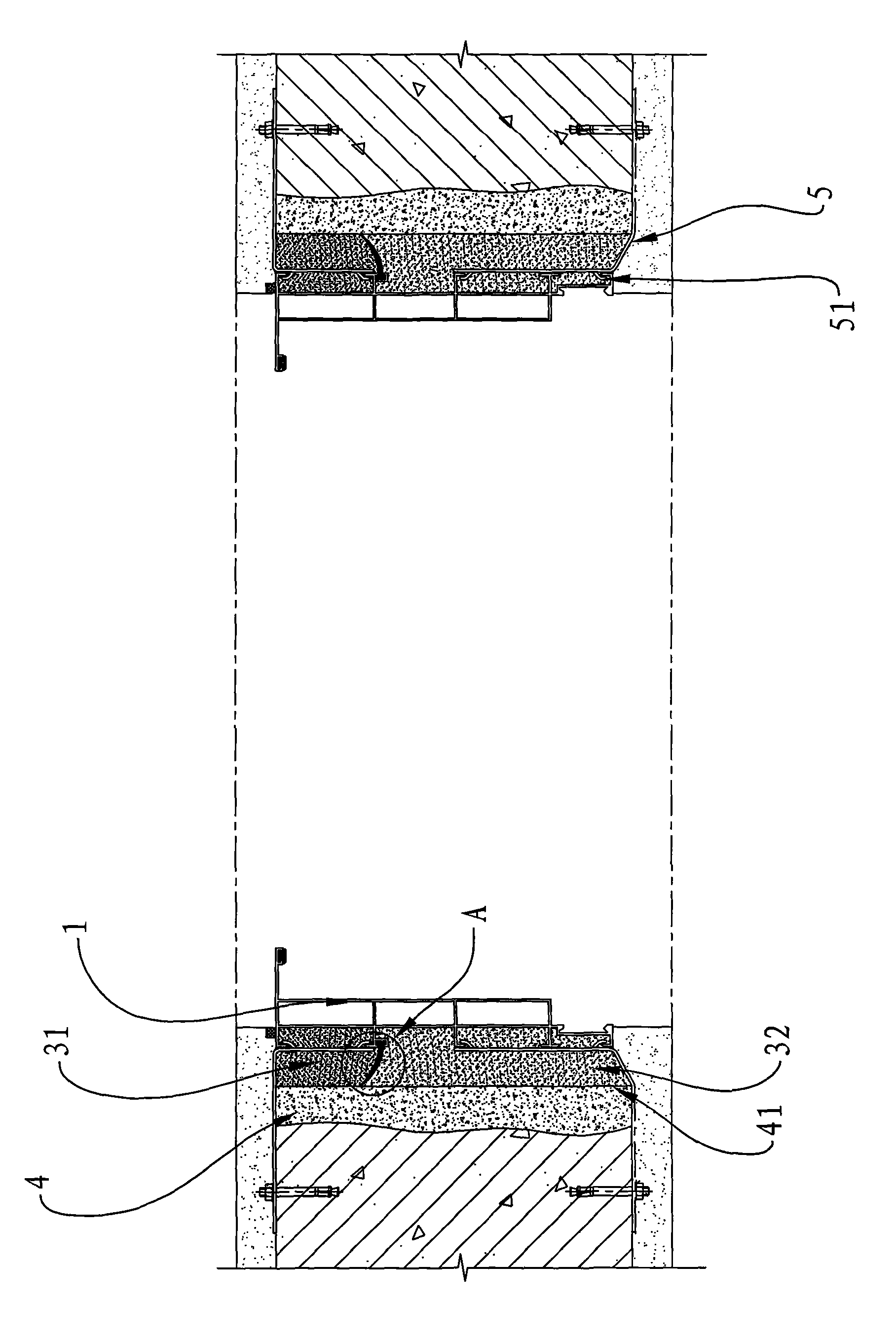

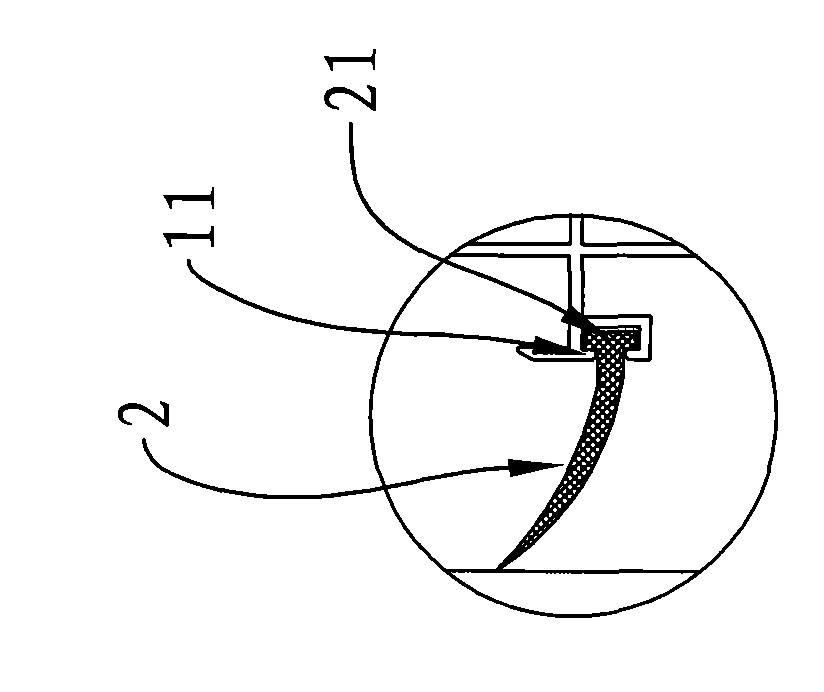

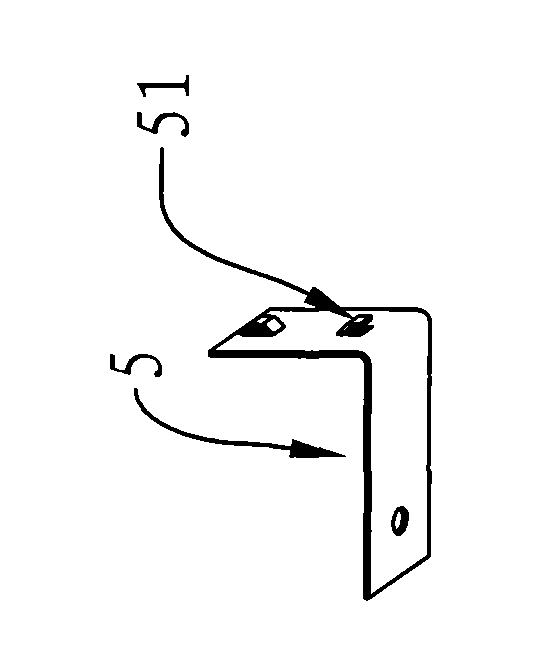

[0025] Specific embodiments of the present invention are described with reference to the above drawings.

[0026] Such as Figure 1 to Figure 3 As shown, the present invention provides a kind of building door and window hole and general attached frame, the construction technology of frame pressure injection caulking comprises the following steps:

[0027] A. Install a retaining strip 2 near the outer side of the supplementary frame and frame 1 on the outer side of the supplementary frame and frame 1, and the retaining strip 2 is continuously distributed along the periphery of the supplementary frame and border 1;

[0028] B. Embed the attached frame and frame 1 described in step A into a predetermined position in the hole from the outward side of the hole, and the continuously distributed retaining strip 2 separates the gap between the attached frame, frame 1 and the hole to the outside Slit 31 and inner slit 32;

[0029] C. Use mechanical pressure to inject filler material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com