Composite synergistic close-graded ultrathin wearing layer asphalt mixture

A technology of asphalt mixture and compound efficiency, applied in the field of road paving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The asphalt mixture in this example is mainly composed of three components: 100 parts by mass of mineral aggregate, 5.8 parts by mass of SBS modified asphalt and 0.35 parts by mass of composite synergist. The SBS modified asphalt is SBS from Jiangsu Baoli Modified asphalt, mineral materials include basalt aggregate and limestone powder, the quality of basalt aggregate and limestone powder accounted for 96% and 4% of the mineral material respectively, basalt aggregate is divided into three groups according to aggregate particle size, the first A group of aggregate particle size: 5 ~ 10mm; the second group of aggregate particle size: 3 ~ 5mm; the third group of aggregate particle size: 0 ~ 3mm, and the percentage of the aggregate mass of the three groups in the total mass of mineral materials is as follows: 58%, 6%, 32%.

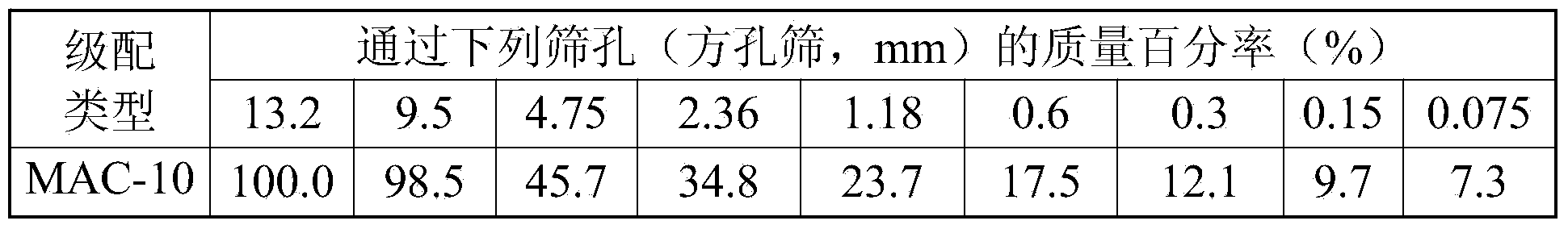

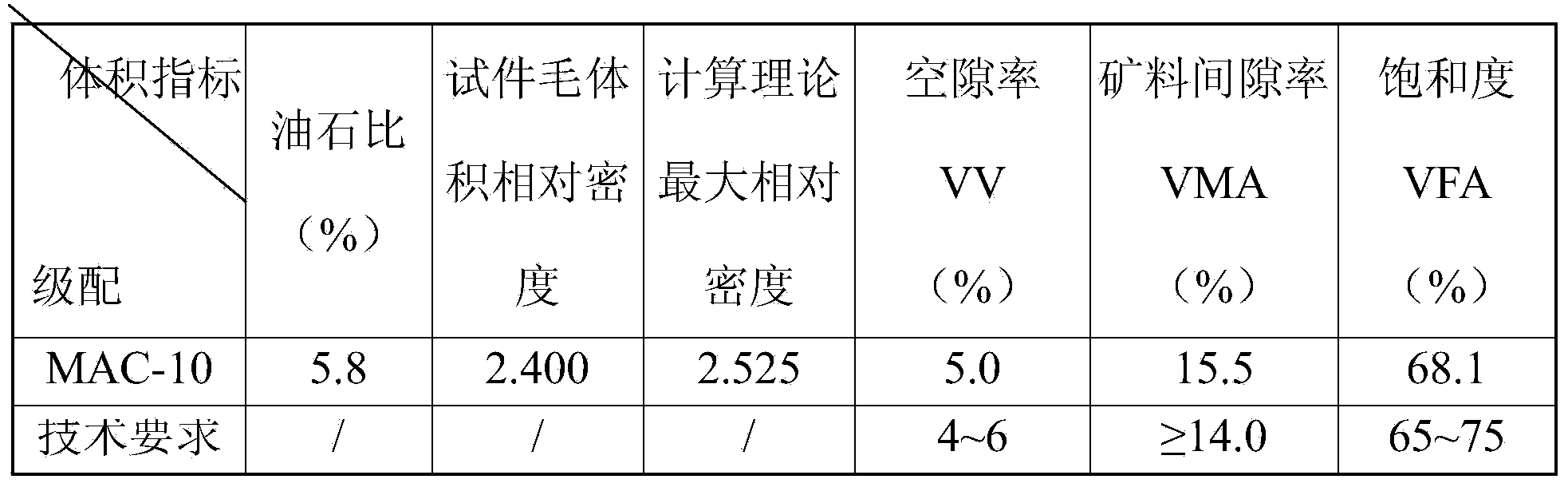

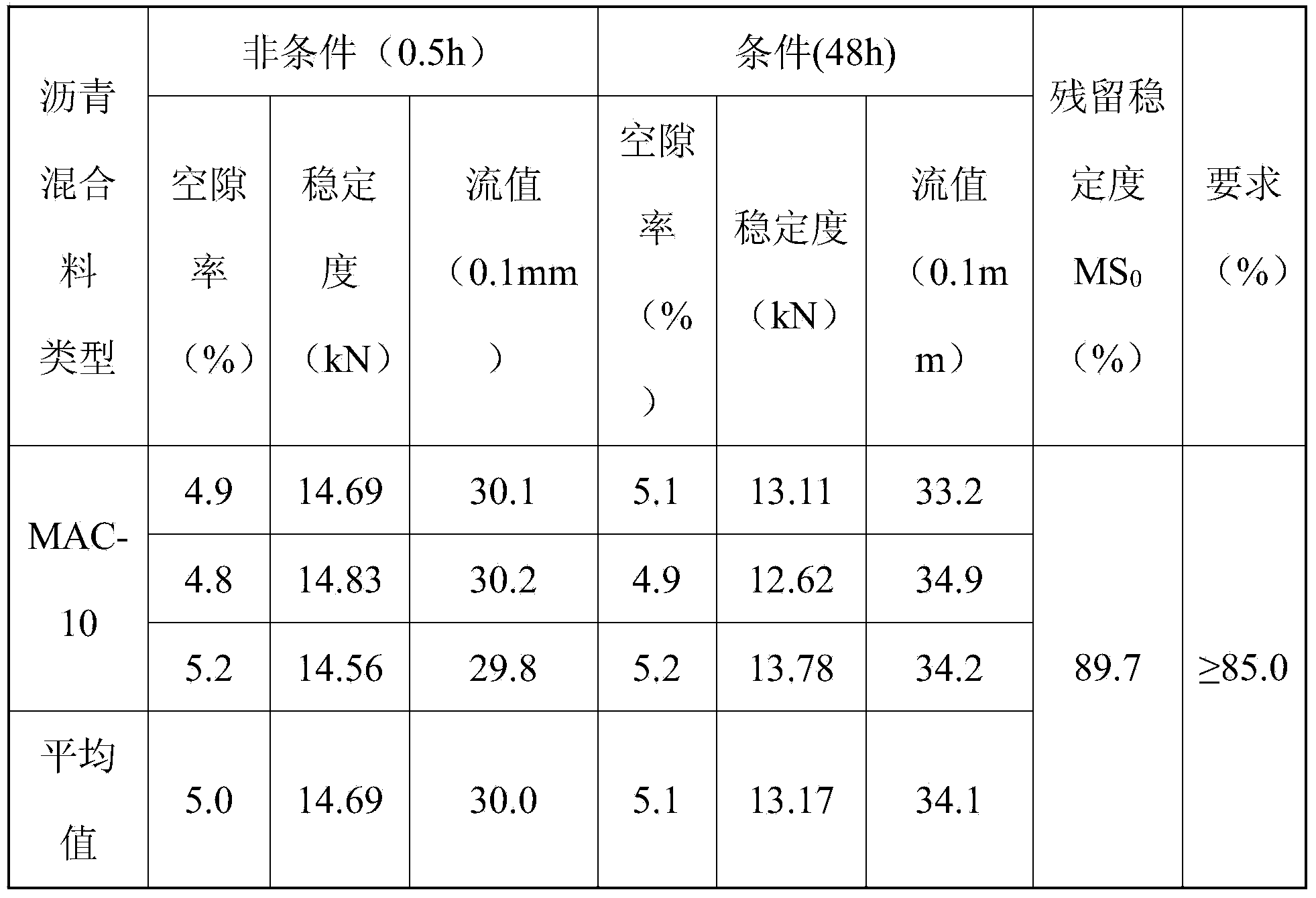

[0027] According to the requirements, the density test of SBS modified asphalt (see Table 1 for the results), the density test of each group of aggrega...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com