Steel pipe annealing equipment and steel pipe annealing technology

A technology of annealing equipment and annealing process, used in heat treatment equipment, manufacturing tools, furnaces, etc., can solve the problems of uneven hardness of steel pipes, low tensile strength and elongation of steel pipes, easy rupture of steel pipes, etc., to eliminate internal stress and yield. The effect of reducing strength and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

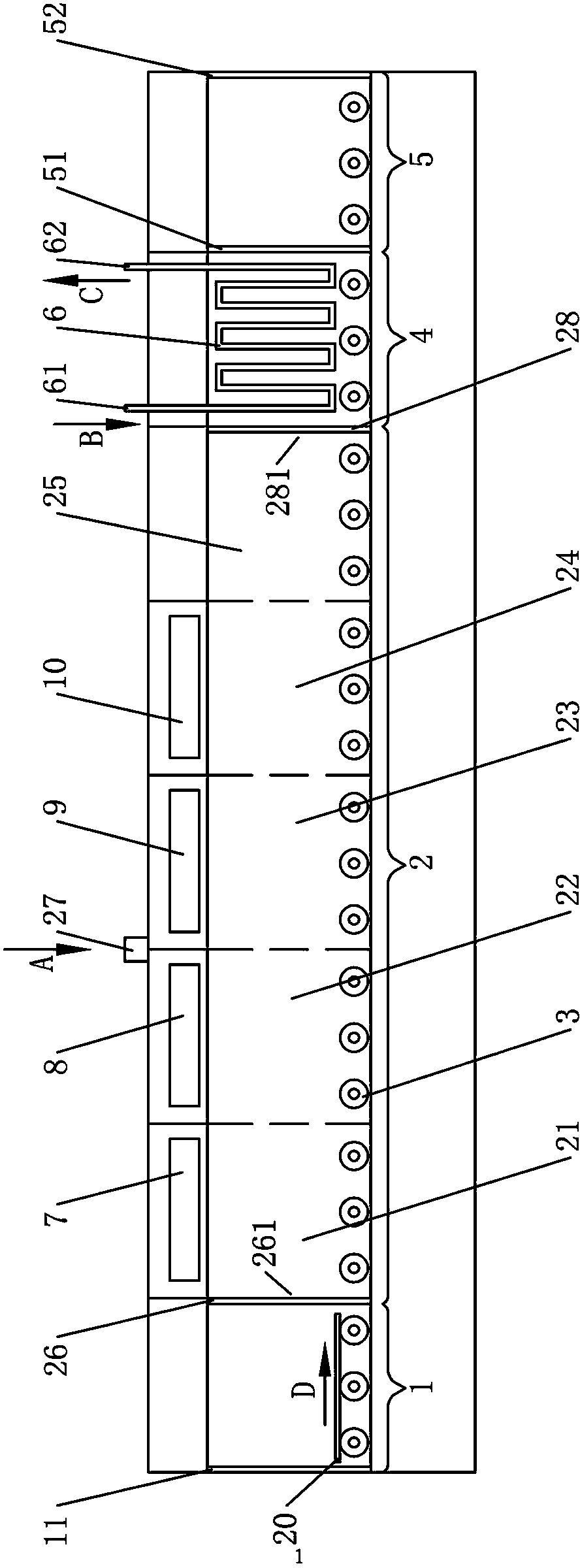

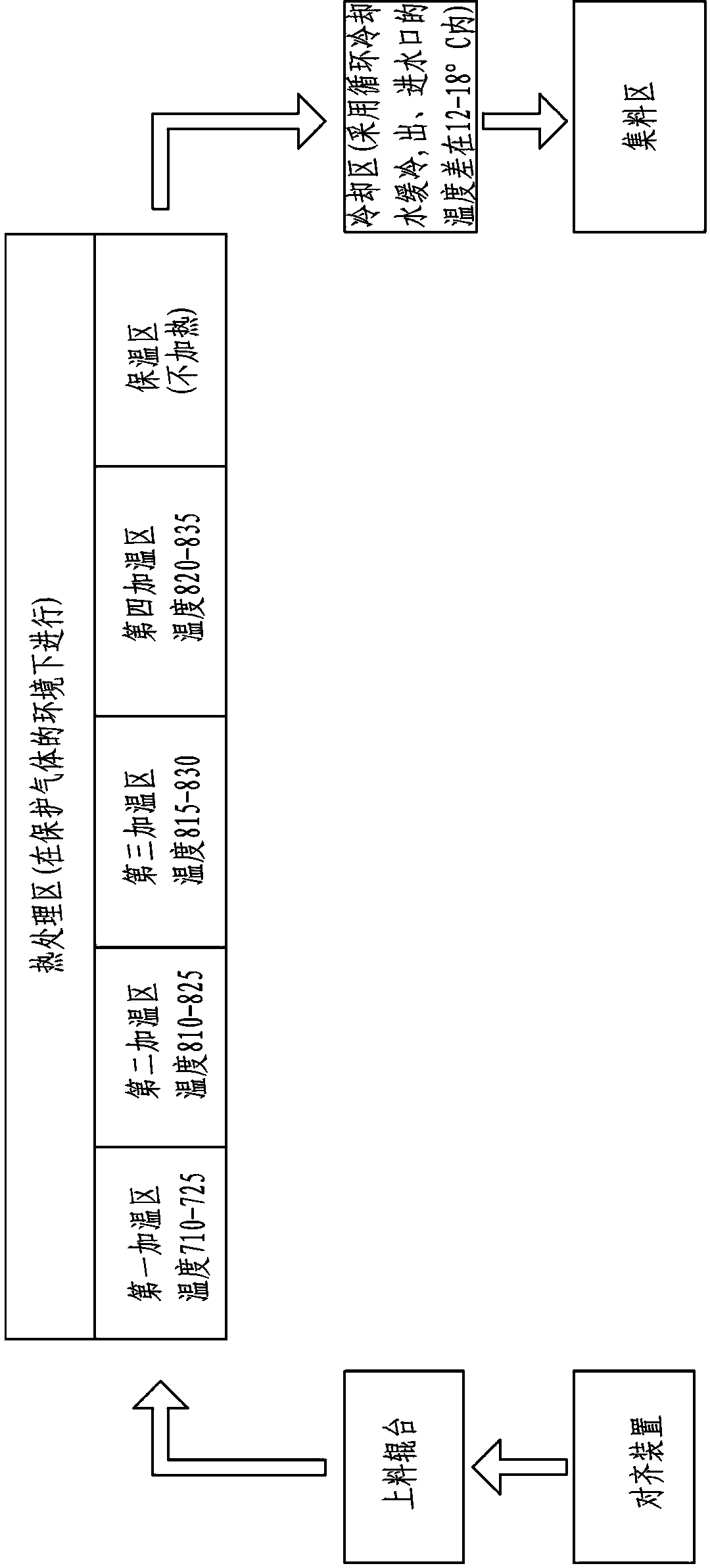

[0032] Such as figure 1 As shown, a steel pipe annealing equipment includes a heat treatment furnace 2 and a cooling box 4. The heat treatment furnace 2 is provided with a feed port 261 and a discharge port 281, and the cooling box 4 is connected outside the discharge port 281. It is characterized in that the The heat treatment furnace 2 is provided with a protective gas filling port 27, and the inside of the heat treatment furnace 2 is provided with a first heating zone 21, a second heating zone 22, and a third heating zone in sequence from the feed port 261 to the discharge port 281. 23. The fourth heating zone 24 and the heat preservation zone 25, the first heating zone 21, the second heating zone 22, the third heating zone 23 and the fourth heating zone 24 are respectively provided with the first heating device 7, the second heating zone Two heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com