Manufacturing method for colored fluorine-free imitation ceramic glaze

A manufacturing method and fluoroform technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., to achieve the effect of good opacification, low cooling rate, and improved phase separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

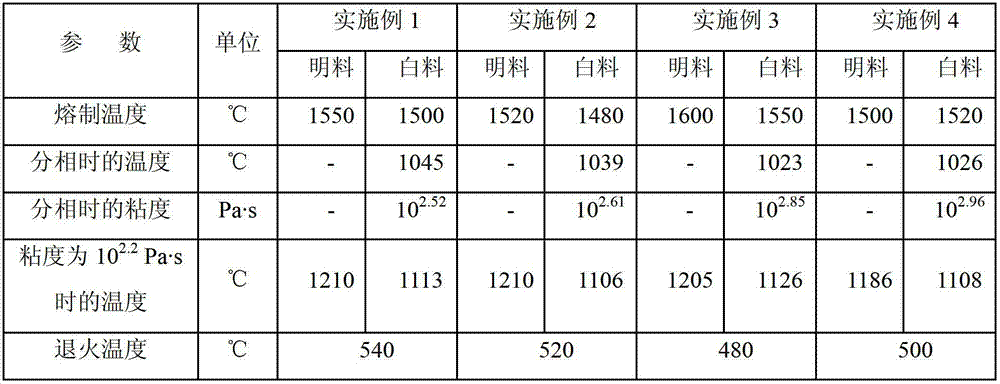

Embodiment 1

[0030] The composition of each raw material weight part of the bright material melt is:

[0031] Quartz sand 74.6 parts, alumina 1.01 parts, aluminum hydroxide 1.51 parts, boric acid 2.93 parts, soda ash 25.19 parts, calcite 8.06 parts, potassium carbonate 5.02 parts.

[0032] The weight parts of the raw materials of the white material melt are:

[0033] Quartz sand 61.2 parts, alumina 2.5 parts, aluminum hydroxide 1.6 parts, boric acid 1.8 parts, sodium pyrophosphate 11.7 parts, soda ash 14.02 parts, potassium carbonate 5.5 parts, barium carbonate 11.0 parts, calcite 5.23 parts.

[0034] The composition of the color material melt is based on the white material plus 0.1 part of Cr 2 O 3 .

[0035] The specific steps of the manufacturing method are as follows:

[0036] (a) According to the chemical composition of bright material, white material and color material, accurately weigh and mix them evenly. The bright material is melted and homogenized at 1550°C in the furnace, and the white m...

Embodiment 2

[0045] The composition of each raw material weight part of the bright material melt is:

[0046] 72.24 parts of quartz sand, 0.51 parts of alumina, 1.55 parts of aluminum hydroxide, 1.79 parts of boric acid, 26.39 parts of soda ash, 8.69 parts of calcite, 8.75 parts of potassium carbonate.

[0047] The weight parts of the raw materials of the white material melt are:

[0048] Quartz sand 58.9 parts, alumina 2.0 parts, aluminum hydroxide 1.9 parts, boric acid 2.1 parts, soda ash 17.6 parts, potassium carbonate 6.3 parts, barium carbonate 11.0 parts, calcite 5.6 parts, sodium pyrophosphate 11.36 parts.

[0049] The color material melt composition is based on the white material plus 0.02 parts of CoO.

[0050] The specific steps of the manufacturing method are the same as in Example 1, except for 1. # Small bubble wall thickness and dipping coating 1 # The thickness of the white material of the small bubbles and the coating 3 # The thickness of the small bubble pigment is 4.8mm, the thickn...

Embodiment 3

[0053] The composition of each raw material weight part of the bright material melt is:

[0054] 73.8 parts of quartz sand, 0.83 parts of alumina, 0.46 parts of aluminum hydroxide, 3.07 parts of boric acid, 27.33 parts of soda ash, 7.79 parts of calcite, and 6.15 parts of potassium carbonate.

[0055] The weight parts of the raw materials of the white material melt are:

[0056] Quartz sand 61.5 parts, alumina 1.9 parts, aluminum hydroxide 1.9 parts, boric acid 3.8 parts, soda ash 13.6 parts, potassium carbonate 5.6 parts, barium carbonate 11.4 parts, calcite 5.6 parts, sodium pyrophosphate 10.98 parts.

[0057] The composition of the pigment melt is based on the white material plus 0.03 parts of CoO, 1.5 parts of NiO and 0.1 parts of Cr 2 O 3 .

[0058] The specific steps of the manufacturing method are the same as in Example 1, except for 1. # Small bubble wall thickness and dipping coating 1 # The thickness of the white material of the small bubbles and the coating 3 # The thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com