Preparation method of megawatt wind power high-strength high-toughness low-temperature (-30 DEG C) spheroidal graphite iron casting

A technology of nodular cast iron, high strength and high toughness, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of long production cycle, complex structure and large size of wind power castings, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Ductile iron castings made for Xinjiang Goldwind Science and Technology Co., Ltd.—1.5MW fixed shaft, bushing, hub, and base

[0025] Using pig iron as the material, the element composition of the ductile iron material: C:3.7-3.9wt%, Si:1.9-2.2wt%, Mn≤0.2wt%, P%≤0.035wt%, S%≤0.02wt%, Sb: 0.0015-0.002wt%; the residual content of Mg is 0.03-0.045wt%, and the rest is iron and impurities produced during the preparation process.

[0026] The ductile iron material of the above formula is smelted first, and the temperature of the molten iron is controlled to be 1420-1460°C. After spheroidizing treatment, the formula of nodulizing agent is Mg5-7wt%, Si40-50wt%, and the rest is iron. The amount of nodulizing agent added is 1.0~1.2wt%, and the spheroidizing treatment temperature is 1420~1460°C.

[0027] Add silicon calcium barium inoculant after the spheroidization reaction starts, the composition formula is: Si70-80wt%, Ca1.5-2.5wt%, Ba8-12%, the rest is iron, the add...

Embodiment 2

[0030] Example 2: Ductile iron castings—2.5MW hub and base made for Xinjiang Goldwind Science and Technology Co., Ltd.

[0031] Elemental composition of ductile iron materials: C:3.7-3.9wt%, Si:1.9-2.1wt%, Mn≤0.2wt%, P%≤0.035wt%, S%≤0.02wt%, Sb:0.001-0.002wt% The amount of nodulizing agent added is 1.0-1.3%; the inoculant is added after the nodularization reaction starts, and the amount of inoculant added is 0.5-1.0wt%; others are the same as in Example 1.

[0032]The 2.5MW hub and base products prepared by the method in this example have stable performance meeting the strength requirements of GJS-400-18U-LT in EN1563 and the impact toughness requirements at -30°C low temperature, and the performance of the main body sample is greater than that required by the auxiliary test block. 80%, which is suitable for the performance requirements of high-strength and high-toughness castings for wind power in low-temperature wind farms at -30°C. Casting auxiliary test block performance:...

Embodiment 3

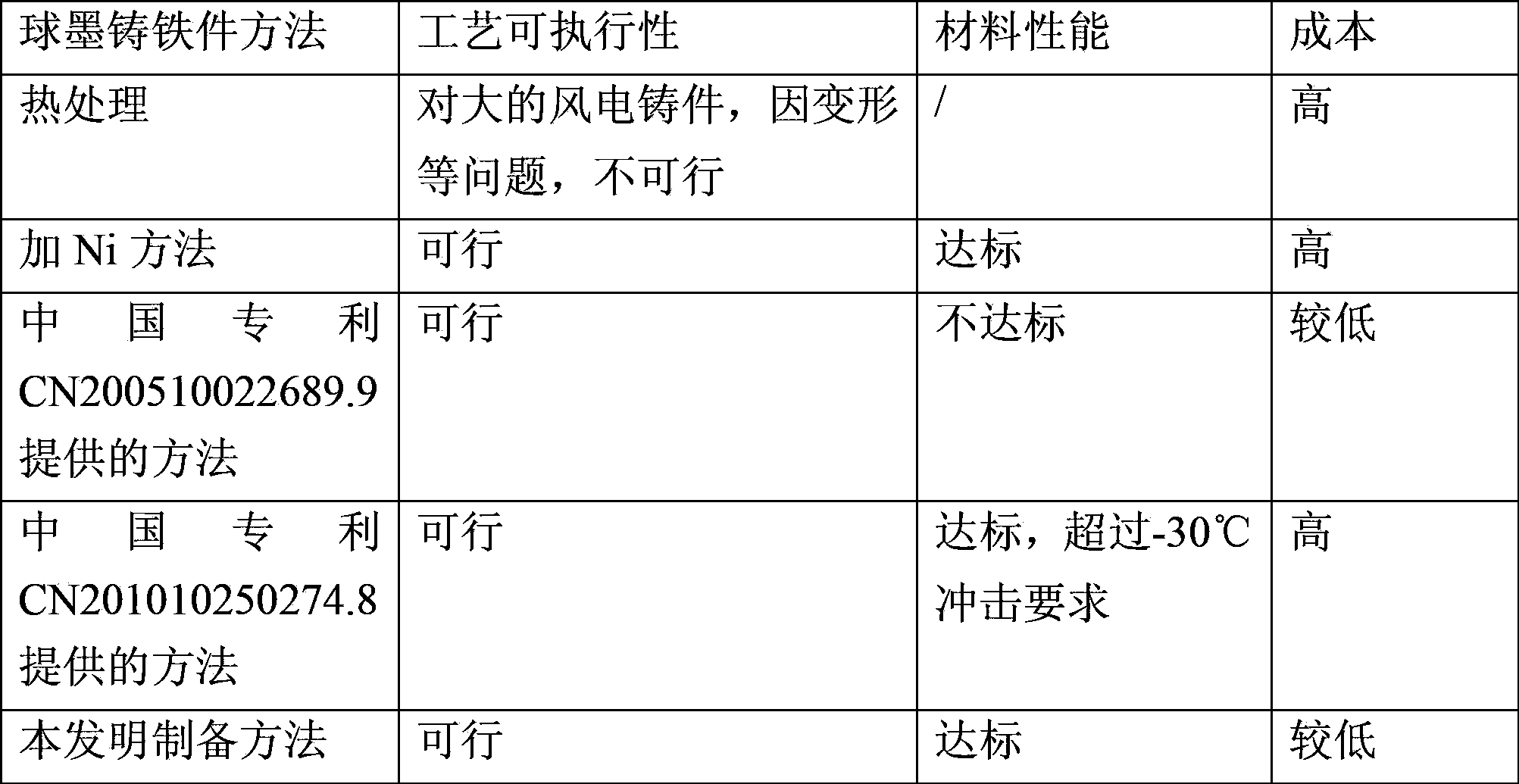

[0033] Embodiment 3: the comparison of preparation method of the present invention and prior art

[0034] Table 1: Comparison of preparation method of the present invention and prior art

[0035]

[0036] In Table 1, the method provided by Chinese patent CN201010250274.8 greatly increases the production cost because the nodulizer used is an expensive rare earth (due to strict requirements on composition and content, the price is expensive); and the nodulizer used in the preparation method of the present invention The chemical agent does not contain rare earth, and the added trace element Sb has basically no influence on the cost. The preparation method of the present invention can stably meet the strength requirements of GJS-400-18U-LT in EN1563 and -30℃ low temperature impact toughness requirements. The preparation method of the present invention has lower cost, and the casting cost is reduced: 80-100 yuan / ton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com