Degradable PHA/PLA mixture film and preparation method thereof

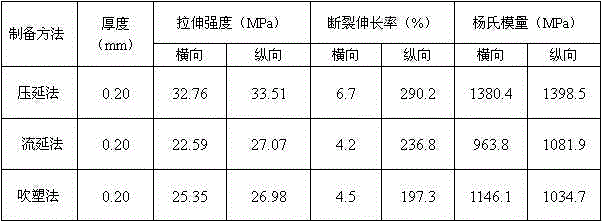

A blend and film technology, which is applied in the field of degradable PHA/PLA blend film and its preparation, can solve the problem of low transverse strength, inability to meet the strict requirements of card making and packaging material film mechanical properties, many crystal points, etc. problems, to achieve high melt strength and tensile strength, excellent industrial application value, high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: PHA / PLA blend film formulation 1 and calendering molding process thereof

[0036] Material formula: PHA resin EM2001030 parts by weight, PLA resin 4032D70 parts by weight, 4.5% plasticizer tri-n-butyl citrate of the total weight of PHA and PLA, 0.8% inorganic filler calcium carbonate, PHA and 0.2% of the total weight of PLA Antioxidant 1076, 0.3% of the total weight of PHA and PLA lubricant pentaerythritol stearate, 0.1% of the total weight of PHA and PLA antistatic agent ethoxylated alkylamine.

[0037]Calendering process:

[0038] Weigh 100Kg of raw materials according to the formula, among which PHA and PLA resins are ground into powder by a disc mill. After drying, add it to a high-speed mixer together with other additives for mixing. The spindle speed of the high-speed mixer is 1300r / min, and the mixing time is 15min; the mixed raw materials are sent to the planetary exhaust extruder for melting and plasticization, and the extruder works The tempera...

Embodiment 2

[0039] Embodiment 2: PHA / PLA blend film formulation 2 and calendering molding process thereof

[0040] Material formula: PHA resin EM2001031 parts by weight, PLA resin 4032D69 parts by weight, 6.0% plasticizer tri-n-butyl citrate of the total weight of PHA and PLA, 0.9% inorganic filler calcium carbonate, PHA and 0.3% of total weight of PLA Antioxidant 1076, 0.34% of total weight of PHA and PLA Lubricant pentaerythritol stearate, 0.14% of total weight of PHA and PLA Antistatic agent ethoxylated alkylamine.

[0041] Weigh 100Kg of raw materials according to the formula, among which PHA and PLA resins are ground into powder by a disc mill. After drying, add it to a high-speed mixer together with other additives for mixing. The spindle speed of the high-speed mixer is 1300r / min, and the mixing time is 15min; the mixed raw materials are sent to the planetary exhaust extruder for melting and plasticization, and the extruder works The temperature is 200°C, the screw speed is 150r / m...

Embodiment 3

[0042] Embodiment 3: PHA / PLA blend film formulation 3 and calendering molding process thereof

[0043] Material formula: PHA resin EM2001033 parts by weight, PLA resin 4032D67 parts by weight, 7.5% plasticizer tri-n-butyl citrate of the total weight of PHA and PLA, 1.0% inorganic filler calcium carbonate, PHA and 0.4% by total weight of PLA Antioxidant 1076, 0.38% by total weight of PHA and PLA Lubricant Pentaerythritol Stearate, 0.18% by total weight of PHA and PLA Antistatic agent ethoxylated alkylamine.

[0044] Weigh 100Kg of raw materials according to the formula, among which PHA and PLA resins are ground into powder by a disc mill. After drying, add it to a high-speed mixer together with other additives for mixing. The spindle speed of the high-speed mixer is 650r / min, and the mixing time is 30min; the mixed raw materials are sent to the planetary exhaust extruder for melting and plasticization, and the extruder works The temperature is 152°C, the screw speed is 150r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com