A kind of sulfur cathode material with functional intermediate layer and its preparation and application

A sulfur cathode material and intermediate layer technology, applied in the field of lithium-sulfur battery electrode materials, can solve the problems affecting the cycle performance and coulombic efficiency of Li-S batteries, the irreversible damage of the sulfur-containing structure of the cathode, and the poor cycle stability of lithium-sulfur batteries. Effects of suppressing the shuttle effect, mature production technology, and widening the applicable temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

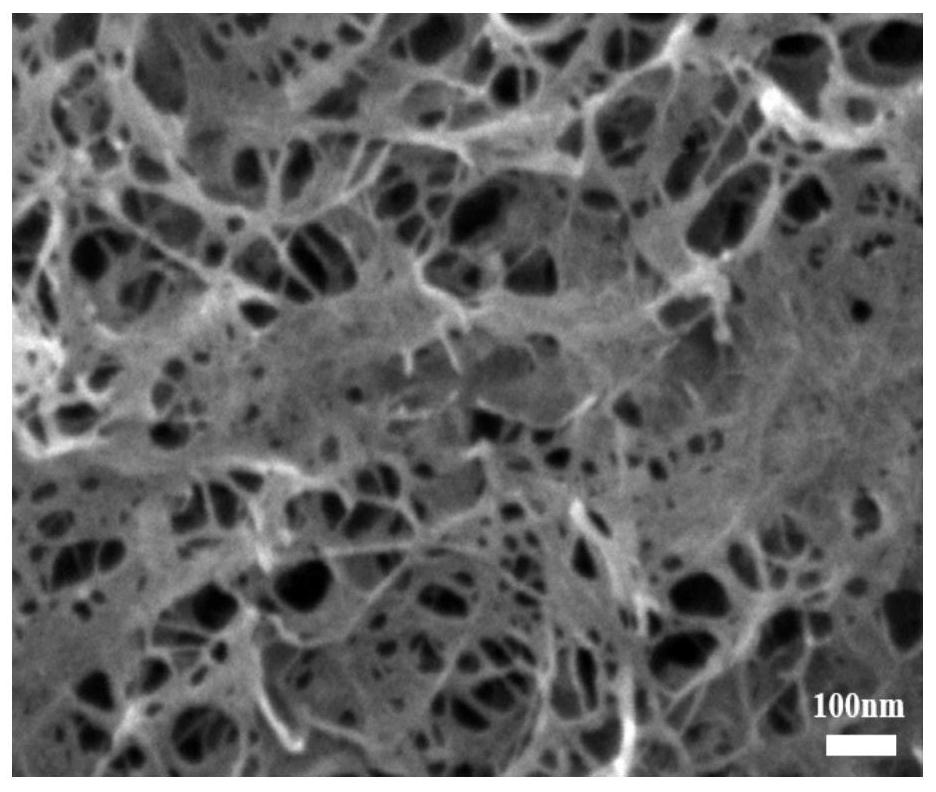

[0039] A kind of preparation method that adopts commercial Kevlar fiber and transition metal salt solution as raw material to obtain dispersion liquid, and coats lithium-sulfur battery cathode material to form functional intermediate layer, comprises the following steps:

[0040] 1) Add 1.0g of Kevlar fiber and 1.5g of potassium hydroxide to 500mL of anhydrous dimethyl sulfoxide, stir and dissolve for 7 days to obtain a Kevlar nanofiber / dimethyl sulfoxide dispersion;

[0041]2) Dissolve 20 mg of nickel acetate in 10 mL of dimethyl sulfoxide, and add it dropwise to 30 mL of the Kevlar nanofiber / dimethyl sulfoxide dispersion obtained in step 1), stir at room temperature for 1 h, and then 30mL of deionized water was slowly added dropwise to the vigorously stirred mixed solution, reacted for 1 day, and obtained a composite dispersion of nickel hydroxide and Kevlar fiber-nickel ion fiber through simple solvent blending and in-situ reduction;

[0042] 3) 40mL of the nickel hydroxide...

Embodiment 2

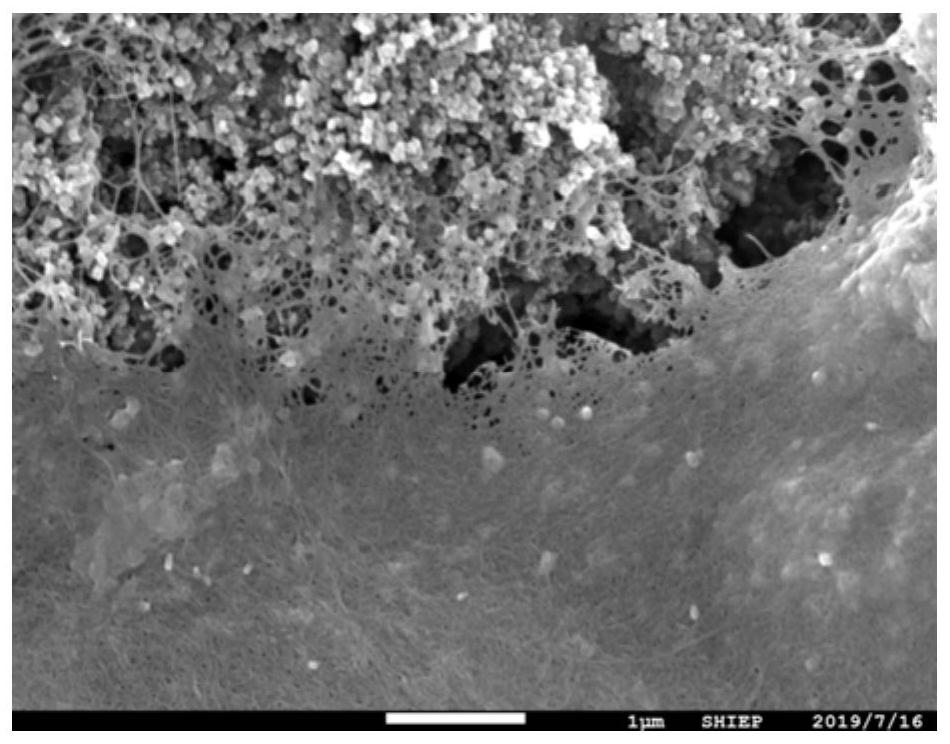

[0056] A kind of preparation method that adopts commercial Kevlar fiber and transition metal salt solution as raw material to obtain dispersion liquid, and coats lithium-sulfur battery cathode material to form functional intermediate layer, comprises the following steps:

[0057] 1) Add 3.0g of Kevlar fiber and 1.5g of potassium hydroxide to 200mL of anhydrous dimethyl sulfoxide, stir and dissolve for 7 days to obtain a Kevlar nanofiber / dimethyl sulfoxide dispersion;

[0058] 2) Dissolve 60 mg of nickel acetate in 10 mL of dimethyl sulfoxide, and add it dropwise to 30 mL of the Kevlar nanofiber / dimethyl sulfoxide dispersion obtained in step 1), stir at room temperature for 1 h, and then 30mL of deionized water was slowly added dropwise to the vigorously stirred mixed solution, reacted for 1 day, and obtained a composite dispersion of nickel hydroxide and Kevlar fiber-nickel ion fiber through simple solvent blending and in-situ reduction;

[0059] 3) 40mL of the nickel hydroxid...

Embodiment 3

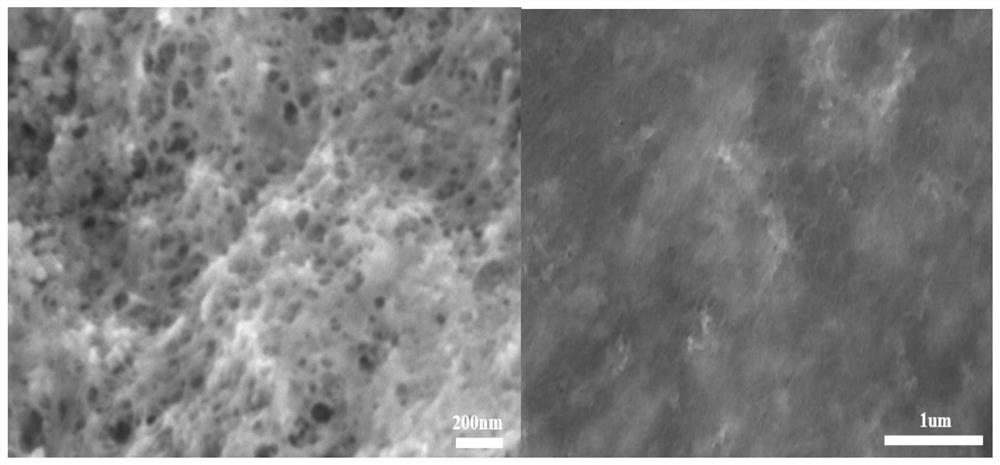

[0064] A kind of preparation method that adopts commercial Kevlar fiber and transition metal salt solution as raw material to obtain dispersion liquid, and coats lithium-sulfur battery cathode material to form functional intermediate layer, comprises the following steps:

[0065] 1) Add 2.0g of Kevlar fiber and 1.5g of potassium hydroxide to 400mL of anhydrous dimethyl sulfoxide, stir and dissolve for 7 days to obtain a Kevlar nanofiber / dimethyl sulfoxide dispersion;

[0066] 2) Dissolve 100 mg of nickel acetate in 10 mL of dimethyl sulfoxide, and add it dropwise to 30 mL of the Kevlar nanofiber / dimethyl sulfoxide dispersion obtained in step 1), stir at room temperature for 1 h, and then 30mL of deionized water was slowly added dropwise to the vigorously stirred mixed solution, reacted for 1 day, and obtained a composite dispersion of nickel hydroxide and Kevlar fiber-nickel ion fiber through simple solvent blending and in-situ reduction;

[0067] 3) 40mL of the nickel hydroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com