A kind of epoxy resin supported phosphotungstic acid catalyst and its preparation method and application

A technology of epoxy resin and phosphotungstic acid, which is applied in the chemical industry, can solve the problems of environmental pollution, easy deactivation, separation, etc., and achieve the effects of high conversion rate, short reaction time and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

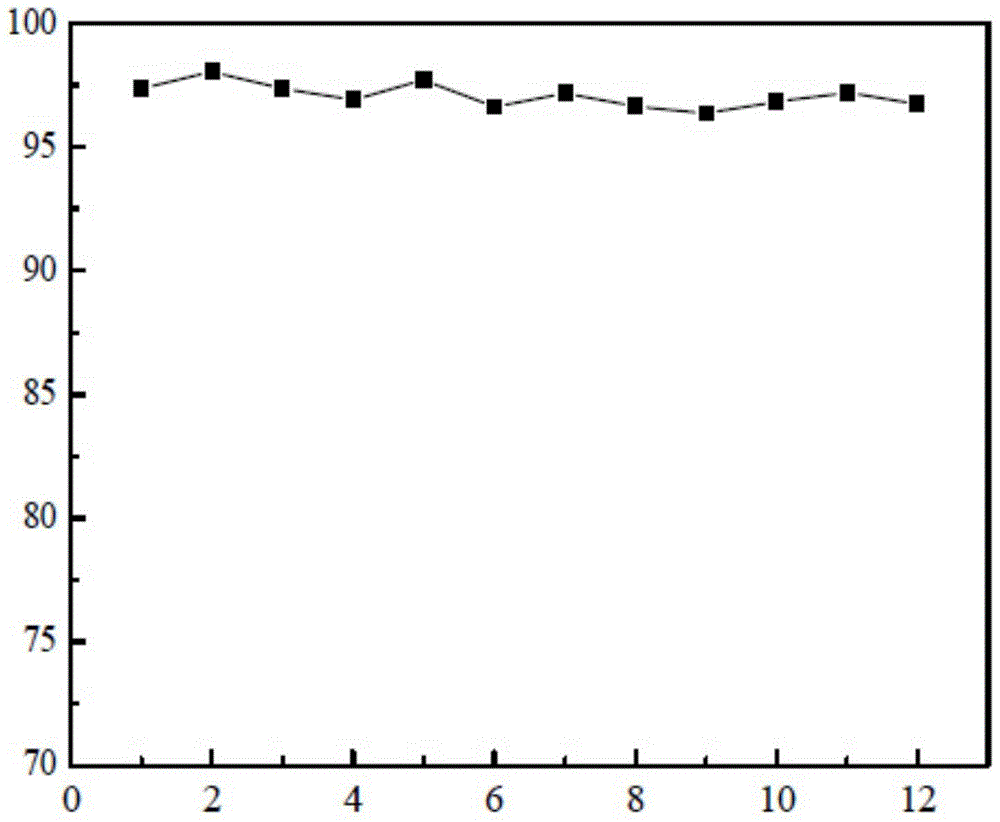

Image

Examples

Embodiment 1

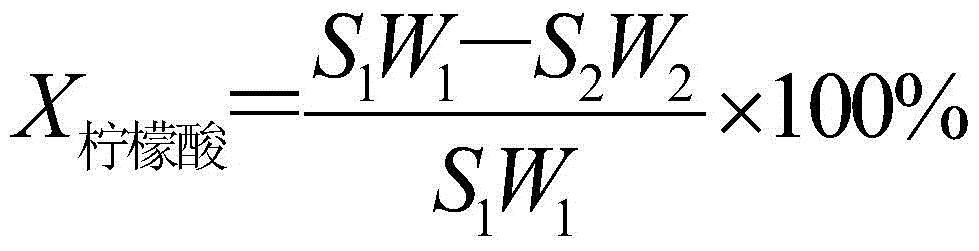

[0020] Catalyst preparation with a phosphotungstic acid loading of 5%: Weigh 0.5g of phosphotungstic acid (analytical pure) and dissolve it in 1.5ml of distilled water, stir to fully dissolve it, weigh 10g of ground epoxy resin 604 powder (25- 30 mesh) in a 100ml beaker, transfer the phosphotungstic acid aqueous solution to the beaker so that it is just submerged in the epoxy resin powder, stir magnetically for 3 hours at room temperature (25°C) to make it evenly mixed, and then place the resulting mixture at room temperature ( 25°C), let it stand for 8 hours to allow the water to evaporate naturally, and then dry it in an oven at 80°C overnight (12 hours) to obtain a phosphotungstic acid loading of 5% (PW 12 to the weight ratio of the support) of the supported catalyst.

Embodiment 2

[0022] Catalyst preparation with a phosphotungstic acid loading of 10%: the preparation method is the same as in Example 1, wherein the mass of phosphotungstic acid is 1.0 g, dissolved in 1.6 ml of distilled water, and the mass of epoxy resin 604 powder is 10 g.

Embodiment 3

[0024] Catalyst preparation with a phosphotungstic acid loading of 15%: the preparation method is the same as in Example 1, wherein the mass of phosphotungstic acid is 1.5 g, dissolved in 1.8 ml of distilled water, and the mass of epoxy resin 604 powder is 10 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com