Low-calorific-value coal steam-hot air combined cycle power generation system

A combined cycle power generation and cycle power generation technology, applied in the direction of steam generation, steam generation device, steam engine device, etc., can solve the problems of aggravating air pollution, greenhouse effect, waste of non-renewable resources, etc., to improve stability and burnout rate, The effect of reducing NOx and SOx generation and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

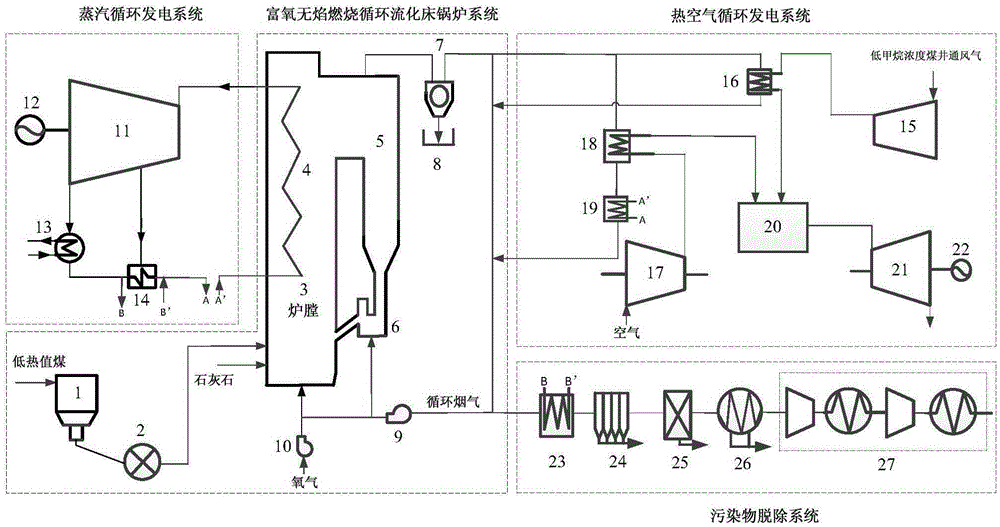

[0016] The present invention provides a low calorific value coal steam-hot air combined cycle power generation system; the working principle of the system will be further described below in conjunction with the accompanying drawings and specific implementation methods.

[0017] figure 1 Shown is a low calorific value coal steam-hot air combined cycle power generation system that can recover low methane concentration coal mine ventilation.

[0018] like figure 1 As shown, the system includes four subsystems: an oxygen-enriched flameless combustion circulating fluidized bed boiler system, a steam cycle power generation system, a hot air cycle power generation system and a pollutant removal system; the oxygen-enriched flameless combustion circulating fluidized bed The boiler system is respectively connected with the other three subsystems, its high-temperature and high-pressure steam outlet is connected with the steam turbine 11 inlet of the steam cycle power generation system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com