Infrared electric heating film heating tube with double-film layer structure as well as preparation method and application thereof

A technology of film layer structure and electric heating film, which is applied in the direction of ohmic resistance heating parts, heating elements, heating element materials, etc., can solve the problem of small radiation-convective heat transfer ratio, less "doping" amount, and low film layer emission ratio To achieve the effect of strong shape selectivity, reduce convective heat transfer, and enhance radiation heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

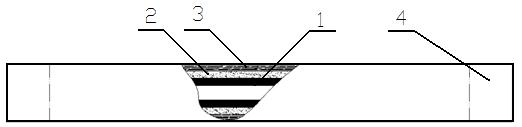

[0034] See attached figure 1 , 2 In the first embodiment of the present invention, the infrared electrothermal film heating tube with a double-layer structure includes a ceramic tube electrothermal film substrate 1 and electrodes 4 arranged at both ends of the electrothermal film substrate 1. The electrothermal film substrate 1 has a diameter of 16mm and a wall Thickness 3mm, tube length 230mm, its surface is vapor-deposited with a conductive film layer 2, the surface of this conductive film layer 2 is vapor-deposited with an infrared high-emitting film layer 3, and the conductive film layer 2 is SnO 2 : Sb thin film layer, the infrared high-emitting film layer 3 comprises the following substances in parts by weight: manganese dichloride 40, nickel dichloride 15, chromium trichloride 5.

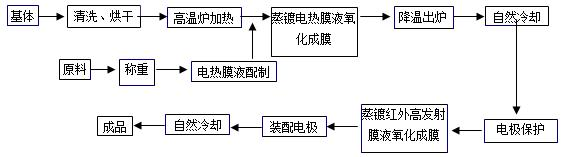

[0035] The preparation method of the infrared electrothermal film heating tube of the present embodiment double film structure, its steps are:

[0036] Pretreatment 1. Cleaning and drying of...

Embodiment 2

[0045] The difference between the second embodiment of the present invention and the first embodiment is:

[0046] ① The electrothermal film liquid contains by weight and number: 45 tin tetrachloride, 2.0 antimony trichloride, 1.0 nickel trichloride, 0.6 indium trichloride, 10 glycerol, 6 nitric acid, and 25 deionized water;

[0047] ②The infrared high-emissivity film solution contains: 35 parts by weight of manganese dichloride, 20 parts of nickel dichloride, 5 parts of chromium trichloride, 10 parts of glycerol, and 25 parts of deionized water.

[0048] See attached Figure 5 , the heating device prepared by using the heating tube of this embodiment, the structure includes two infrared electrothermal film heating tubes 11 with a double-layer structure, the two ends of the two heating tubes 11 are fixed on the rectangular bracket 20, and the two heating tubes 11 The front end is provided with a safety net cover II 21, the rear end is provided with a reflector II 22, the rect...

Embodiment 3

[0050] The difference between the third embodiment of the present invention and the first embodiment is:

[0051] ① The electrothermal film solution contains by weight and number: 55 tin tetrachloride, 1.5 antimony trichloride, 0.5 nickel trichloride, 0.5 indium trichloride, 10 ethanol, 10 nitric acid, and 25 deionized water;

[0052] ②The infrared high-emissivity film liquid contains: 45 parts by weight of manganese dichloride, 15 parts of nickel dichloride, 5 parts of chromium trichloride, 10 parts of ethanol, and 25 parts of deionized water.

[0053] The application method of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com