Industrial pulverized coal swirl combustion system using natural gas for supporting combustion

A combustion system and natural gas technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of coal type adaptability, low load, stable combustion capacity, etc., and achieve uniform distribution of pulverized coal concentration, good combustion stability, and high combustion efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail below in conjunction with the accompanying drawings.

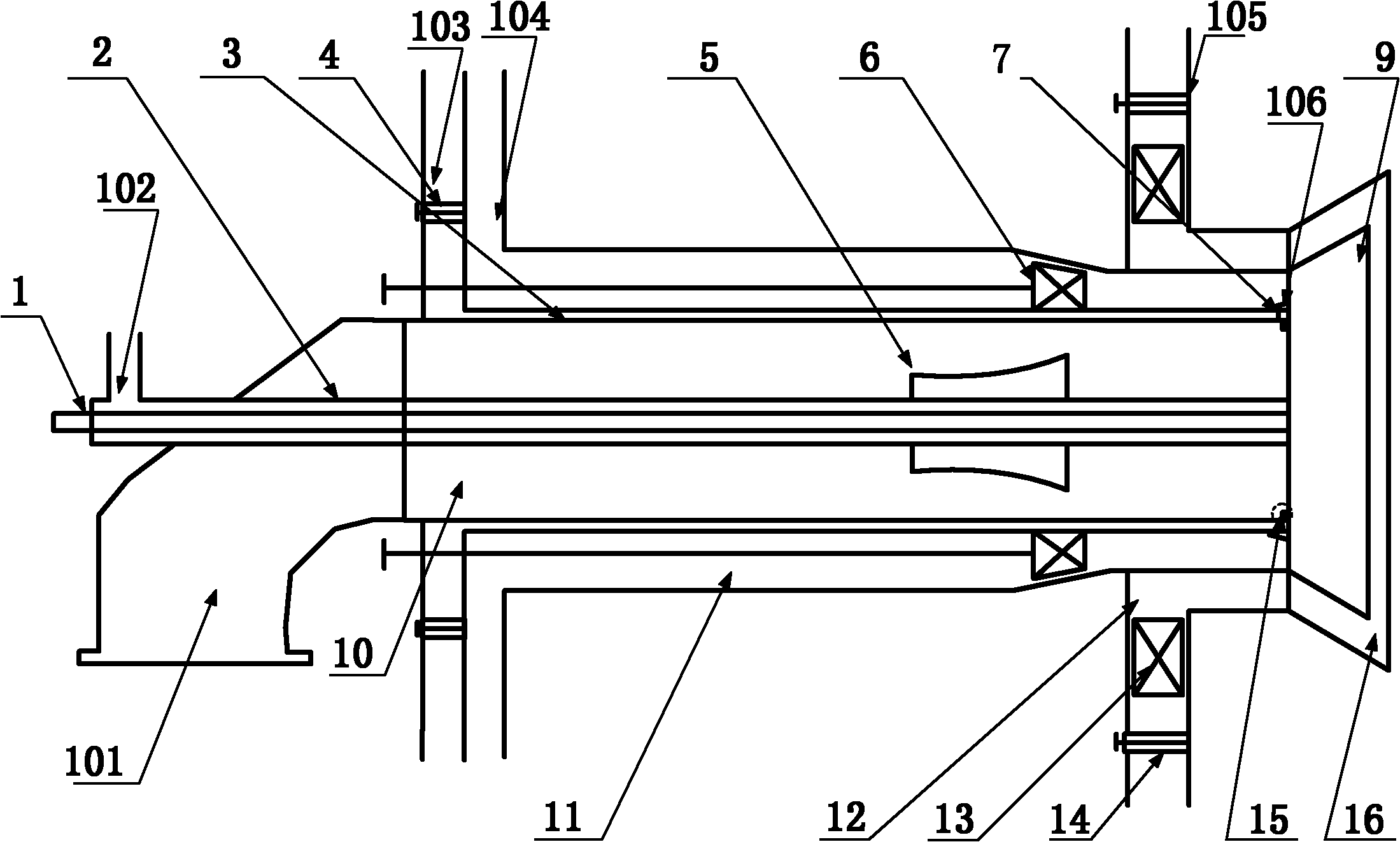

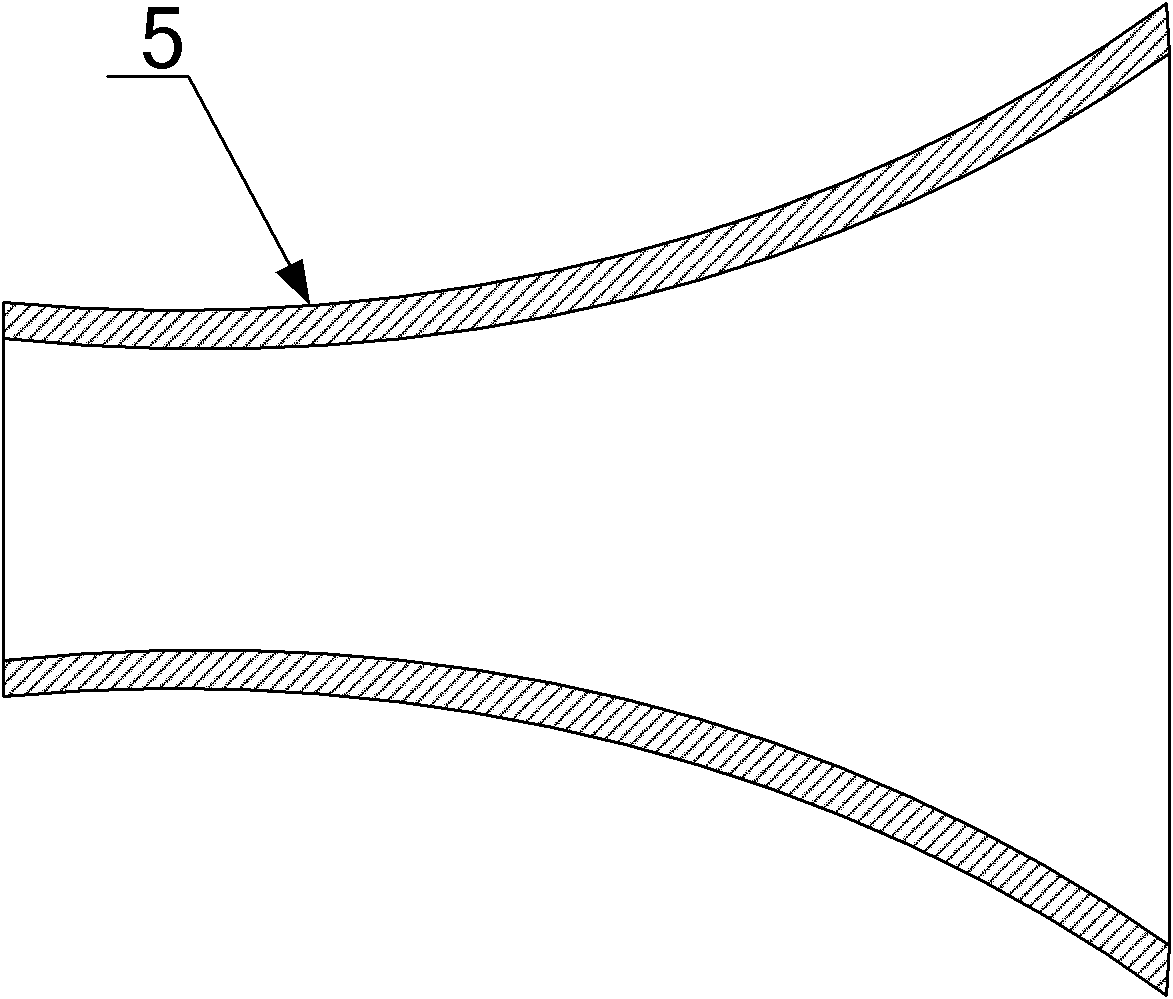

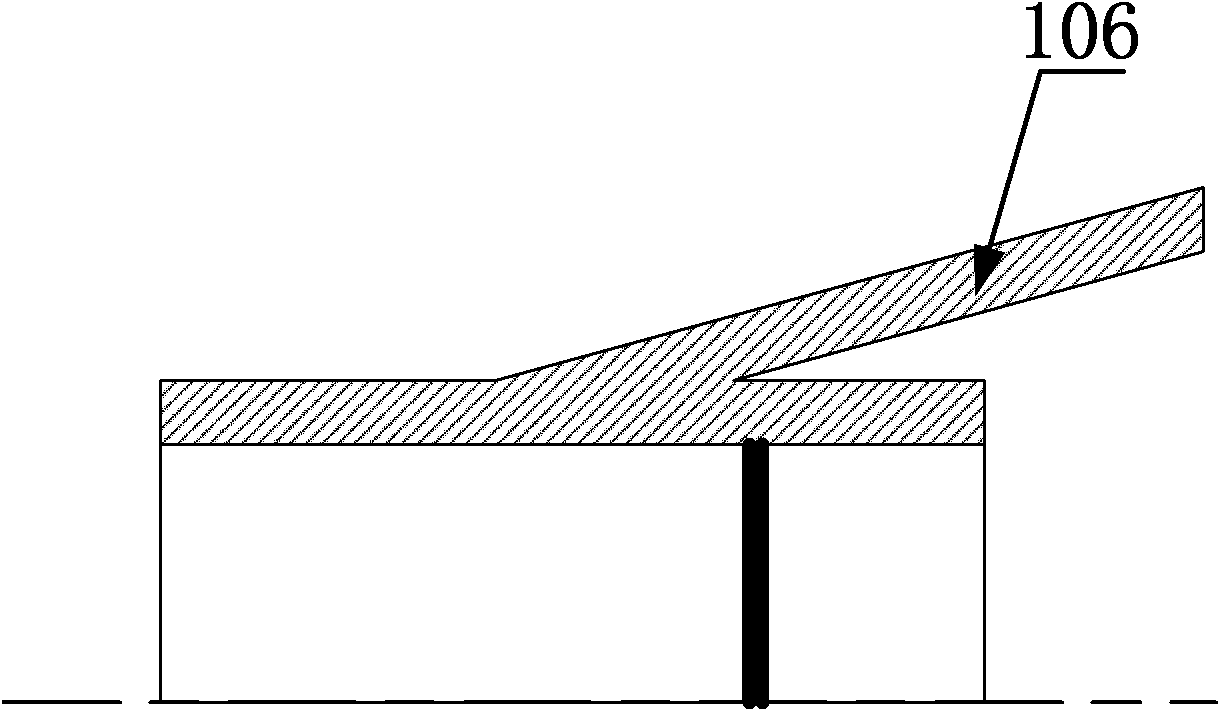

[0022] Such as figure 1 As shown, the natural gas-supported industrial pulverized coal swirling combustion system includes a horizontal columnar igniter 1 with a igniter nozzle at the right end, and a central wind inlet 102 on the left upper surface that overlaps the outer surface of the igniter 1 from the inside to the outside. The horizontal column ring-shaped central air channel 2, the horizontal column ring-shaped primary air channel 10 with a vertically bent primary air inlet 101 on the left end, the horizontal column ring-shaped direct-flow channel with a vertical direct-flow natural gas inlet 103 at the left end The natural gas channel 3, the horizontal column annular inner swirl secondary air passage 11 with the vertical inner swirl secondary air inlet 104 on the left end and the level of the outer swirl secondary air inlet 105 with the vertical outer sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com