Parallel flow heat exchanger with double-row flat tubes and air-conditioning device with heat exchanger

A parallel flow heat exchanger and flat tube technology, applied in evaporator/condenser, lighting and heating equipment, refrigeration components, etc., can solve the problem of uneven temperature distribution of parallel flow heat exchanger and heat exchange of parallel flow heat exchanger Efficiency reduction, uneven flow of refrigerant and other problems, to achieve the effect of long flow channel, improved energy efficiency ratio, and small flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

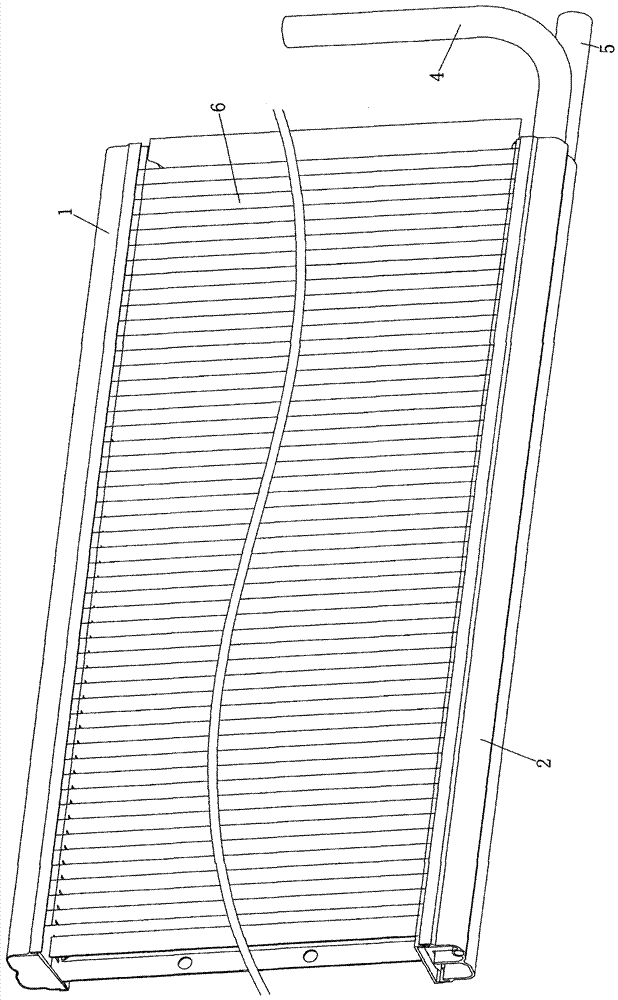

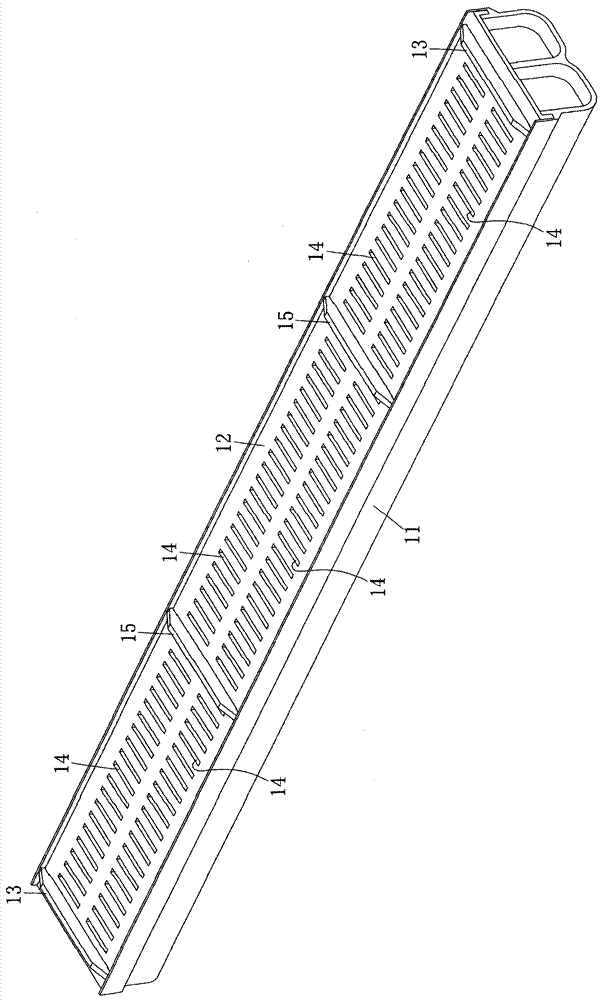

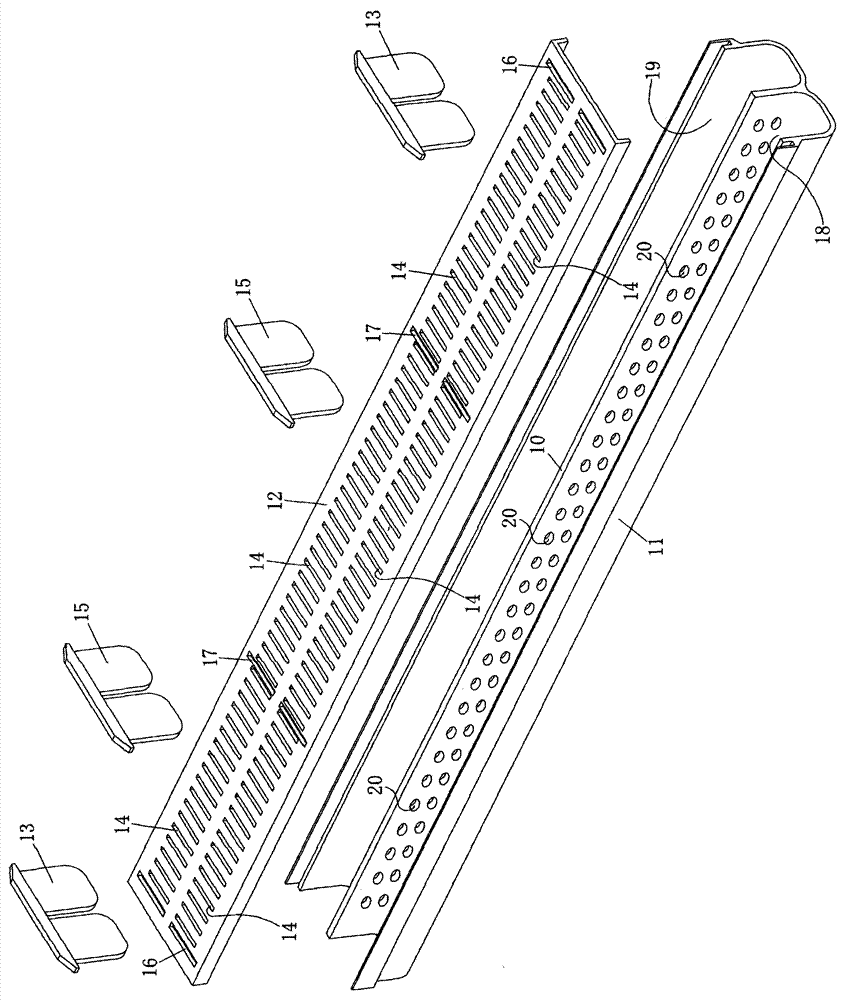

[0018] Example: see Figure 1~5 The parallel flow heat exchanger with double rows of flat tubes of the present invention comprises an upper header 1, a lower header 2 and several flat tubes 6 arranged between the upper and lower headers. Wherein the upper header 1 is composed of the upper header cover 12 buckled on the upper header base 11, the upper header cover 12 is provided with two rows of upper header flat tube cutouts 14, two rows The flat tube cutouts 14 of the upper header correspond to the overflow cavity 19 and the return cavity 18 in the upper header 1 respectively. The holes 20 are connected, and the two ends of the upper header 1 are provided with upper header end plates 13, and the upper header end plates 13 at both ends of the upper header pass through the upper headers on the upper header cover plate 12. The end plate cutout 16 is inserted into the upper header base 11 . The lower header 2 is formed by fastening the lower header cover 22 on the lower header ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com