Finned heat exchanger

A finned heat exchanger and fin technology, which is applied in heat exchange equipment, lighting and heating equipment, tubular elements, etc., can solve the problems of insignificant improvement of gas side heat exchange performance, increase flow resistance, etc., and save energy. The effect of producing consumables, increasing flow resistance, and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

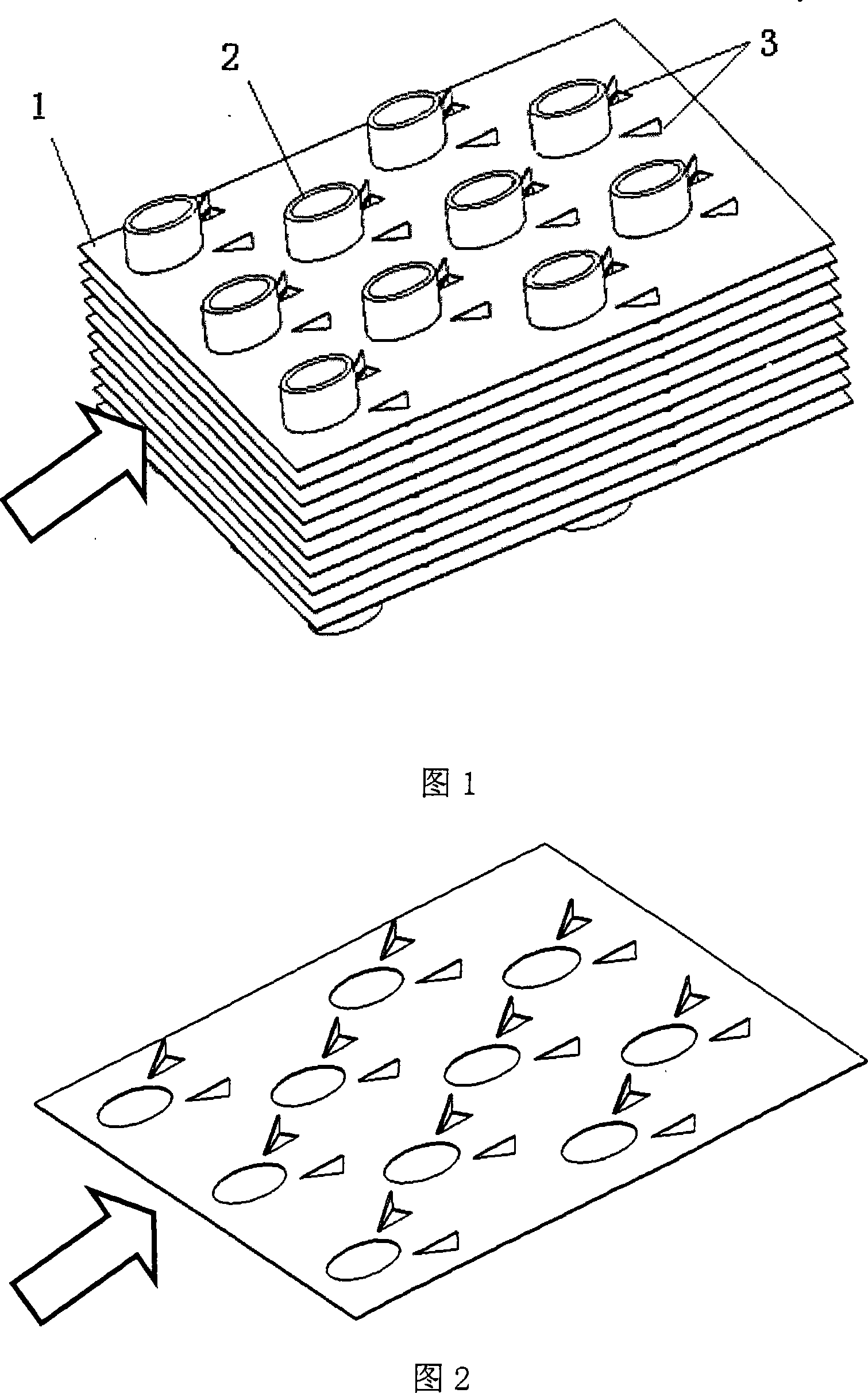

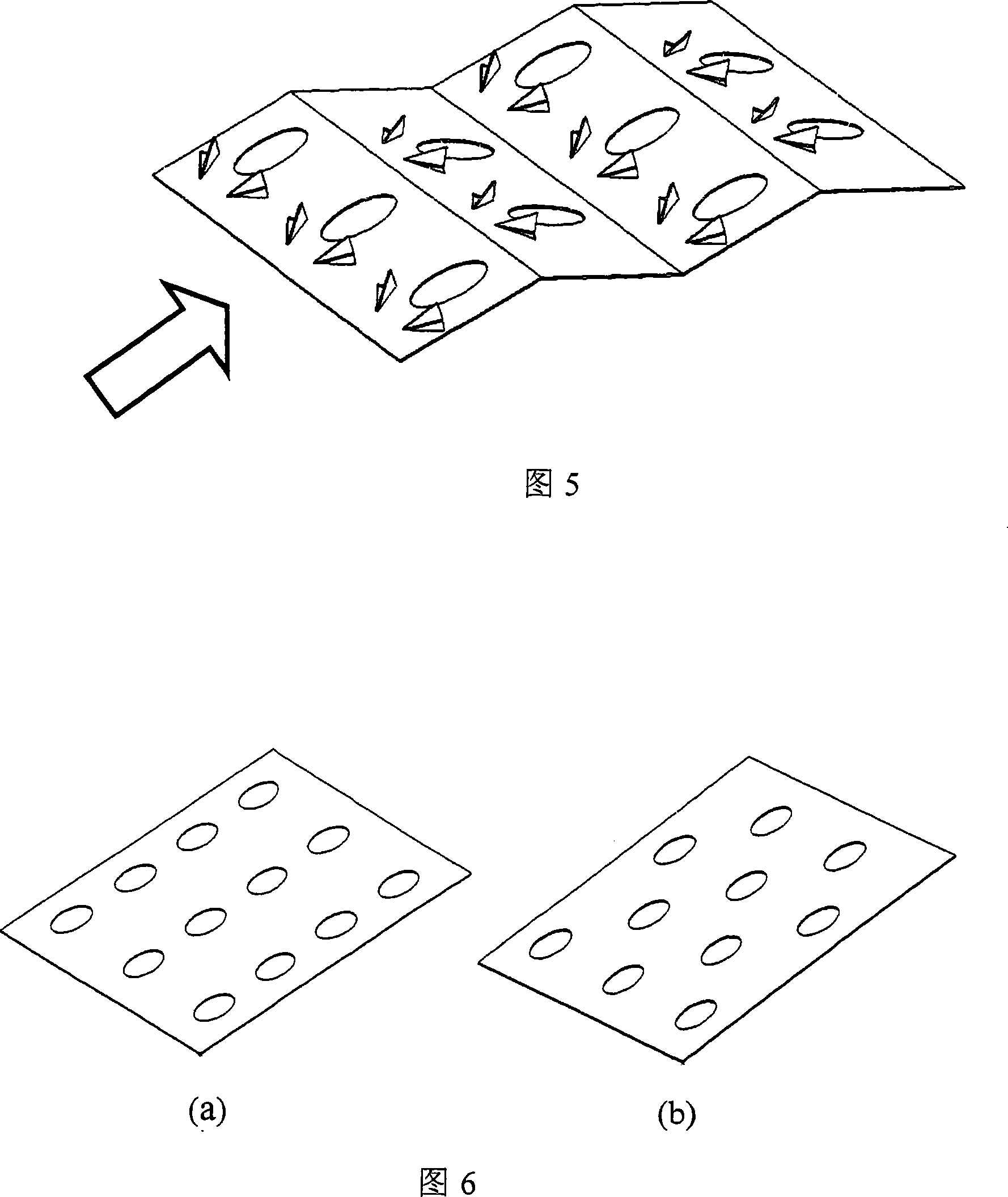

[0023] Referring to Figure 1, in this embodiment, the fin 1 is a flat continuous fin, and the longitudinal vortex generator is a triangular winglet 6, which is pasted on the fin 1. After the air side fluid enters the heat exchanger, it meets the ellipse The longitudinal vortex generator 3 around the heat exchange tube 2 produces a strong tangential rotation, forming a longitudinal vortex that develops along the main flow direction. Under the strong rotational entrainment of the longitudinal vortex, it thins or even destroys the boundary layer generated by the air side fluid along the flow channel, and introduces high-velocity fluid into the wake area, thereby inhibiting the development of the wake area and enhancing the wake area and the mainstream The longitudinal vortex produces strong rotation in the tangential direction, and the fluid in the inner edge area of the entrained gas side flow channel enters the main flow area to aggravate the mixing between the gas side fluids an...

Embodiment 2

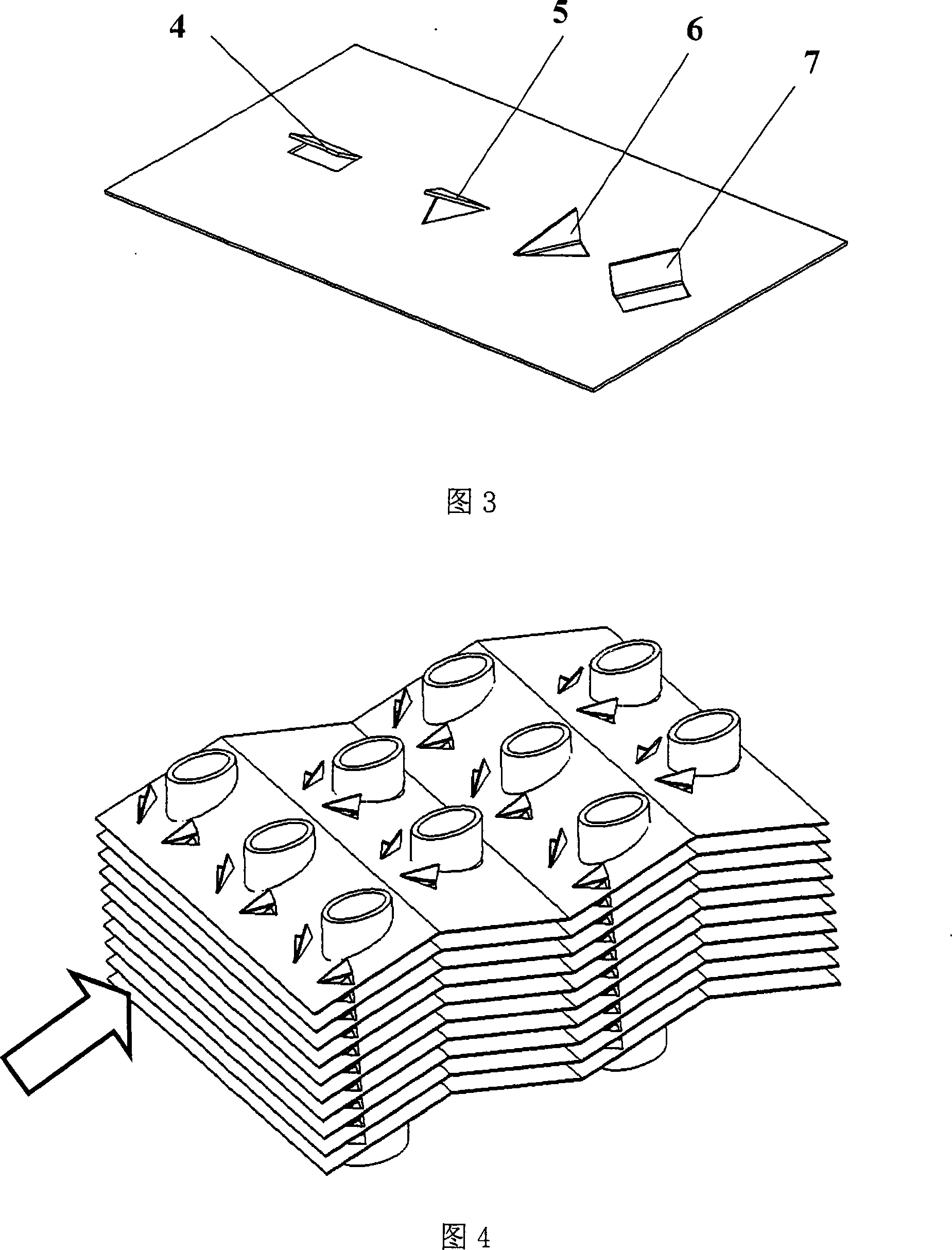

[0025] In this embodiment, compared with Embodiment 1, the difference lies in that the fin plate 1 uses corrugated continuous fins, see FIG. 3 and FIG. 4. Because the corrugated continuous fin 5 is used, in addition to the heat transfer enhancement effect described in Example 1, the disturbance of the air side fluid perpendicular to the main flow direction is further enhanced, so that the growth cycle of the fluid flow boundary layer and the thermal boundary layer Due to the fracture, the flow and heat transfer boundary layer has been further disturbed and destroyed, so that the heat transfer coefficient of the air side has been further improved. In a limited space, the use of corrugated continuous fins can get a larger heat exchange area. Therefore, the use of corrugated continuous fins can increase the heat exchange area and increase the heat exchange coefficient at the same time, so that the overall performance of the heat exchanger is further improved.

[0026] The actual appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com