Patents

Literature

56results about How to "Improve waste heat power generation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

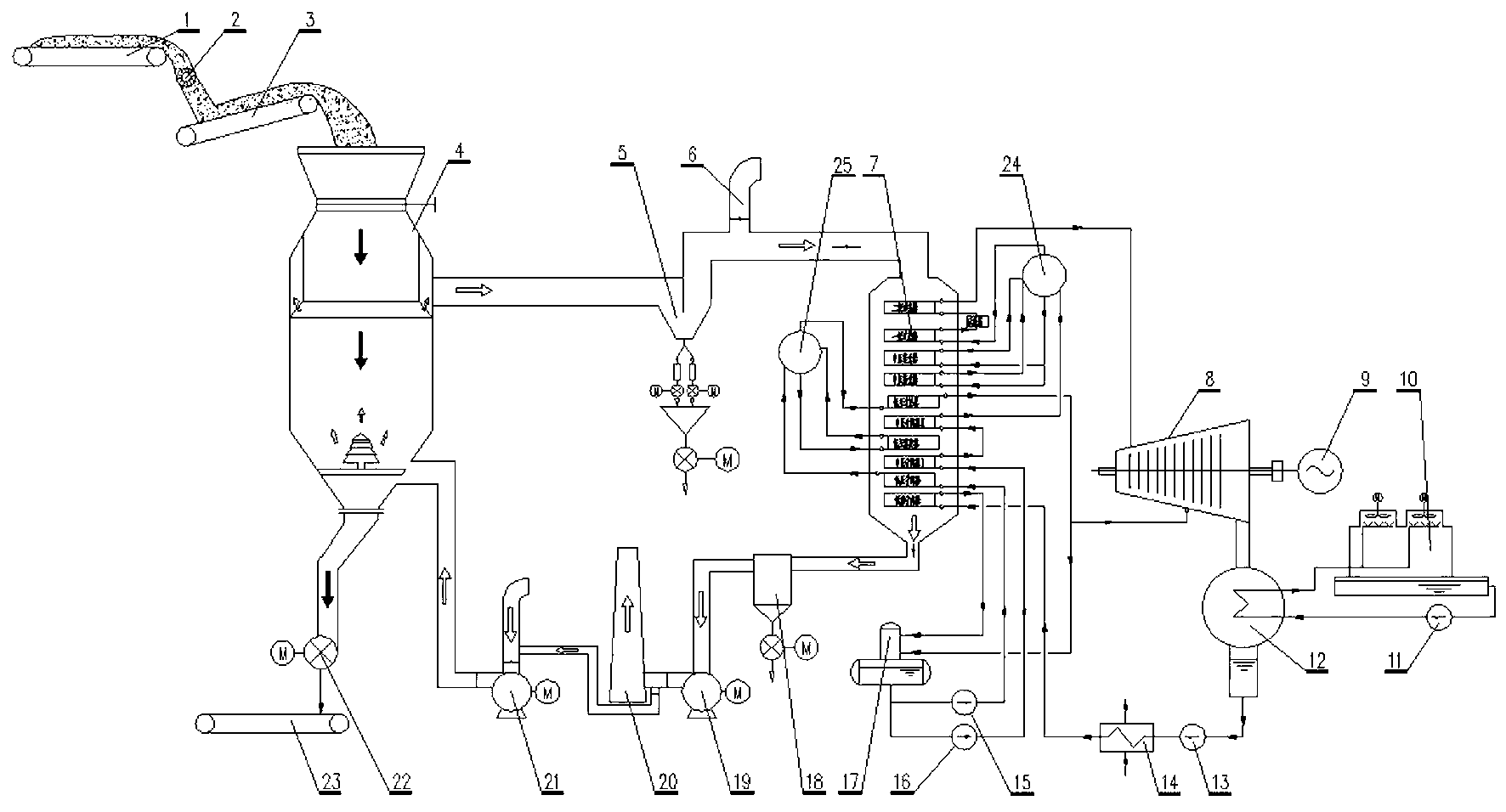

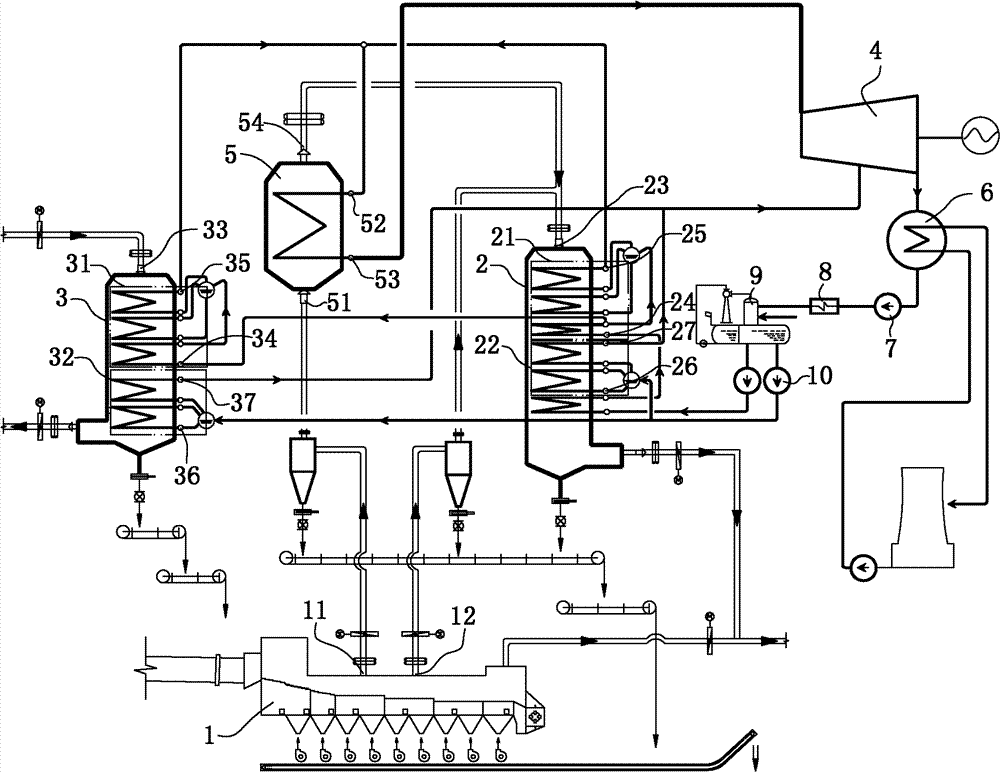

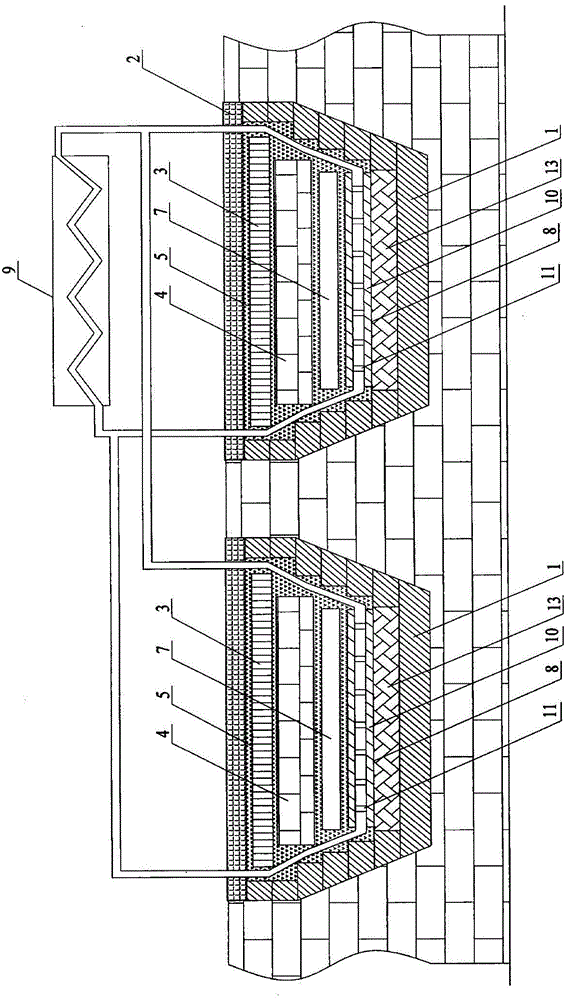

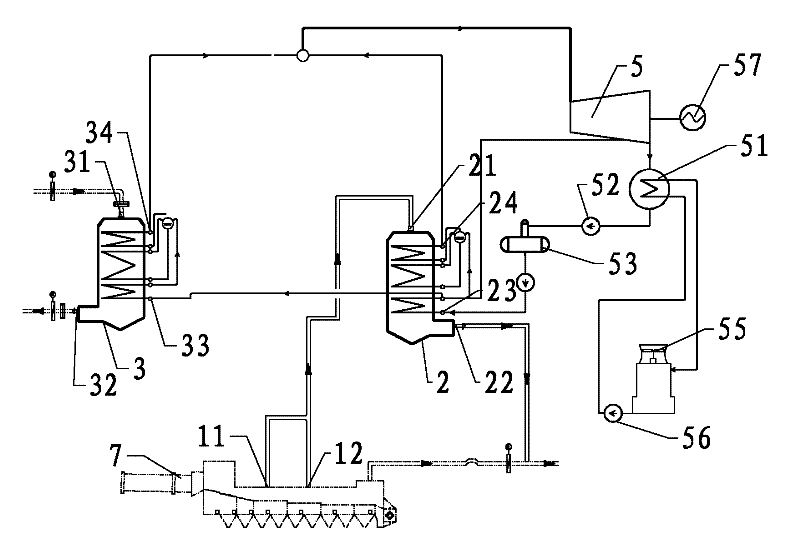

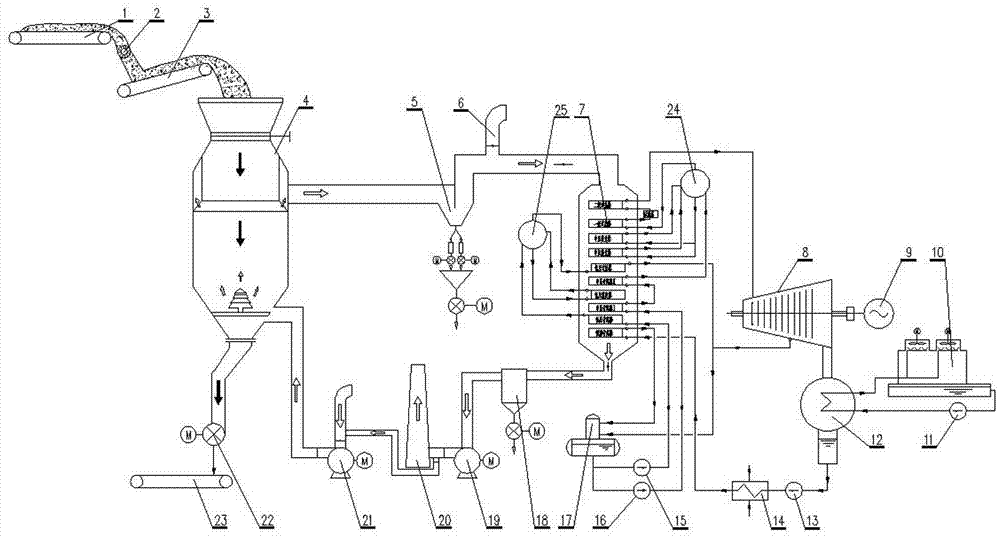

Device and process for generating power through efficient recovery of waste heat of sintered ores

ActiveCN103234362AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialCogenerationMaterials science

The invention discloses a device and a process for generating power through efficient recovery of waste heat of sintered ores and belongs to the technical field of cogeneration. The device comprises a sintered ore cooling system, a waste heat power generating system and a smoke system, wherein the sintered ore cooling system and the waste heat cycling power generating system are connected through the smoke system to form a loop. The process comprises the steps of 1), cooling of sintered ores; 2) the smoke system; and 3) waste heat power generating. The device and the process for generating power through waste heat have the advantages that discharged waste heat is used fully during cooling of sintered ores, the electric energy production is improved significantly, the power rate of the system is reduced significantly, and the energy-saving effect is significant.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

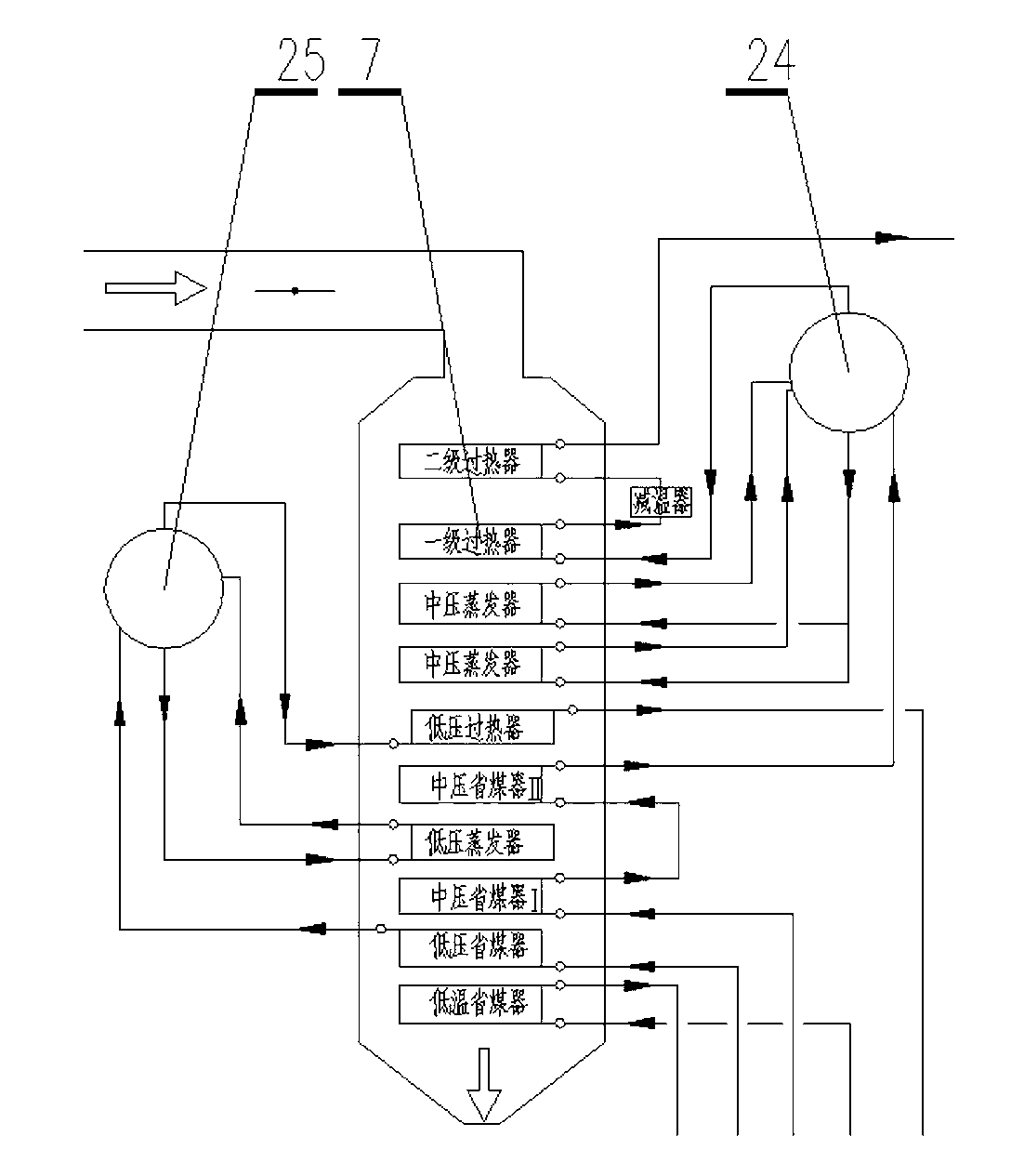

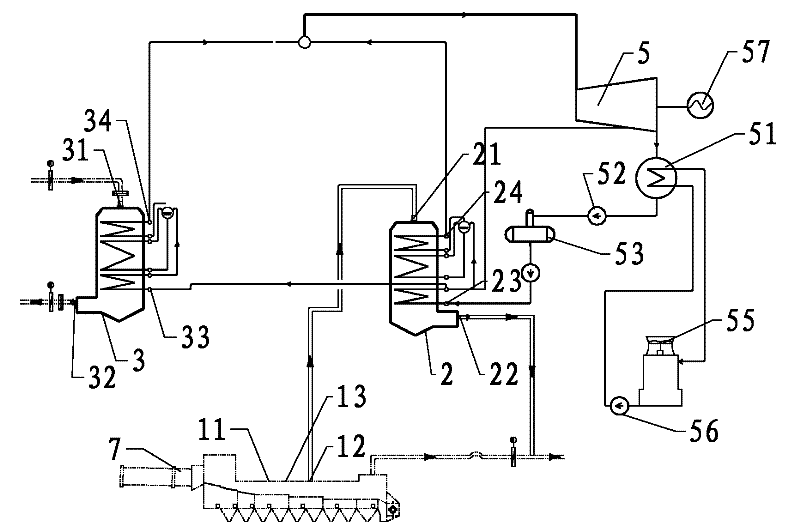

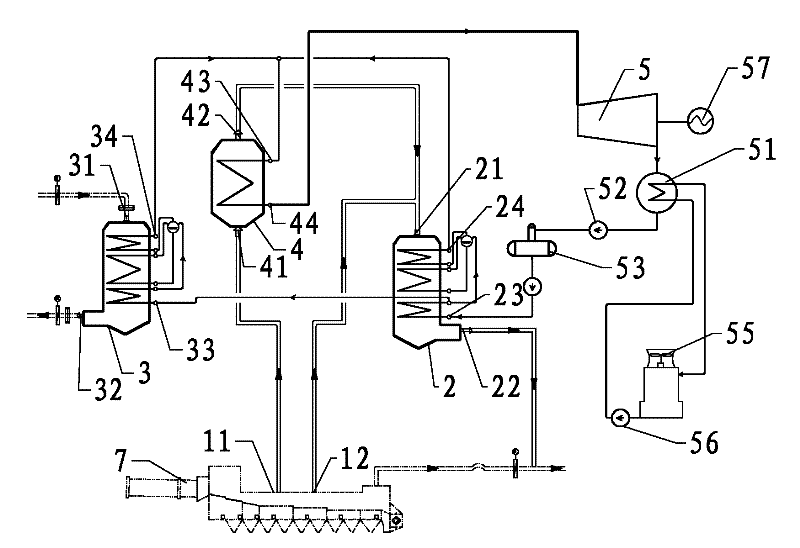

Single-pressure recovery generating system of waste heat of dry method cement production line

InactiveCN101871732AReliable temperatureIncrease steam enthalpyIncreasing energy efficiencySteam engine plantsSuperheaterEngineering

The invention discloses a single-pressure recovery generating system of waste heat of a dry method cement production line, being capable of improving generating efficiency. The kiln head grate cooler of the single-pressure recovery generating system is provided with at least two gas picking-up openings including a high-temperature gas picking-up opening and a moderate-temperature gas picking-up opening. A high-temperature superheater is arranged in the system; the high-temperature gas picking-up is connected to the gas inlet of the high-temperature superheater; the moderate-temperature gas picking-up opening is connected to the gas inlet of an AQC (Air Quench Cooler) boiler; the steam outlet of the AQC boiler and the steam outlet of a kiln tail SP (Suspend Preheater) boiler are connected to the steam outlet of the high-temperature superheater; the steam outlet of the high-temperature superheater is connected to a steam turbine, which makes the primary superheat steam of the kiln tail SP boiler and the AQC boiler obtain reliable secondary superheating in the high-temperature superheater; moderate-temperature flue gas and the heat-exchanged flue gas of the high-temperature superheater are taken as the heat source of the AQC boiler to realize the stepwise recovery of the energy of the flue gas of the waste heat of the grate cooler, increase steam enthalpy and improve effective enthalpy drop; the steam quality is improved and the flow is reduced, which reduce the exhaust loss of the waste heat in a condenser of the steam turbine and promote the improvement of waste heat generating efficiency.

Owner:CHENGDU HOT NEW ENERGY TECH

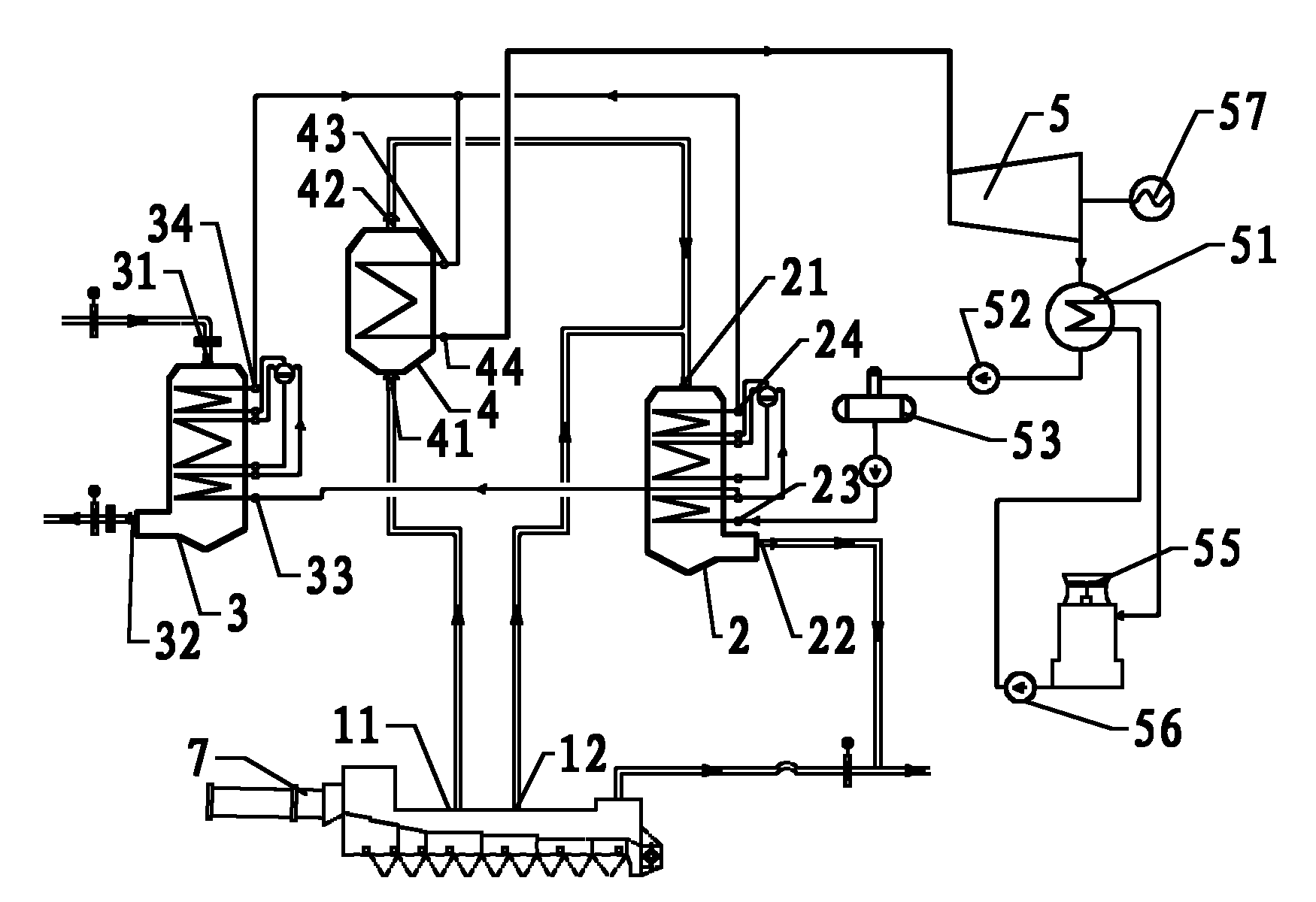

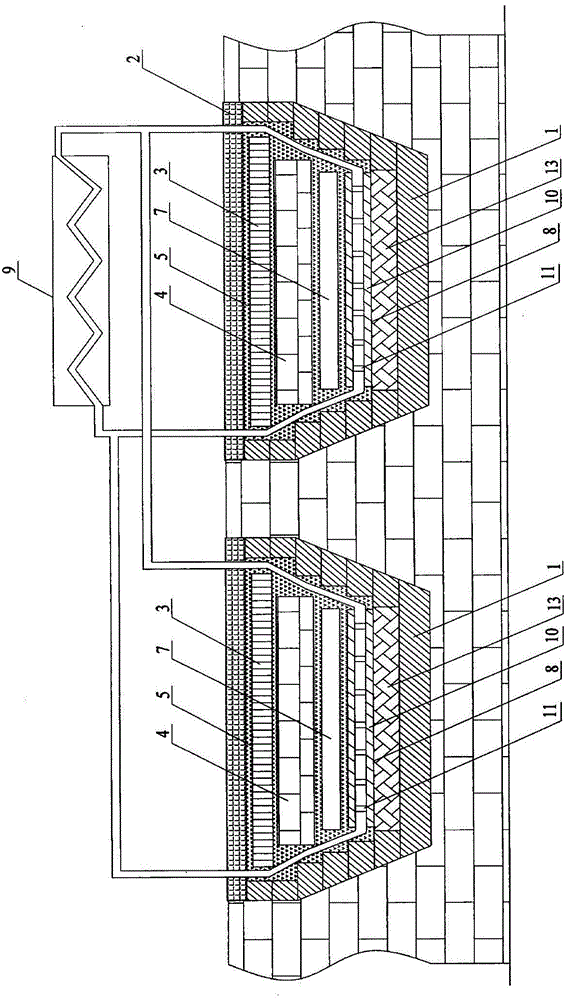

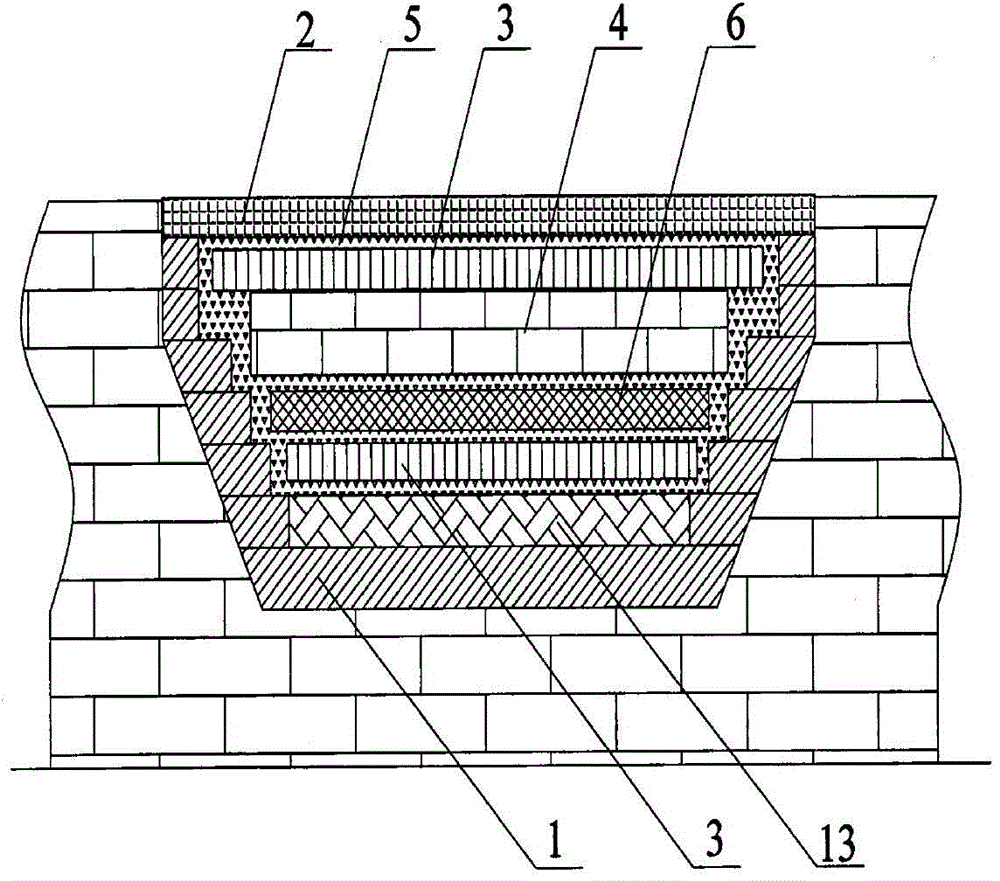

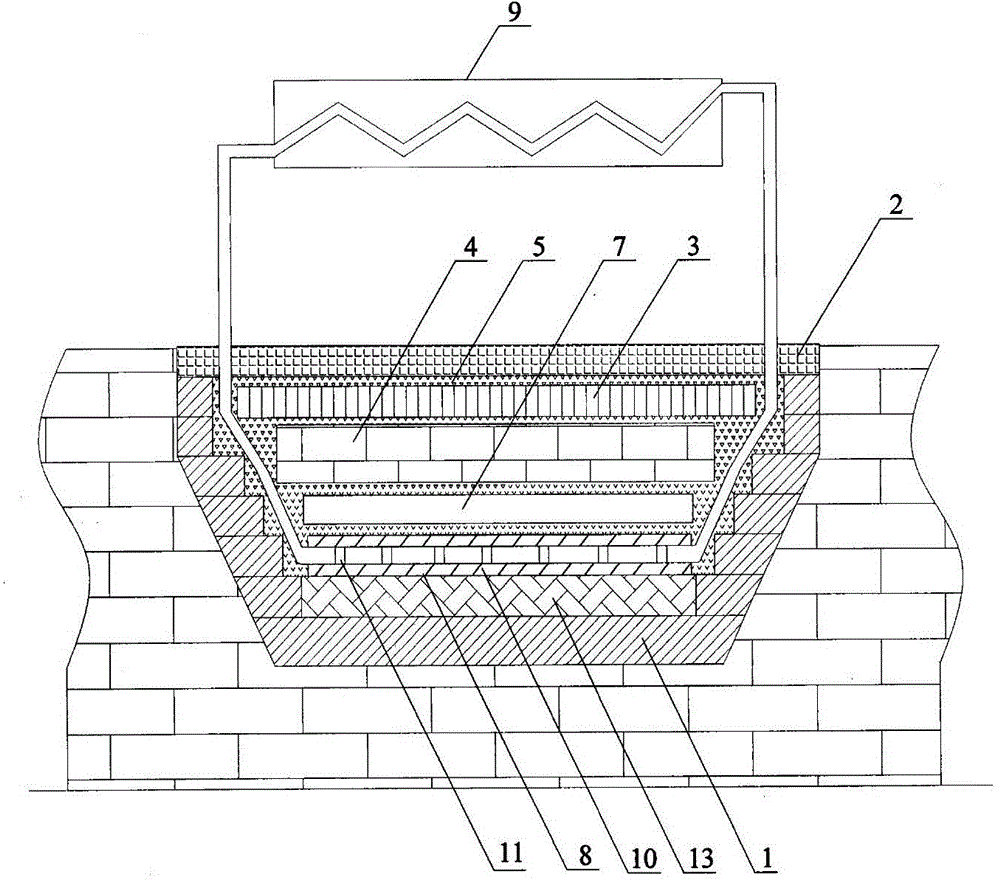

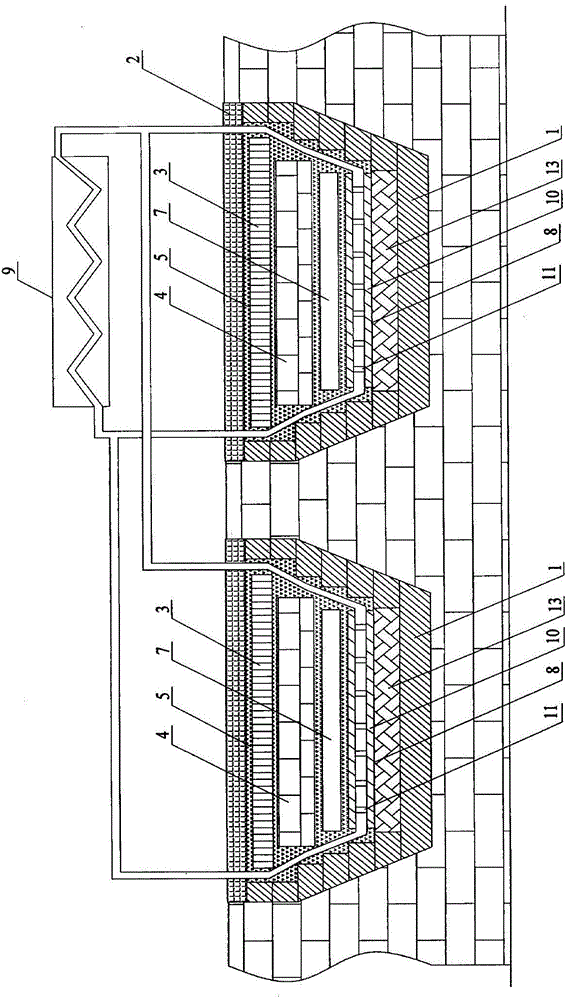

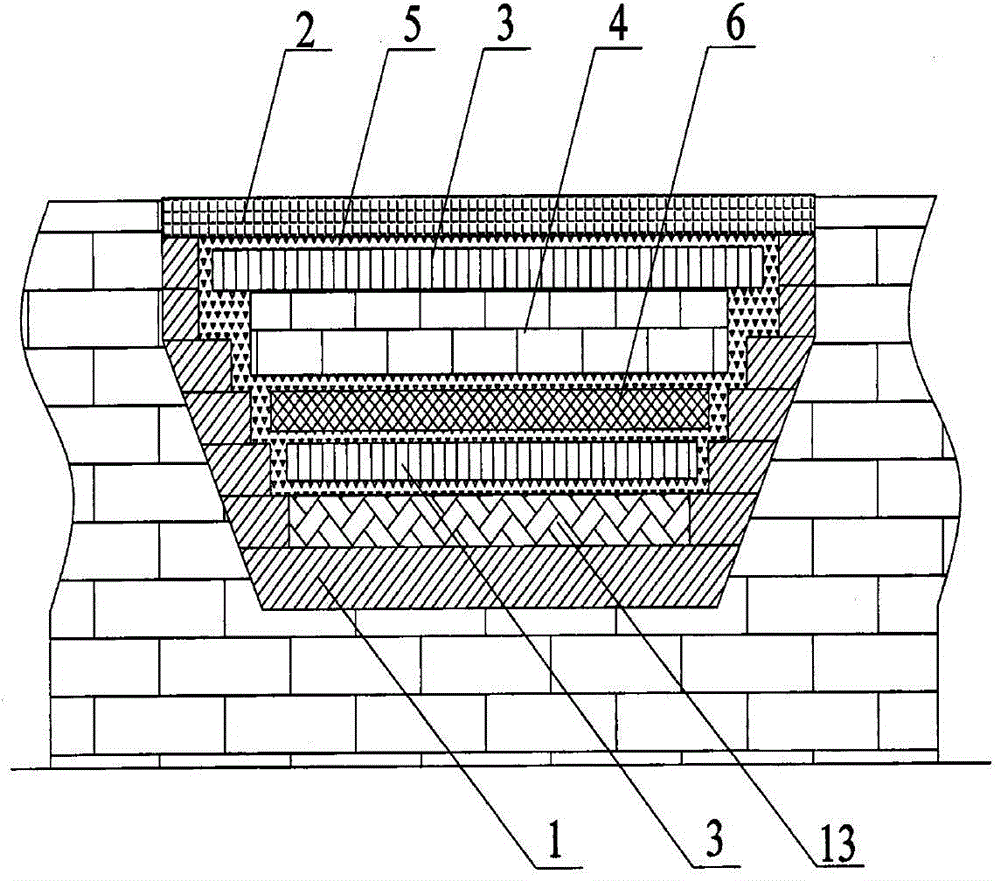

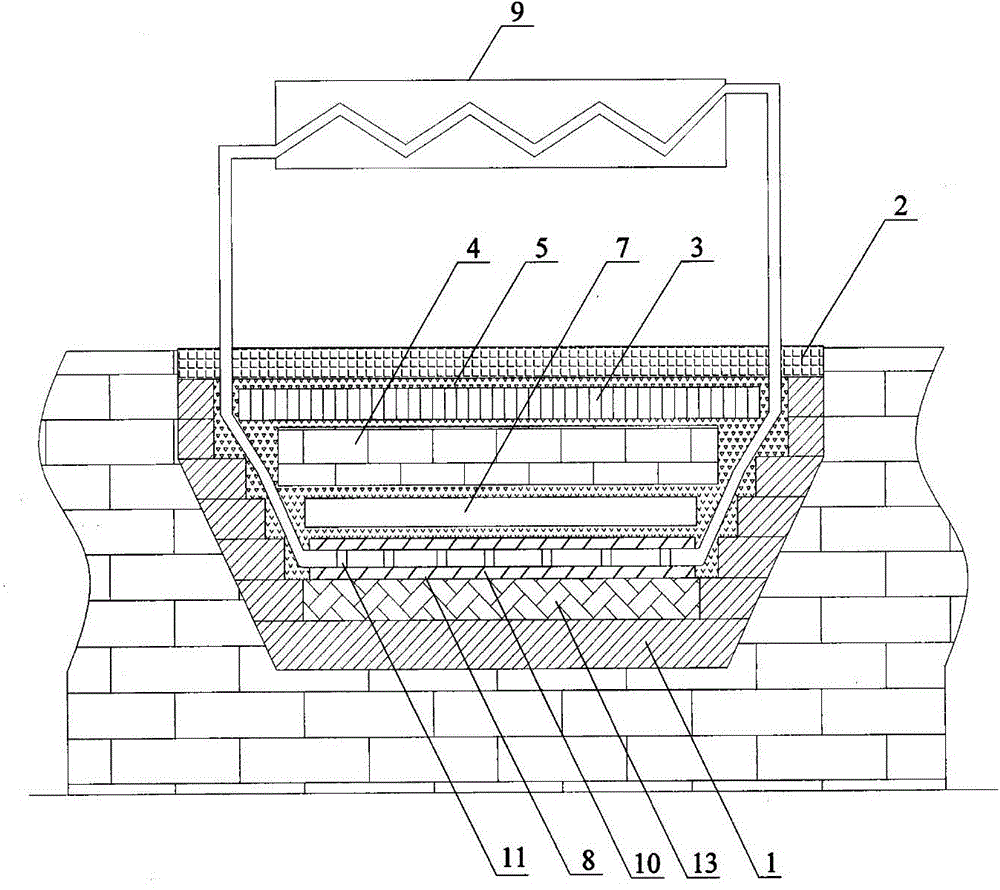

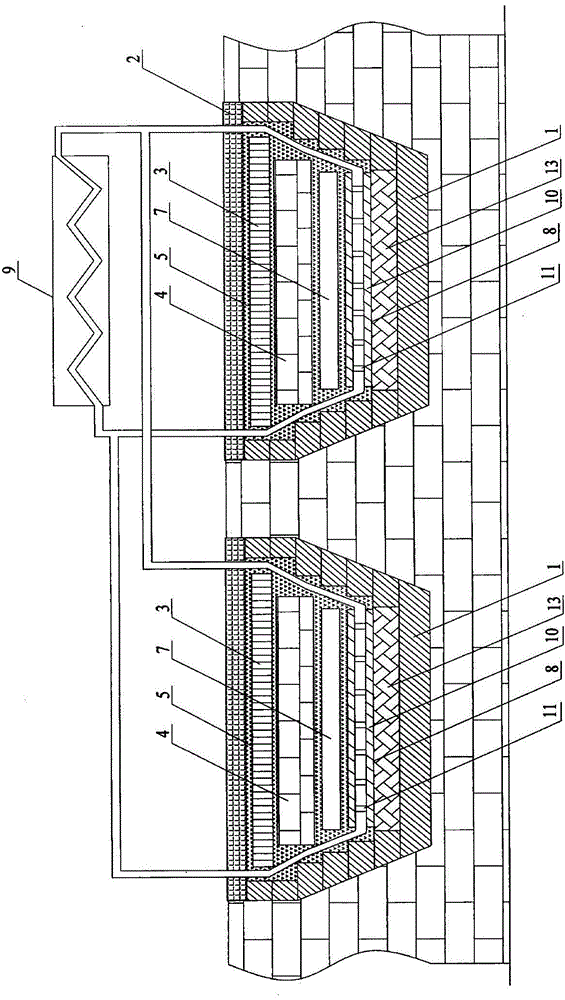

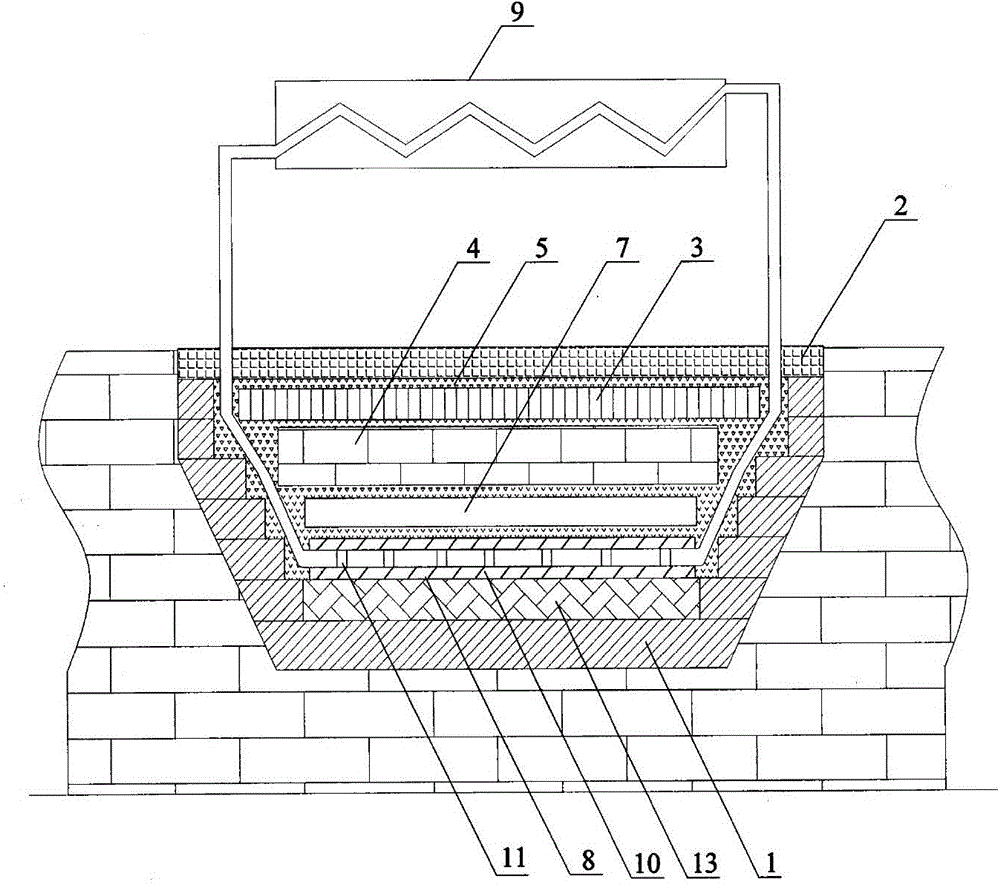

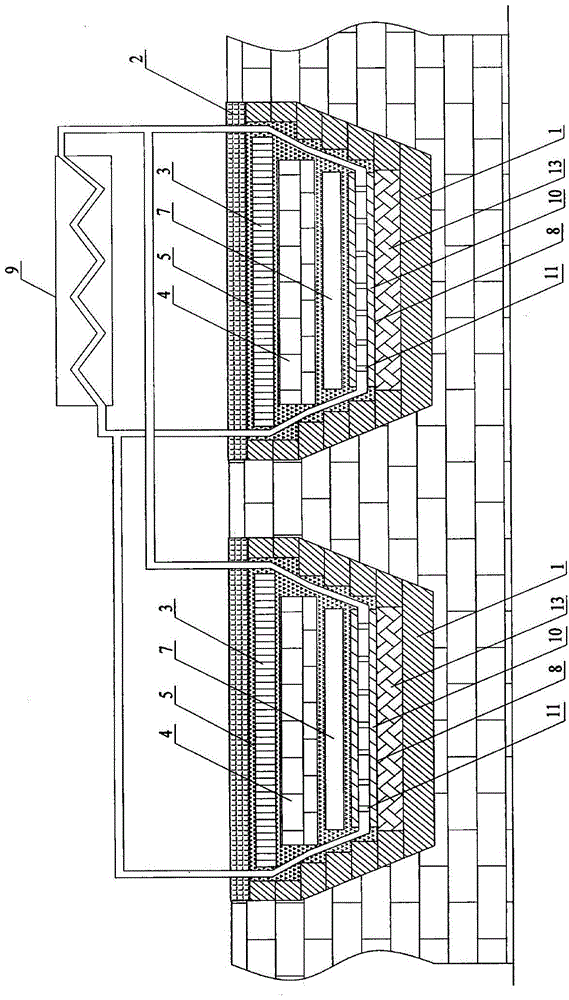

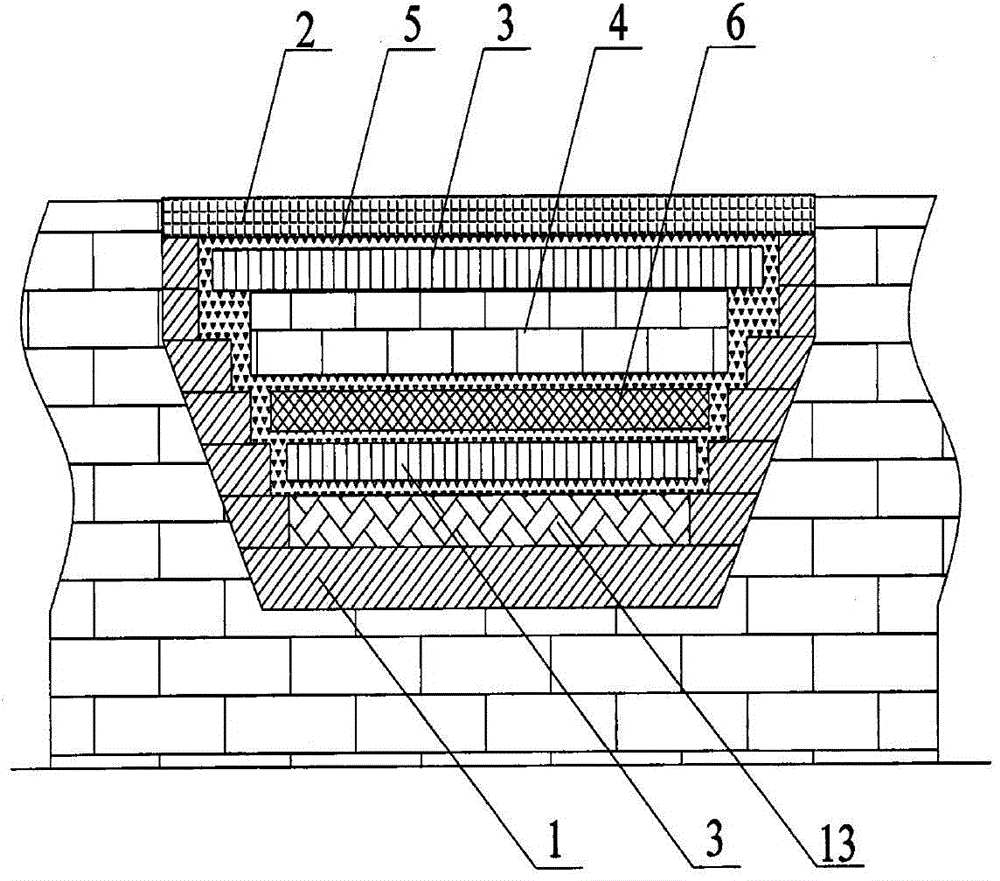

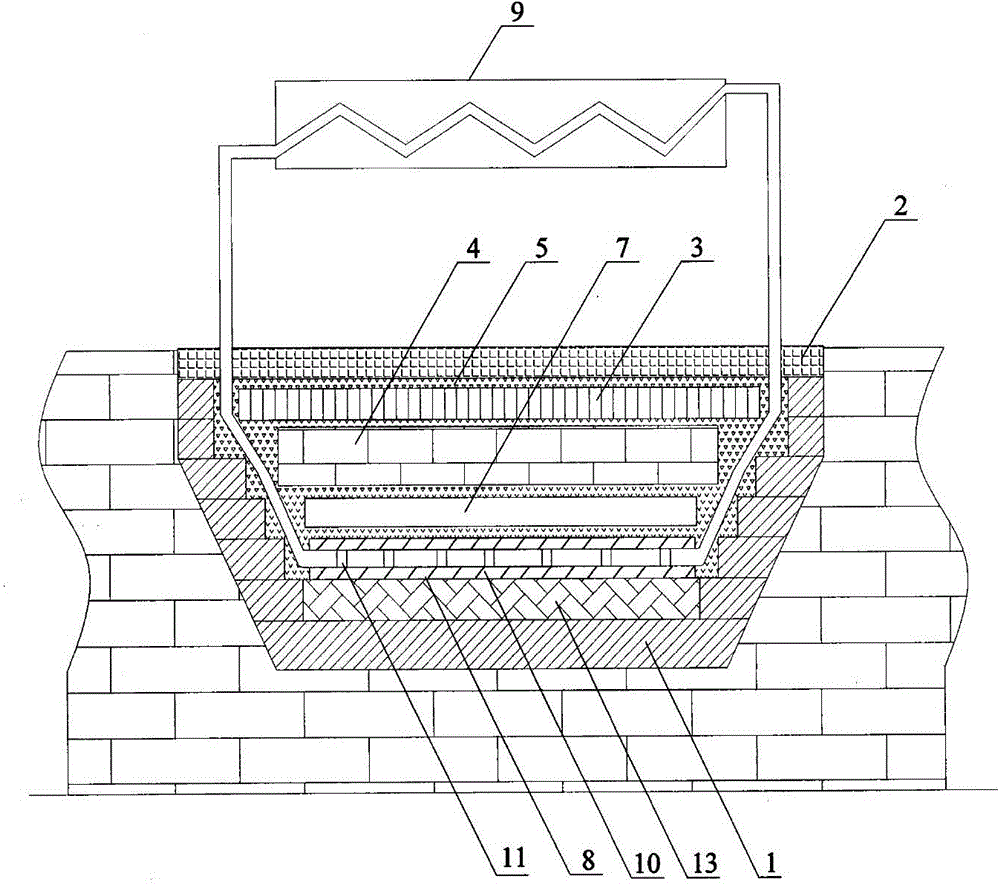

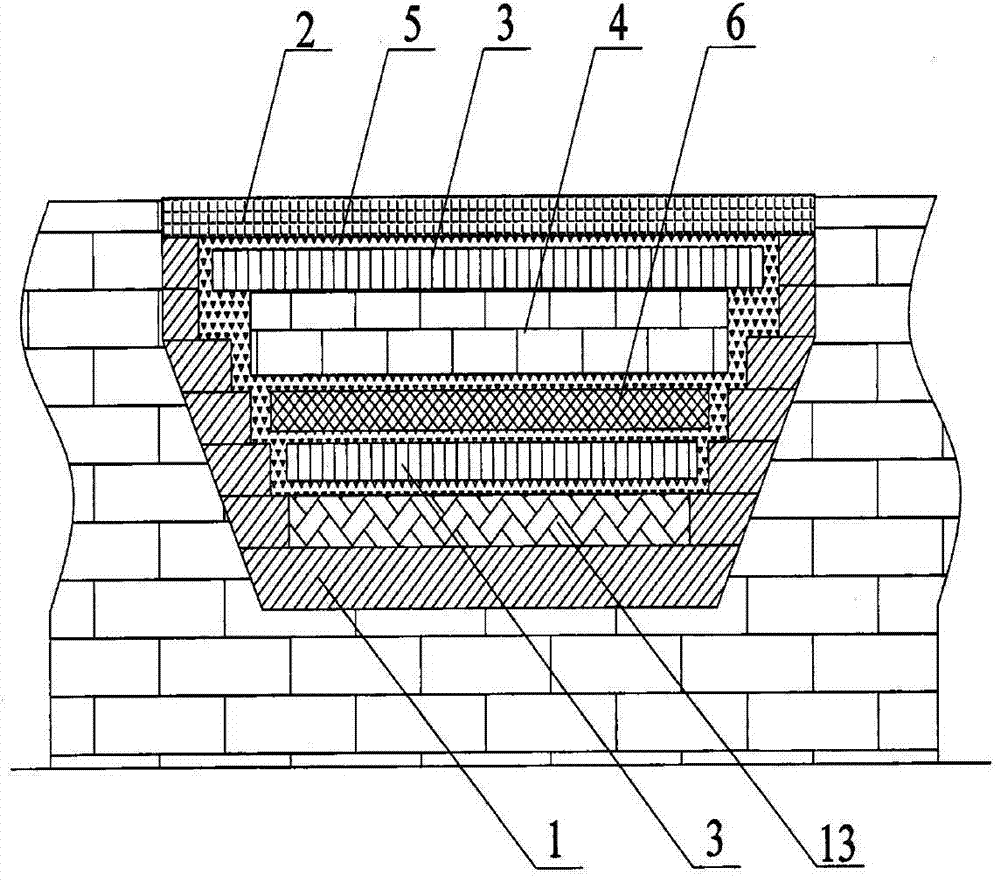

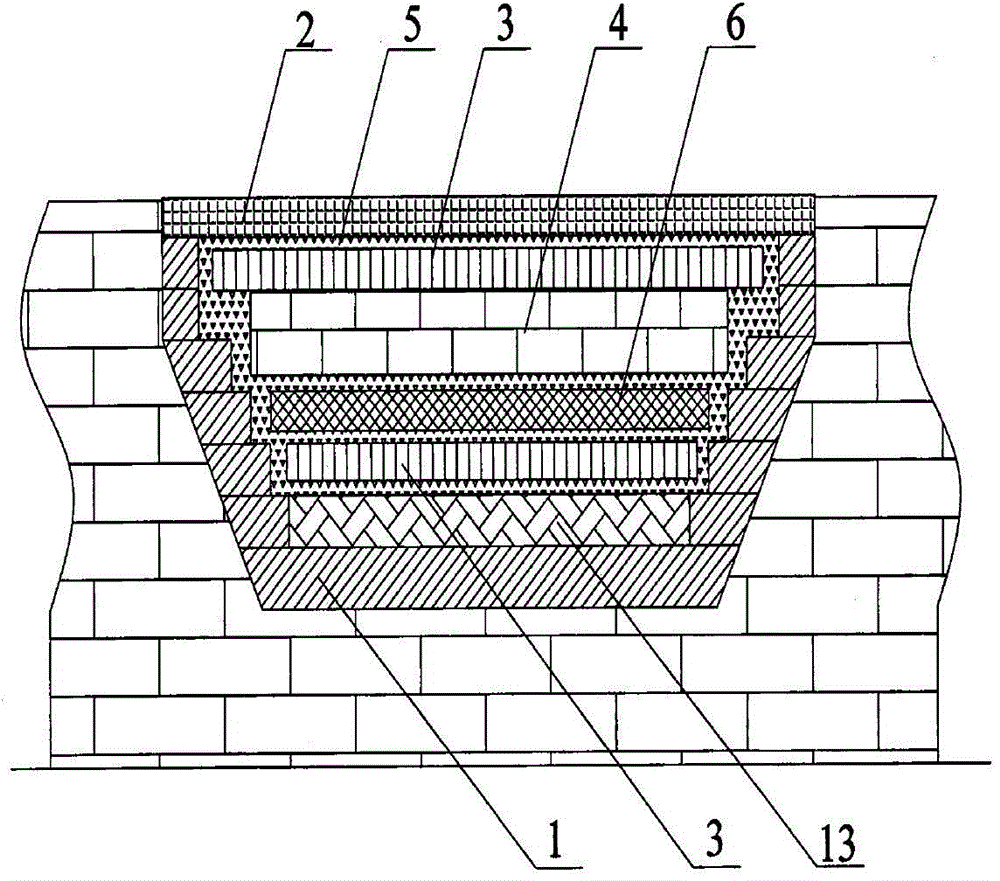

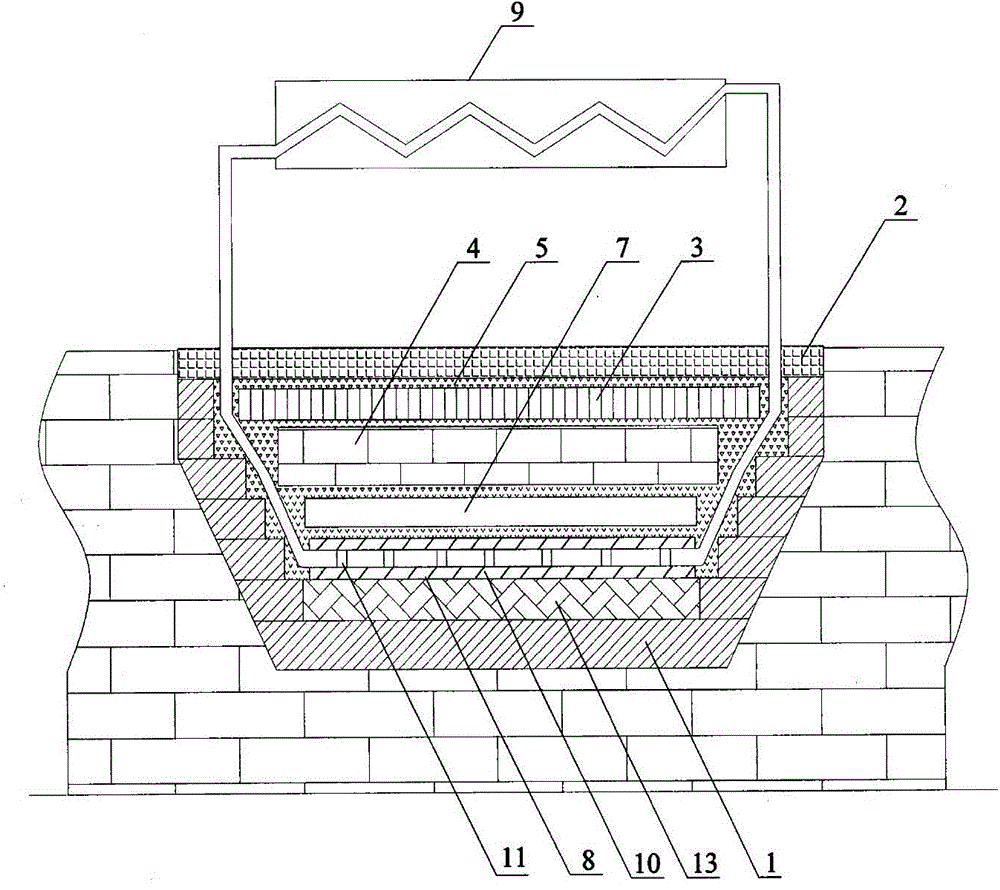

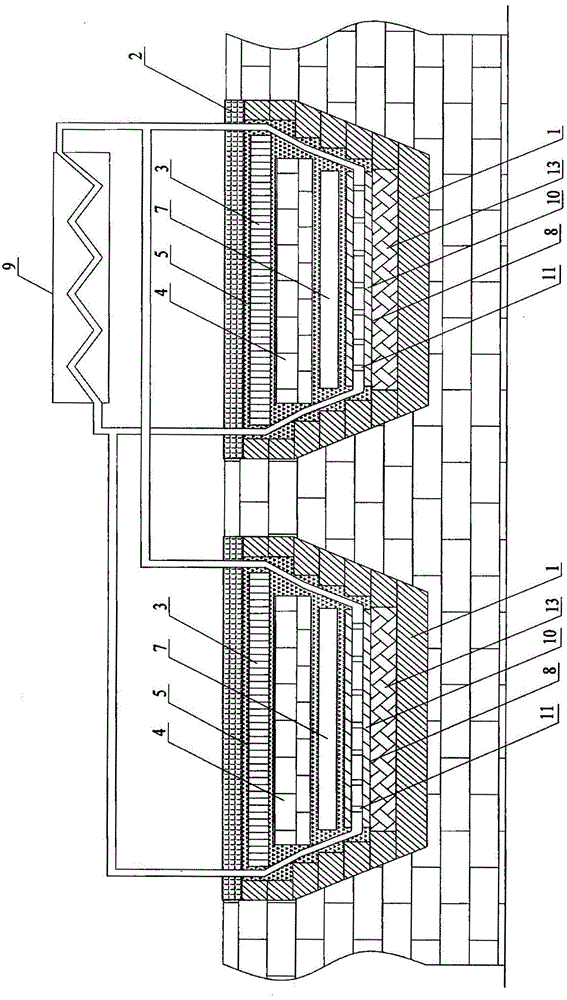

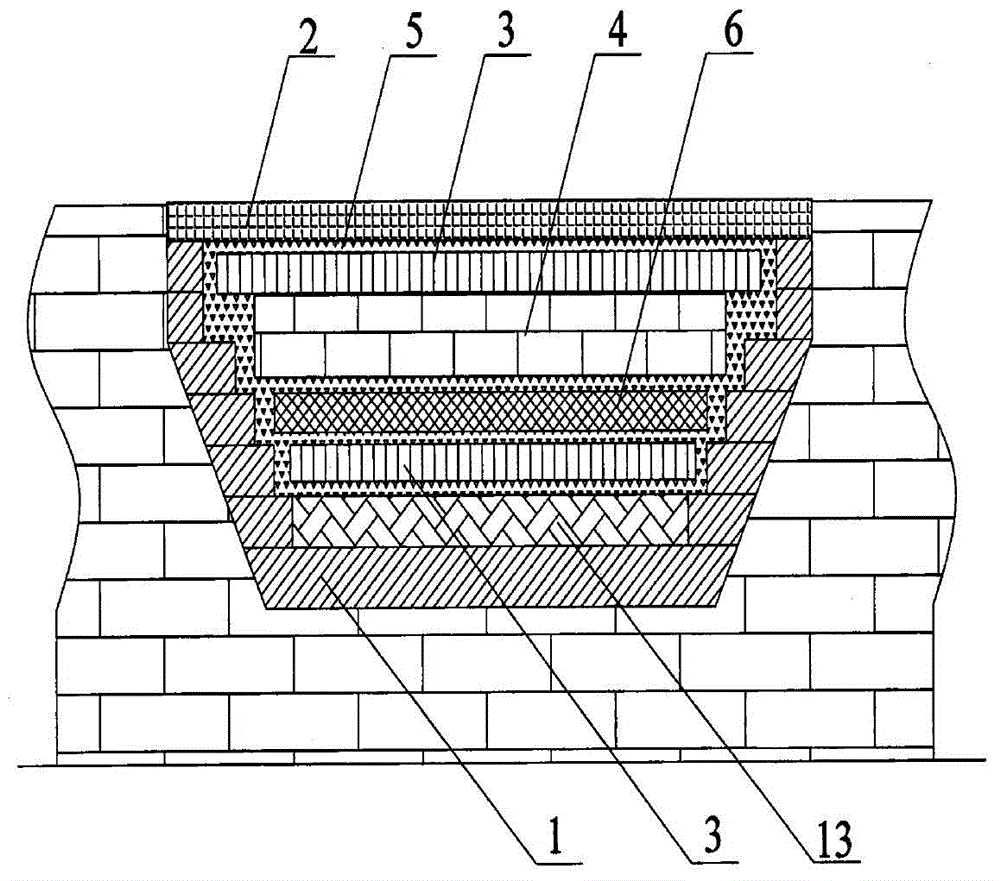

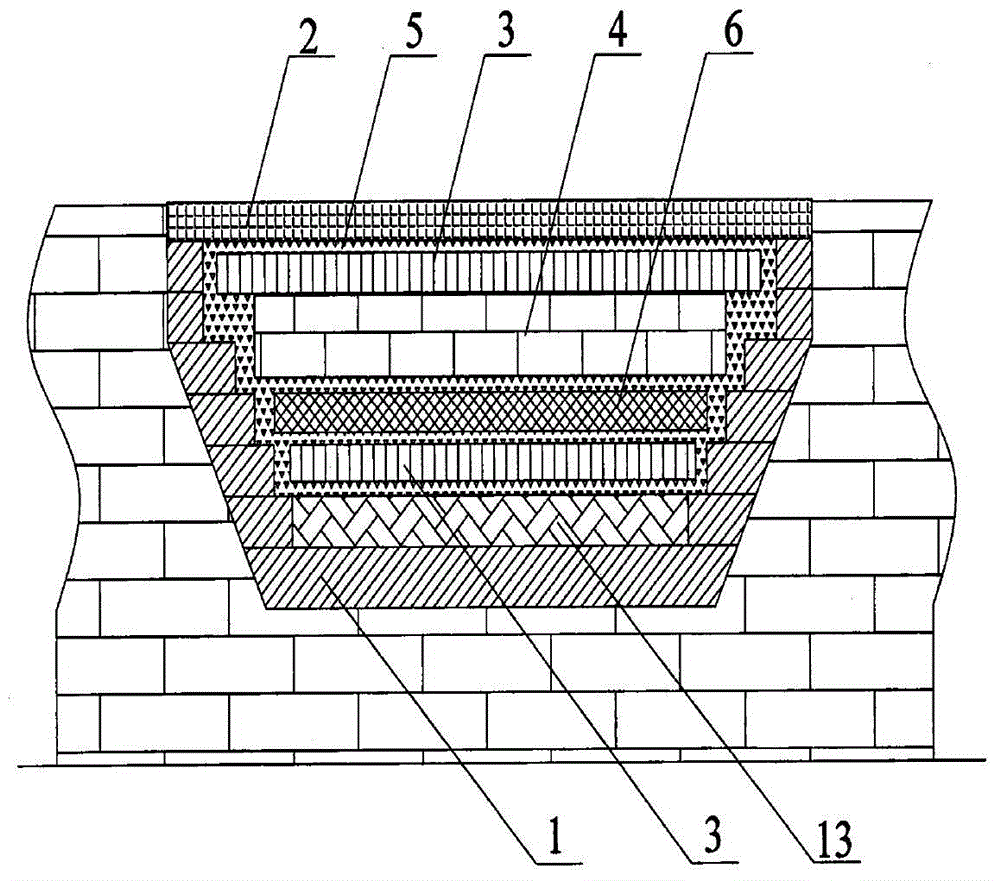

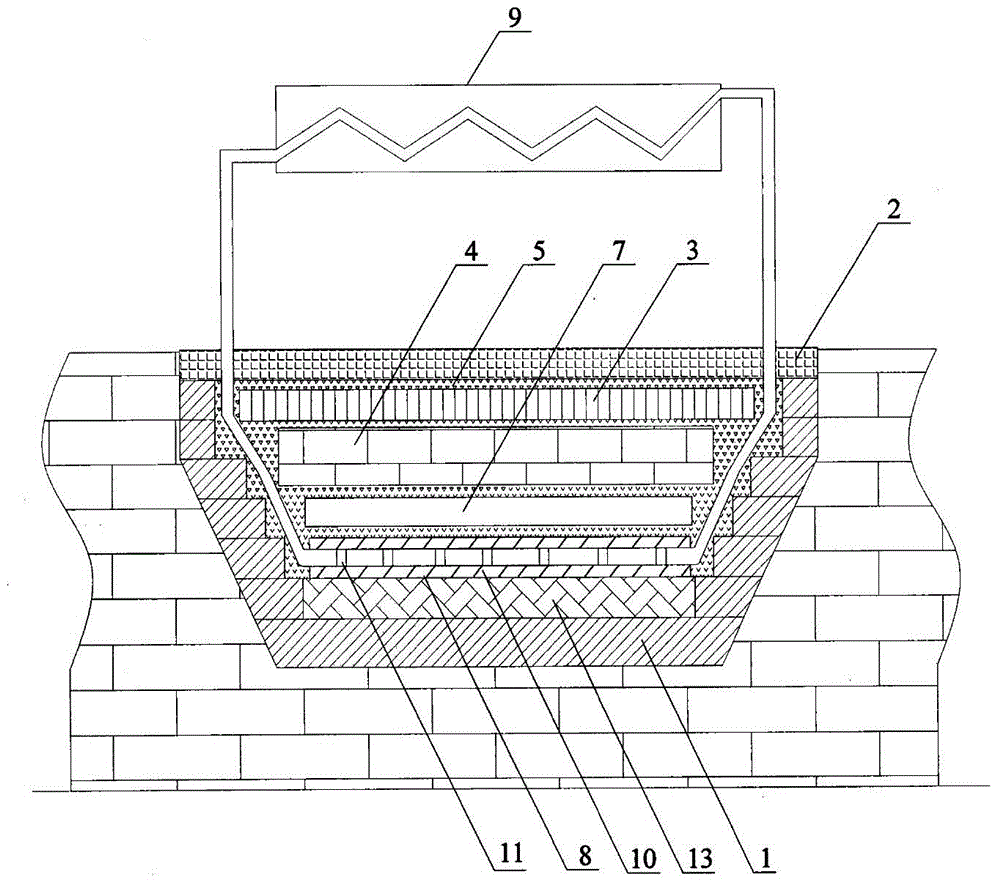

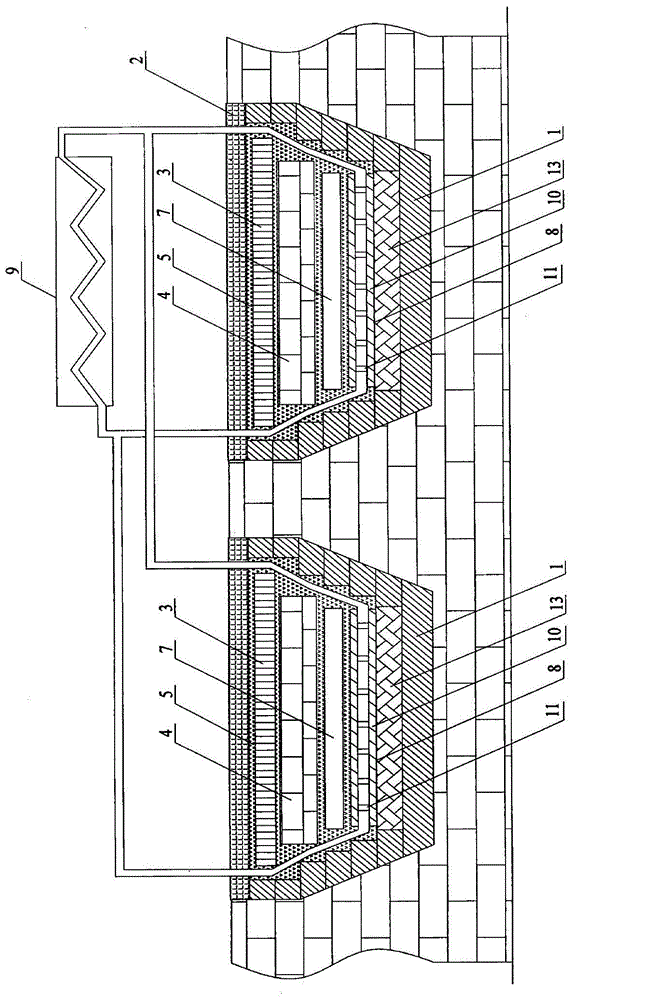

Device with griddle and process for generating power by efficiently recycling sinter waste heat

ActiveCN103234364AIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialProcess engineeringUtilization rate

A device with a griddle and a process for generating power by efficiently recycling sinter waste heat relate to the technical field of waste heat power generation. The device comprises a sinter cooling system, a waste heat power generation system and a smoke system. The sinter cooling system and the waste heat circulation power generation system are connected through the smoke system to form a loop. The process includes 1) sinter cooling, 2) the smoke system and 3) waste heat power generation. The device and the technological process for waste heat power generation have the advantages of completely utilizing waste heat discharged in the sinter cooling process, obviously increasing power generation quantity, obviously reducing system self power utilization rate and being remarkable in energy-saving effect.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

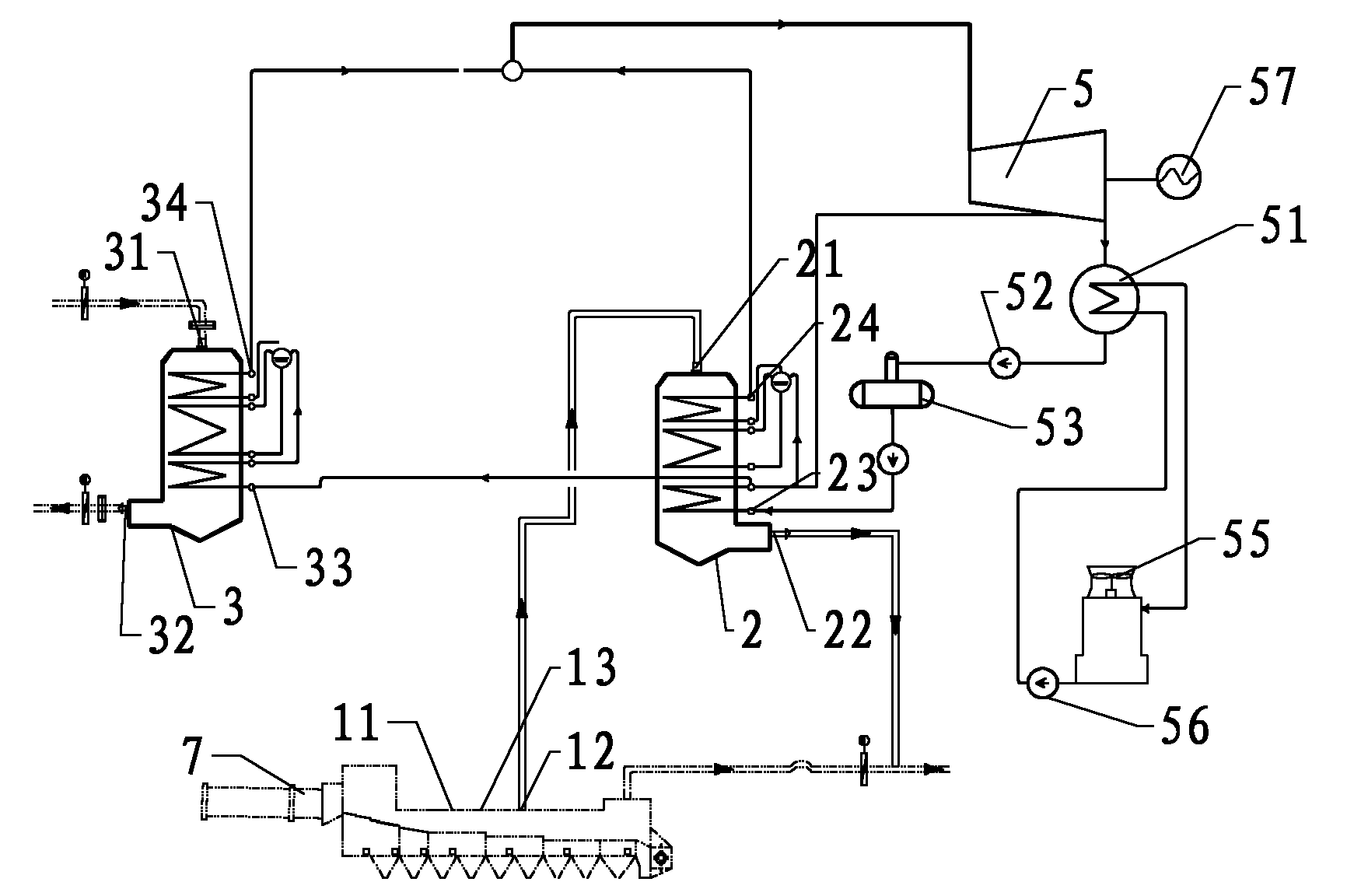

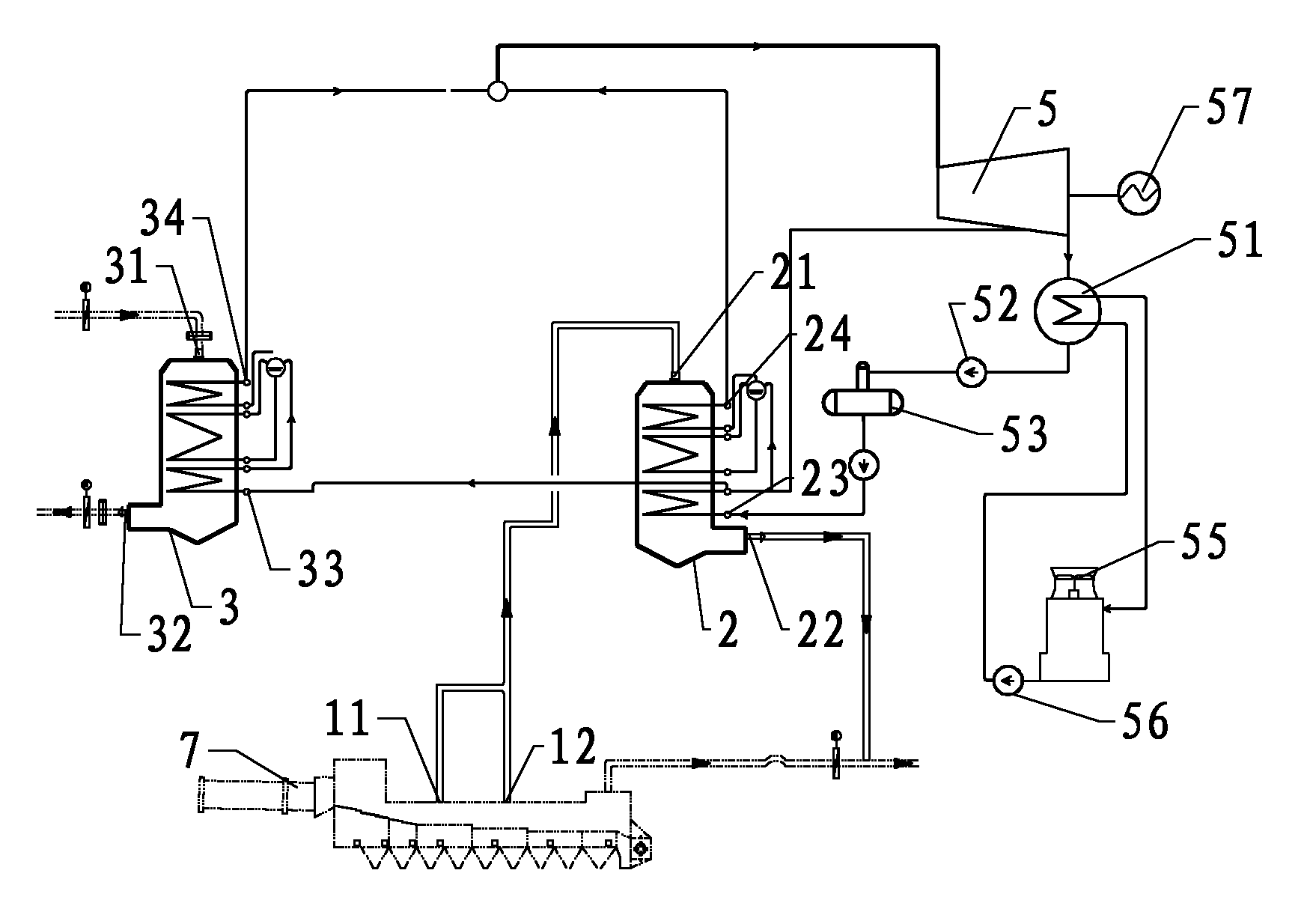

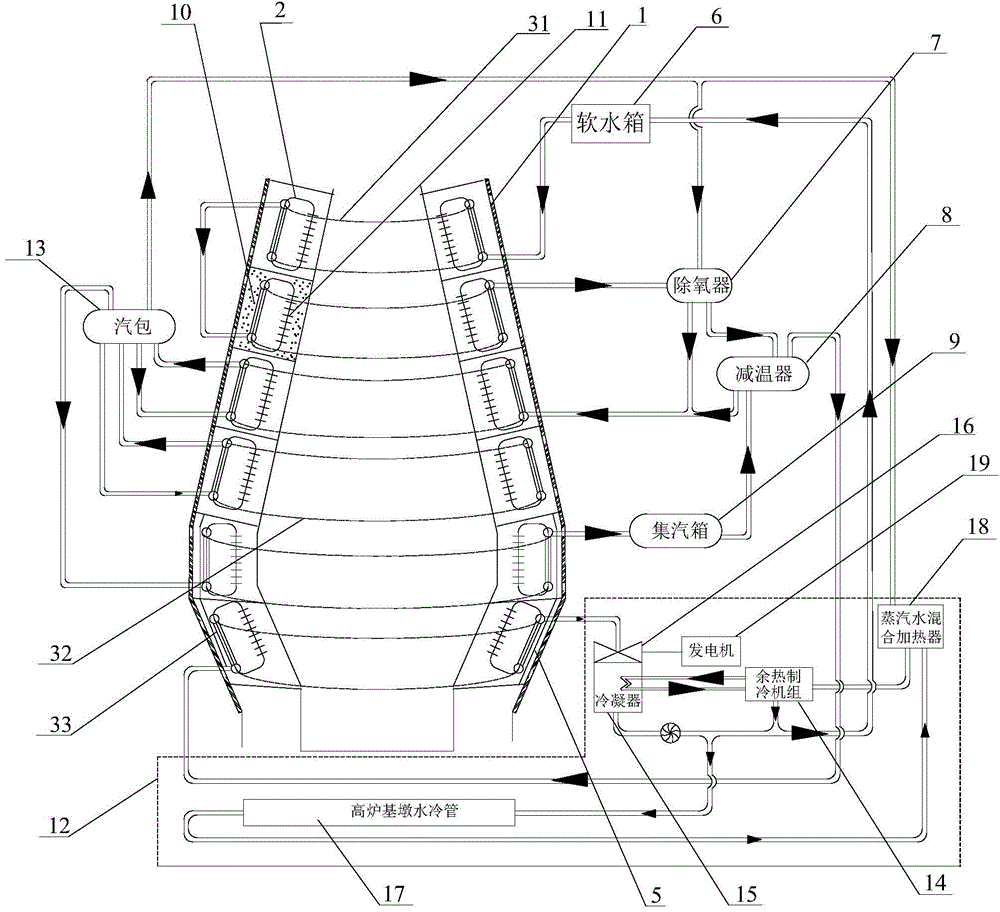

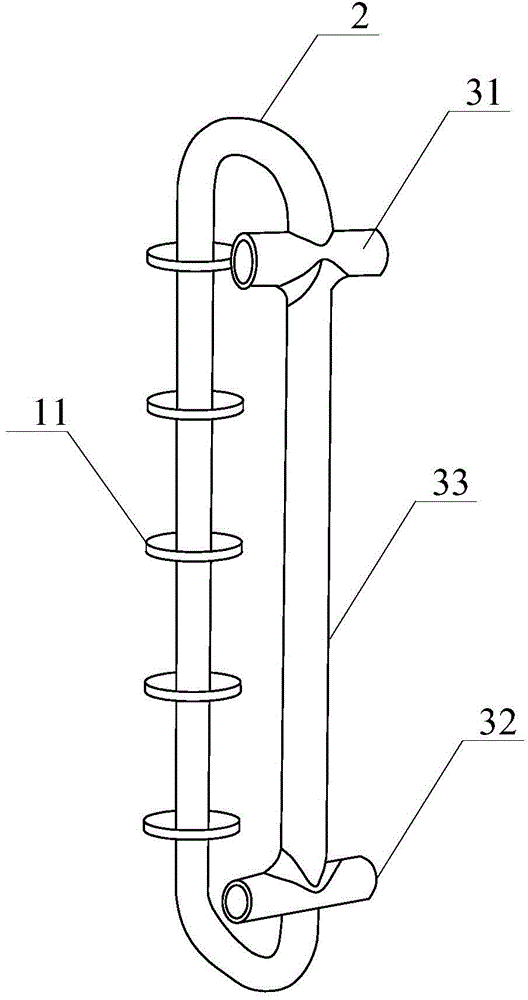

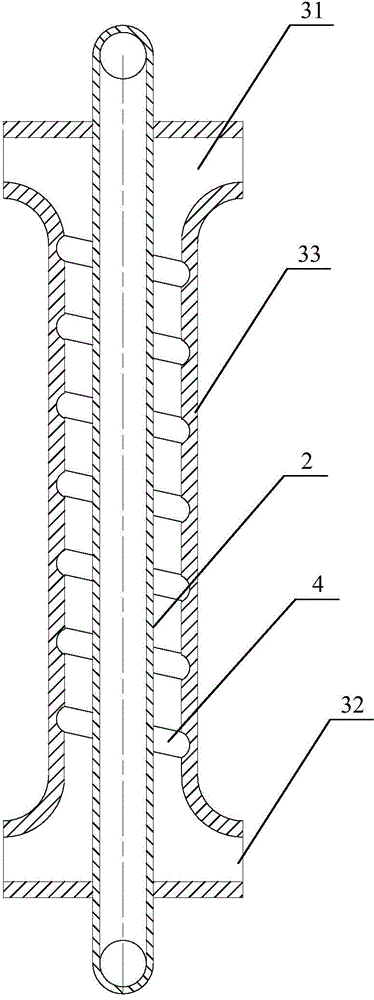

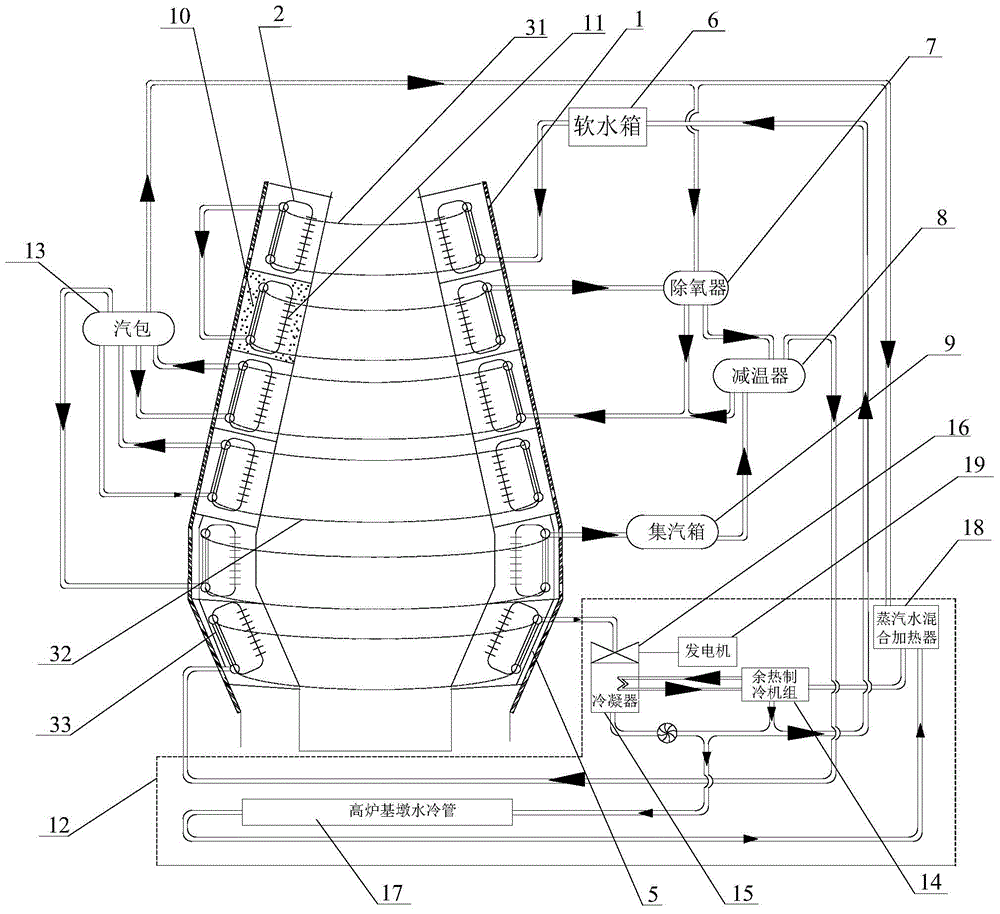

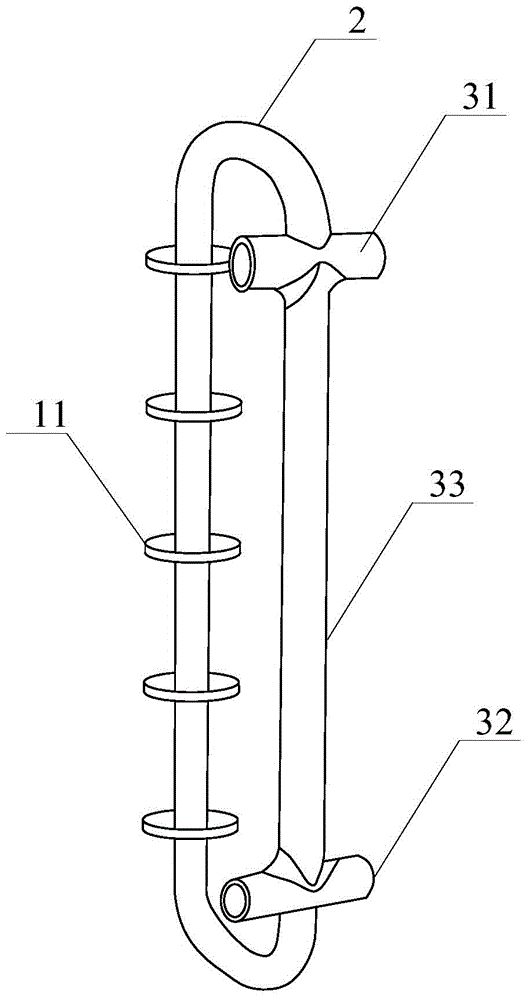

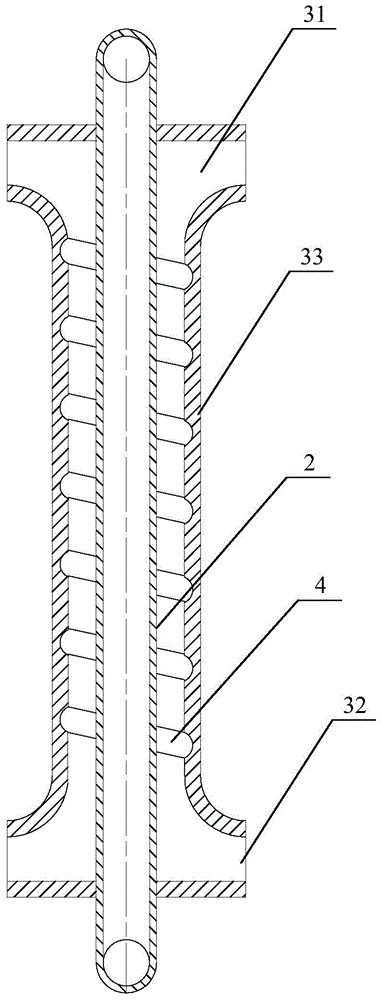

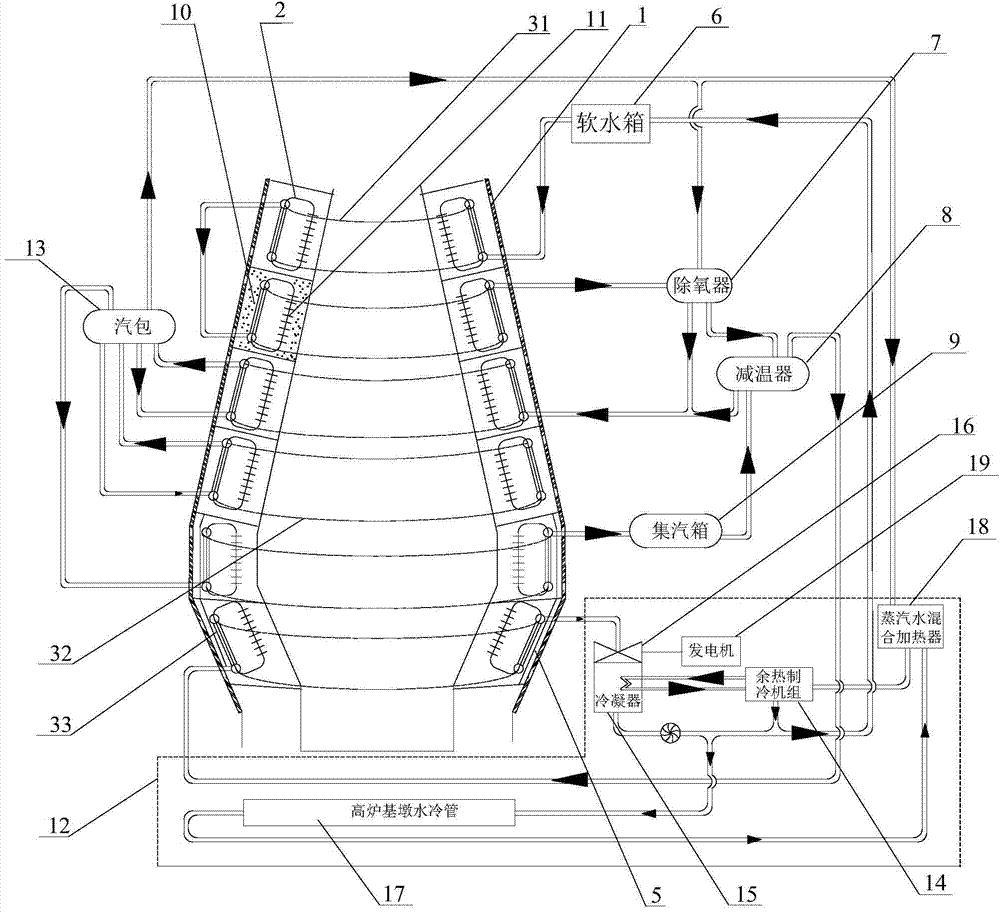

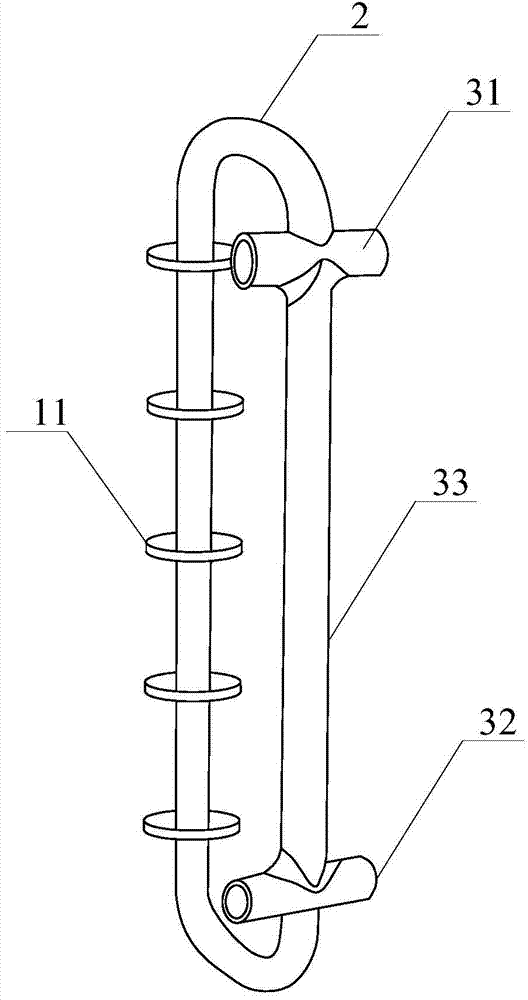

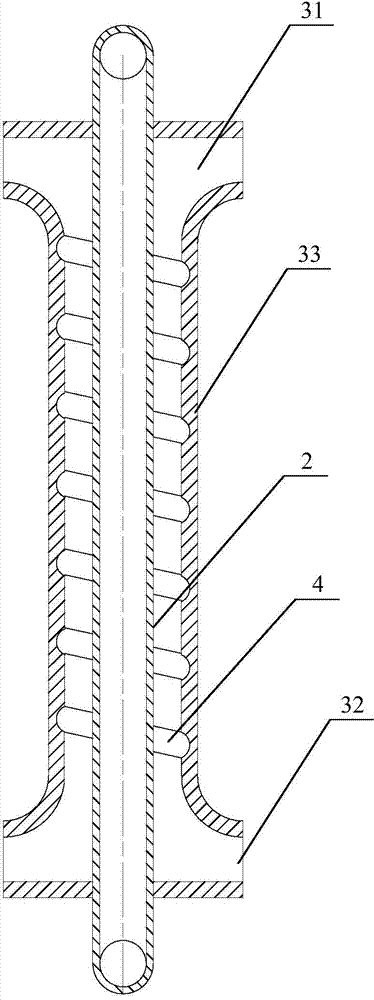

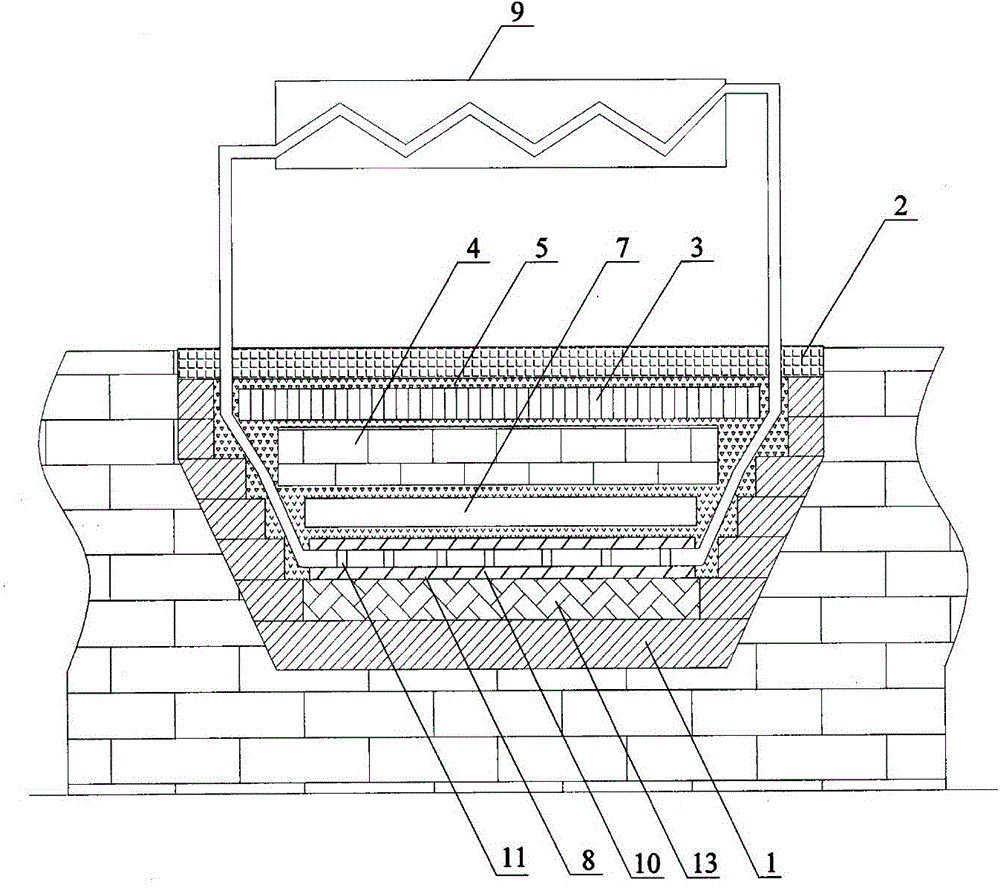

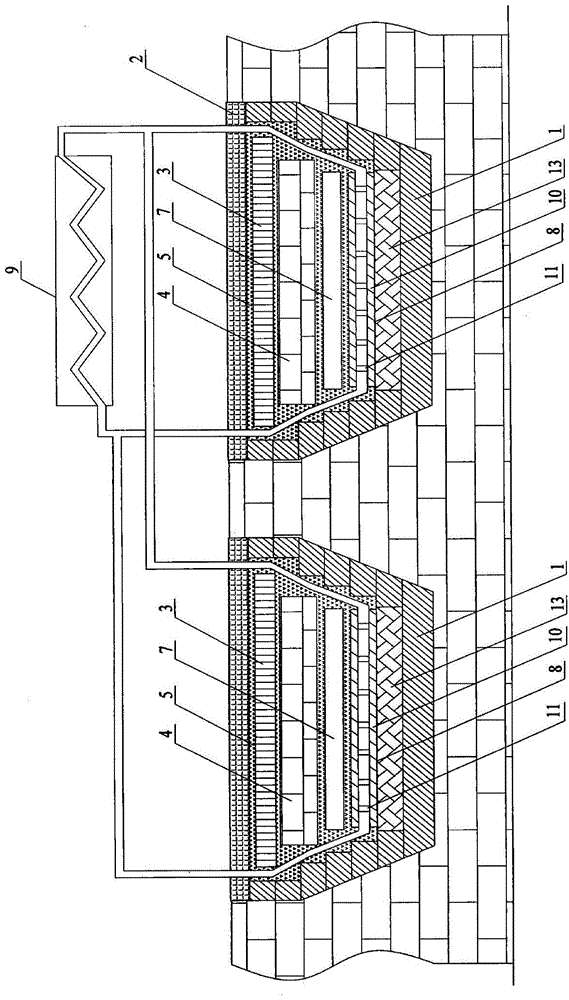

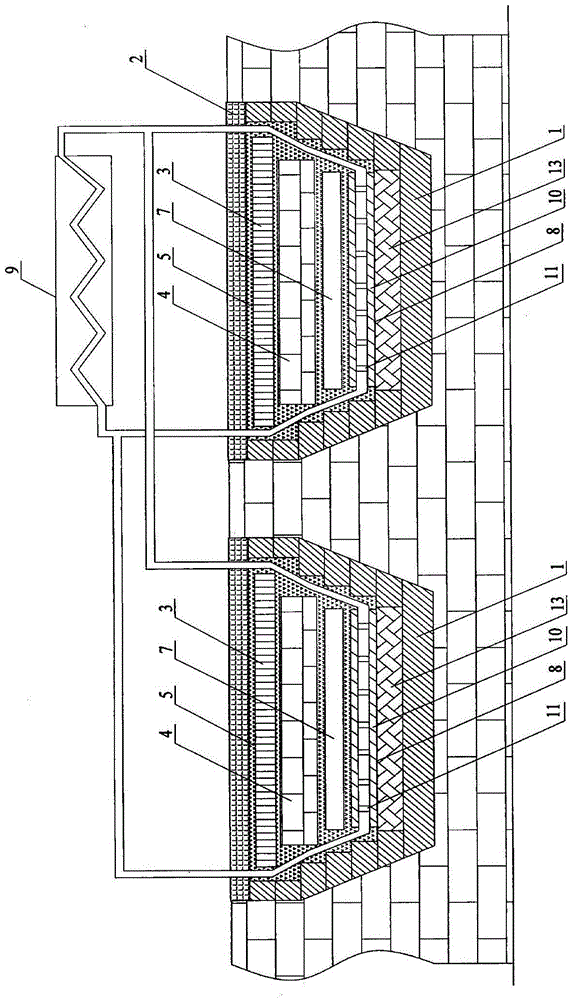

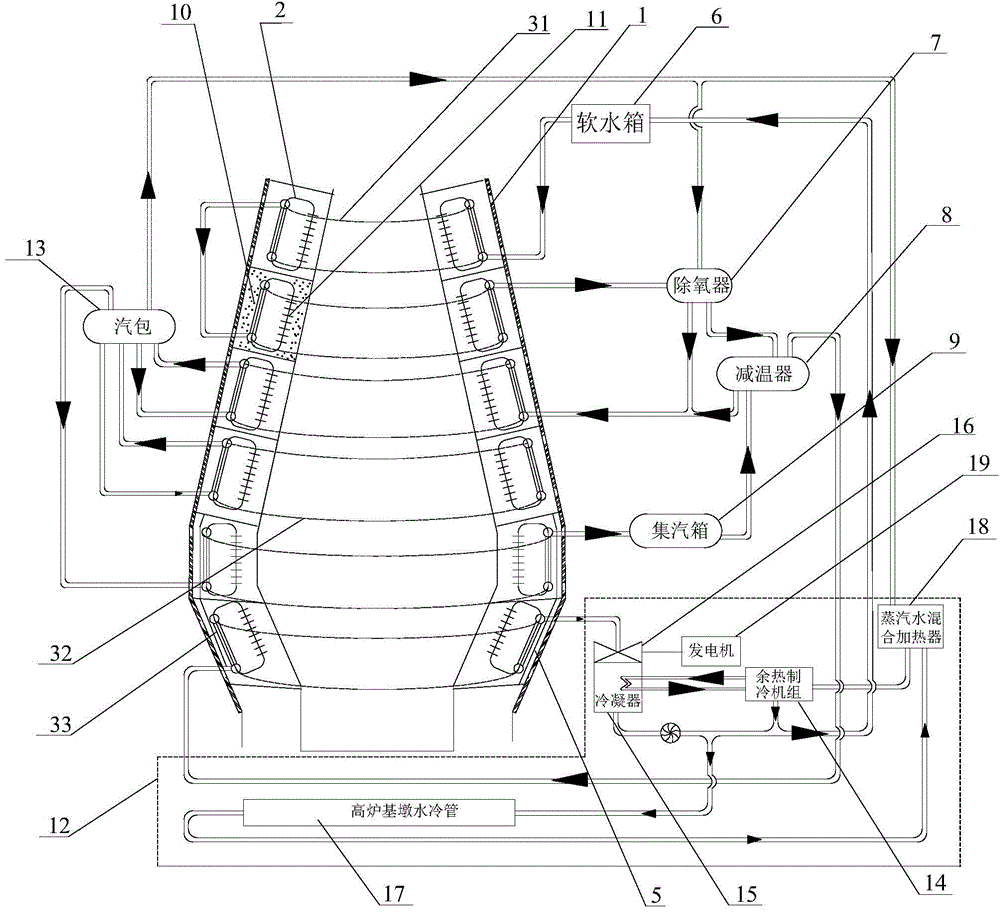

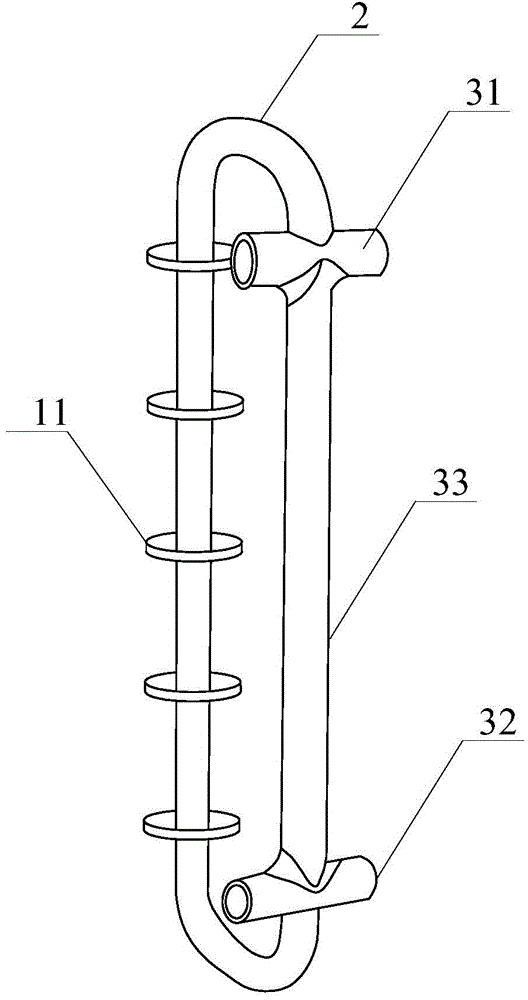

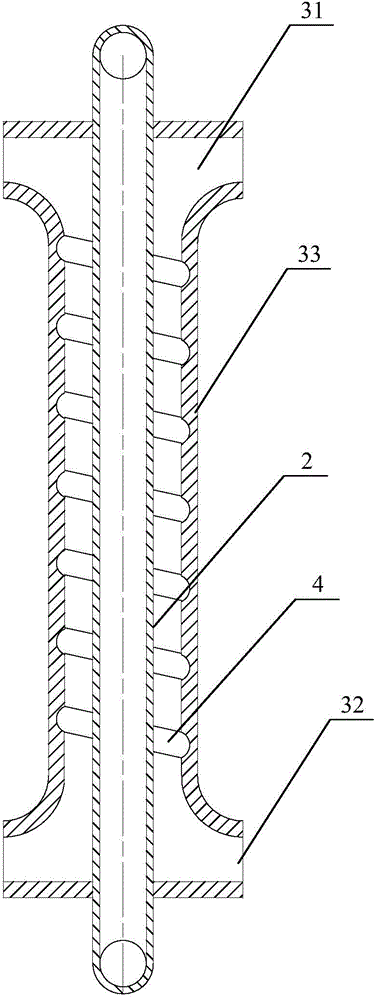

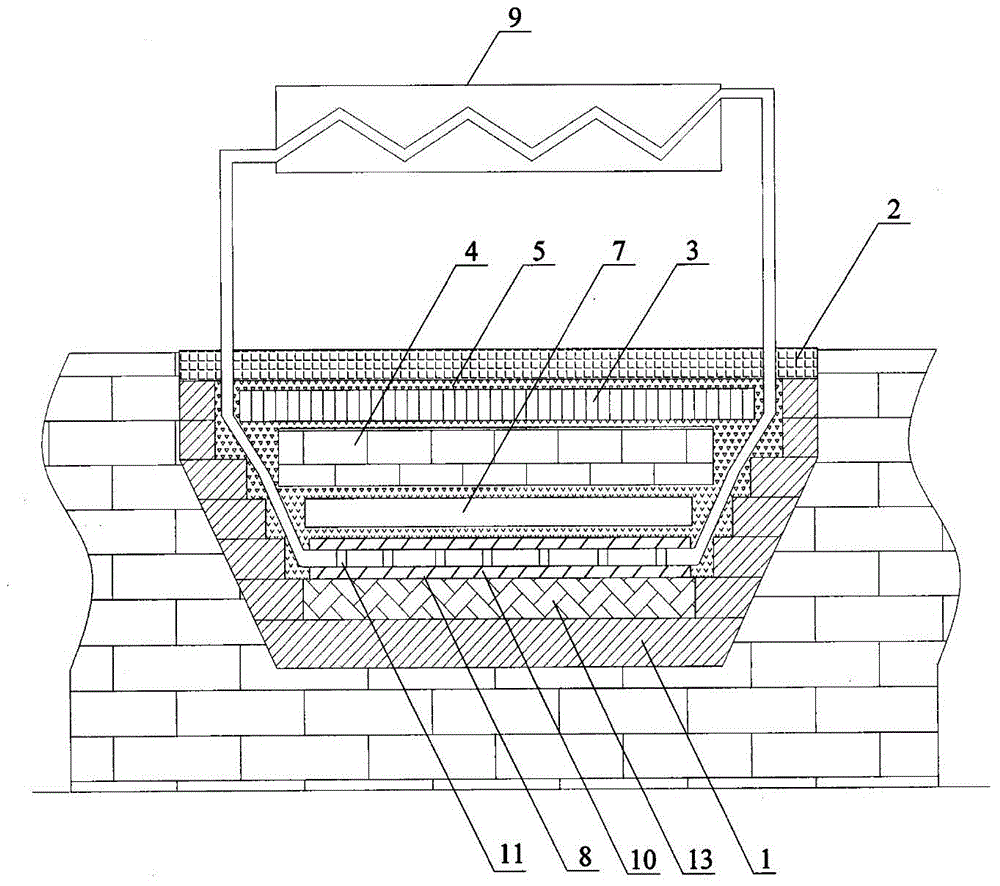

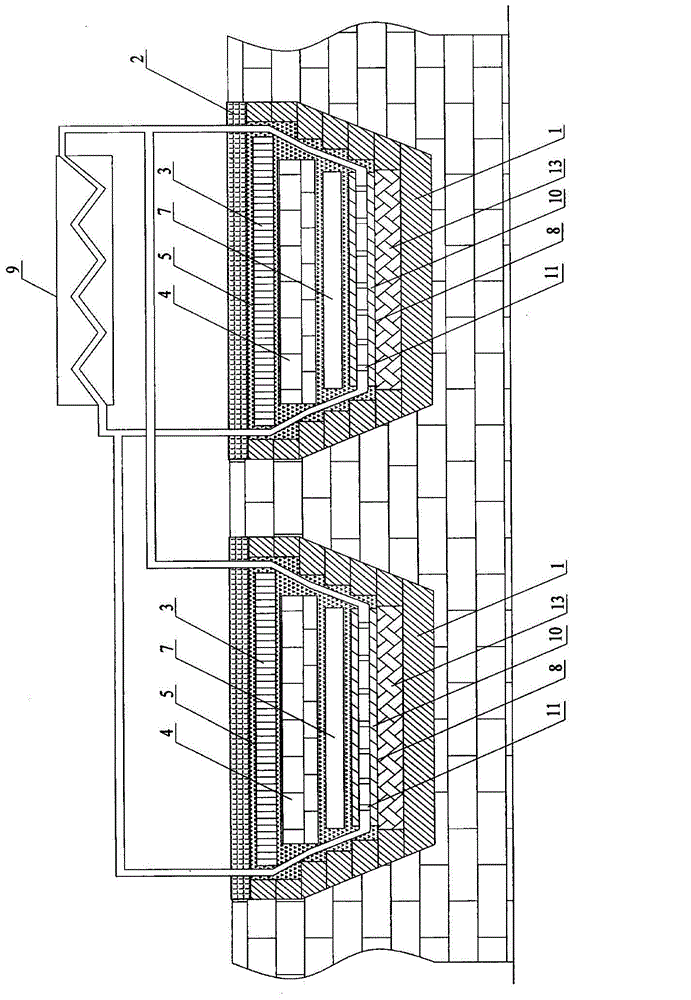

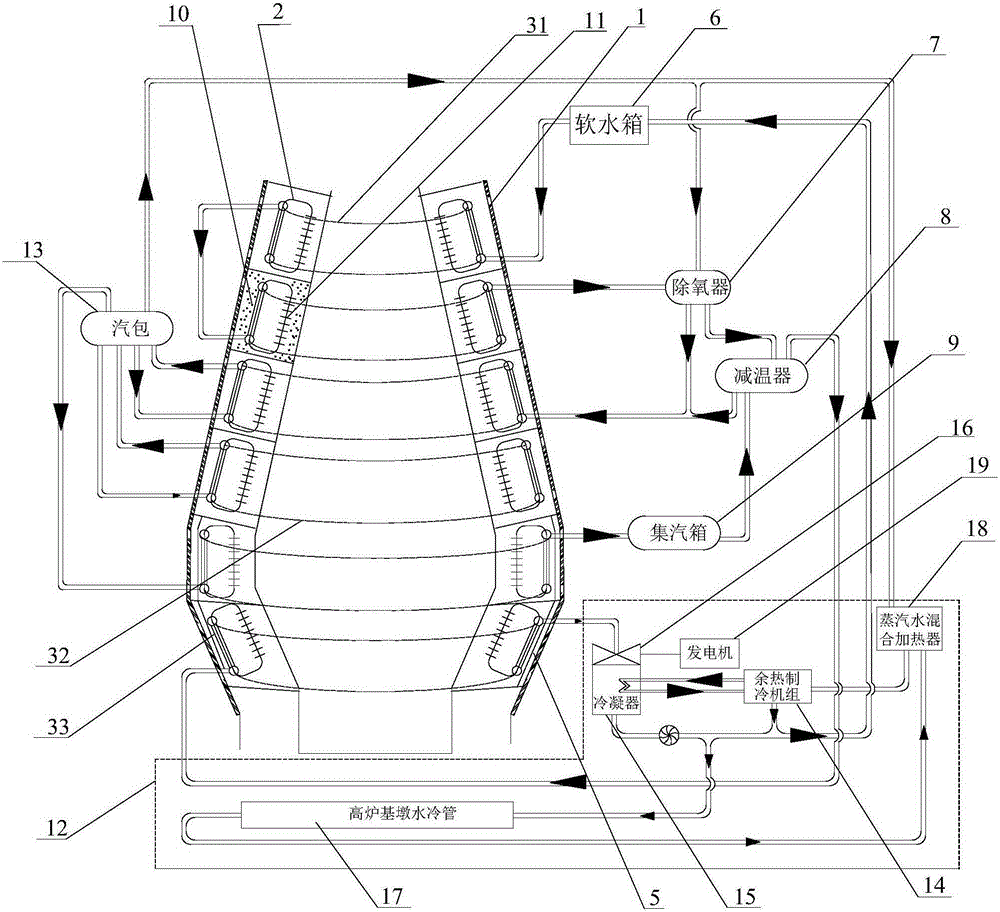

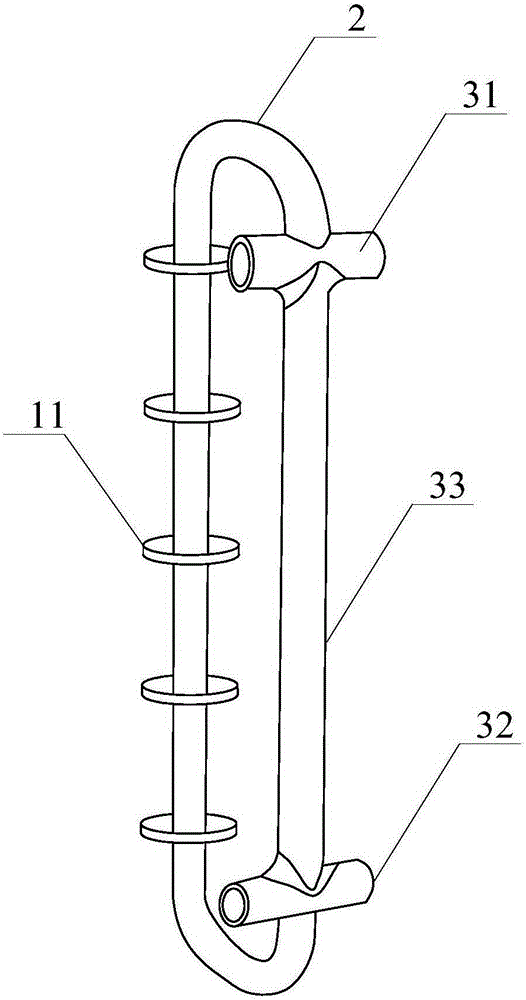

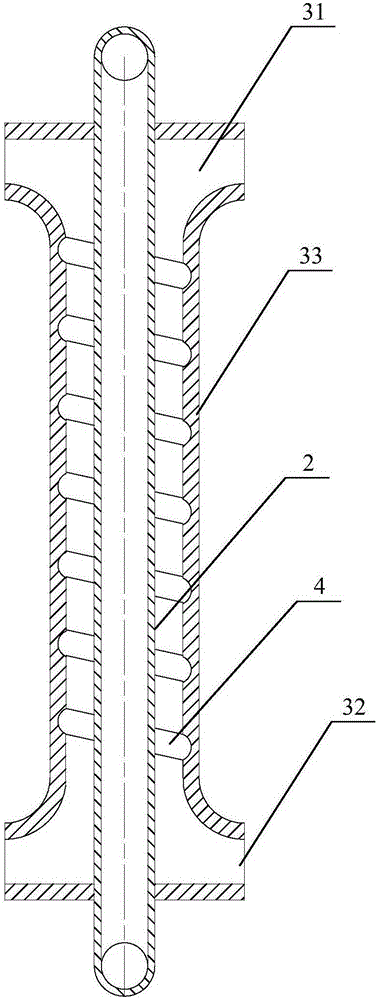

Waste heat power generation system based on blast furnace superconducting cooling

InactiveCN104805245AReasonable designSimple structureCooling devicesSteam engine plantsCooling water temperatureWear resistant

The invention discloses a waste heat power generation system based on blast furnace superconducting cooling. The waste heat generating system mainly comprises a blast furnace body (1), a power generation system (12), a steam utilization device, one or more superconducting ring-shaped heat exchange rings (2) arranged along the side wall of the blast furnace body (1) in a layered encircling manner, poured solidified bodies (10), and lower guide pipes (32), wherein the poured solidified body is arranged on each superconducting ring-shaped heat exchange ring and made from a wear-resistant heatproof anti-seismic carburizing-proof elastic castable refractory; each lower guide pipe is used for being connected with the lower circulation opening of the corresponding superconducting ring-shaped heat exchange ring in series. According to the waste heat power generation system, hot water subjected to heat exchange is centrally discharged through the superconducting ring-shaped heat exchange rings embedded on the side wall of the blast furnace body and a ring-shaped pipeline system corresponding to the superconducting ring-shaped heat exchange rings, so that the heat exchange intensity is enhanced, the heat exchange efficiency and the cooling efficiency are improved, the temperature of traditional cooling water is increased to 250 DEG C from 40 DEG C, and can be increased to 400 DEG C after the traditional cooling water passing the superconducting ring-shaped heat exchange rings twice, so that the cooling waste heat can be utilized to realize power generation.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

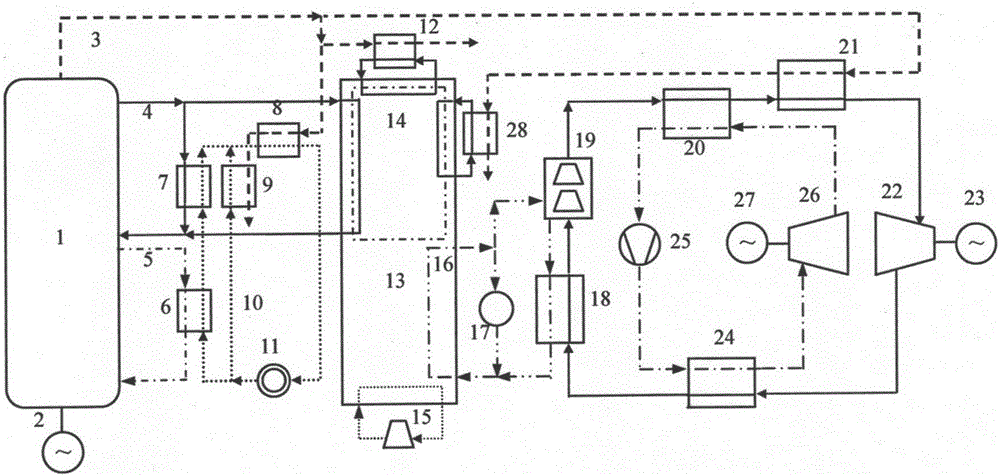

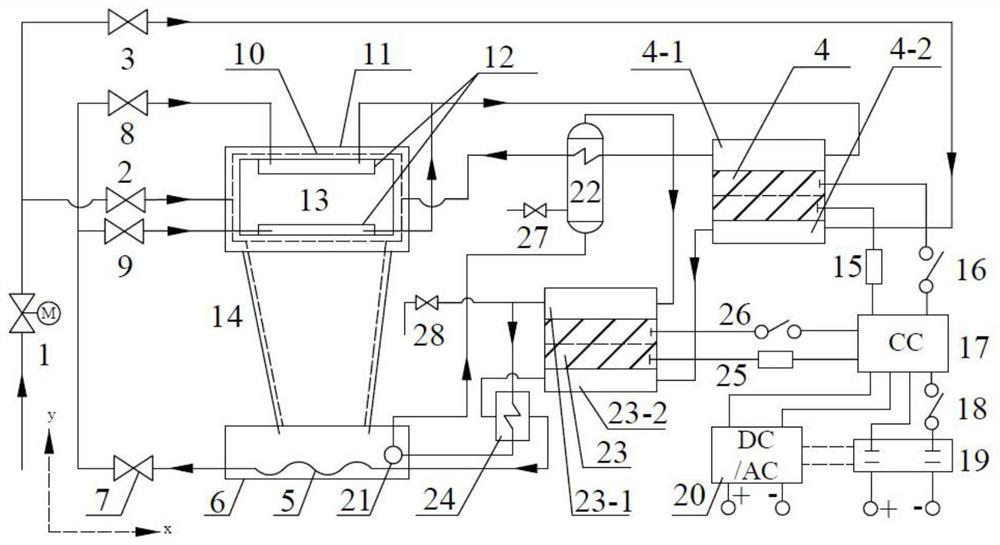

Combined cooling-heating-power system and method

ActiveCN107178436AImprove cycle efficiencyImprove waste heat power generation efficiencyInternal combustion piston enginesClimate change adaptationLithium bromideElectric generator

The invention provides a combined cooling-heating-power system. The combined cooling-heating-power system comprises a gas internal combustion engine, an exhaust gas discharging loop, a cylinder sleeve cooling water loop, a low-temperature cooling water loop, a heat supply loop, a lithium-bromide absorption-type refrigerating machine, a supercritical carbon dioxide cycle subsystem, and an organic working medium cycle subsystem. The invention further provides a combined cooling-heating-power method. The method comprises the steps that the gas internal combustion engine works and drives an electric generator to generate electricity, released waste heat is recycled and utilized through the exhaust gas discharging loop, the cylinder sleeve cooling water loop and the low-temperature cooling water loop, waste heat of the gas internal combustion engine is distributed, the effect that cold energy, heat energy and electric energy of different proportions are output to the heat supply loop, the supercritical carbon dioxide cycle subsystem and the organic working medium cycle subsystem is achieved, and combined cooling, heating and power supply is achieved. According to the combined cooling-heating-power system and method, the combined supercritical carbon dioxide and organic working medium cycle efficiency is high, and the waste heat electricity generation efficiency and output power of the gas internal combustion engine are remarkably improved. The combined cooling-heating-power system is simple, compact in structure, low in cost and capable of being applied to distributed energy resources.

Owner:SHANGHAI POWER EQUIP RES INST

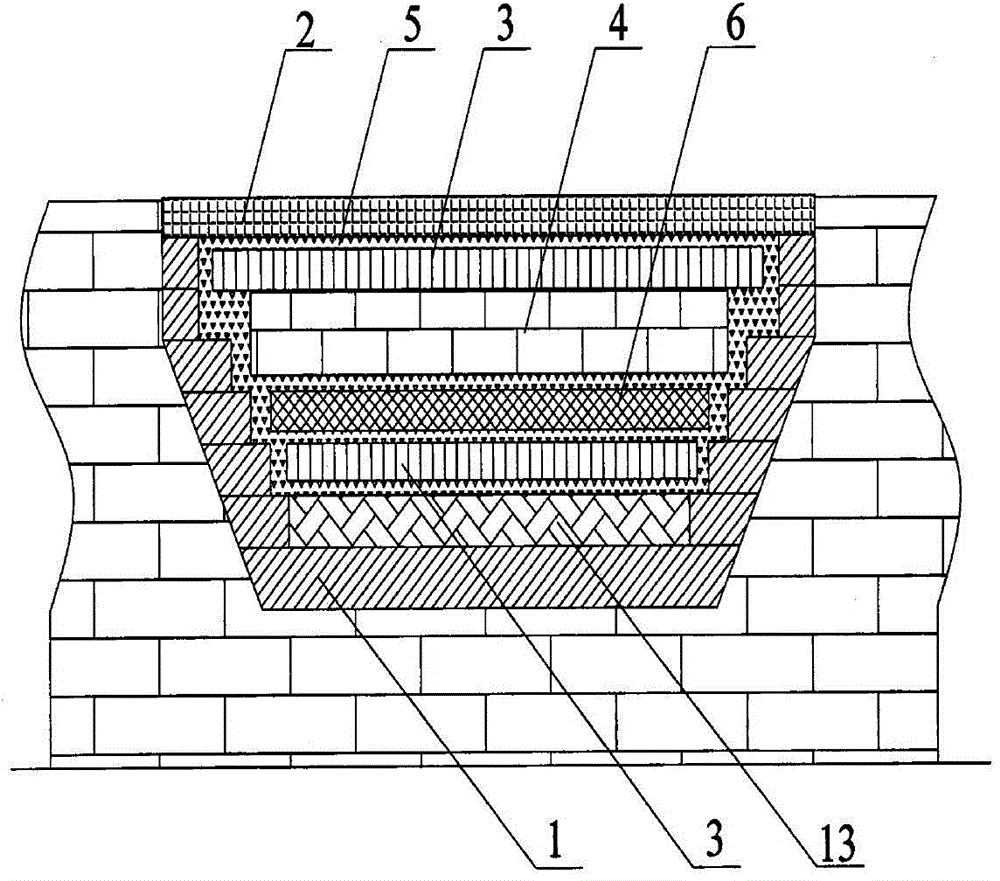

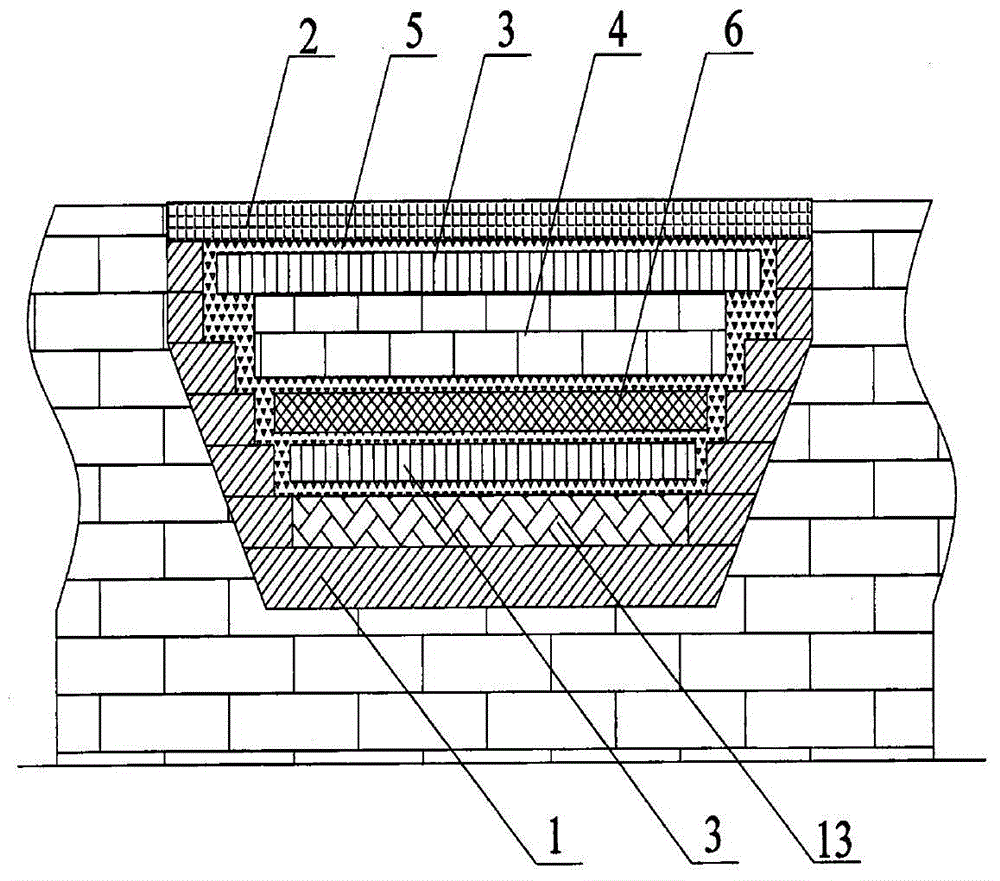

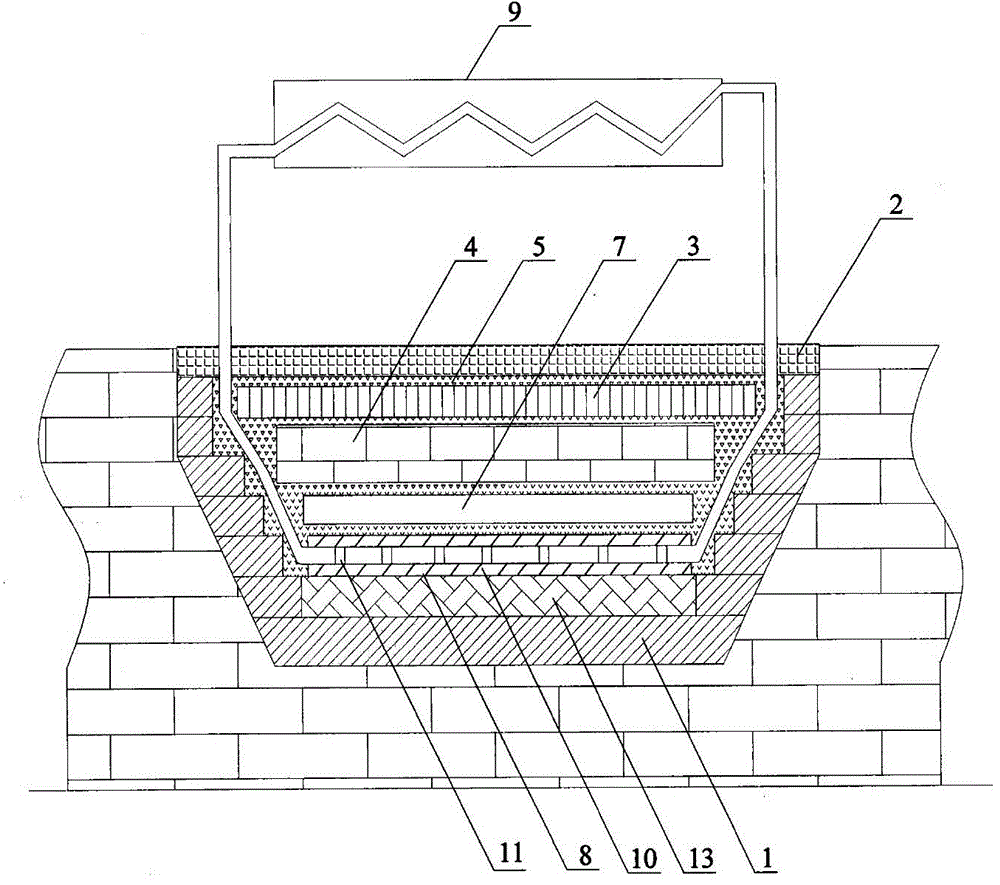

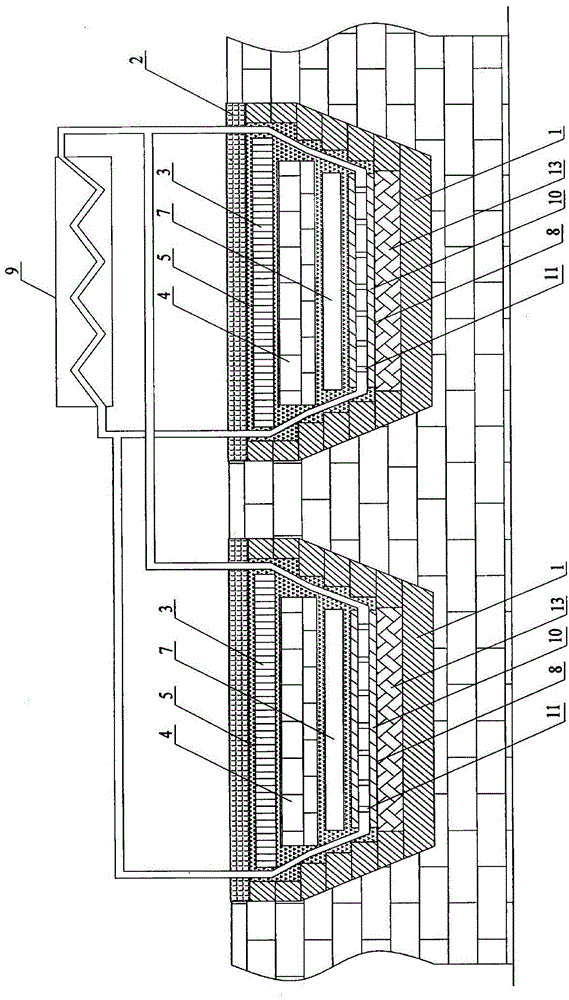

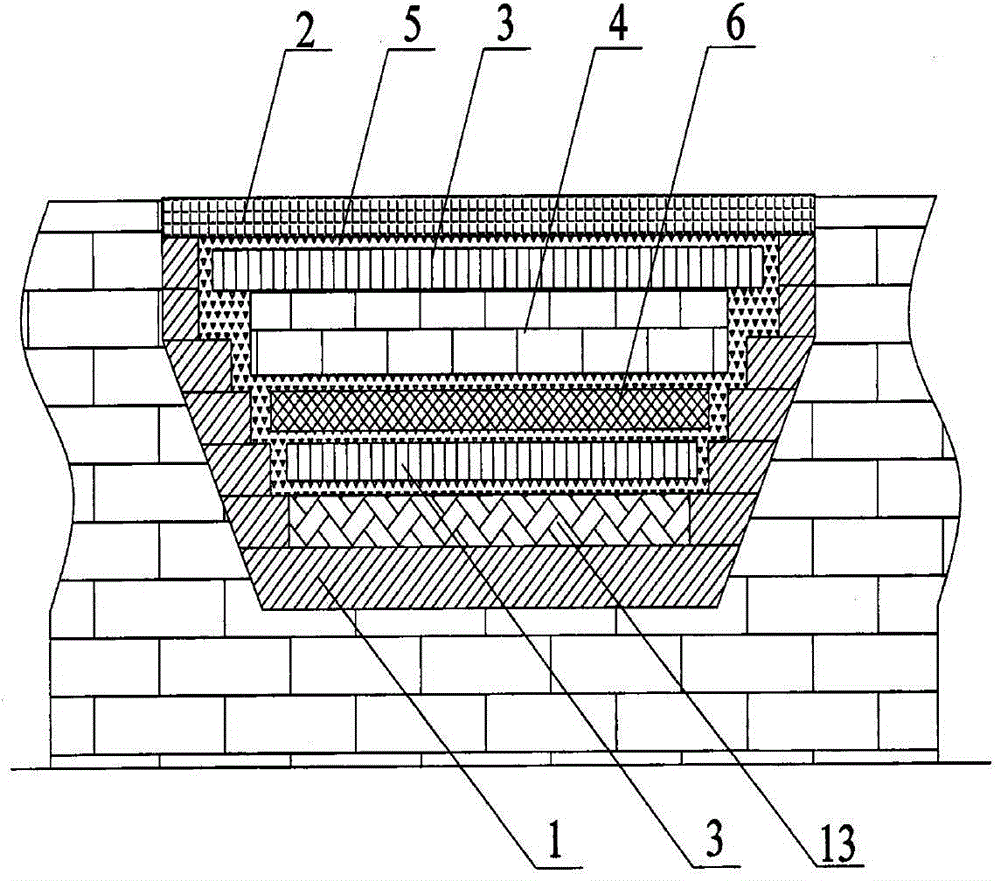

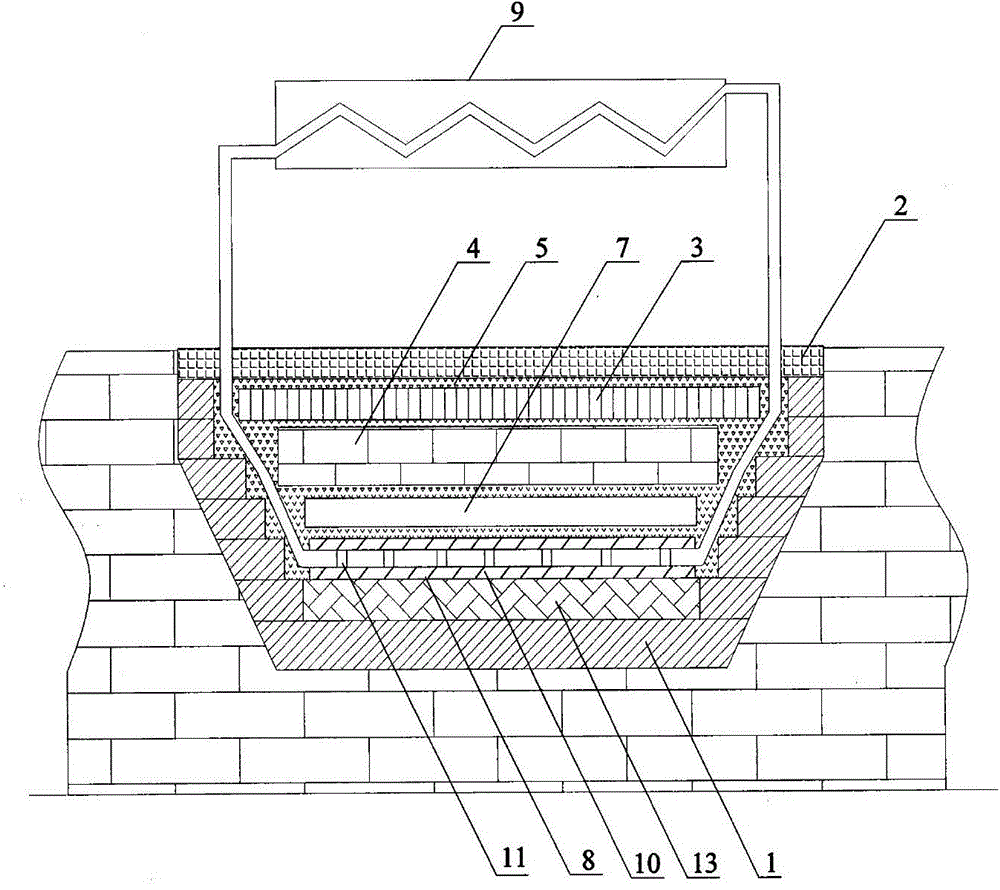

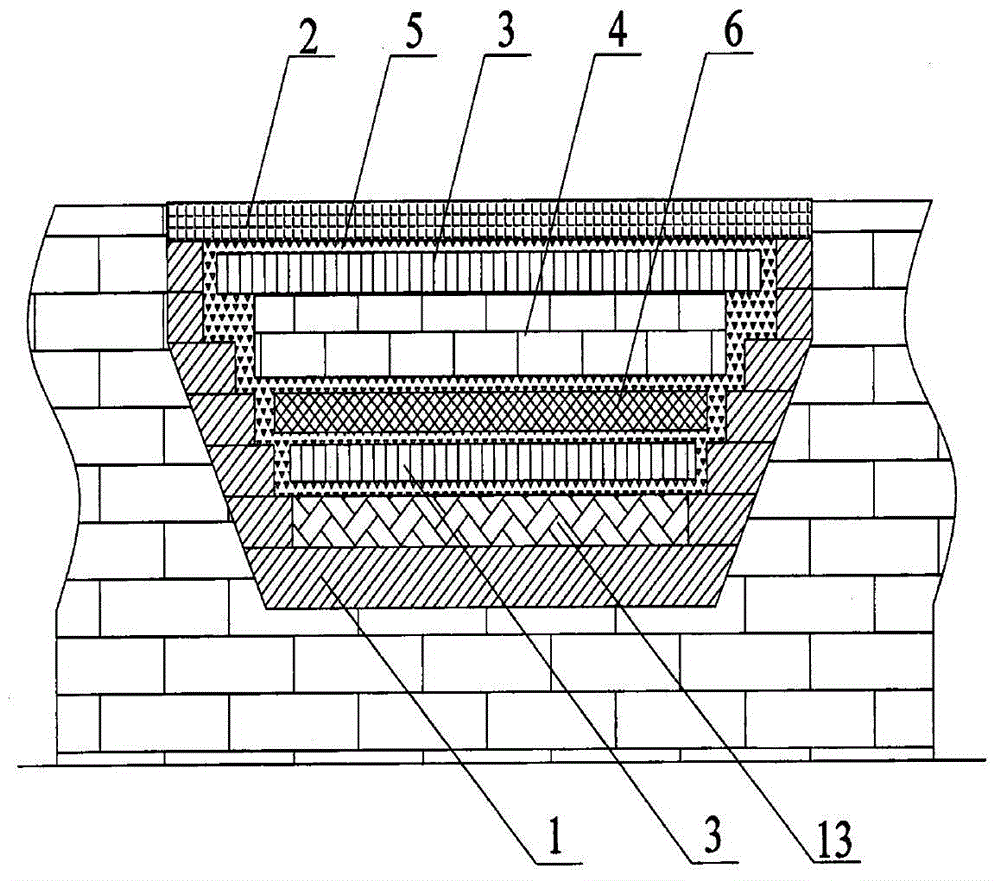

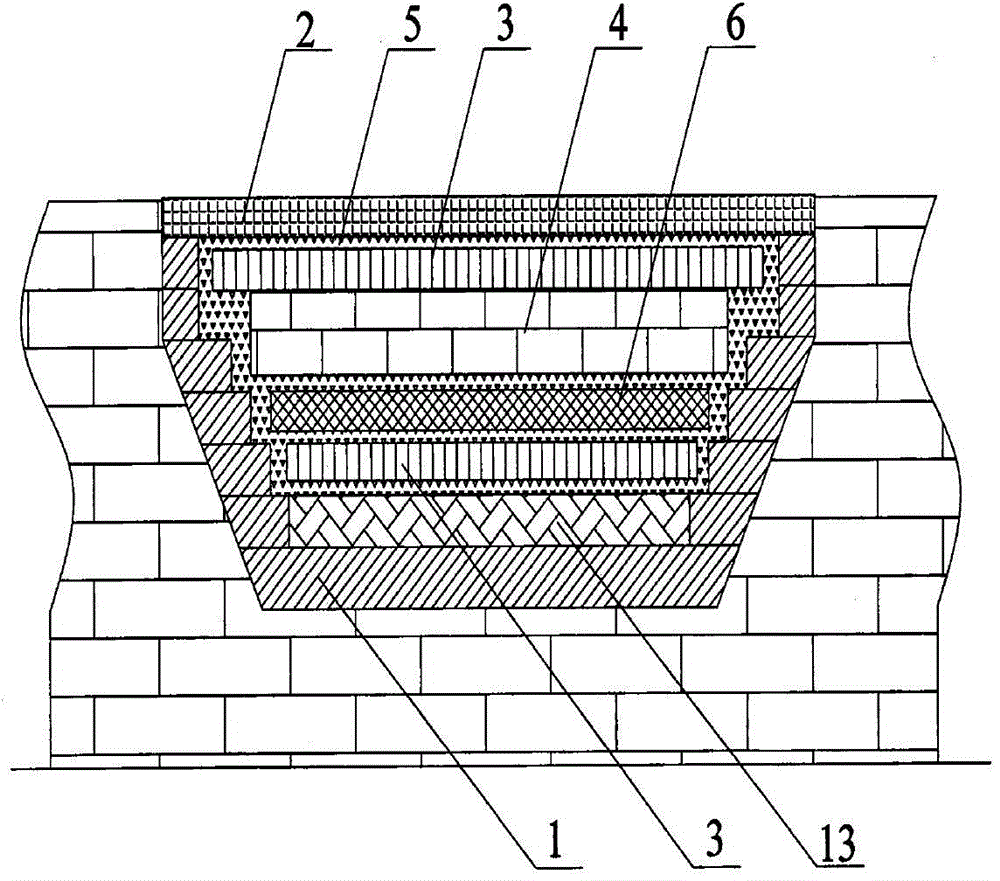

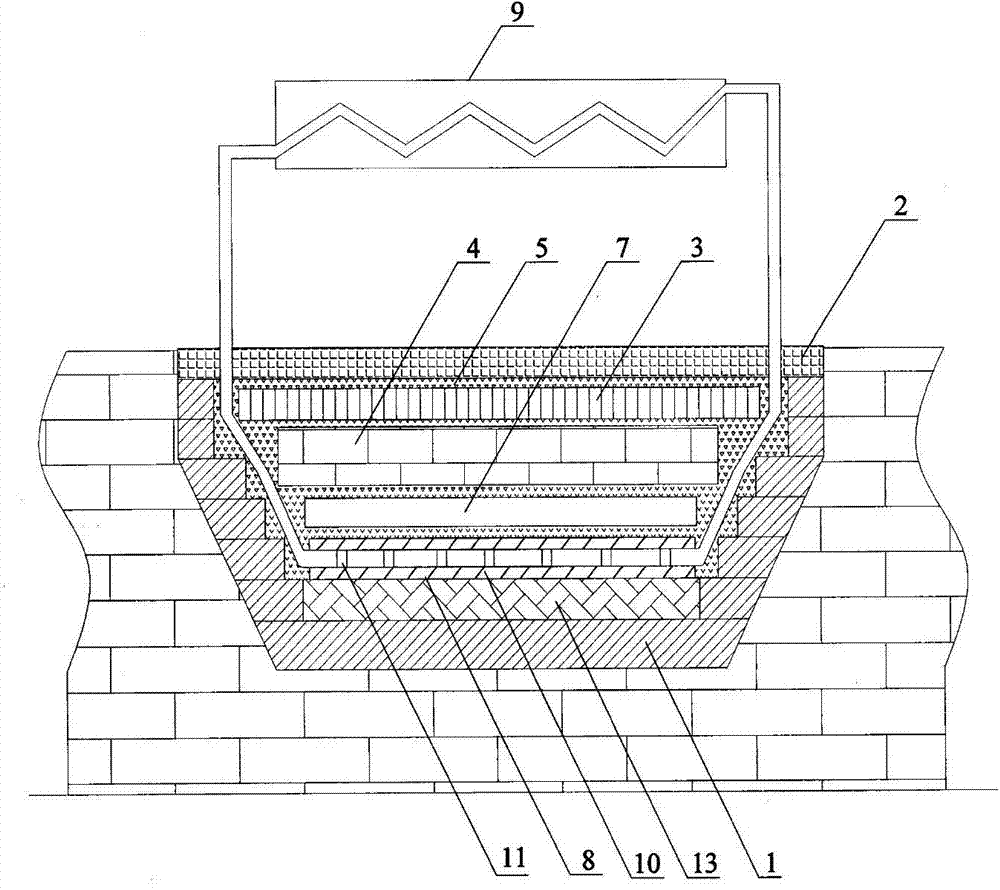

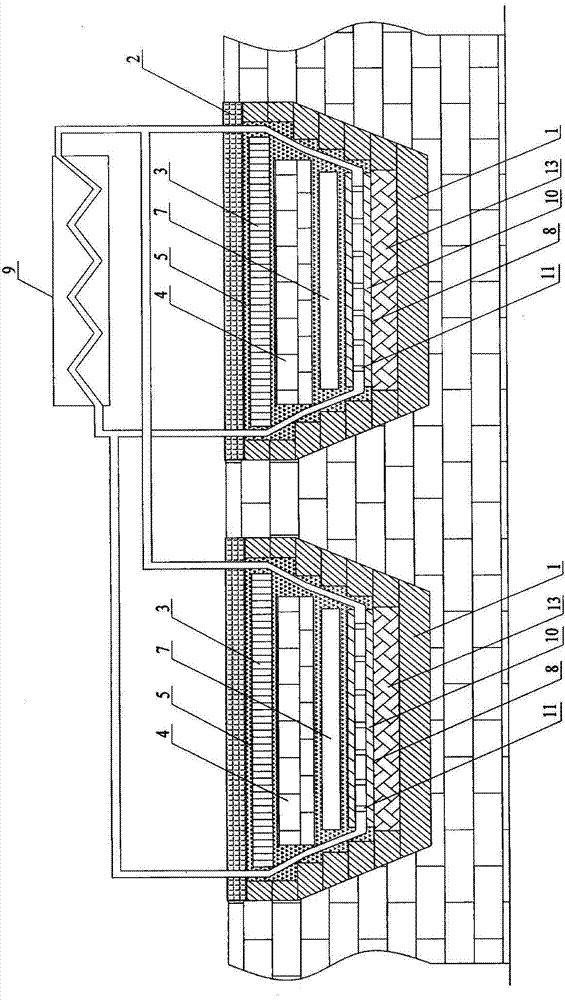

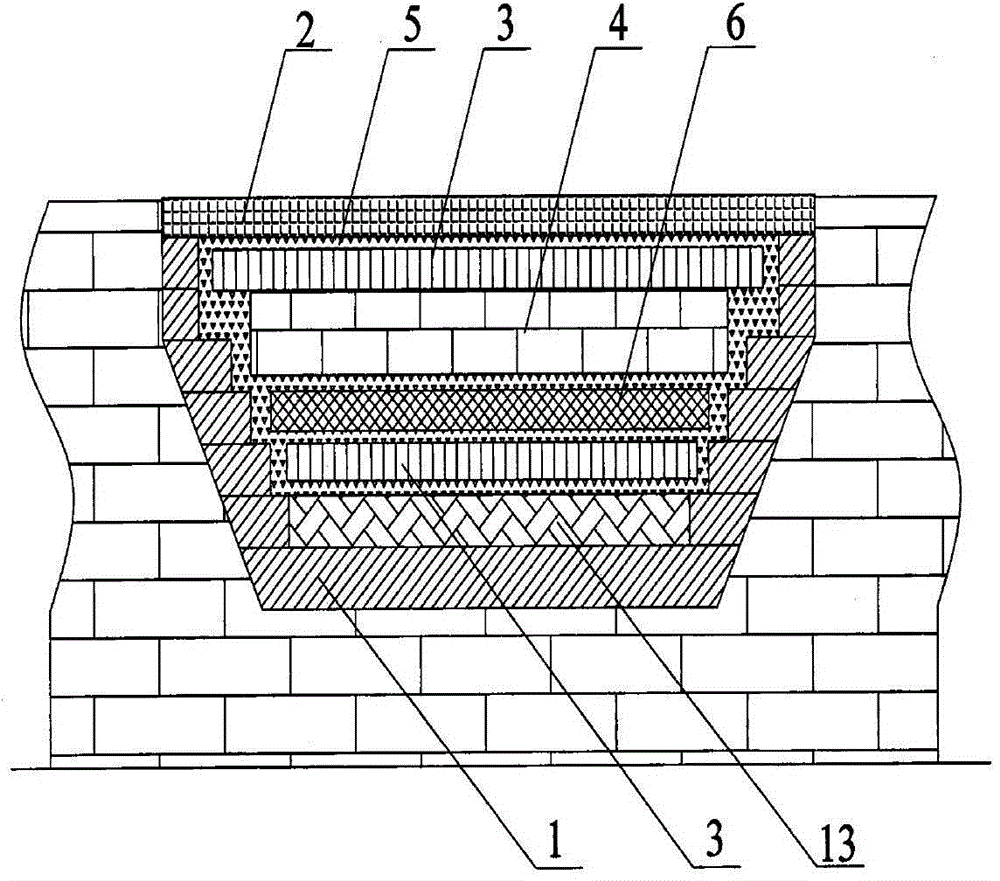

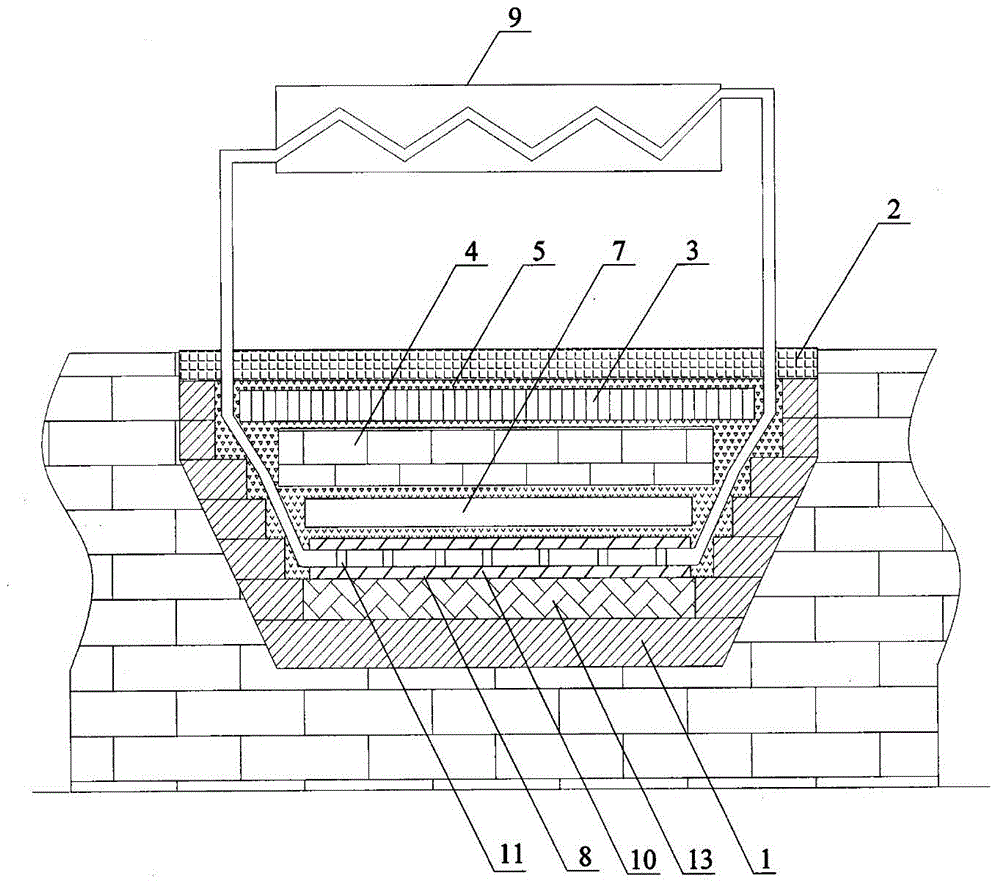

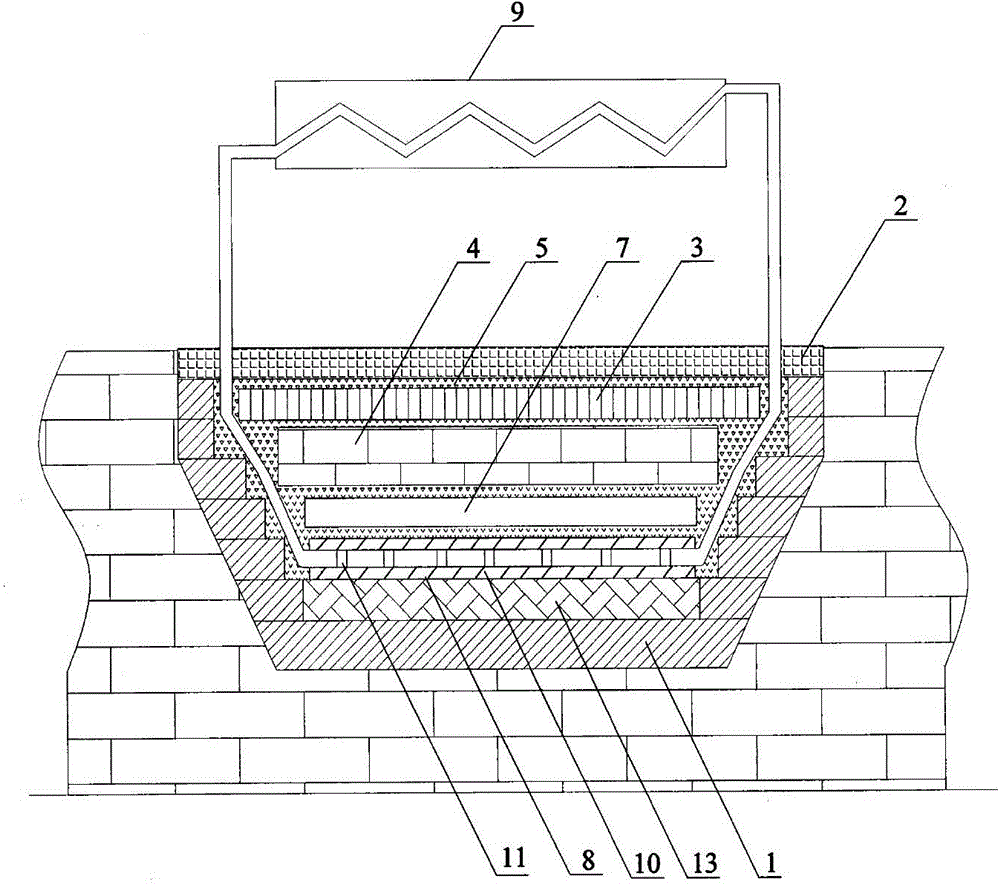

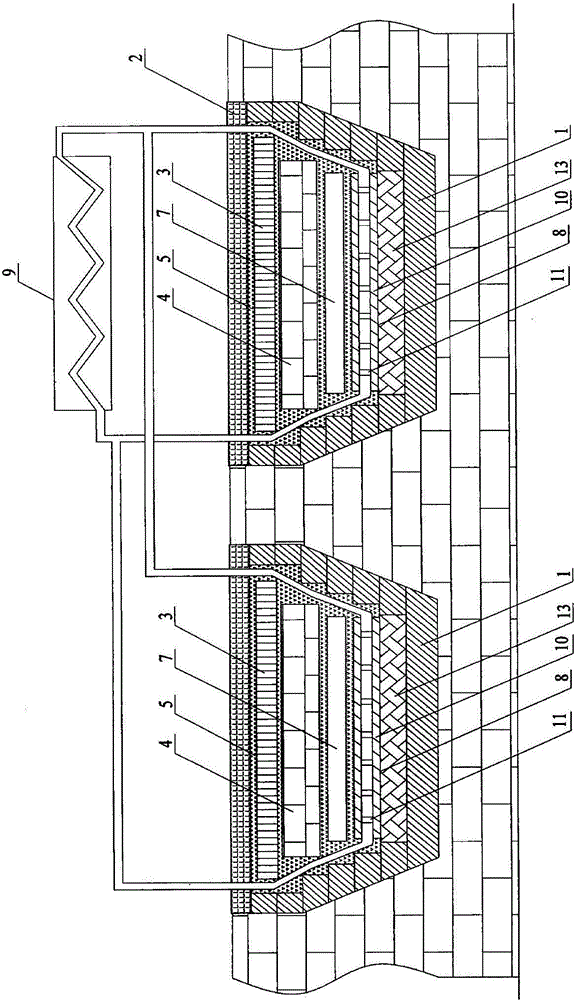

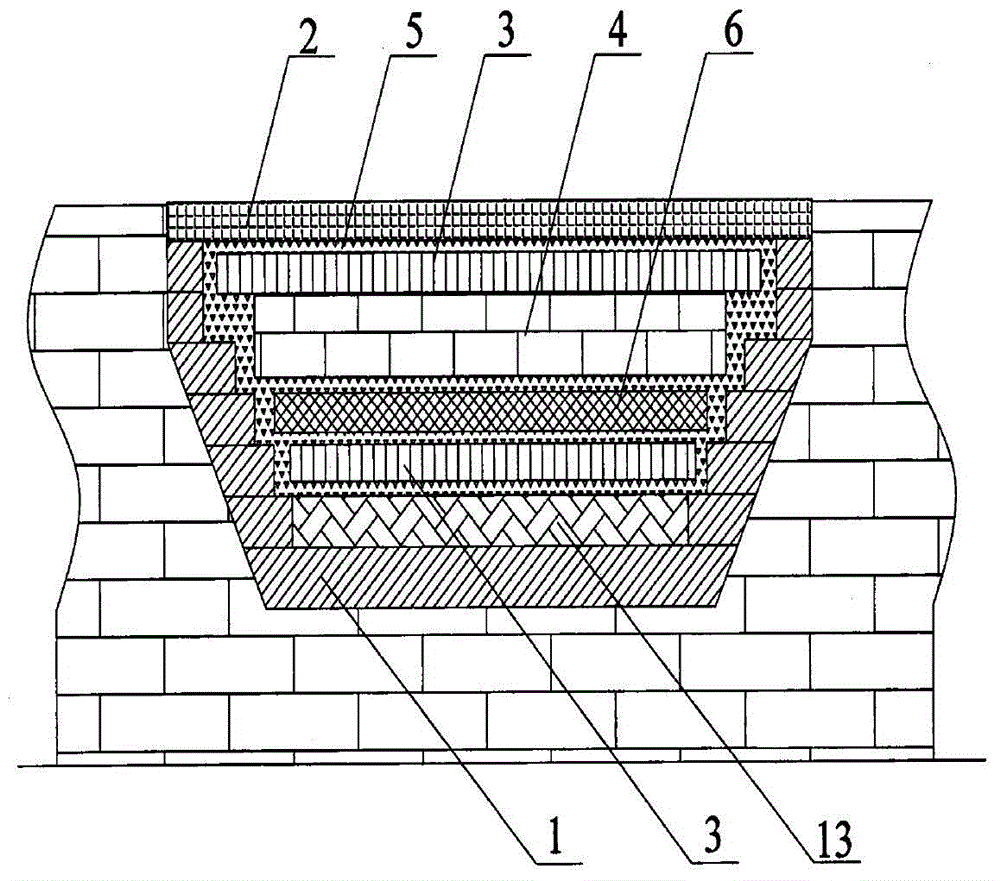

Eliminating type coke oven afterheat recovery power generating system based on voltage stabilizing power supply circuit

InactiveCN104810975AReduce dosageReasonable designAc-dc conversionIncreasing energy efficiencyBrickSlurry

The invention discloses an eliminating type coke oven afterheat recovery power generating system based on a voltage stabilizing power supply circuit. The eliminating type coke oven afterheat recovery power generating system mainly consists of a coke oven top big pit and an oven top cylinder brick covering the top surface of the coke oven top big pit, wherein a perforated steel plate, a heat insulation plate layer and a perforated steel plate are sequentially arranged inside the coke oven top big pit from bottom to top, a heat insulation brick layer arranged between the perforated steel plate and the heat insulation plate layer is formed by filling heat-resistant sealing slurry in an inside gap part of the coke oven top big pit, a heat exchanger and an evaporator forming a sealed loop are arranged outside the coke oven top big pit, an afterheat power generating system is also arranged on the evaporator, an afterheat control circuit is arranged in the afterheat power generating system, a static electricity eliminating circuit, an overcurrent protection circuit, a control type power supply circuit, a voltage stabilizing power supply circuit and a control type output circuit are arranged in the afterheat control circuit, and the overcurrent protection circuit, the control type power supply circuit, the voltage stabilizing power supply circuit and the control type output circuit are in sequential connection.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

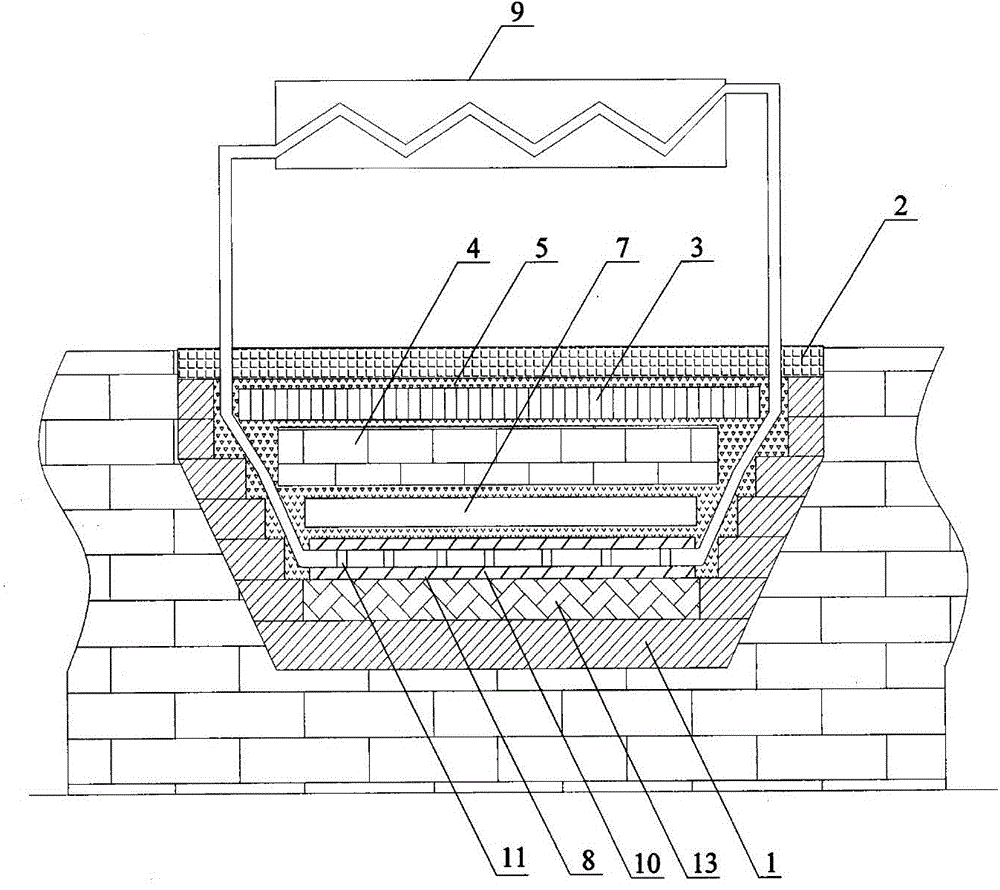

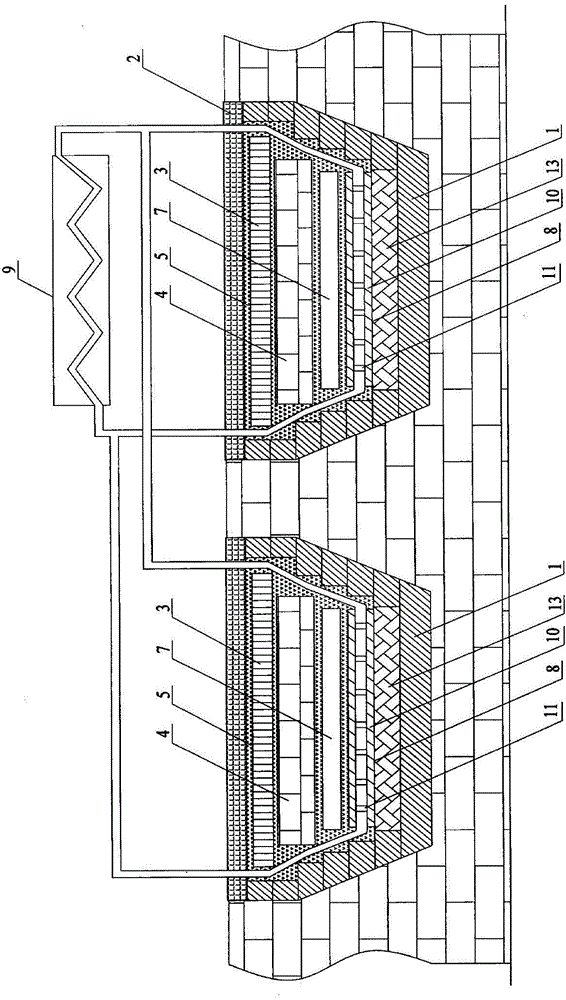

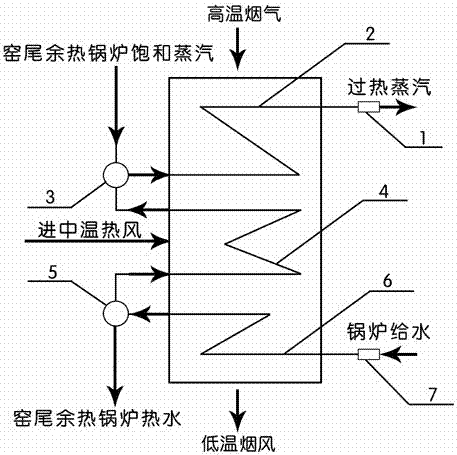

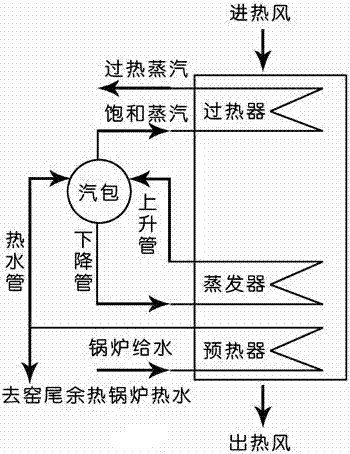

Cement kiln head high-temperature high-pressure waste heat boiler

InactiveCN107091469AImprove waste heat power generation efficiencyEnergy industryIncreasing energy efficiencyThermal energyEnergy gradient

The invention provides a cement kiln head high-temperature high-pressure waste heat boiler composed of a superheated steam device, a superheater, a saturated steam device, an evaporator, a hot water device, a preheater and a boiler water feeding device. Cement kiln head high-temperature smoke enters the waste heat boiler in the vertical direction or the horizontal direction, intermediate-temperature hot air enters the waste heat boiler from the side or in the up-and-down direction, and after the cement kiln head high-temperature smoke and the intermediate-temperature hot air conduct heat exchange with the superheater, the evaporator and the preheater, low-temperature smoke and air are discharged. As to water feeding to the boiler, the boiler water feeding device feeds water into the preheater, so that hot water is generated, the hot water is fed into the evaporator through the hot water device, so that saturated steam is generated, the saturated steam is fed into the superheater through the saturated steam device, and then superheated steam is generated and discharged by the superheated steam device. The cement kiln head high-temperature high-pressure waste heat boiler has the beneficial effects that traditional cement kiln head low-temperature low-pressure waste heat boiler is converted and upgraded into the cement kiln head high-temperature high-pressure waste heat boiler, the cement kiln head high-temperature high-pressure waste heat boiler and a cement kiln tail high-pressure waste heat boiler form energy gradient utilization and a heat energy coupling technology for energy conservation and emission reduction of cement, and the purpose of greatly improving the waste heat power generation efficiency of the cement is achieved.

Owner:北京鑫泽清源植物秸秆技术有限公司

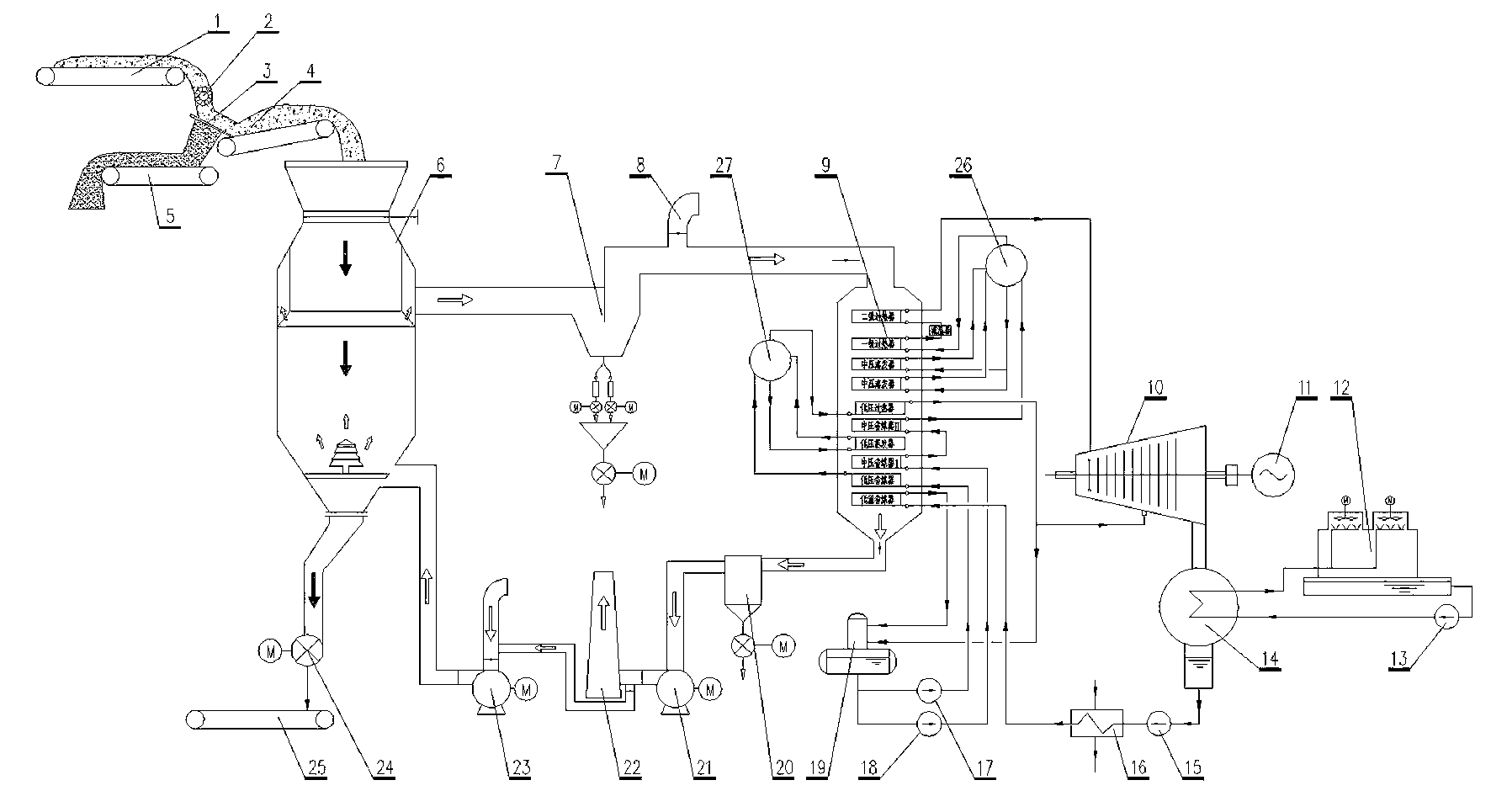

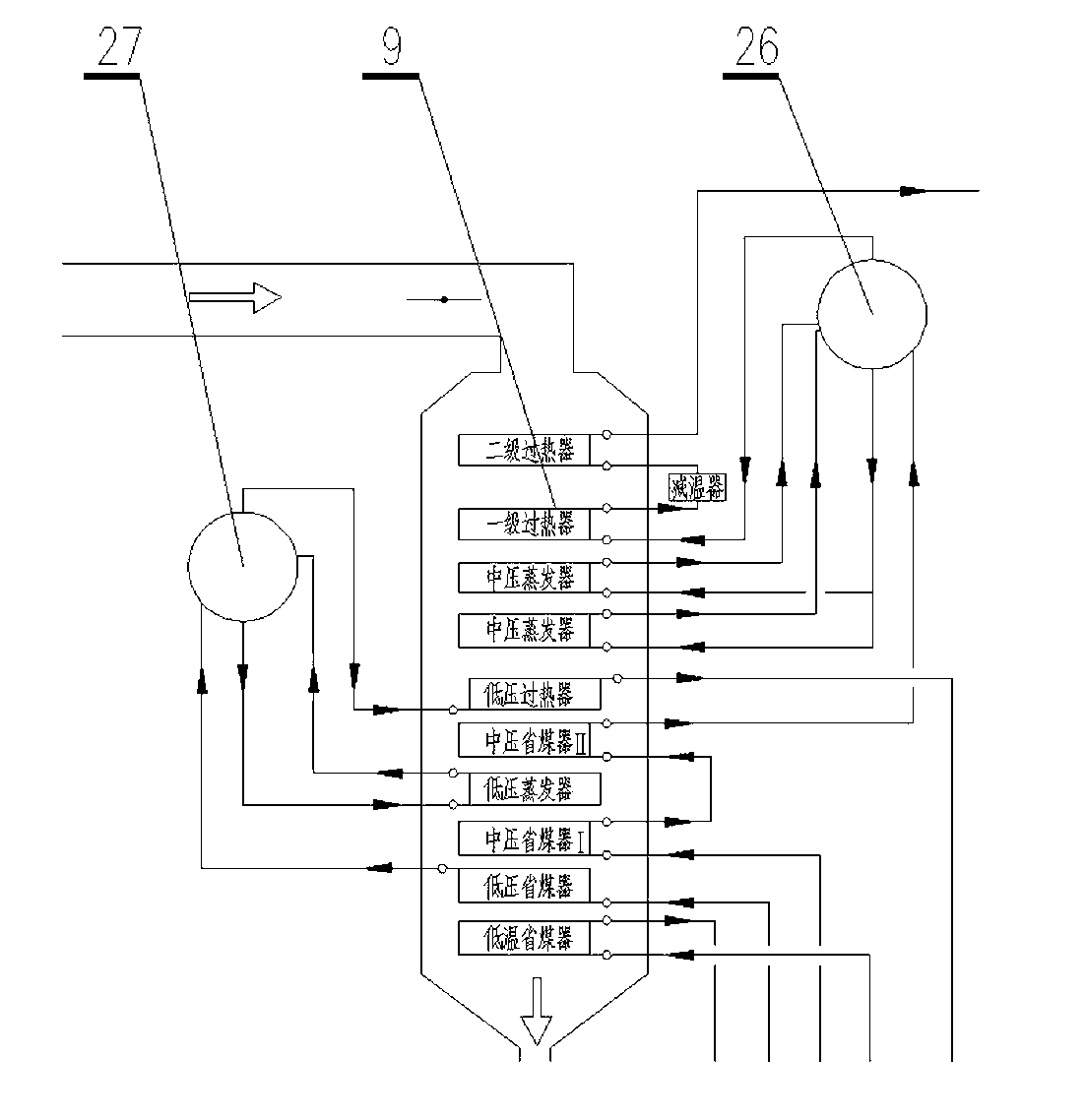

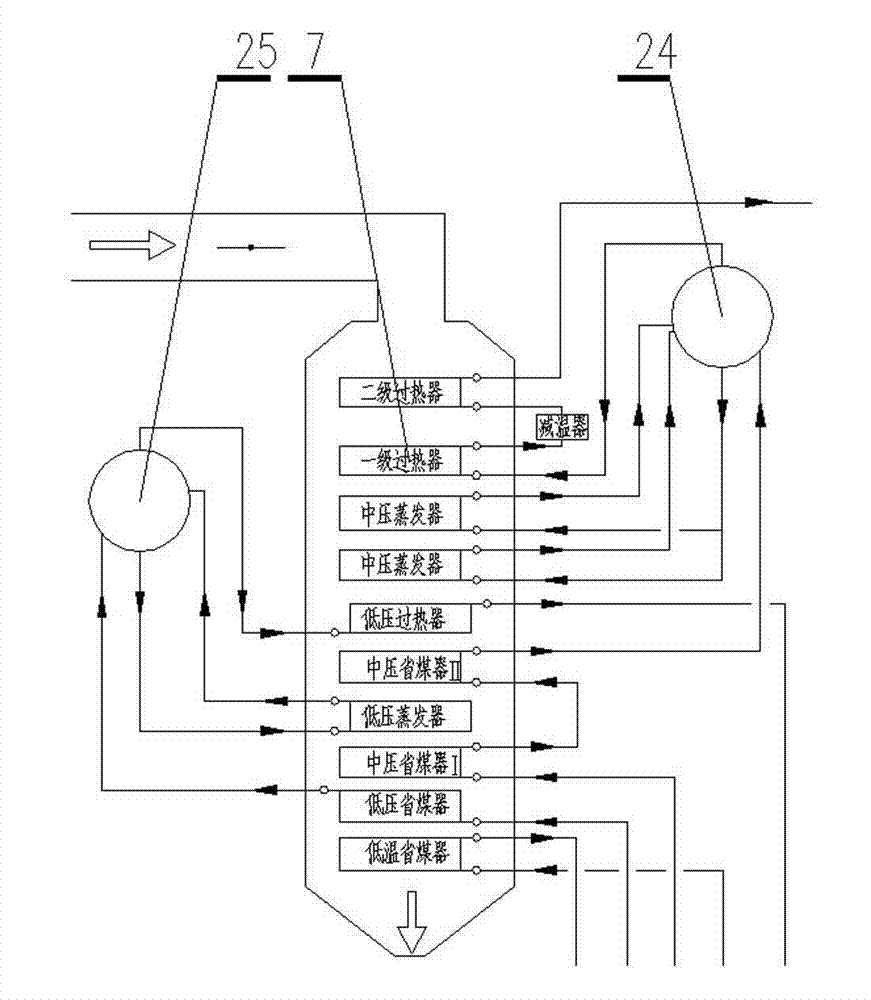

Afterheat double-voltage recovery and generation system of dry cement production line

InactiveCN101949651BIncrease enthalpyImprove qualityIncreasing energy efficiencyClinker productionProduction lineComing out

The invention discloses an afterheat double-voltage recovery and generation system of a dry cement production line, having the characteristic of improving the afterheat generation efficiency. The afterheat double-voltage recovery and generation system of a dry cement production line is provided with a high-temperature kiln head afterheat boiler, and a kiln head grate cooler is provided with a high-temperature gas taking port and a medium-temperature gas taking port. Through the device, high-temperature waste gas is led to the high-temperature kiln head afterheat boiler by combining the temperature distribution characteristics in the kiln head grate cooler; medium-temperature smoke is led to a medium-temperature kiln head afterheat boiler, and steam coming out of the medium-temperature kiln head afterheat boiler and a kiln tail afterheat boiler is subjected to secondary heat exchange through the high-temperature kiln head afterheat boiler; the temperature of the steam after secondary heat exchange is improved to about 350-410 DEG C, and then the steam is sent into a steam turbine generator. The invention improves the steam enthalpy value, the effective enthalpy drop and the steam quality, reduces the flow and the steam exhaust loss of afterheat in a turbine condenser, promotes the improvement of the afterheat generation efficiency and is suitable for being popularized and applied in systems utilizing afterheat generation.

Owner:CHENGDU HOT NEW ENERGY TECH

Coke oven roof waste heat recovery power generation system based on power supply adjusting circuit

InactiveCN104910925AReduce dosageReasonable designEnergy inputCoke oven detailsBrickThermal insulation

The invention discloses a coke oven roof waste heat recovery power generation system based on a power supply adjusting circuit. The system is composed of a coke oven roof pit and roof quarry tiles covering the surface of the roof. A hole steel plate, a thermal insulation plate layer and a hole steel plate are arranged inside the coke oven roof pit from bottom to top in order. an insulation tile layer arranged between the hole steel plate and the thermal insulation plate layer is poured with heatproof sealing slurry at the internal seam of the coke oven roof pit. A heat exchanger and an evaporator forming an enclosed loop are arranged outside the coke oven roof pit. A waste heat power generation system is arranged on the evaporator. A waste heat control circuit is arranged in the waste heat power generation system. A control-type power supply circuit, a power supply adjusting circuit and a control-type output circuit are arranged in the waste heat control circuit and the control-type power supply circuit, the power supply adjusting circuit and the control-type output circuit are connected in order.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Current source feedback type waste heat generating system based on blast furnace superconducting cooling

InactiveCN104946834AReduce dosageReasonable designBlast furnace detailsIncreasing energy efficiencyControl treatmentEngineering

The invention discloses a current source feedback type waste heat generating system based on blast furnace superconducting cooling. The current source feedback type waste heat generating system based on the blast furnace superconducting cooling mainly comprises a blast furnace body (1), an electrical power generating system (12), a steam utilizing device, more than one superconducting annular heat exchange ring (2) which is hierarchically arranged along the side wall of the blast furnace body (1) in a surrounding manner and a waste heat control treatment system. The current source feedback type waste heat generating system based on the blast furnace superconducting cooling has the advantages that hot water after heat exchange is discharged in a concentrated manner by virtue of the superconducting annular heat exchange rings which are embedded in the side wall of the blast body and a corresponding annular pipeline system, so that heat exchange intensity is improved, heat exchange efficiency and cooling efficiency are improved; and temperature of the traditional cooling water is increased to 250 DEG C from 40 DEG C, and then the traditional cooling water is overheated to 400 DEG C by applying the superconducting heat exchange rings twice, so that cooling waste used for power generation is realized.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Blast furnace superconductive cooling waste heat power generation system based on bias adjustable current source

InactiveCN104846139AReduce dosageReasonable designCooling devicesIncreasing energy efficiencyEngineeringHeat transfer efficiency

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Thermal protection type coke oven waste heat recovery power generation system based on power source voltage adjustment circuit

InactiveCN104833222AReduce dosageReasonable designIncreasing energy efficiencyMachines/enginesBrickThermal insulation

The invention discloses a thermal protection type coke oven waste heat power generation system based on a power source voltage adjustment circuit. The system is mainly composed of coke oven top large pits and oven top clinker bricks covering the surfaces of the tops of the coke oven top large pits, a pored steel plate, a thermal insulation board layer and a pored steel plate are arranged inside each coke oven top large pit in sequence from bottom to top, a thermal insulation brick layer is arranged between each pored steel plate and the corresponding thermal insulation board layer, gaps, inside the corresponding coke oven top large pit, of each thermal insulation brick layer are filled with heatproof sealing slurry in a poured mode, heat exchangers and an evaporator forming a closed loop are arranged outside the coke oven top large pits, a waste heat power generation system body is further arranged on the evaporator, a waste heat control circuit is arranged in the waste heat power generation system body, and a thermal inductance automatic switching circuit and a control type power source circuit, the power source voltage adjustment circuit and a control type output circuit which are connected in sequence are arranged in the waste heat control circuit.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Protection type coke oven waste heat recovery power generation system based on boost power supply circuit

InactiveCN104833221AReduce dosageReasonable designDc-dc conversionIncreasing energy efficiencyBrickClosed loop

The invention discloses a protection type coke oven waste heat recovery power generation system based on a boost power supply circuit. The system is mainly composed of a coke oven top large pit and oven top quarry tiles covering the surface of the top of the coke oven top large pit. A porose steel plate, a heat insulation plate layer and a porose steel plate are sequentially arranged in the coke oven top large pit from bottom to top. Heat preservation brick layers between the porose steel plates and the heat insulation plate layer are formed by filling the inner gaps inside the coke oven top large pit with heat-resisting sealing slurry. A heat exchanger and an evaporator which form a closed loop are arranged outside the coke oven top large pit. A waste heat power generation system is arranged on the evaporator. A waste heat control circuit is arranged in the waste heat power generation system. An over-current protection circuit, a control type power supply circuit, the boost power supply circuit and a control type output circuit are connected in sequence and arranged in the waste heat control circuit.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Coke oven top waste heat recycling and electricity generation system based on efficient drive power source circuit

InactiveCN104913646AReduce dosageReasonable designDc-dc conversionIncreasing energy efficiencyBrickSlurry

The invention discloses a coke oven top waste heat recycling and electricity generation system based on an efficient drive power source circuit. The coke oven top waste heat recycling and electricity generation system is mainly composed of a large coke oven top pit and oven top quarry tiles covering the surface of the top of the pit. The large coke oven top pit is internally and sequentially provided with a porous steel plate, a heat insulation plate layer and the porous steel plate from bottom to top. A heat preservation tile layer arranged between the porous steel plates and the heat insulation plate layer is formed by pouring heat-resisting sealing slurry into seams of the large coke oven top pit. A heat exchanger and an evaporator for forming a sealing loop are arranged outside the large coke oven top pit. The evaporator is further provided with a waste heat electricity generation system. The waste heat electricity generation system is internally provided with a waste heat control circuit. The waste heat control circuit is internally provided with a control type power circuit, the efficient drive power source circuit, and a control type output circuit which are sequentially connected.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Alarm type coke oven waste heat recovery power generation system based on power supply adjustment circuit

InactiveCN104836374AReduce dosageReasonable designDc-dc conversionIncreasing energy efficiencyBrickClosed loop

The invention discloses an alarm type coke oven waste heat recovery power generation system based on a power supply adjustment circuit. The system is mainly formed by a coke oven top large pit and oven top clinker tiles which cover the top surface of the coke oven top large pit. The internal part of the coke oven top large pit is orderly provided with a perforated steel plate, a heat insulation plate layer and a perforated steel plate from bottom to top. A heat preservation tile layer arranged between the perforated steel plate and the heat insulation plate layer, and the internal gap of the coke oven top large pit is filled with heat resistant sealing slurry. The external part of the coke oven top large pit is provided with a heat exchanger and an evaporator to form a closed loop. The evaporator is provided with a waste heat power generation system which is internally provided with a waste heat control circuit. The waste heat control circuit is internally provided with a power-off alarm circuit and is also provided with an overcurrent protection circuit, a control type power supply circuit, a power supply adjustment circuit and a control type output circuit which are connected in order.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Thermoelectric power generation system of boiler slag bucket heat source

ActiveCN112532111AImprove waste heat power generation efficiencyGood energy saving and emission reduction effectGenerators/motorsBoiler slagProcess engineering

The invention belongs to the technical field of semiconductor thermoelectric power generation using a low-grade heat source, and particularly relates to a thermoelectric power generation system of a boiler slag bucket heat source. The system is formed by combining a steam-water type semiconductor thermoelectric generator and an organic working medium type semiconductor thermoelectric generator, alow-temperature side cold source is provided for cooling water supply of a slag hopper shared by steps, a two-stage heat storage mode is adopted, and a slag hopper coke slag heat source is used for thermoelectric power generation; wherein the high-temperature side heat source of the steam-water type semiconductor thermoelectric generator is 95-160 DEG C, the high-temperature side heat source of the organic working medium type semiconductor thermoelectric generator is 85-150 DEG C, the low-temperature sides of the steam-water type semiconductor thermoelectric generator and the organic working medium type semiconductor thermoelectric generator are cooled by adopting a slag hopper cooling water source, and the temperature range is 1-30 DEG C; the critical temperature range of an organic working medium selected by the organic working medium type semiconductor thermoelectric generator is 35-140 DEG C. The coke residue waste heat power generation efficiency is improved, the cooling water amount is saved, and the remarkable energy conservation and emission reduction effects are achieved.

Owner:SHANXI UNIV

Voltage stabilizing power supply circuit based elimination type coke oven waste heat power generation system

InactiveCN104819649AReduce dosageReasonable designIncreasing energy efficiencyMachines/enginesBrickCoke oven

The invention discloses a voltage stabilizing power supply circuit based elimination type coke oven waste heat power generation system. The voltage stabilizing power supply circuit based elimination type coke oven waste heat power generation system is mainly formed by a large hole and an oven top clinker brick, wherein the large hole is formed at the oven top of a coke oven and the oven top clinker brick covers the surface of the top of the large hole; a porose steel plate, a heat insulation plate layer and a porose steel plate are arranged inside the large hole from bottom to top in turn; an internal gap formed between the large hole and a heat insulation brick layer which is arranged between each porose steel plate and the heat insulation plate layer is filled with heatproof sealing paste; a heat exchanger and an evaporator which form a closed circuit are arranged outside the large hole; the evaporator is provided with a waste heat power generation system; a waste heat control circuit is arranged in the waste heat power generation system; a static elimination circuit, a control type power supply circuit, a voltage stabilizing power supply circuit and a control type output circuit are arranged in the waste heat control circuit, wherein the control type power supply circuit, the voltage stabilizing power supply circuit and the control type output circuit are connected in turn.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Wet protection type coke oven after heat power generating system based on stabilization power supply circuit

InactiveCN104880081AReduce dosageReasonable designIncreasing energy efficiencySteam engine plantsBrickEngineering

The invention discloses a wet protection type coke oven after heat power generating system based on a stabilization power supply circuit. The wet protection type coke oven after heat power generating system based on the stabilization power supply circuit mainly consists of a coke oven top hollow place and oven top cylinder bricks covering the surface of the top thereof. A porous steel plate, a heat insulation plate layer and another porous steel plate are sequentially arranged inside the coke over top hollow place from top to bottom. Heat preservation brick layers are arranged among the porous steel plates and the heat insulation plate layer; and a heat-resisting sealing pulp is filled inside the seam of the coke oven top hollow place. A heat exchanger and an evaporator forming an enclosed loop are arranged outside the coke oven top hollow place. The evaporator is further provided with an after heat power generating system. An after heat control circuit is arranged inside the after heat power generating system. The after heat control circuit is provided with a thermal induction automatic switching circuit, and a controlled power supply circuit, a stabilization power supply circuit as well as a controlled output circuit that are sequentially connected with one another.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

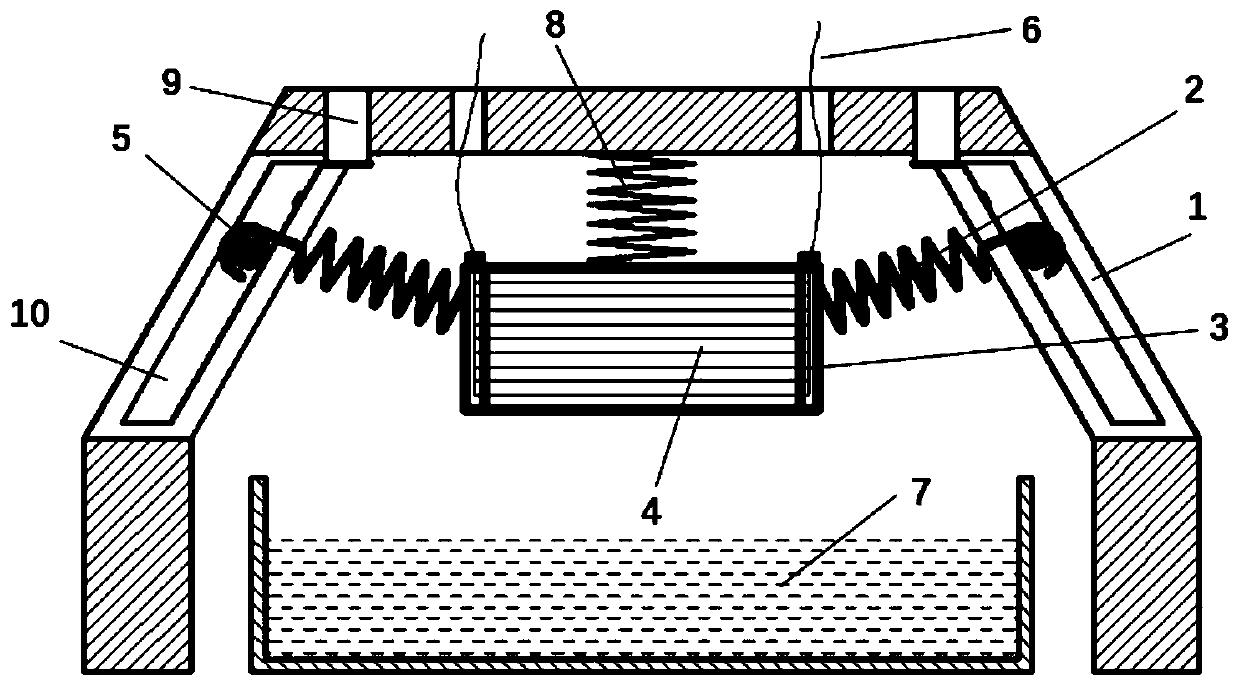

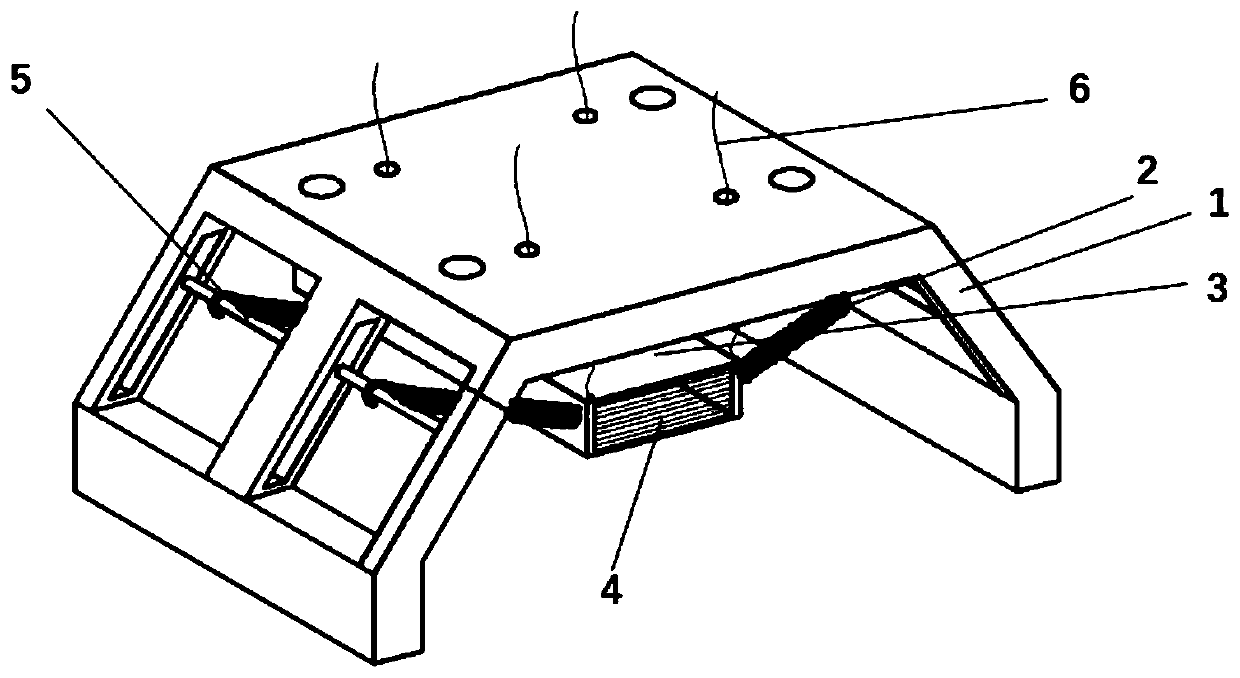

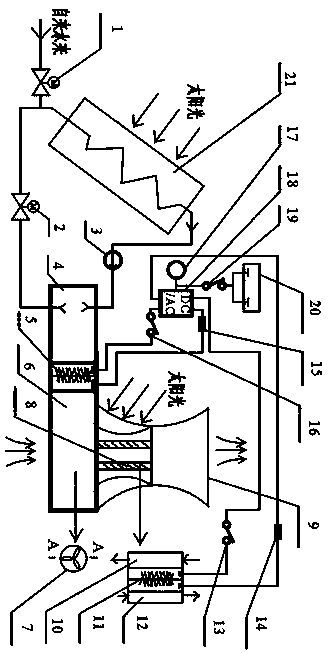

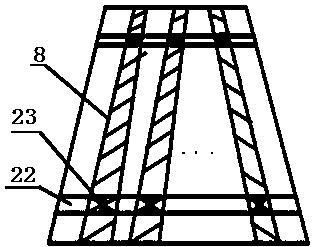

Medium and low temperature waste heat sliding power generation device based on shape memory alloy

ActiveCN109209801BReduce constraintsSimple structureMachines/enginesMechanical power devicesShape-memory alloyBrush

The invention discloses a medium-low temperature waste heat sliding power generator based on shape memory alloy. The medium-low temperature waste heat sliding power generator comprises a trapezoid bracket located in a magnetic field. A sliding block is connected into the trapezoid bracket. The top end of the sliding block is connected with the top of the trapezoid bracket by a spring. Two sides ofthe sliding block are connected with guide rods fixed to the left and right sides of the trapezoid bracket by SAM springs respectively. Wires are arranged on the front and rear ends of the sliding block in a winding mode. Electric brushes are connected to the corners of the top of the sliding block. The electric brushes penetrate through wire holes formed in the top of the trapezoid bracket. A heat source is arranged below the sliding block. The structure is simple, installation is convenient, the cost of the device is low, and economic benefits are high. When the device is positioned in themagnetic field, the medium-low heat can be fully used, and waste heat power generating efficiency is improved. Universality is high, and limitation on application places is low. The device can collectlarge heat sources of factory waste pipes or small heat sources of domestic exhausting pipes after appropriate size modification. Application and maintenance are simple, and energy supplying except the heat source to be collected is not required.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Dry method single-pressure recovery generating system of waste heat for cement production line

InactiveCN101871732BReliable temperatureIncrease enthalpyIncreasing energy efficiencySteam engine plantsProduction lineFlue gas

The invention discloses a single-pressure recovery generating system of waste heat of a dry method cement production line, being capable of improving generating efficiency. The kiln head grate cooler of the single-pressure recovery generating system is provided with at least two gas picking-up openings including a high-temperature gas picking-up opening and a moderate-temperature gas picking-up opening. A high-temperature superheater is arranged in the system; the high-temperature gas picking-up is connected to the gas inlet of the high-temperature superheater; the moderate-temperature gas picking-up opening is connected to the gas inlet of an AQC (Air Quench Cooler) boiler; the steam outlet of the AQC boiler and the steam outlet of a kiln tail SP (Suspend Preheater) boiler are connected to the steam outlet of the high-temperature superheater; the steam outlet of the high-temperature superheater is connected to a steam turbine, which makes the primary superheat steam of the kiln tail SP boiler and the AQC boiler obtain reliable secondary superheating in the high-temperature superheater; moderate-temperature flue gas and the heat-exchanged flue gas of the high-temperature superheater are taken as the heat source of the AQC boiler to realize the stepwise recovery of the energy of the flue gas of the waste heat of the grate cooler, increase steam enthalpy and improve effective enthalpy drop; the steam quality is improved and the flow is reduced, which reduce the exhaust loss of the waste heat in a condenser of the steam turbine and promote the improvement of waste heat generating efficiency.

Owner:CHENGDU HOT NEW ENERGY TECH

A solar thermoelectric power generation system

ActiveCN109742975BImprove waste heat power generation efficiencyReduce the amount of cooling waterSolar heating energyBatteries circuit arrangementsThermodynamicsEngineering

The invention discloses a solar energy thermoelectric power generation system, and belongs to the technical field of solar thermoelectricity. The solar energy thermoelectric power generation system iscomposed of a hot water-air cooling type thermoelectric power generation system and a hot plate-air cooling type thermoelectric power generation system, and is characterized in that the hot water-aircooling type thermoelectric power generation system and the hot plate-air cooling type thermoelectric power generation system share a cooling ventilation tower; the temperature of a hot water sourceis 60-99 DEG C, the temperature of the cooling air is 20-30 DEG C, and the temperature difference of thermoelectric power generation is 30-79 DEG C; and the temperature of sunlight acting on a heat absorption plate is 60-390 DEG C, the temperature of cooling air is 20-30 DEG C, and the temperature difference of thermoelectric power generation is 30-360 DEG C. The double-temperature-difference power generation system is adopted, so that the solar energy waste heat power generation efficiency is improved; and the cooling water amount is reduced by adopting an air cooling mode, and remarkable energy-saving and emission-reducing effects are achieved.

Owner:SHANXI UNIV

Warning type coke oven waste heat recovery power generation system based on boosting power supply circuit

InactiveCN104848699AReasonable designSimple structureDc-dc conversionIncreasing energy efficiencySteel platesProcess engineering

The invention discloses a warning type coke oven waste heat recovery power generation system based on a boosting power supply circuit. The warning type coke oven waste heat recovery power generation system based on the boosting power supply circuit is mainly composed of a big coke oven top pit, oven top clinker bricks which cover the top surface of the big coke oven top pit, a porous steel plate, an insulation board layer and a porous steel plate arranged in the big coke oven top pit in sequence from the bottom to top, an insulating brick layer arranged between the porous steel plate and insulation board layer, and heat-resistant sealing slurry filled in a gap in the big coke oven top pit, a heat exchanger and an evaporator which form a closed loop are arranged at the outside of the big coke oven top pit, the evaporator is further provided with a waste heat power generation system, a waste heat control circuit is arranged in the waste heat power generation system, and the waste heat control circuit is provided with an outage warning circuit, and an over-current protection circuit, a control type power circuit, the boosting power supply circuit and a control type output circuit connected in sequence.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Thermal protection type coke oven waste heat power generation system based on power source adjustment circuit

InactiveCN104833232AReduce dosageReasonable designIncreasing energy efficiencyControl devices for furnacesBrickThermal insulation

The invention discloses a thermal protection type coke oven waste heat power generation system based on a power source adjustment circuit. The system is mainly composed of coke oven top large pits and oven top clinker bricks covering the surfaces of the tops of the coke oven top large pits, a pored steel plate, a thermal insulation board layer and a pored steel plate are arranged inside each coke oven top large pit in sequence from bottom to top, a thermal insulation brick layer is arranged between each pored steel plate and the corresponding thermal insulation board layer, gaps, inside the corresponding coke oven top large pit, of each thermal insulation brick layer are filled with heatproof sealing slurry in a poured mode, heat exchangers and an evaporator forming a closed loop are arranged outside the coke oven top large pits, a waste heat power generation system body is further arranged on the evaporator, a waste heat control circuit is arranged in the waste heat power generation system body, and an over-temperature protection circuit and a control type power source circuit, the power source adjustment circuit and a control type output circuit which are connected in sequence are arranged in the waste heat control circuit.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Protection type coke oven afterheat recycling power generation system based on efficient driving power circuit

InactiveCN104807340AReduce dosageReasonable designDc-dc conversionIncreasing energy efficiencyBrickClosed loop

The invention discloses a protection type coke oven afterheat recycling power generation system based on an efficient driving power circuit. The protection type coke oven afterheat recycling power generation system consists of a coke oven top big hole and oven top cylinder bricks covering the surface of the top of the coke oven top big hole, wherein a perforated steel plate, a heat insulation plate layer and a perforated steel plate I are arranged in the coke oven top big hole from bottom to top; a heat preservation brick layer arranged between each perforated steel plate and the heat insulation plate layer is formed by filling inner gaps of the coke oven top big hole with heat-resistant sealing slurry; a heat exchanger and an evaporator which form a closed loop are arranged outside the coke oven top big hole; an afterheat power generation system is also arranged on the evaporator; an afterheat control circuit is arranged in the afterheat power generation system; an overcurrent protection circuit, a control type power circuit, an efficient driving power circuit and a control type output circuit which are connected in sequence are arranged in the afterheat control circuit.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Current source-based bipolar oscillating type waste heat power generating system

ActiveCN104807337AReduce dosageReasonable designIncreasing energy efficiencySteam engine plantsEngineeringUltimate tensile strength

The invention discloses a current source-based bipolar oscillating type waste heat power generating system. The current source-based bipolar oscillating type waste heat generating system mainly comprises a blast furnace body (1), a power generation system (12), a steam utilization device, more than one superconductive annular heat exchange ring (2) arranged along the side wall of the blast furnace body (1) in a layered surrounding type, a waste heat control processing system and the like. According to the current source-based bipolar oscillating type waste heat power generating system, hot water subjected to heat exchange is concentrately guided out through the superconductive annular heat exchange rings embedded in the side wall of the blast furnace body and an annular pipeline system corresponding to the superconductive annular heat exchange rings, so that the heat exchange strength is increased, the heat exchange efficiency and the cooling efficiency are improved, and in addition, the temperature of cooling water in a traditional mode is increased to 250 DEG C from 40 DEG C, and is overheated to 400 DEG C after being treated by the superconductive heat exchange rings twice, and thus cooling waste heat can be used for power generation.

Owner:西安石大能源股份有限公司

Thermal protection type coke oven waste heat electricity generation system based on boost power circuit

InactiveCN104913651AReduce dosageReasonable designDc-dc conversionIncreasing energy efficiencyBrickSlurry

The invention discloses a thermal protection type coke oven waste heat electricity generation system based on a boost power circuit. The thermal protection type coke oven waste heat electricity generation system is mainly composed of a large coke oven top pit and oven top quarry tiles covering the surface of the top of the pit. The large coke oven top pit is internally and sequentially provided with a porous steel plate, a heat insulation plate layer and the porous steel plate from bottom to top. A heat preservation tile layer arranged between the porous steel plates and the heat insulation plate layer is formed by pouring heat-resisting sealing slurry into seams of the large coke oven top pit. A heat exchanger and an evaporator for forming a sealing loop are arranged outside the large coke oven top pit. The evaporator is further provided with a waste heat electricity generation system. The waste heat electricity generation system is internally provided with a waste heat control circuit. The waste heat control circuit is internally provided with a thermal automatic switching circuit, a control type power supply circuit, the boost power circuit and a control type output circuit, wherein the control type power supply circuit, the boost power circuit and the control type output circuit are sequentially connected.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Protection-type coke oven waste heat recovery and power generation system based on power adjustment circuit

InactiveCN104833219AReasonable designSimple structureDc-dc conversionIncreasing energy efficiencyPower circuitsEvaporator

The invention discloses a protection-type coke oven waste heat recovery and power generation system based on a power adjustment circuit. The protection-type coke oven waste heat recovery and power generation system mainly comprises a coke oven top big hole and oven top clinker tiles covering the top surface of the big hole; the coke oven top big hole is internally provided with a porous steel plate, a heat insulation plate layer and a porous steel plate in sequence from bottom to top; a heat preservation brick layer is arranged between each porous steel plate and the heat preservation plate layer and is formed by pouring heat-resistant sealing slurry in internal slots of the coke oven top big hole; a heat exchanger and an evaporator which form a closed loop are arranged outside the coke oven top big hole; a waste heat power generation system is also arranged on the evaporator; a waste heat control circuit is arranged in the waste heat power generation system; an overcurrent protection circuit, a control type power circuit, the power adjustment circuit and a control type output circuit which are sequentially connected are arranged in the waste heat control circuit.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Device and process for generating power through efficient recovery of waste heat of sintered ores

ActiveCN103234362BIncrease ore volumeImprove sintering qualityIncreasing energy efficiencyHandling discharged materialThermodynamicsCogeneration

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Thermal induction type coke oven waste heat recovery power generation system based on stabilized power supply circuit

InactiveCN104833228AReduce dosageReasonable designIncreasing energy efficiencyMachines/enginesBrickClosed loop

The invention discloses a thermal induction type coke oven waste heat recovery power generation system based on a stabilized power supply circuit. The system is mainly composed of a coke oven top large pit and oven top quarry tiles covering the surface of the top of the coke oven top large pit. A porose steel plate, a heat insulation plate layer and a porose steel plate are sequentially arranged in the coke oven top large pit from bottom to top. Heat preservation brick layers between the porose steel plates and the heat insulation plate layer are formed by filling the inner gaps inside the coke oven top large pit with heat-resisting sealing slurry. A heat exchanger and an evaporator which form a closed loop are arranged outside the coke oven top large pit. A waste heat power generation system is arranged on the evaporator. A waste heat control circuit is arranged in the waste heat power generation system. A control type power supply circuit, the stabilized power supply circuit and a control type output circuit which are connected in sequence and a thermal induction automatic switching circuit are arranged in the waste heat control circuit.

Owner:CHENGDU SINOMETALLURGY ENERGY CONSERVATION ENVIRONMENTAL PROTECTION ENG CO LTD

Trilinear drive type waste heat power generation energy-saving control system based on overvoltage and overcurrent protection

InactiveCN105177205AGuaranteed uptimeEnsure waste heat utilizationCooling devicesIncreasing energy efficiencyOvervoltageTerminal voltage

The invention discloses a trilinear drive type waste heat power generation energy-saving control system based on overvoltage and overcurrent protection. The system is composed of a blast furnace body (1), a power generation system (12), a steam utilizing device, two or more annular superconduction heat exchange rings (2) which are annularly arranged along the side wall of the blast furnace body (1) in a layered mode, a waste heat control and treatment system and the like. The waste heat control and treatment system comprises a diode rectifier U, a voltage stabilization and transformation circuit, a three-terminal voltage stabilizing control circuit and a trilinear driving circuit. The trilinear drive type waste heat power generation energy-saving control system is characterized in that an overvoltage and overcurrent protection circuit is further connected in series between the voltage stabilization and transformation circuit and the trilinear driving circuit. According to the trilinear drive type waste heat power generation energy-saving control system, due to the annular superconduction heat exchange rings which are embedded in the side wall of the blast furnace body and annular pipeline systems corresponding to the annular superconduction heat exchange rings, hot water produced after heat exchange can be led out in a concentrated mode, and heat exchange efficiency and cooling efficiency are improved; besides, due to the fact that the superconduction heat exchange rings are applied twice to be overheated to 400 DEG C, cooling waste heat can be used for generating electricity.

Owner:成都申川节能环保工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com