Medium and low temperature waste heat sliding power generation device based on shape memory alloy

A memory alloy, low-temperature waste heat technology, applied in machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., can solve the problems of low economic benefit of equipment, poor device universality, and complex device structure, so as to improve the efficiency of waste heat power generation. , Simple use and maintenance, high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

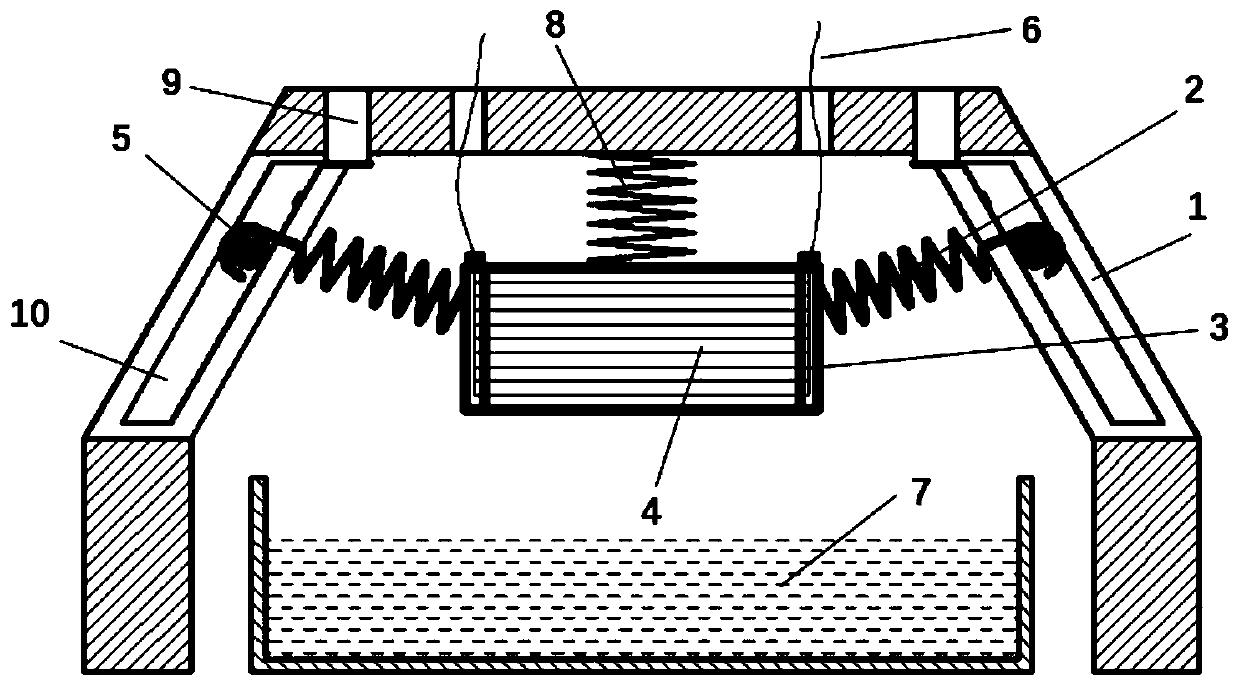

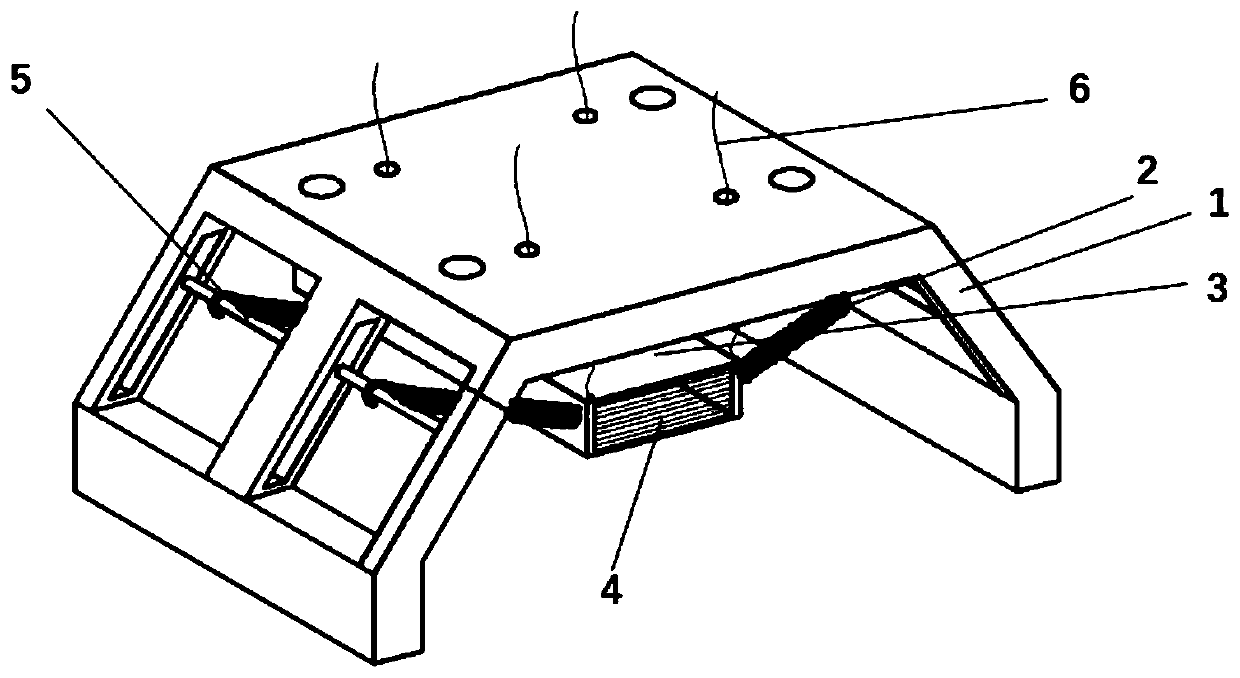

[0019] Such as figure 1 and figure 2 As shown, the present invention includes a trapezoidal bracket 1 , an SMA spring 2 , a slider 3 , a wire 4 , a guide rod 5 , a brush 6 , a heat source 7 , a spring 8 , a water injection hole 9 and a guide rail 10 . The whole device is placed in the magnetic field. The trapezoidal bracket 1 is made of thermal insulation material, and the slider 3 is connected inside it. The slider 3 is made of insulating and heat-insulating material, and is formed by splicing six insulating and heat-insulating plates. The top of the slider 3 is connected to the top of the trapezoidal bracket 1 through a spring 8, and the two sides of the slider 3 are respectively connected to the guide rods 5 defined on the left and right sides of the trapezoidal bracket 1 through two SMA springs 2. The SMA spring 2 has shape memory , shrinks when heated and returns to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com