Thermoelectric power generation system of boiler slag bucket heat source

A technology of thermoelectric power generation and thermoelectric generator, which is applied to generators/motors, electrical components, etc., can solve the problems of deterioration of furnace combustion, low recovery efficiency of boiler coke slag waste heat, and low recovery quality, and achieves the effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

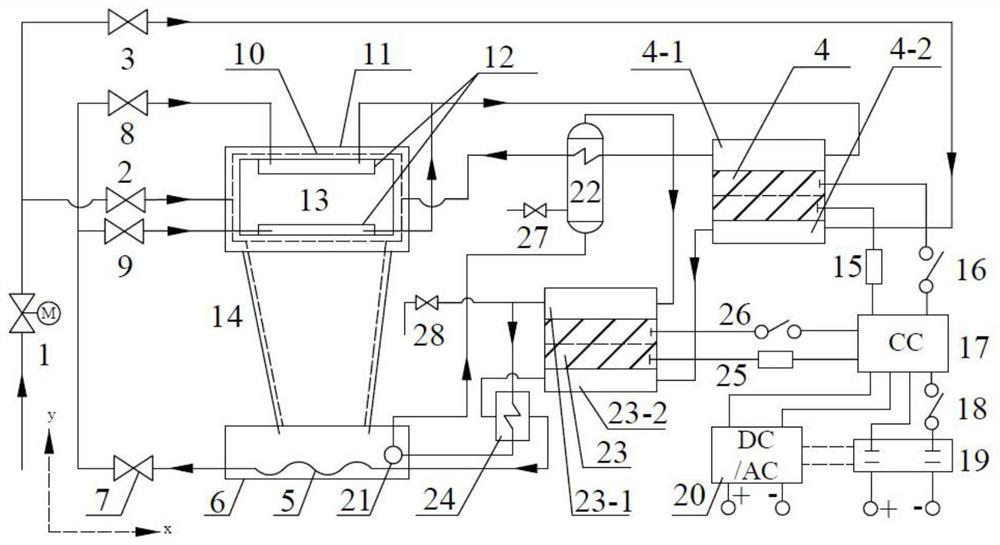

[0023] Thermoelectric power generation system of boiler slag hopper heat source, including steam-water type semiconductor thermoelectric generator system, organic working medium type semiconductor thermoelectric generator system, between steam-water type semiconductor thermoelectric generator system and organic working medium type semiconductor thermoelectric generator system Thermal connection parts, controller group 17, battery pack energy storage connection switch 18, battery pack 19, frequency converter 20;

[0024]The soda-type semiconductor thermoelectric generator system includes a slag hopper cooling main water supply electric door 1, a furnace bottom water seal tank feedwater gate 2, a low-temperature side water supply gate 3 of the soda-water type semiconductor thermoelectric generator, and a soda-water type semiconductor thermoelectric generator. 4. The high temperature side of the soda-water type semiconductor thermoelectric generator 4-1, the low-temperature side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com