Dry method single-pressure recovery generating system of waste heat for cement production line

A dry process cement and power generation system technology, applied in waste heat treatment, machine/engine, lighting and heating equipment, etc., can solve the problem of low power generation efficiency, achieve the effect of improving steam quality, increasing effective enthalpy drop, and promoting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

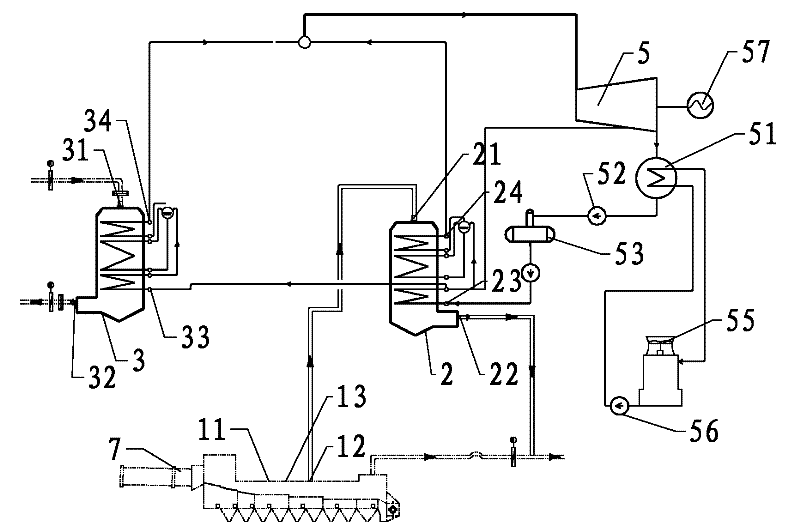

Embodiment 1

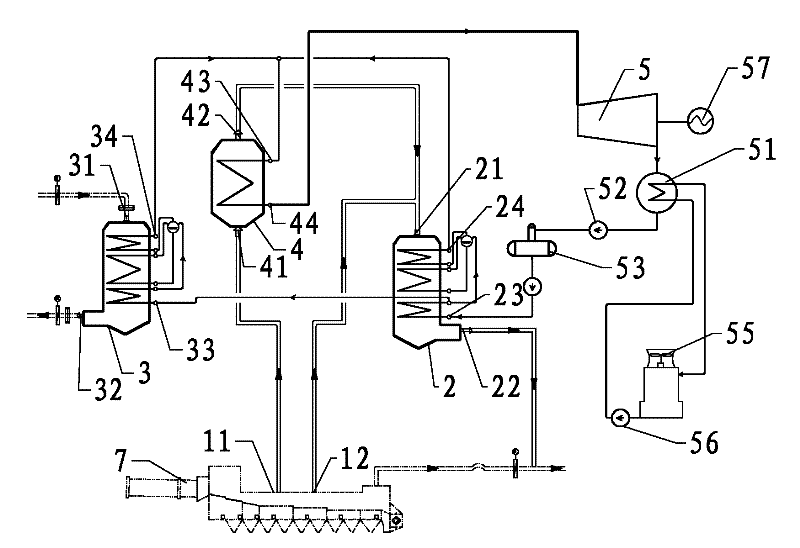

[0023] Such as image 3 As shown, the waste heat single-pressure recovery power generation system of the dry process cement production line of the present invention, the flue gas from the kiln tail C1 enters the kiln tail SP boiler 3 through the air inlet 31 to the raw material system after heat exchange, and the kiln head grate cooler 1 There are two gas inlets on the top, which are high temperature gas inlet 11 and medium temperature gas inlet 12. A high temperature superheater 4 is installed in the system. The flue gas from the high temperature gas inlet 11 enters the high temperature superheater 4 through the air inlet 41. After heat exchange The flue gas from the medium-temperature gas inlet 12 enters the dust removal system after heat exchange with the AQC boiler 2 through the air inlet 21, and the primary superheated steam from the steam outlet 24 of the AQC boiler 2 and the steam outlet 34 of the SP boiler 3 at the kiln tail is at high temperature After secondary super...

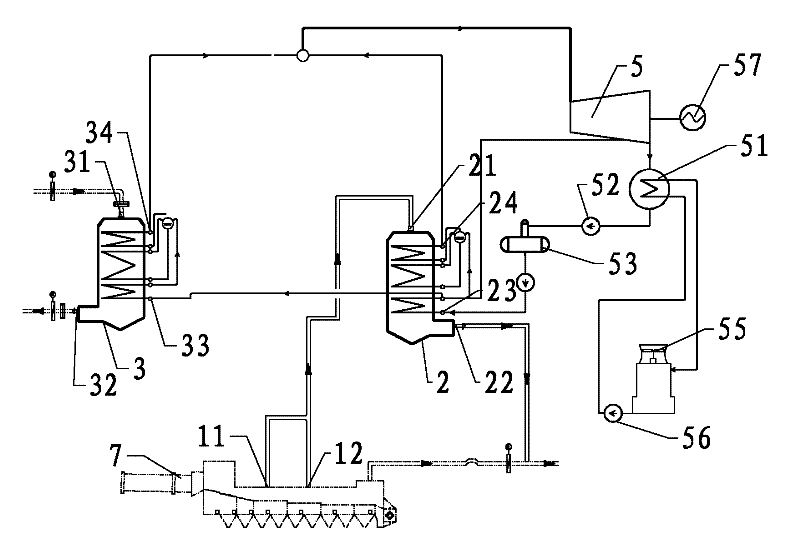

Embodiment 2

[0026] Such as Figure 4 As shown, the waste heat single-pressure recovery power generation system of the dry process cement production line of the present invention, the flue gas from the kiln tail C1 enters the kiln tail SP boiler 3 through the air inlet 31 to the raw material system after heat exchange, and the kiln head grate cooler 1 There are three air intakes on the top, which are high-temperature air intake 11, sub-high temperature air intake 13 and medium-temperature air intake 12, and a high-temperature superheater 4 is installed in the system. After mixing in 6, it enters the high-temperature superheater 4 through the air inlet 41, and after heat exchange, it enters the dust removal system of the AQC boiler 2 after heat exchange with the flue gas from the medium-temperature gas inlet 12 through the air inlet 21, and the steam outlet of the AQC boiler 2 24 and the primary superheated steam from the steam outlet 34 of the kiln tail SP boiler 3 is sent to the steam tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com