Drum-shaped evaporator and cabinet air conditioner with drum-shaped evaporator

A technology for air-conditioning cabinets and evaporators, which is used in evaporators/condensers, refrigerators, household appliances, etc., can solve the problems of low heat exchange efficiency of flat-plate or U-shaped evaporators, and reduce the speed and increase the exchange rate. Heat area, sufficient heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below with reference to the accompanying drawings and examples.

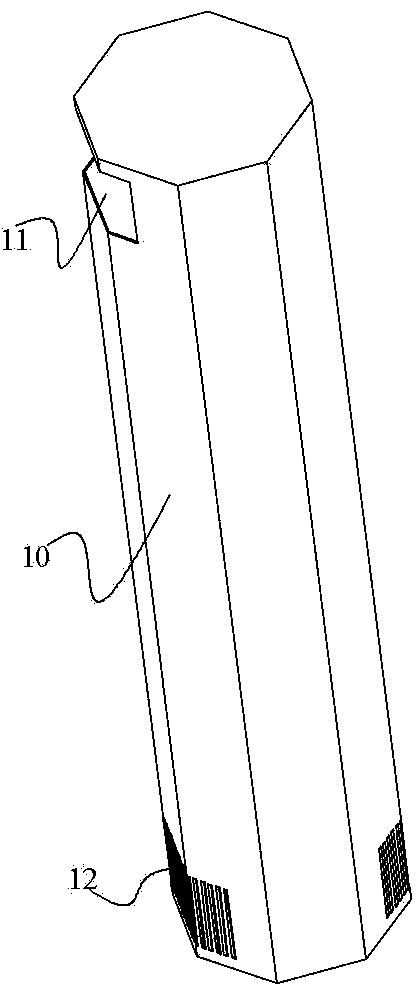

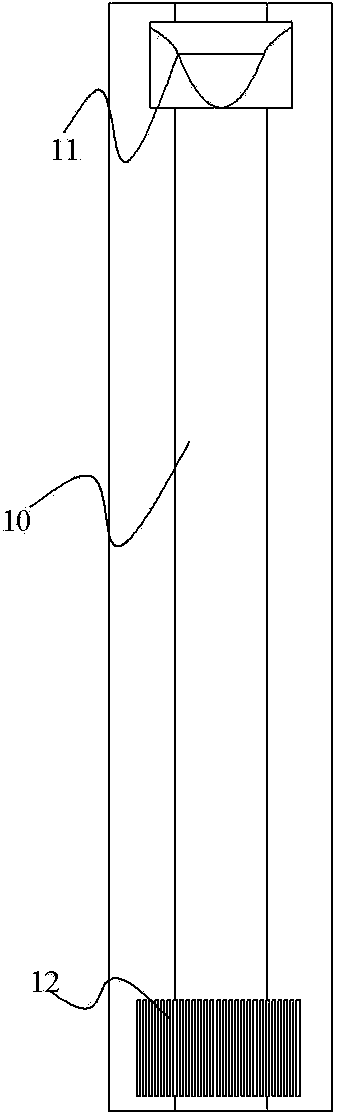

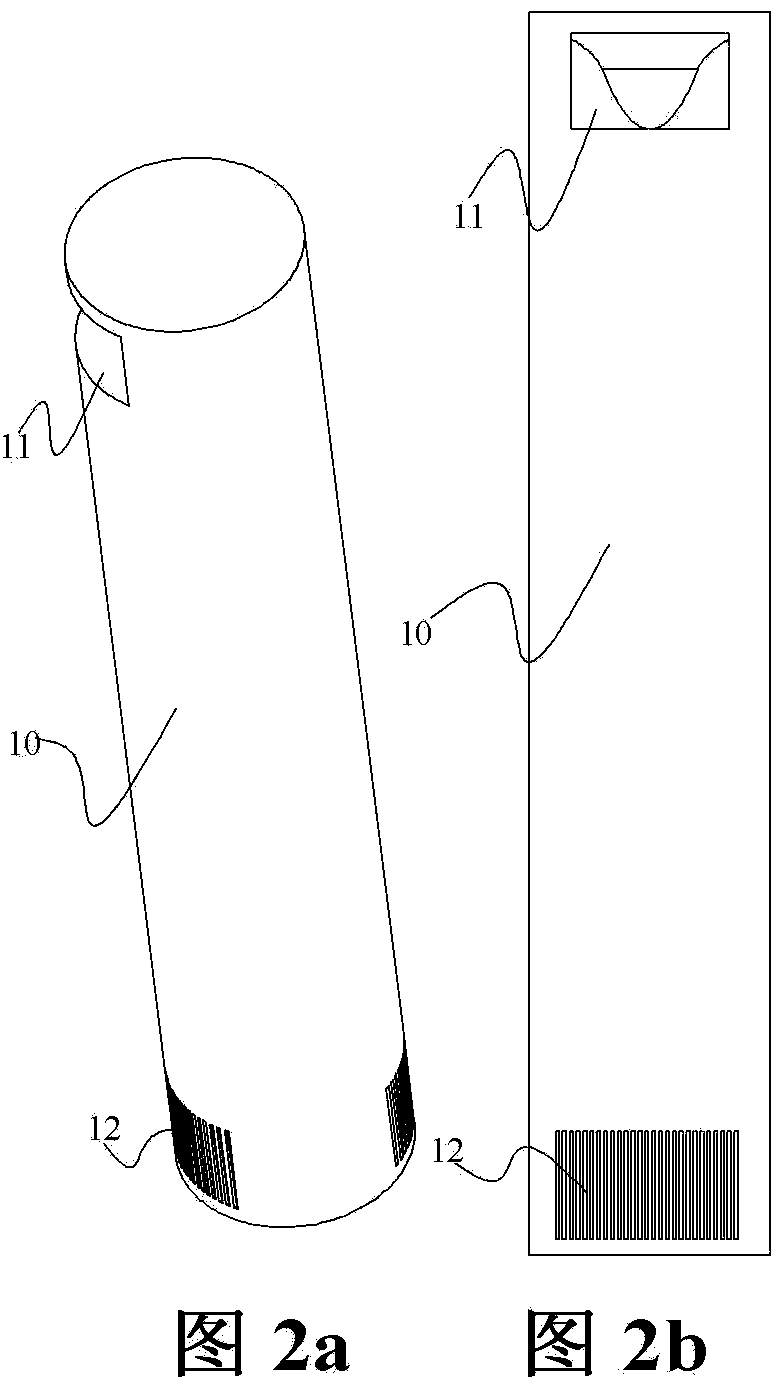

[0061] The invention provides a cylindrical evaporator, which comprises a cylindrical evaporator body, one of the inner peripheral side and the outer peripheral side of the evaporator body is an air inlet side, and the other side is an air outlet side. In the present invention, the evaporator is arranged in a cylindrical shape, and one side of the inner peripheral side and the outer peripheral side is the air inlet side, and the other side is the air outlet side, even if the air flow flows into the interior of the cylindrical evaporator from the surroundings or from the inside. It flows out to the periphery of the cylindrical evaporator, so that the heat exchange area between the airflow and the evaporator is the entire surrounding surface, thus effectively increasing the heat exchange area of the evaporator compared with ordinary U-shaped evaporators or fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com