Electrode applied to electrochemical energy storage device and preparation method of electrode

An energy storage device, electrochemical technology, applied in the direction of battery electrodes, hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc., can solve the problem of low power and energy density, poor electrochemical cycle performance, and utilization of electrode active materials High capacity, easy to achieve repeatedly, and shorten the distance of ion penetration and transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

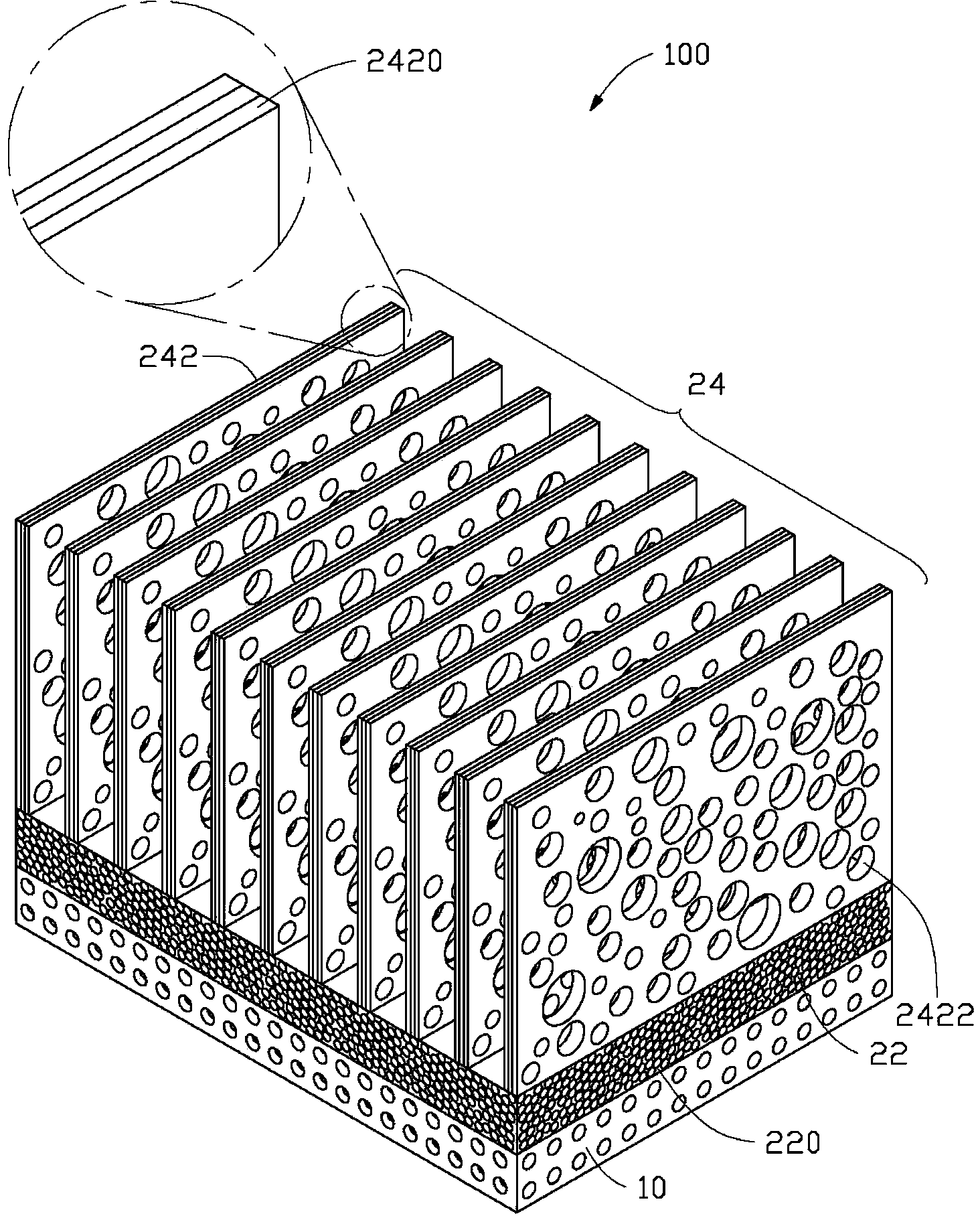

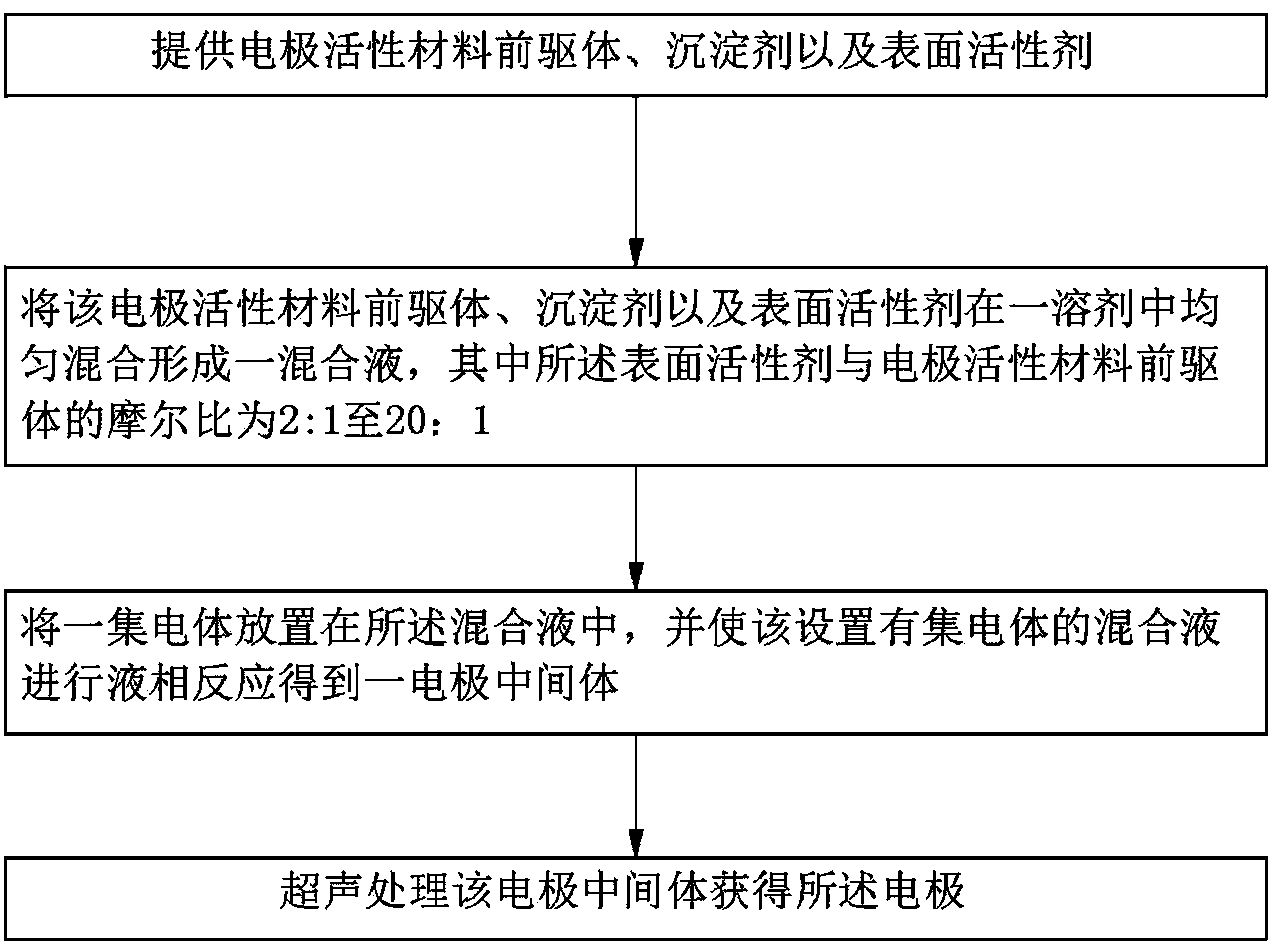

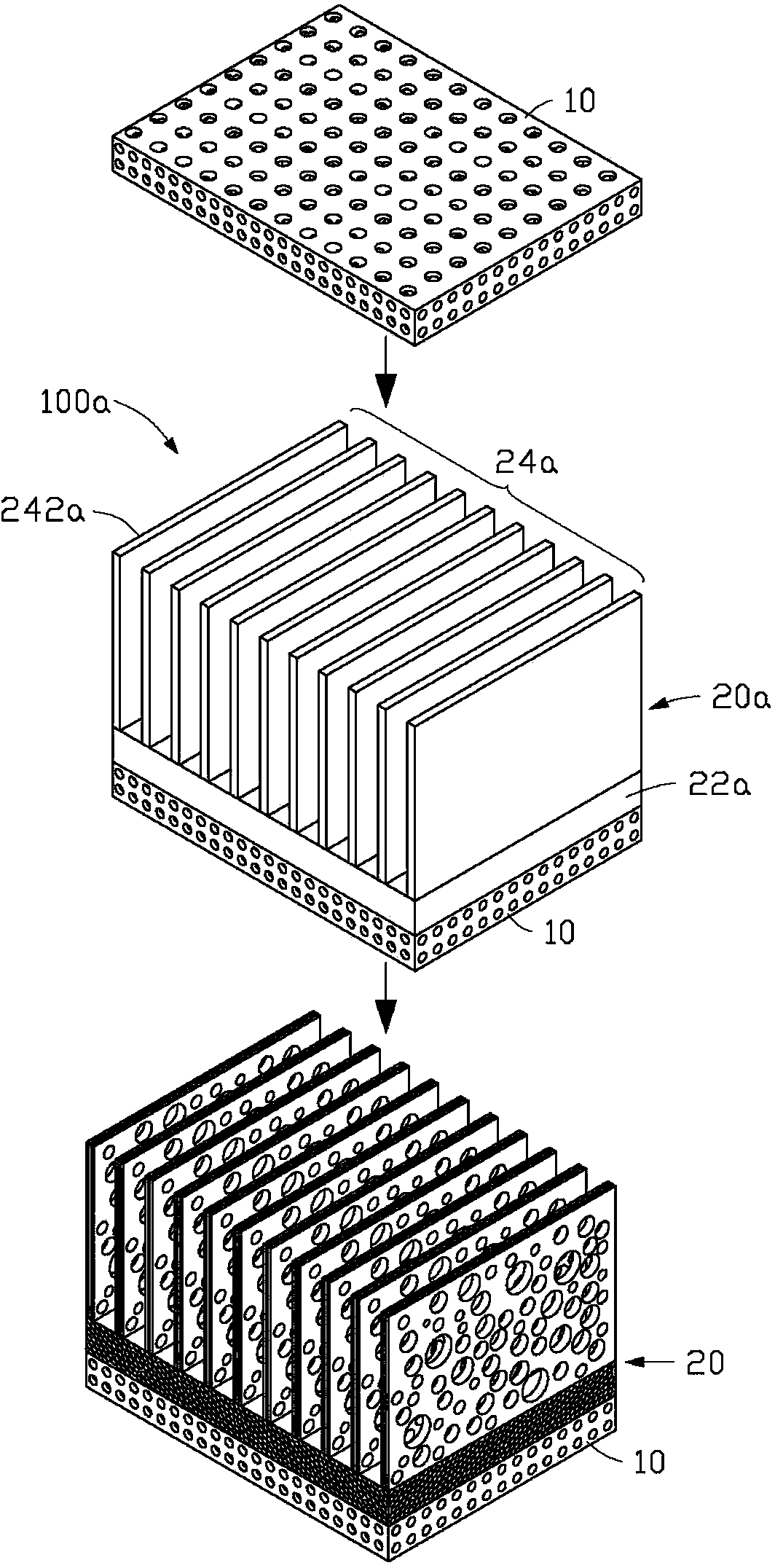

[0037] Please also refer to Figure 2-3 , the embodiment of the present invention further provides a method for preparing an electrode 100 applied to an electrochemical energy storage device, comprising the following steps:

[0038] S1, providing electrode active material precursors, precipitants and surfactants;

[0039] S2, uniformly mixing the electrode active material precursor, precipitant and surfactant in a solvent to form a mixed solution, wherein the molar ratio of the surfactant to the electrode active material precursor is 2:1 to 20:1 ;

[0040] S3, placing the current collector 10 in the mixed solution, and subjecting the mixed solution provided with the current collector 10 to a liquid phase reaction to obtain an electrode intermediate 100a, and

[0041] S4, ultrasonically processing the electrode intermediate 100a to obtain the electrode 100 .

[0042] In the above step S1, the electrode active material precursor is a raw material used to prepare the electrode...

Embodiment 1

[0056] Ni(OH) 2 Electrode preparation

[0057] The soluble divalent nickel salt, ammonia solution as a precipitant, and SDS and HMT as a surfactant are uniformly mixed to form a mixed solution. Wherein the divalent nickel salt is 0.1 mole, the SDS is 0.25 mole, and the HMT is 1 mole. In addition, the volume of ammonia water is 5ml, wherein the mass content of ammonia water in the ammonia solution is 28wt%. The mixed solution was placed in a reaction kettle, and a nickel mesh was placed in the reaction kettle and heated to 90°C, and kept for 4 hours to make Ni(OH) 2 Deposited on the surface of nickel mesh. The reactor was then cooled, and the nickel mesh was taken out and washed several times with deionized water and ethanol. Finally, the washed nickel mesh was ultrasonically treated in deionized water to obtain Ni(OH) 2 Electrode, wherein the power of ultrasonic treatment is 40kW.

Embodiment 2

[0059] This embodiment is basically the same as the above-mentioned embodiment 1, the difference is that the precursor of the electrode active material is a divalent Co salt, and finally the Co(OH) 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com