Graphene-containing heat-insulating energy-saving composite powder, and preparation method and application thereof

A composite powder, graphene technology, applied in metal processing equipment, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as poor infrared absorption or reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

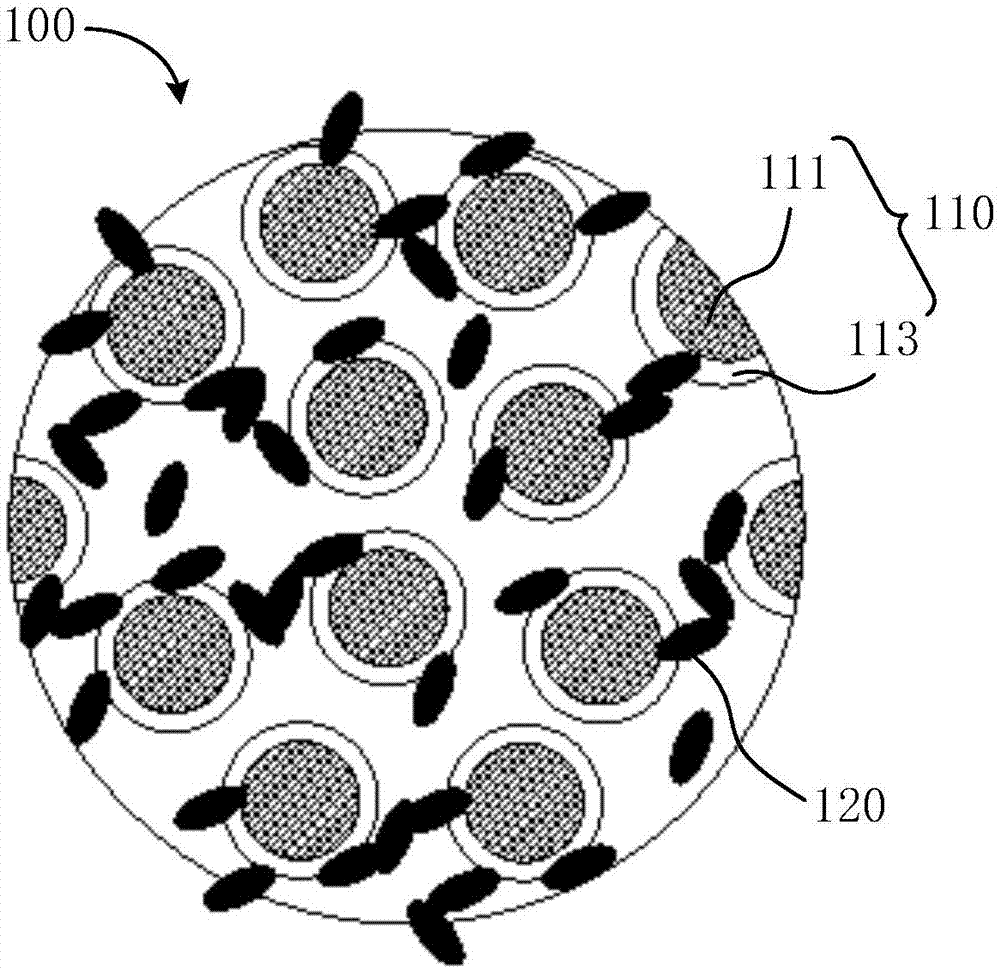

Image

Examples

preparation example Construction

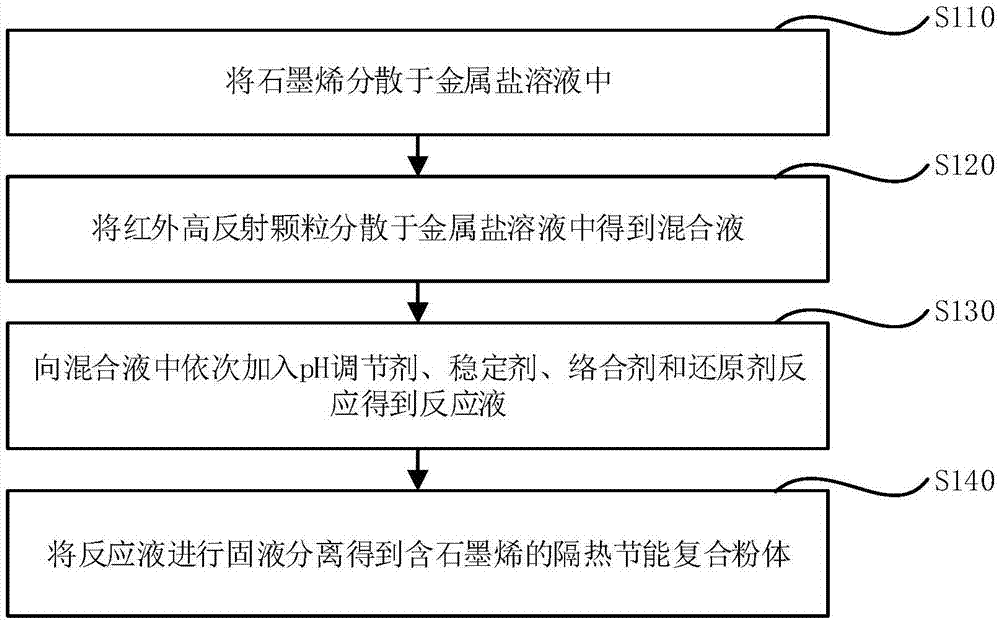

[0055] see figure 2 , the preparation method of the graphene-containing heat-insulating and energy-saving composite powder of an embodiment, comprises the following steps:

[0056] S110, dispersing the graphene in the metal salt solution.

[0057] In one of the embodiments, the metal salt solution is selected from AuCl 3 , AgNO 3 , AgCl, PtCl 4 , PtCl 2 、CuSO 4 , CuCl 2 , Al(NO 3 ) 3 and AlCl 3 at least one of the

[0058] In one embodiment, the concentration of the metal salt solution is 0.001-0.1 mol / L.

[0059] In one embodiment, the molar ratio of graphene to metal salt is 1:10˜10:1.

[0060] In one embodiment, the graphene is dispersed in the metal salt solution by ultrasonic and stirring. The power of ultrasonic dispersion is 20Hz~50Hz. The stirring speed is 200r / min~2000r / min. The time for ultrasonic dispersion and stirring is 10min to 120min.

[0061] S120, and then disperse the infrared highly reflective particles in the metal salt solution to obtain a...

Embodiment 1

[0080] (1) Weigh 4L of AuCl 3 solution, where AuCl 3 The concentration of the solution is 0.01mol / L; 5g of graphene is added thereto, and the graphene is dispersed uniformly by ultrasonic and stirring. Among them, the surface size of graphene is 1μm, the thickness of graphene is 0.5nm, and the specific surface area of graphene is 10m 2 / g. The power of ultrasonic dispersion is 50Hz, the rotation speed of stirring is 200r / min, and the time of ultrasonic dispersion and stirring is 60min.

[0081] (2) Add 90 g of infrared high-reflective particles ITO, and disperse the infrared high-reflective particles evenly by means of ultrasonic and stirring to obtain a mixed solution. The power of ultrasonic dispersion is 50Hz, the rotation speed of stirring is 200r / min, and the time of ultrasonic dispersion and stirring is 60min.

[0082] (3) Add 0.25 g of sodium hydroxide, 0.25 g of methanol, 0.25 g of sodium citrate and 0.25 g of sodium phosphite to the mixed liquid in sequence, and...

Embodiment 2

[0085] (1) Weigh 3L of AgNO 3 solution, where AgNO 3 The concentration of the solution is 0.05mol / L; 10g of graphene is added thereto, and the graphene is uniformly dispersed by ultrasonic and stirring. Among them, the surface size of graphene is 100μm, the thickness of graphene is 50nm, and the specific surface area of graphene is 1000m 2 / g. The power of ultrasonic dispersion is 20Hz, the rotational speed of stirring is 2000r / min, and the time of ultrasonic dispersion and stirring is 90min.

[0086] (2) 80 g of infrared high-reflective particles ATO was added, and the infrared high-reflective particles were uniformly dispersed by means of ultrasonication and stirring to obtain a mixed solution. The power of ultrasonic dispersion is 20Hz, the rotational speed of stirring is 2000r / min, and the time of ultrasonic dispersion and stirring is 90min.

[0087] (3) Add 0.4 g of sodium carbonate, 0.4 g of 2,2-bipyridine, 0.04 g of triethanolamine and 0.25 g of formaldehyde to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com