Spiral-tube heat exchanger

A tubular heat exchanger and spiral tube technology, applied in the field of spiral tube heat exchangers, can solve the problems of inability to achieve heat exchange enhancement at the same time, limited improvement of heat exchange capacity, and inability to fully exchange heat, etc., to achieve small installation space , Improve the heat exchange capacity and the effect of sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

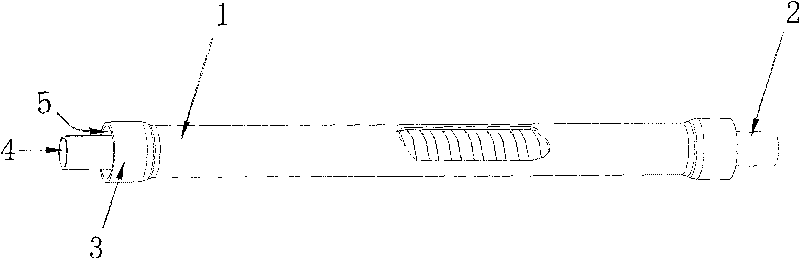

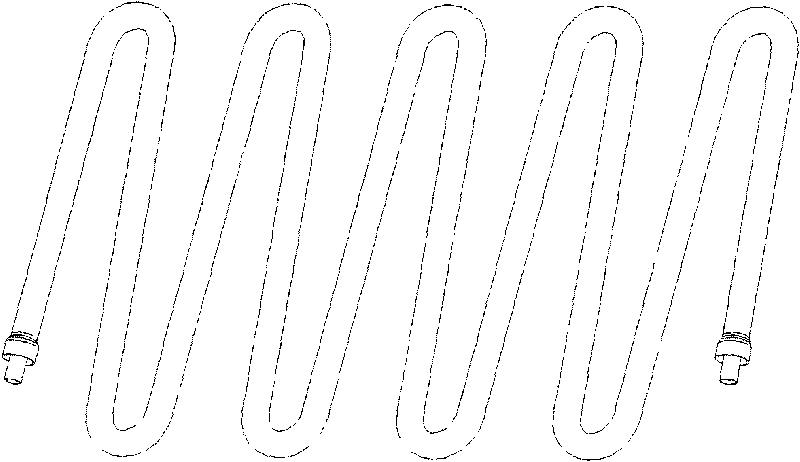

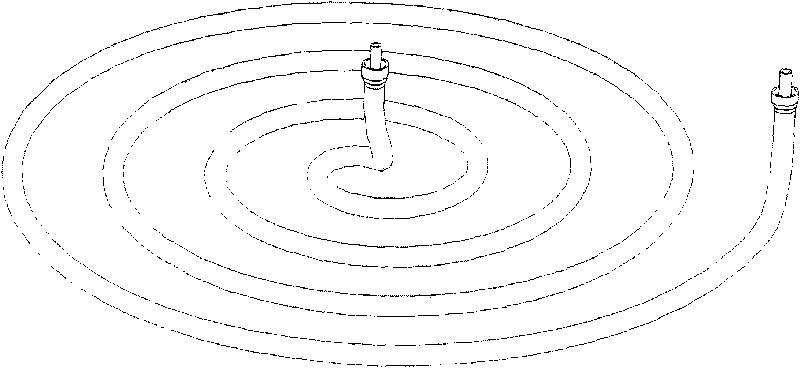

[0017] figure 1 It is a structural schematic diagram of the spiral tube heat exchanger of the present invention, consisting of figure 1 It can be seen that a spiral tube heat exchanger includes a refrigerant channel 5 and a water channel 4, and is characterized in that: the spiral tube 2 is placed inside the outer tube 1, and both ends are exposed, and the spiral tube 2 is placed on the outer tube 1. The pipe wall of the inner part of the pipe 1 is threaded, and the inner wall of the outer pipe 1 is matched with the thread crest of the outer wall of the spiral pipe 2, and connected together by brazing to form a sealing surface.

[0018] The inner wall of the spiral tube 2 is threaded.

[0019] Flared openings 3 are provided at both ends of the outer tube 1 .

[0020] The pipe wall thread of the spiral pipe 2 is a rectangular thread or a trapezoidal thread.

[0021] The screw channel formed by the brazing connection between the outer side of the spiral tube 2 and the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com