Buffer transition bin of foamed plastic vehicle-mounted cold pressing briquetting device

A technology of foamed plastics and transition chambers, applied in the field of buffer transition chambers, can solve the problems of difficult promotion, heavy pollution, and poor practicability, and achieve the effects of improving processing efficiency, large specific surface area, and accelerating transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

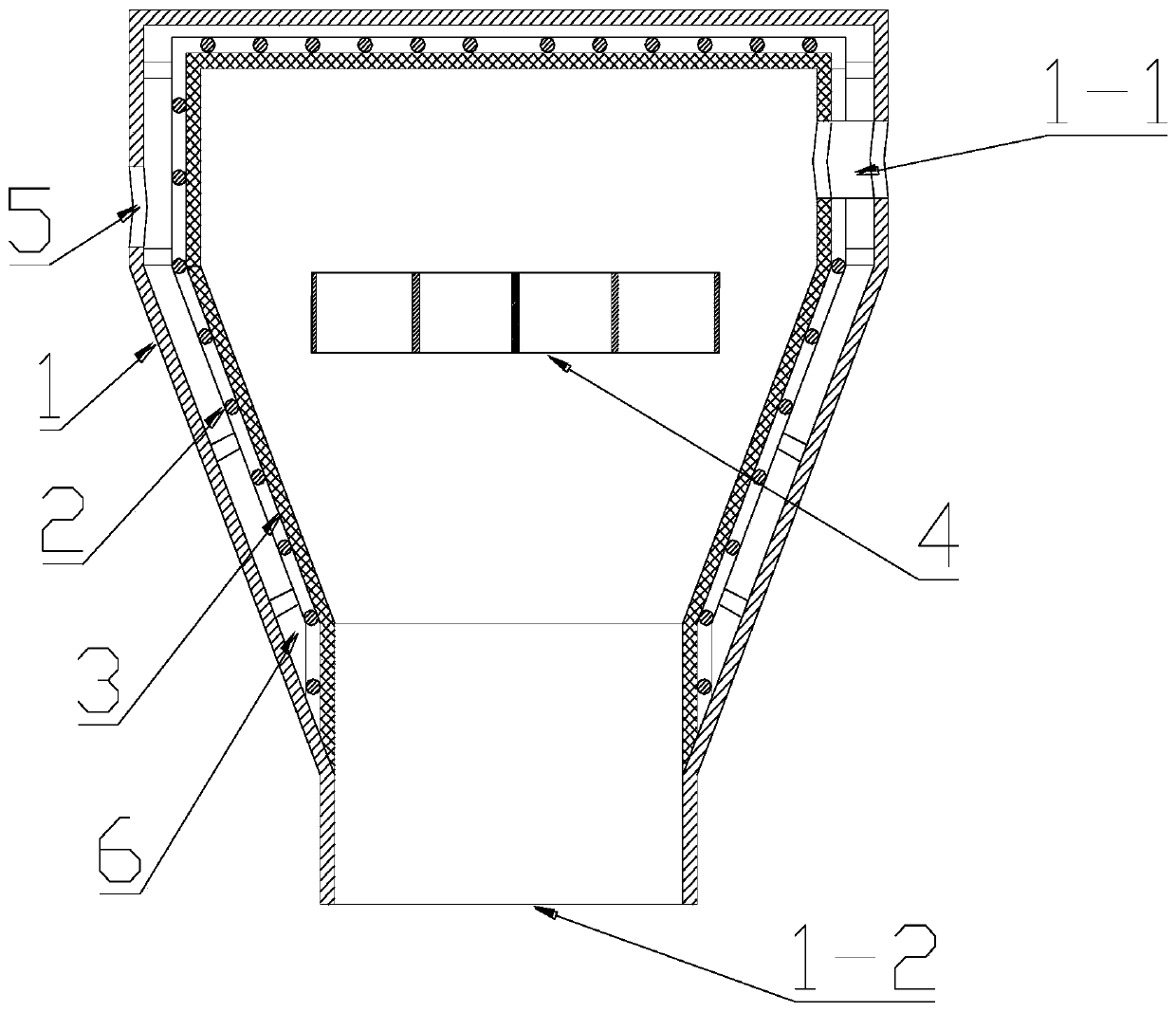

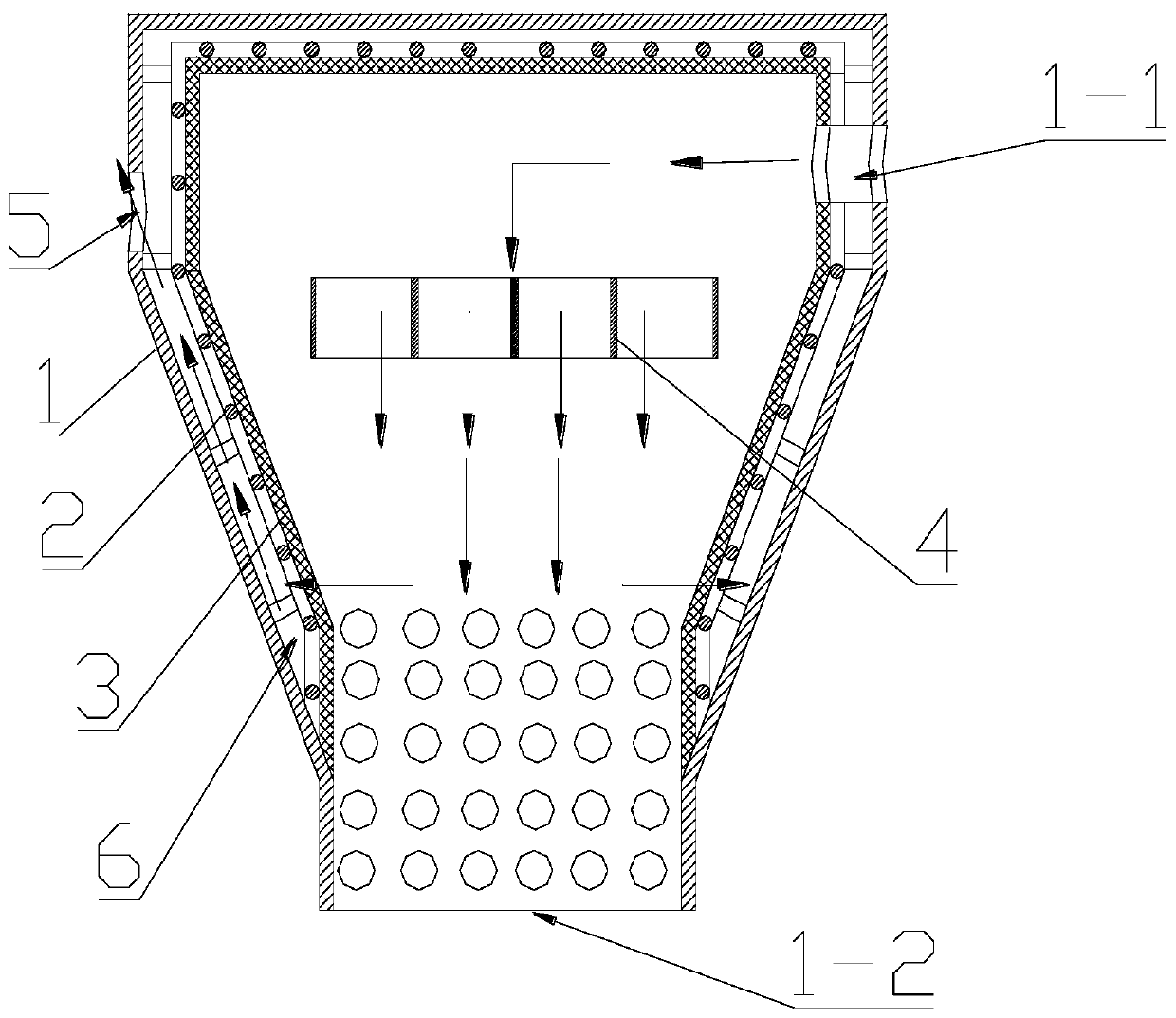

[0032] see Figure 1-Figure 3 , the buffer transition bin of the foamed plastic vehicle-mounted cold-pressing briquetting device of the present invention is arranged between the crushing device and the cold-pressing device, and includes a bin body 1, a diversion space 4 arranged in the bin body 1, and a wind-driven feeding installations and exhaust installations, in which,

[0033]The bin body 1 is vertically arranged, the feed inlet 1-1 is arranged at the upper end of the bin body 1, and the discharge port 1-2 is arranged at the lower end of the bin body 1; the diversion space 4 is located at the It is below the feed port 1-1 and above the discharge port 1-2.

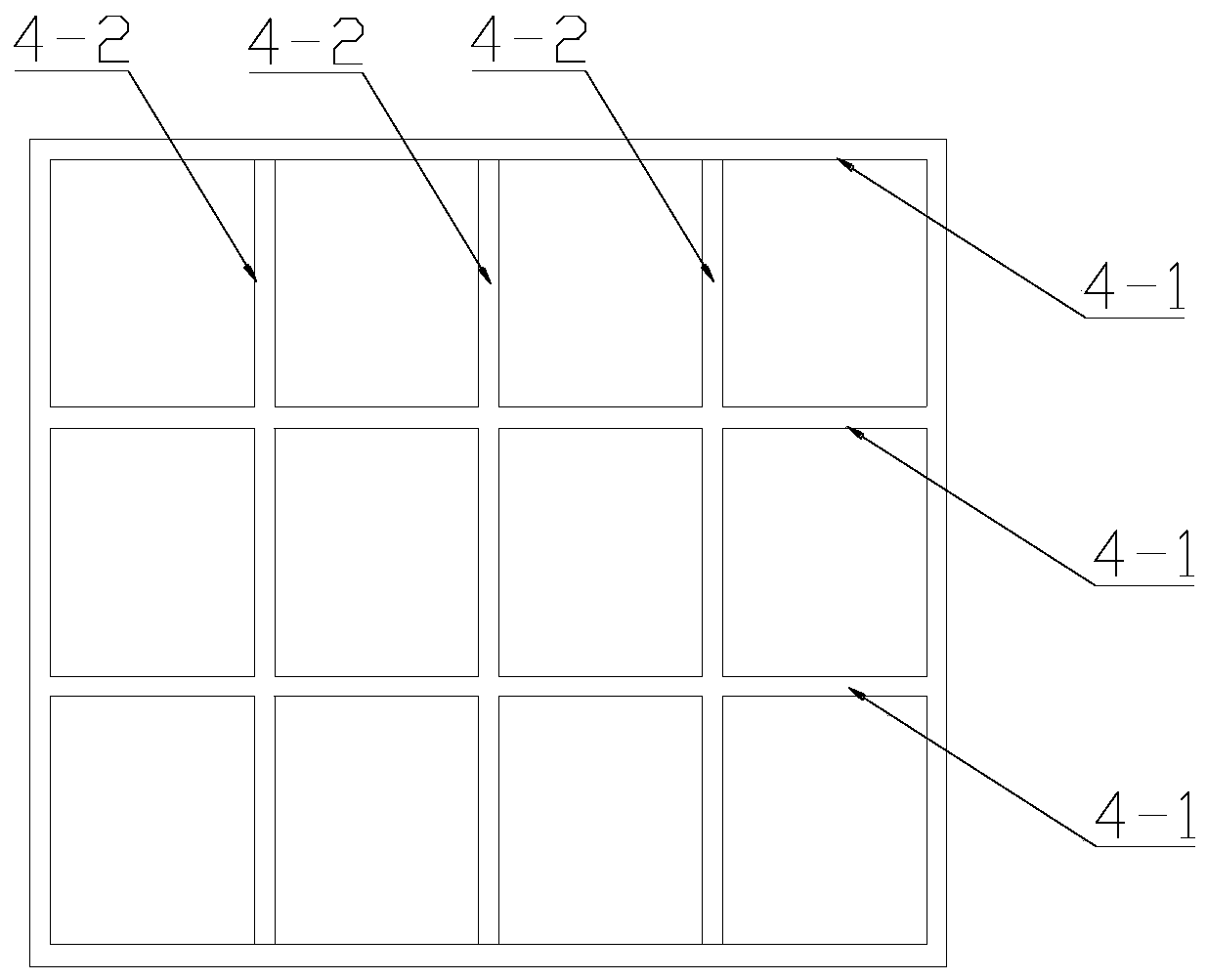

[0034] The diversion space 4 is arranged in the inner cavity of the warehouse body 1, and the diversion space 4 penetrates up and down; the diversion space 4 includes a plurality of transverse deflectors 4-1 and a plurality of longitudinal deflectors 4- 2; the plurality of horizontal deflectors 4-1 and the plurality ...

Embodiment 2

[0043] see Figure 4 , The difference between this embodiment and Embodiment 1 is that: the filter cloth 3 is a bag structure, that is, a filter bag; the support 2 is a columnar structure, and the cross section of the support 2 is circular or polygonal, The upper end of the filter cloth 3 is installed on the top of the bin body 1 , and the lower end is sleeved outside the support 2 .

Embodiment 3

[0045] see Figure 5 and Figure 6 The difference between this embodiment and Embodiment 1 is that the spacer is arranged above the feed port 1-1 of the bin body 1, including an isolation tube arranged at the upper end of the bin body 1 and sleeved on the The filter bag 7 on the isolation tube, wherein the isolation tube is arranged horizontally, one end of the isolation tube is connected to the warehouse body 1 and communicates with the air outlet 5, and the other end of the isolation tube is a certain distance from the inner wall of the warehouse body 1. distance, so as to be inserted into the filter bag 7; the isolation tube and the inner wall of the warehouse body 1 are connected by a detachable structure, specifically, a quick-connect buckle structure, bolt connection, etc. can be used. The internal channel in the isolation pipe constitutes the air duct 6;

[0046] Wherein, there are a plurality of spacers, and a plurality of spacers are evenly arranged along the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com