Device and method for removing dioxin in incinerator smoke carrying airflow

An incinerator and flue gas technology, applied in the field of flue gas treatment in the metallurgical industry, can solve the problems of large wood consumption, carcinogenicity, strong toxicity, etc., and achieve the effects of saving investment and operating costs, avoiding potential safety hazards, and high adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

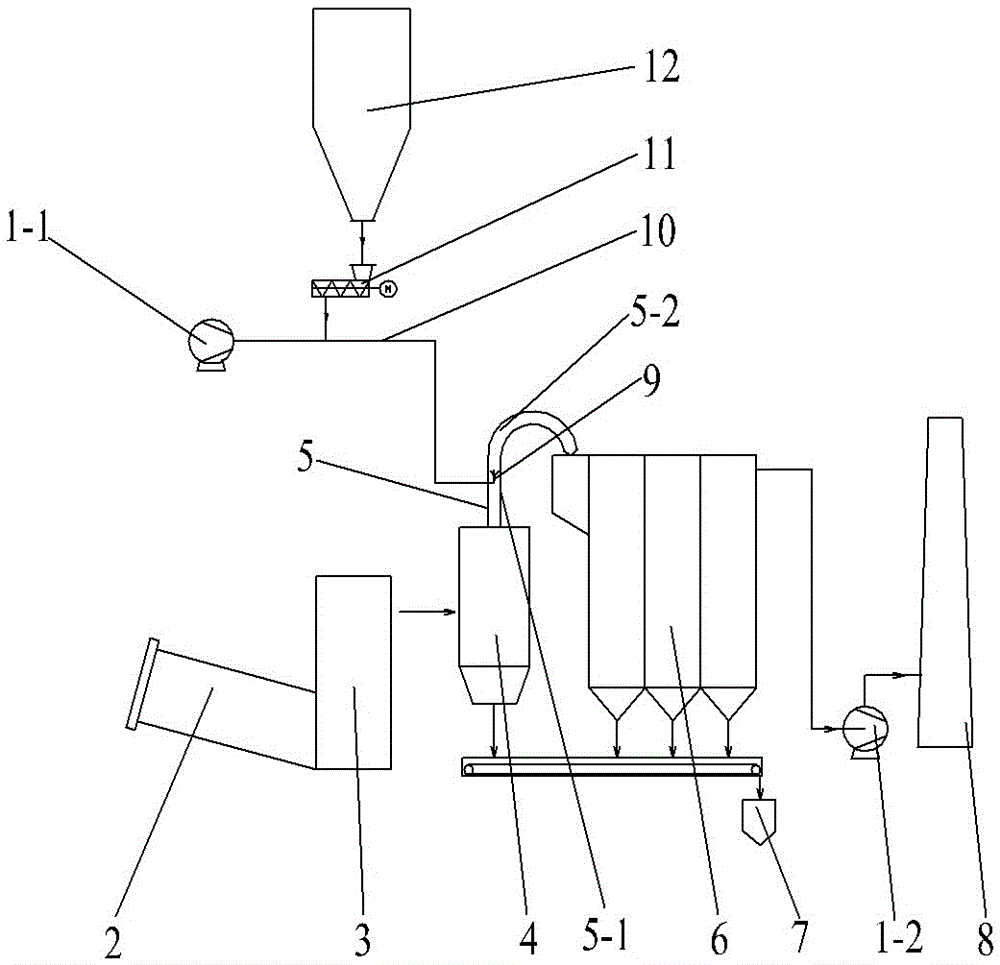

[0032] Set the original flue gas flow rate to 27000Nm 3 / h, the flue gas flow rate is 7.7m / s, the moisture content in the flue gas is 11.4%, the flue gas temperature in the flue 5 in front of the electrostatic precipitator 6 is 200℃~210℃, and the amount of adsorbent sprayed is 4kg / h. When the system is running, the adsorbent is first added to the adsorbent storage bin 12, and according to the set adsorbent injection volume, it is quantitatively delivered to the injection pipeline 10 by means of the quantitative delivery controller 11, and is sprayed into the flue 5 through the nozzle 9, and the smoke Road 5 is formed by connecting a rising vertical straight pipe 5-1 and a U-shaped elbow 5-2. The U-shaped elbow 5-2 is connected with the electrostatic precipitator 6. After the adsorbent enters the straight pipe 5-1, the The straight pipe 5-1 and the U-shaped bend pipe 5-2 rapidly diffuse and mix with the flue gas, and then enter the electrostatic precipitator 6, and various dust...

Embodiment 2

[0034] Set the original flue gas flow rate to 24200Nm 3 / h, the flue gas flow rate is 6.9m / s, the moisture content in the flue gas is 11.1%, the flue gas temperature in the flue 5 in front of the electrostatic precipitator 6 is 180°C-200°C, and the amount of adsorbent injection is 2kg / h. After repeating the above operations, it was obtained through actual industrial operation that the removal rate of dioxin was 79%.

[0035] In summary, the present invention is applicable to the removal of dioxins from the flue gas of high-temperature incinerators equipped with electrostatic precipitators. Under the flue gas temperature of 120°C to 220°C, it still maintains a high adsorption performance, and dioxins The removal rate is greater than 68%, and the dioxin removal rate is high, which can be effectively used in industrial production and has good economic benefits.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com