Device and method for removing acid gases in garbage incineration smoke at high temperature

A waste incineration and acid gas technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as pipeline blockage and pipeline corrosion, reduce corrosion and blockage, reduce poisonous effects, and realize purification and discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

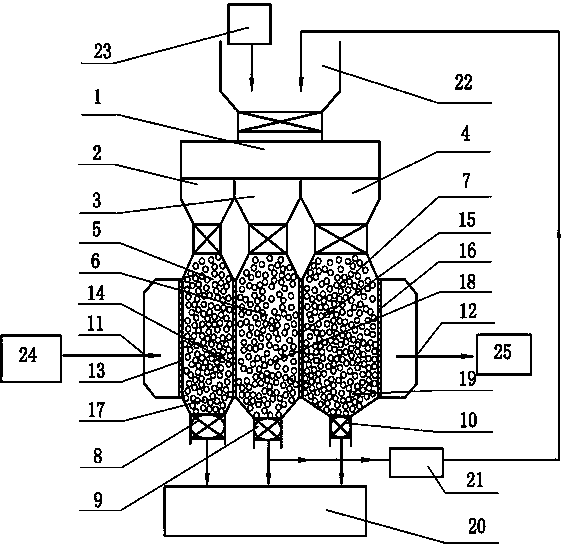

[0035] The present invention will be further described below in conjunction with the drawings and specific embodiments:

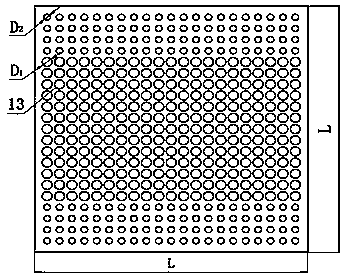

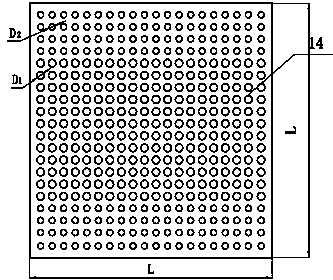

[0036] Such as figure 1 As shown, first, CaO with an average particle size of 10mm is selected as the solid adsorbent. Fresh CaO enters the closed hopper 1 from the replenishment bin 22, and then passes through the first-level hopper 2, the second-level hopper 3, and the third-level hopper. 4 Enter the first-stage cross-flow moving bed reactor 5, the second-stage cross-flow moving bed reactor 6 and the third-stage cross-flow moving bed reactor 7. The selected first-stage cross-flow moving bed reactor has a bed depth of 1m, the second-stage reactor is 1.25m, and the third-stage reactor is 1.5m. The height and width of the three reactors are all 3m. The width of the outlet of the bottom discharging section of the multi-stage cross-flow moving bed reactor is 400mm, 320mm, 240mm, and the discharging speed is respectively selected as 0.9kg / s, 0.675kg / s and 0.45kg / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com