Denitration agent for flue gas denitrification as well as preparation method and application of denitration agent

A technology of denitration agent and denitration reactor, which is applied in the field of denitration agent and its preparation for denitrification from flue gas, to achieve the effects of improving efficiency, simple operation process, reducing energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of a denitrification agent for denitrification from flue gas, the preparation process comprising the following steps:

[0035](1) Prepare the reaction solution. Take calcium hydroxide and yttrium hydroxide powders with a particle size in the range of 0.5-500 μm, dissolve them in 40-200ml glycerol to obtain a first solution, and the Y / Ca molar ratio in the first solution is in the range of 0.1-2 In the solution, the sum of the molar concentrations of Y ions and Ca ions in the solution is 0.01-10mol / L. Place the solution in an ultrasonic generator and sonicate for 0.5-5h under the condition of 200-600W ultrasonic power, so that the calcium hydroxide and yttrium hydroxide are completely dissolved;

[0036] (2) Dipping. Pour titanium dioxide, attapulgite clay or montmorillonite particles with a particle size in the range of 0.6-300 μm as an inert carrier into a beaker, pour the first solution in which calcium hydroxide and yttrium hydroxide powder are...

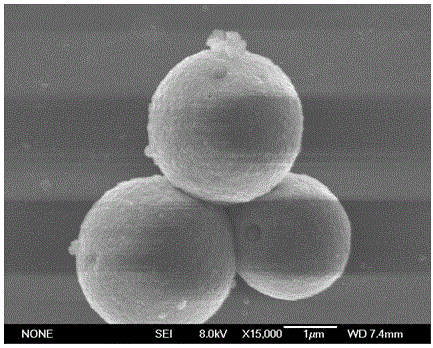

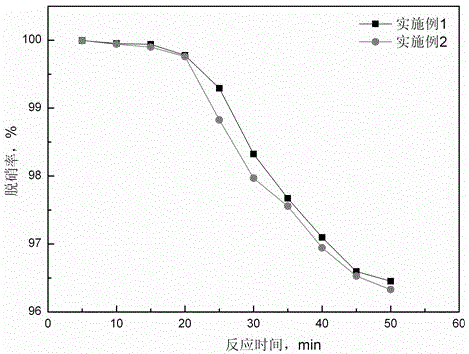

Embodiment 1

[0042] The invention provides a method for removing NO from flue gas x The preparation method of denitration agent, comprises the following steps:

[0043] 1. Prepare the reaction solution: put 1.0g of calcium hydroxide particles and 0.3g of yttrium hydroxide particles in a beaker, add 30ml of glycerol to dissolve to obtain the first solution, put it in an ultrasonic generator and ultrasonicate for 2 hours under the condition of 300W ultrasonic power .

[0044] 2. Impregnation: After the calcium hydroxide and yttrium hydroxide are completely dissolved, pour the solution into 4 g of titanium dioxide particles with a particle size in the range of 0.6-300 μm. Also placed in an ultrasonic generator and ultrasonicated for 0.5h under the condition of 300W ultrasonic power, can realize the uniform impregnation of ions in the solution on the surface of the carrier.

[0045] 3. Add the reaction solution dropwise: Dissolve 1.5g of thial in 70ml of glycerol, and add dropwise in two way...

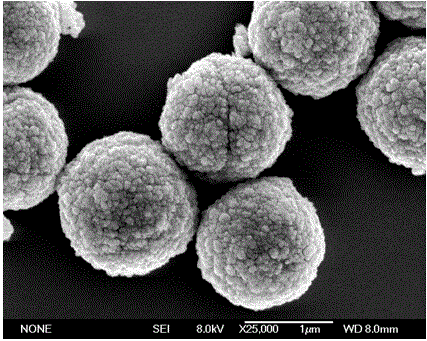

Embodiment 2

[0049] The invention provides a method for removing NO from flue gas x The preparation method of denitration agent, comprises the following steps:

[0050] 1. Prepare the reaction solution: Take 2.0g of calcium hydroxide particles and 0.7g of yttrium hydroxide particles, put them in a beaker and add 30ml of glycerol to dissolve them, put them in an ultrasonic generator and ultrasonicate for 1h under the condition of 300W ultrasonic power.

[0051] 2. Impregnation: After the calcium hydroxide and yttrium hydroxide are completely dissolved, pour 10g of titanium dioxide particles with a particle size in the range of 0.6-300μm as an inert carrier, and also place it in an ultrasonic generator and ultrasonicate for 0.5h under the condition of 300W ultrasonic power .

[0052] 3. Drop reaction solution: Take 3.5g of thial and dissolve it in 70ml of glycerol, drop the solution into the inert carrier impregnated with calcium hydroxide solution at a rate of 1.5ml / s. Stir continuously u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com