Patents

Literature

49results about How to "Continuous recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and adsorbent for recovering kryptsn and xenon from gas stream or liquid stream

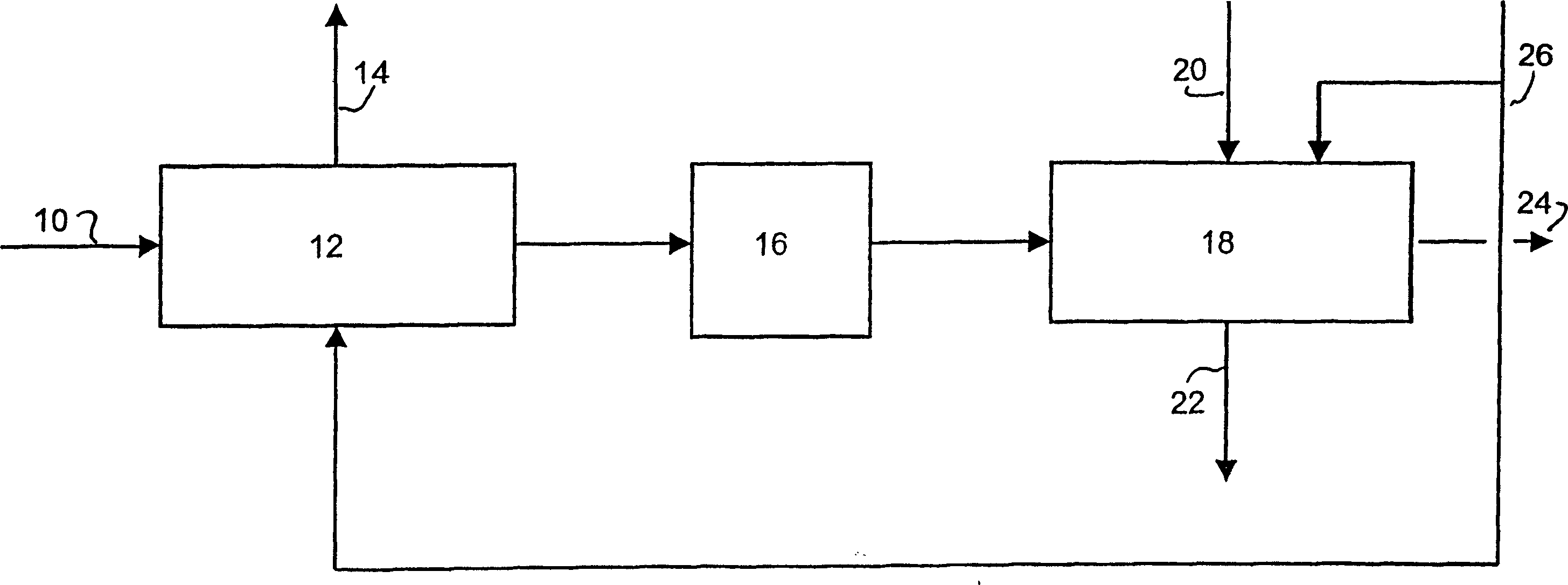

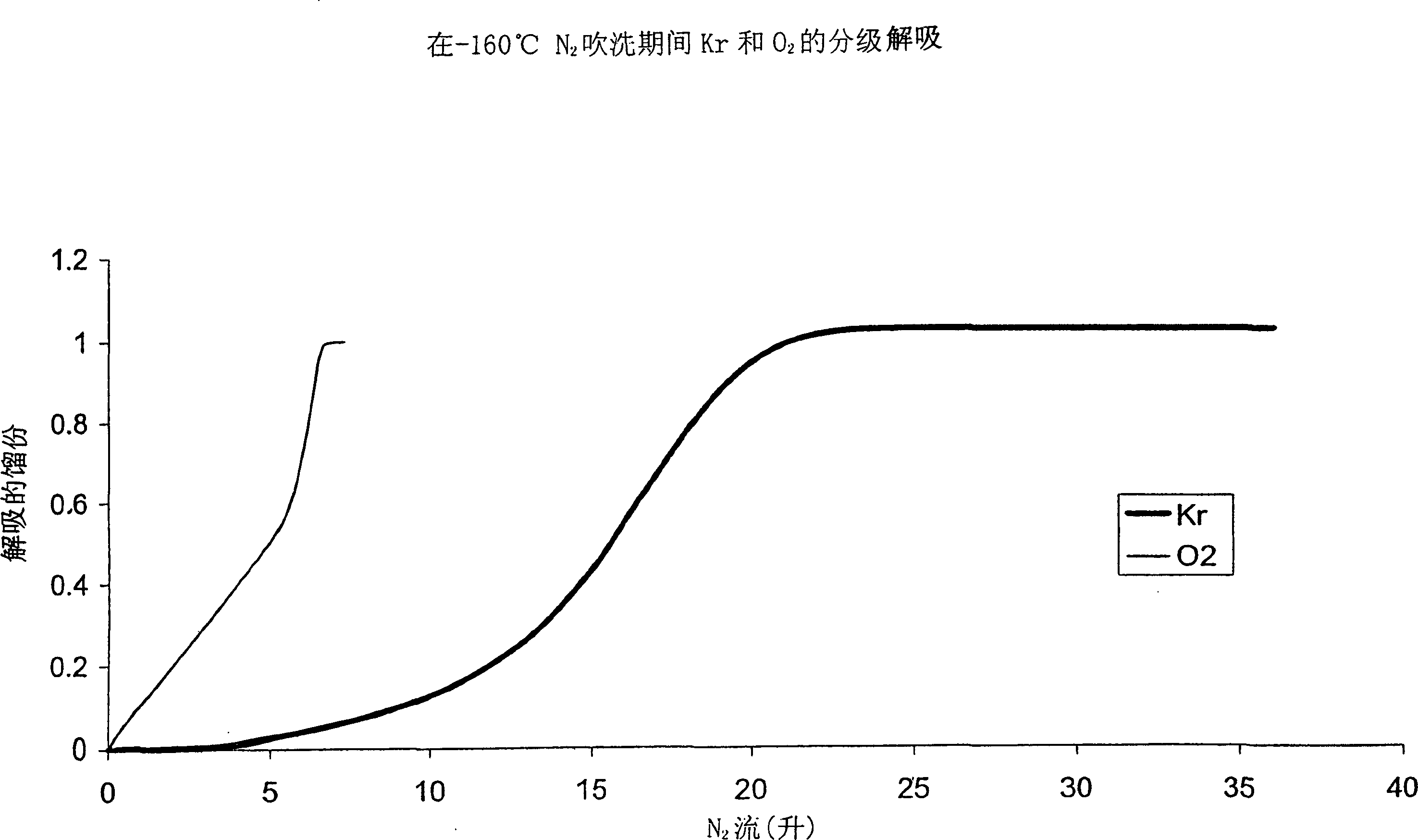

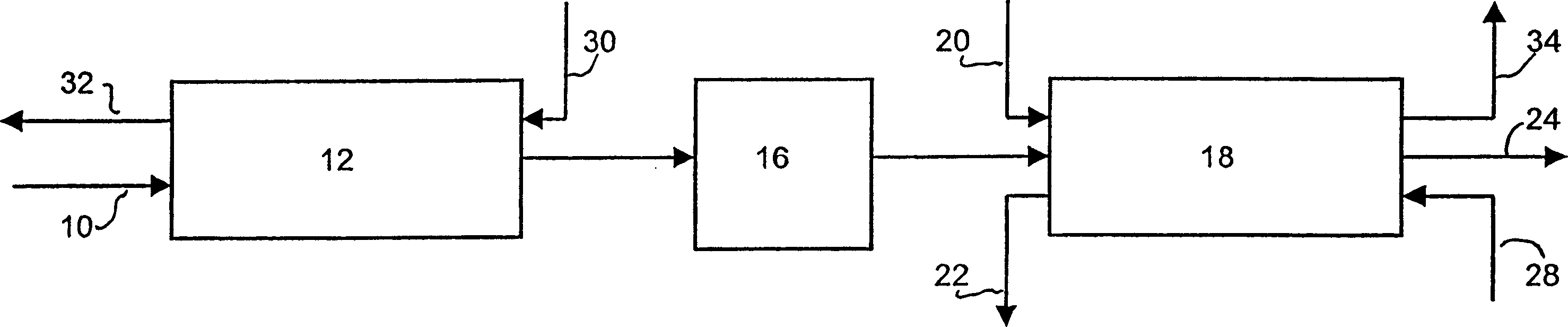

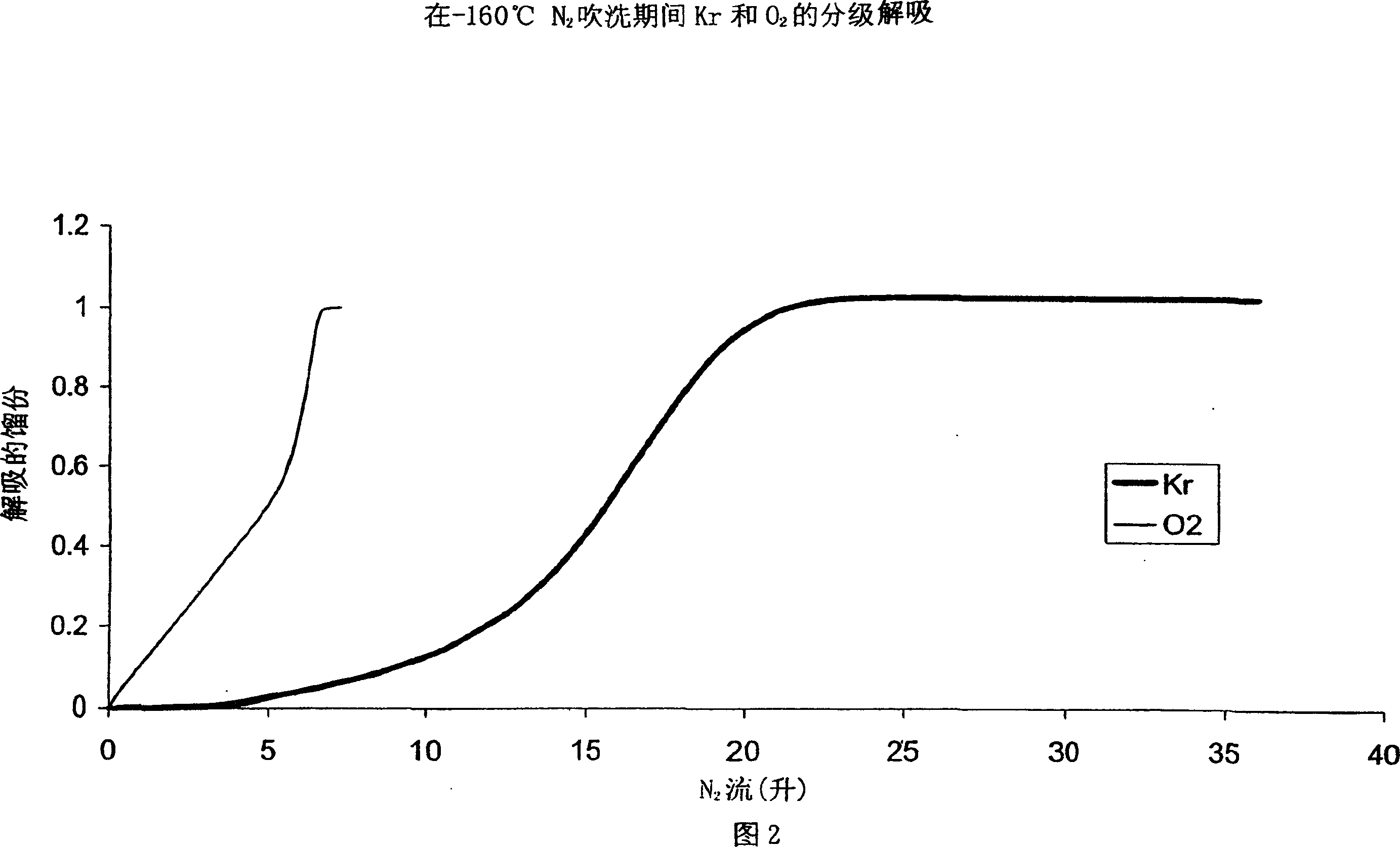

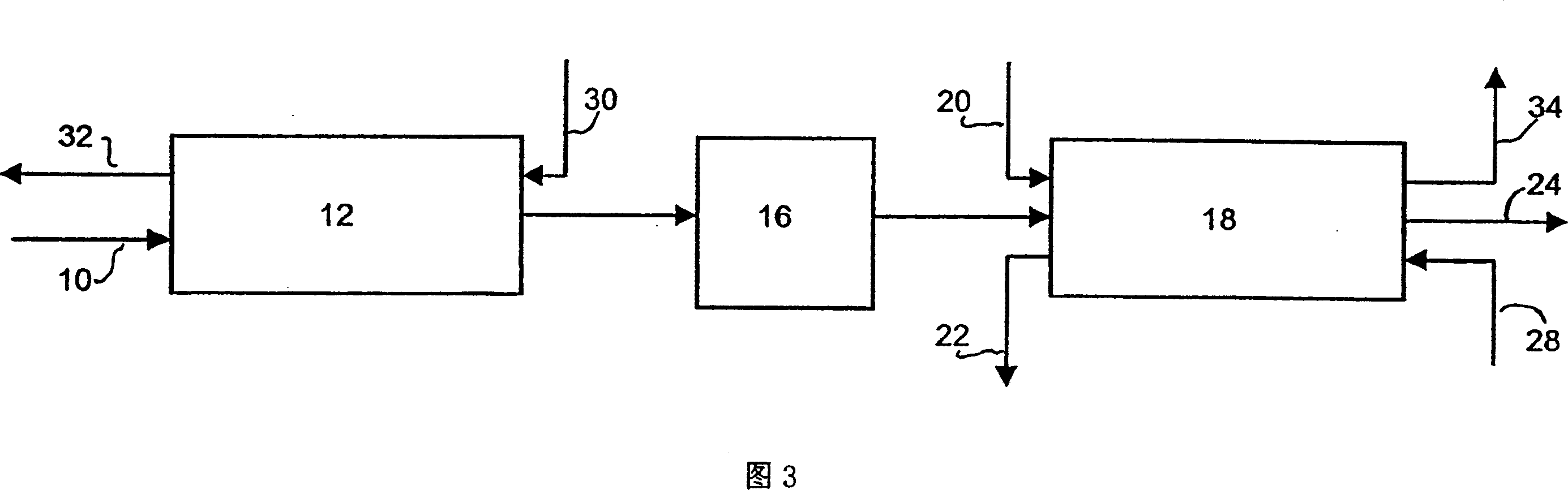

Xenon and / or krypton are recovered from oxygen-containing gas, typically derived from liquid oxygen bottoms in a cryogenic air separation plant, by selective adsorption on a Li and Ag exchange zeolite, preferably containing 5 to 40% Ag exchange capacity on an equivalents basis, with periodic thermal regeneration of the adsorbent.

Owner:AIR PROD & CHEM INC

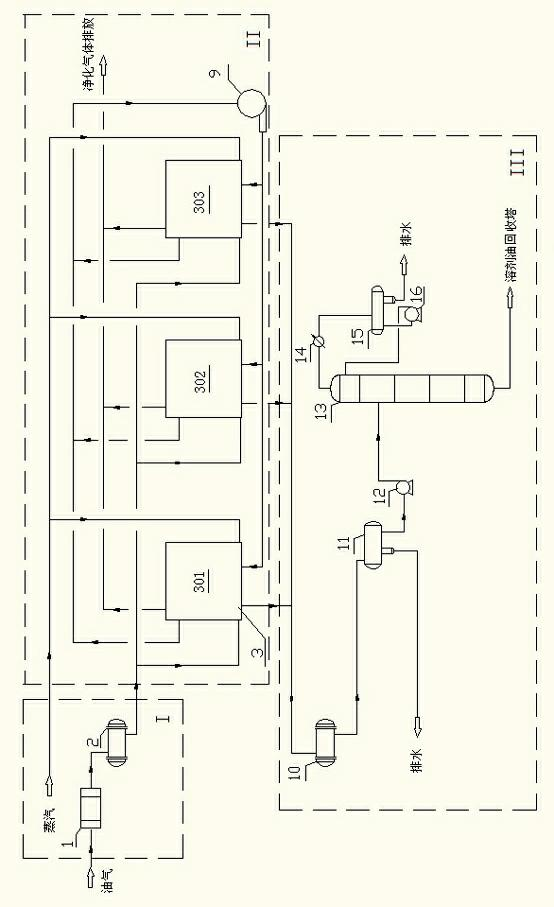

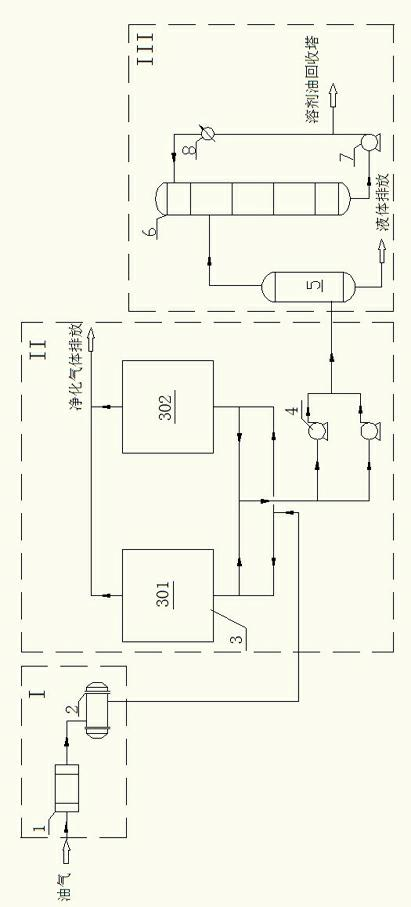

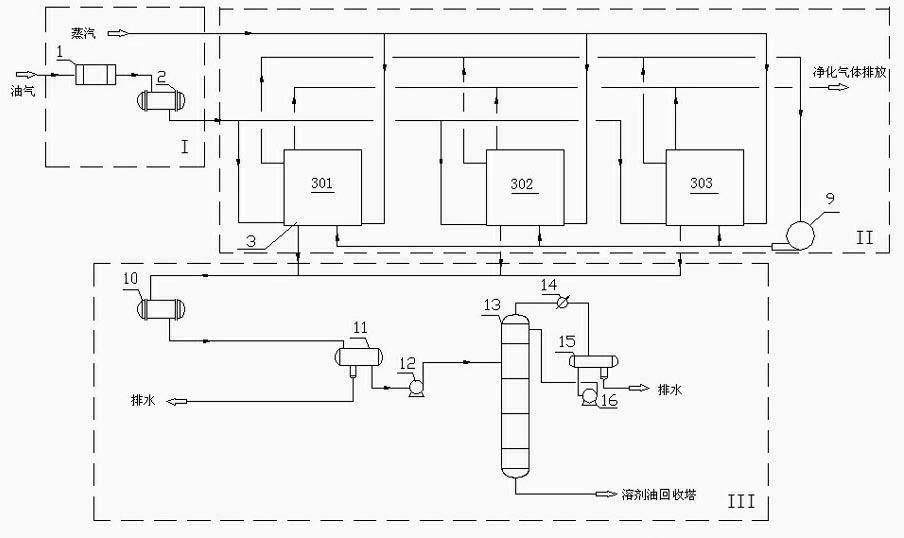

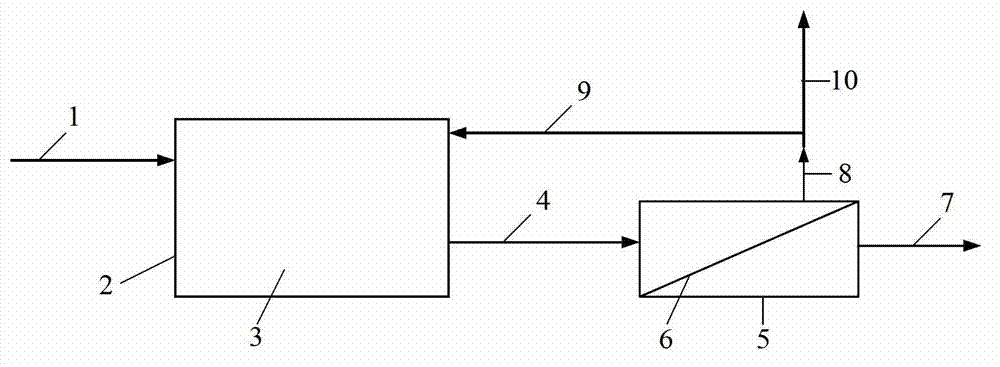

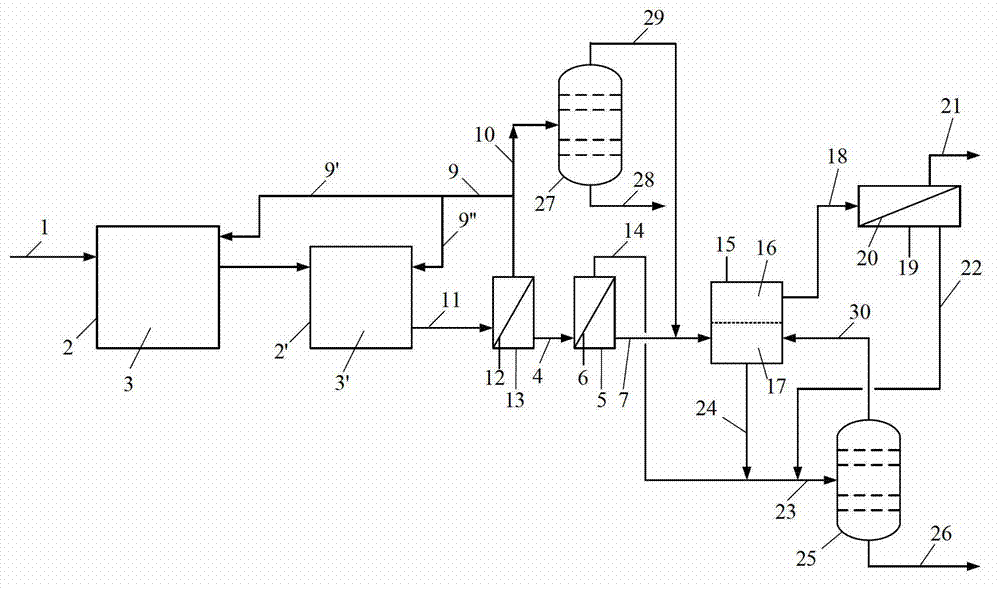

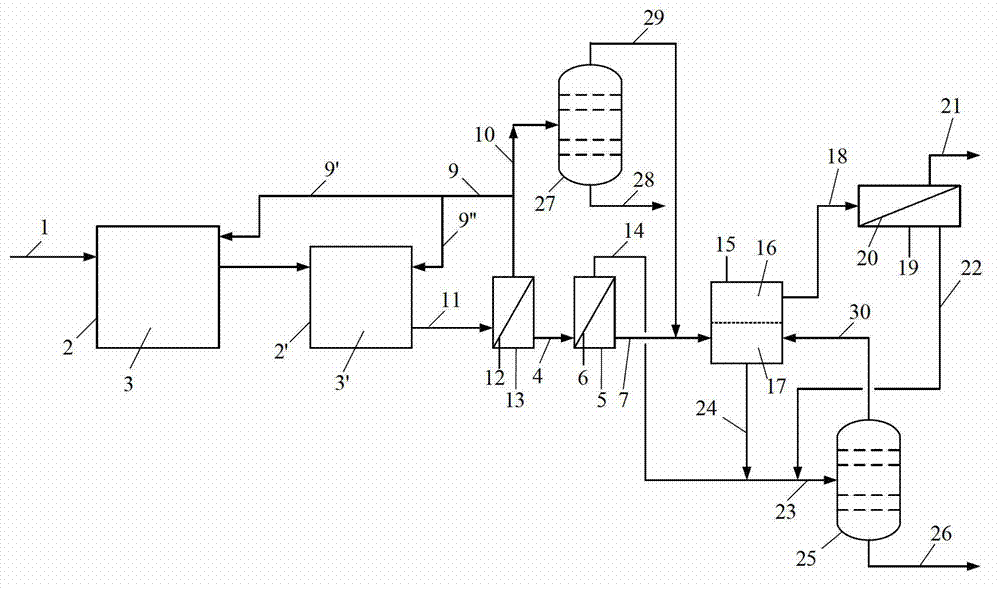

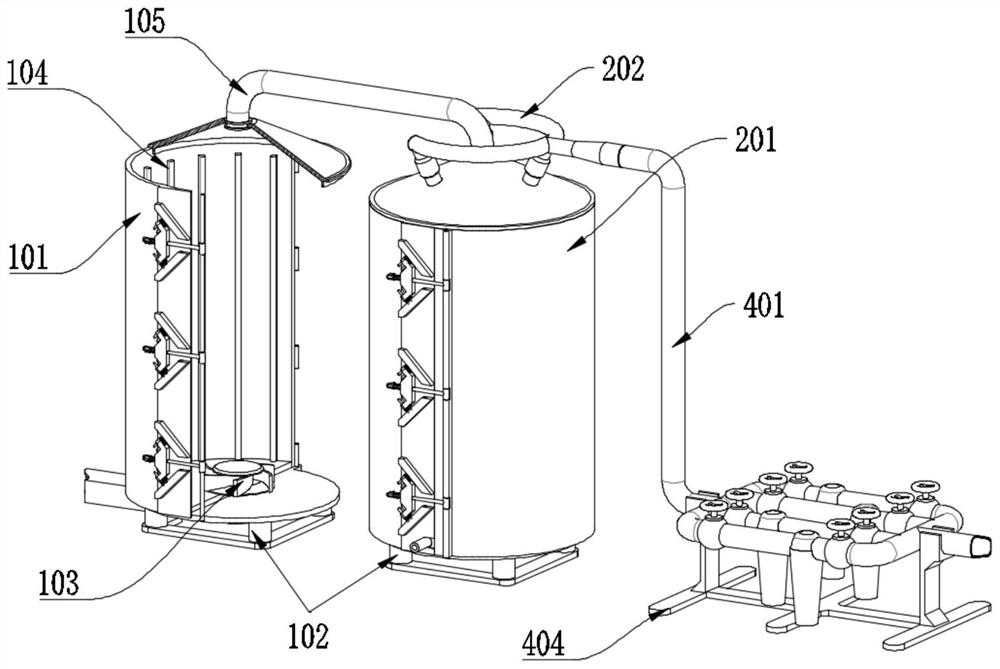

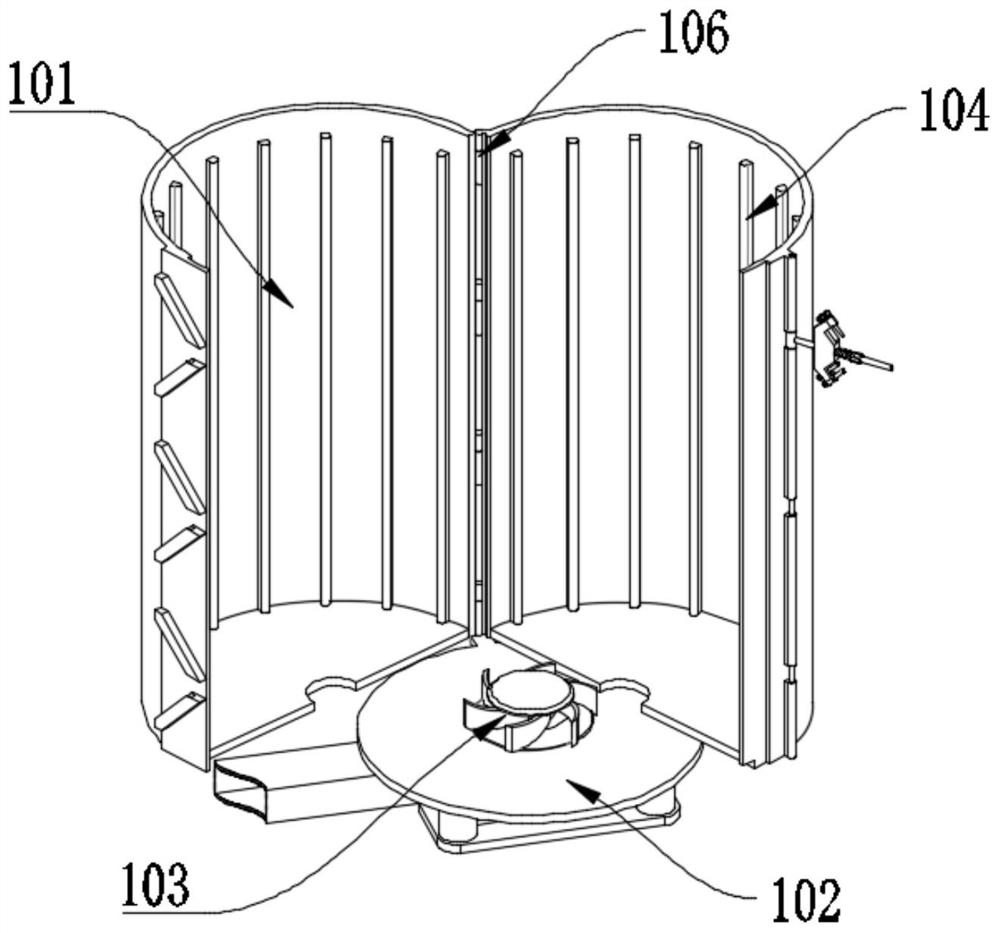

Technology and system for recycling solvent oil from oil gas of butadiene prepared from butane under oxidative dehydrogenation effect

ActiveCN102527186ASimple processSimple and efficient operationDispersed particle separationSolventProcess engineering

The invention relates to a technology and a system for recycling solvent oil from oil gas of butadiene prepared from butane under an oxidative dehydrogenation effect. The technology comprises the following steps: 1) utilizing a fine oil gas filter to filter a catalyst in the oil gas and utilizing an oil gas cooler to cool the oil gas; 2) causing the cooled oil gas to enter into an adsorption / desorption device, adsorbing the solvent oil in the oil gas, and desorbing after fully adsorbing, thereby obtaining desorbed gas of the solvent oil; and 3) separating the solvent oil from the desorbed gas of the solvent oil by utilizing a separating jar, recycling and reusing. The recycling system comprises a preprocessing system, an adsorption / desorption system and a recycling device, wherein the adsorption / desorption system is capable of alternately adsorbing and desorbing or adsorbing, desorbing and drying. The technology has the advantages that the technology is simple; the operation is convenient; the recycling rate of the solvent oil is high; the emission concentration of the oil gas is low; the potential safety hazard is eliminated; the emission load of the oil gas is controlled; the clean production, energy saving and environmental protection are realized; the whole recycling process is continuous; the adsorption efficiency is increased; the solvent oil is recycled from the oil gas; the solvent oil is reused; and the production cost of the butadiene is saved.

Owner:中国石油集团东北炼化工程有限公司锦州设计院

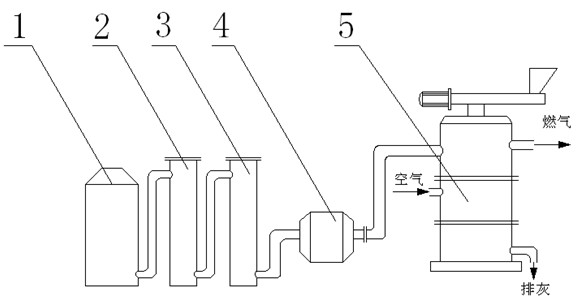

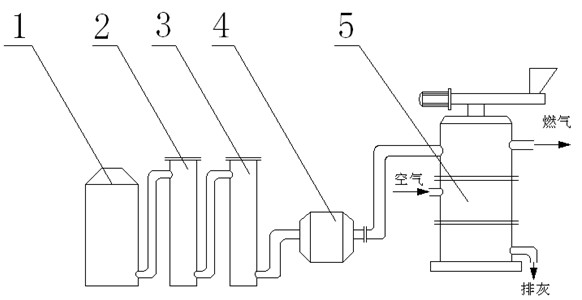

High-temperature cracking system for tar in biomass fuel gas

The invention relates to a high-temperature cracking system for tar in biomass fuel gas. The system comprises a tar collection tower, wherein the outlet of the tar collection tower is connected with a liquid tar conveyer which is connected with a gasification furnace. The invention can realize centralized recycling of the waste tar, improves the tar utilization rate, facilitates production, ensures low manufacturing cost and is suitable for large-scale application.

Owner:山东百川同创能源有限公司

Continuous condensing recovery device for liquid oil of oil field gas

InactiveCN104436744AContinuous recyclingReduce cooling lossVapor condensationGas pipelineRefrigerant

The invention discloses a continuous condensing recovery device for liquid oil of oil field gas. The device comprises a gas inlet pipe, main and auxiliary condensing heat exchangers as well as oil discharge pipes, wherein a gas circuit switching valve is arranged on the gas inlet pipe, the gas inlet pipe is communicated with upper ends of oil field gas pipelines arranged in the main and auxiliary condensing heat exchangers, lower ends of the oil field gas pipelines are communicated with the oil discharge pipes, water discharge pipes and gas discharge pipes respectively, heat-exchange liquid pipelines contacted with the oil field gas pipelines are arranged in the main and auxiliary condensing heat exchangers and provided with inlet / outlet pipes, the inlet / outlet pipes are communicated with refrigerant circulating systems and high-temperature condensing agent circulating systems respectively through switching valves, and gas-liquid separators are arranged on the gas discharge pipes. According to the continuous condensing recovery device for the liquid oil of the oil field gas, one of the main and auxiliary condensing heat exchangers performs condensing recovery, the other one performs defrosting, the main and auxiliary condensing heat exchangers are alternately switched for use, and continuous condensing recovery of the liquid oil is realized.

Owner:WUXI YUDA HEAT EXCHANGER

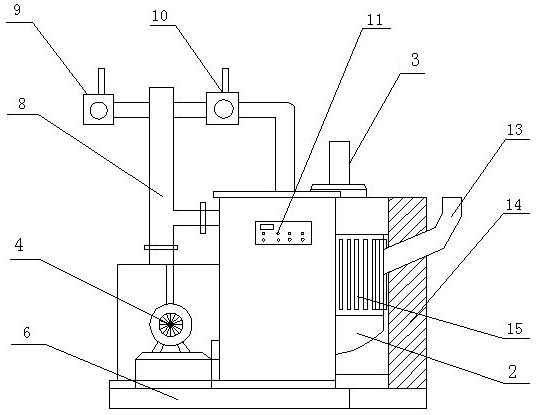

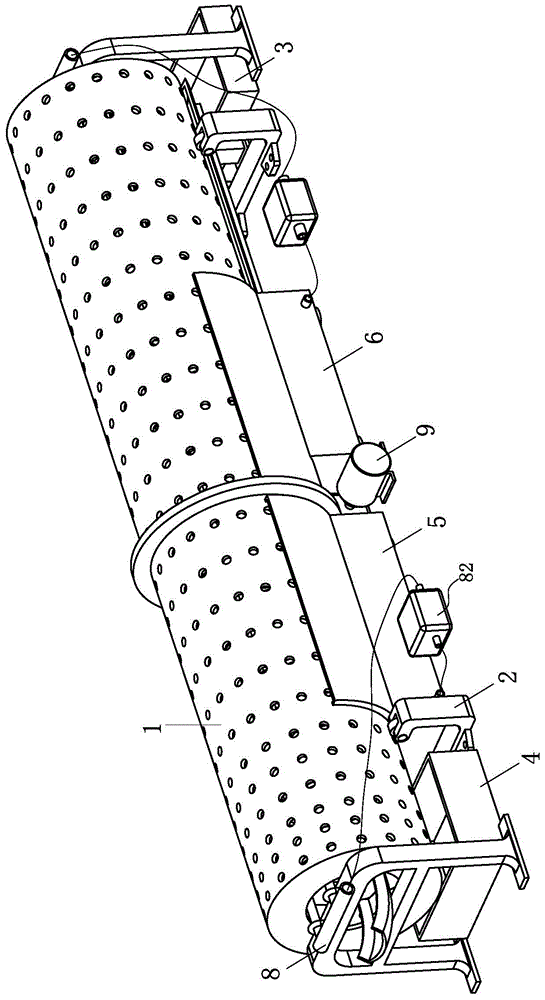

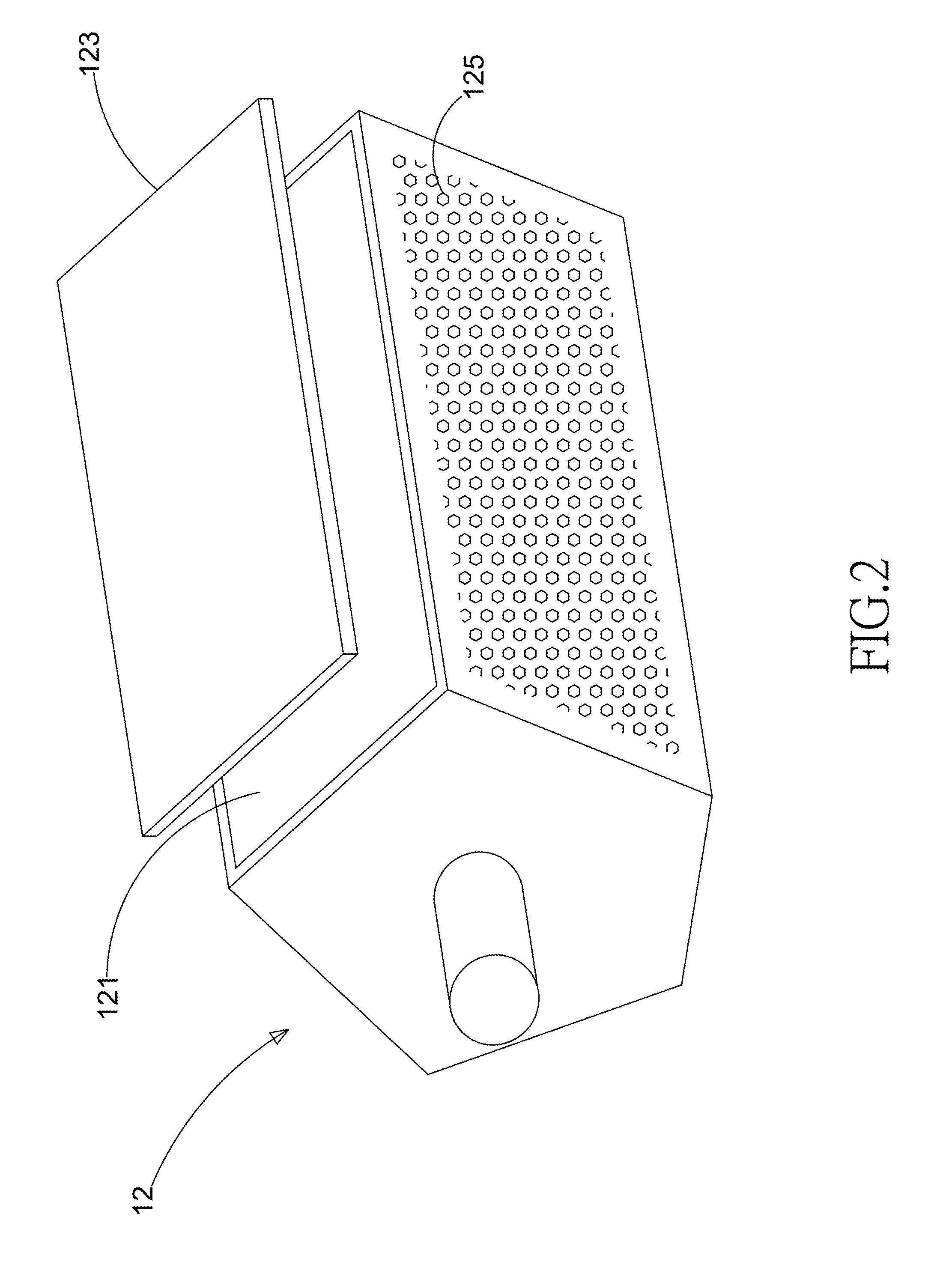

Bearing cleaning and drying equipment

InactiveCN104923509AQuality assuranceNo dead endsDrying machines with progressive movementsCleaning using liquidsReducerWater spray

The invention relates to the technical field of cleaning equipment, in particular to bearing cleaning and drying equipment. The bearing cleaning and drying equipment comprises a rotating cylinder, two supporting seats, a material receiving bin, a waste residue storage tank, a cleaning fluid storage tank, a clear water circulating tank, a drying device, a spraying device and a power device. The rotating cylinder is located on the two supporting seats, and the material receiving bin is arranged on the right side of the rotating cylinder. The waste residue storage tank, the cleaning fluid storage tank and the clear water circulating tank are sequentially distributed below the rotating cylinder, and the drying device used for drying is located in the right side of the rotating cylinder. The water spraying device penetrates through the interior of the rotating cylinder. The power device comprises a large friction wheel, a small friction wheel, a speed reducer, a coupler and a motor, wherein the large friction wheel is fixed to the rotating cylinder, and the power device is used for driving the rotating cylinder to rotate. The bearing cleaning and drying equipment can carry out sundry removing, cleaning and drying on bearings, the problem of an equipment fault caused by waste scrap iron mingled in the cleaning fluid can be solved, continuous work can be achieved, a large amount of labor force can be saved, and the production cost can be reduced.

Owner:ANHUI BAIJI ELECTROMECHANICAL TECH

Pollution-free domestic sewage treating process

InactiveCN102557337AEasy to handlePromote recoveryWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFluidized bedNitration

The invention discloses a pollution-free domestic sewage treating process. The process comprises the following steps of: 1, performing solid and liquid crude separation on sewage in a solid and liquid separator; 2, adding a flocculating agent and magnetic seeds into the sewage subjected to solid and liquid separation, putting into a stirrer, and uniformly stirring; 3, adding a coagulant aid into the stirred sewage; 4, importing the sewage into a biological membrane nitration reaction fluidized bed for biological treatment; 5, introducing ozone for disinfection; and 6, adding into a fiber membrane filter, and finely filtering. By the process, a plurality of processes are used for treating the sewage, so that the sewage can be effectively treated, and the cost can be saved; and in addition, magnetic seed type sewage technologies are organically combined, so that the magnetic seeds can be effectively, quickly and continuously recovered, and the recovered magnetic seeds can be put into a sewage treating system again for recycling.

Owner:张荣斌

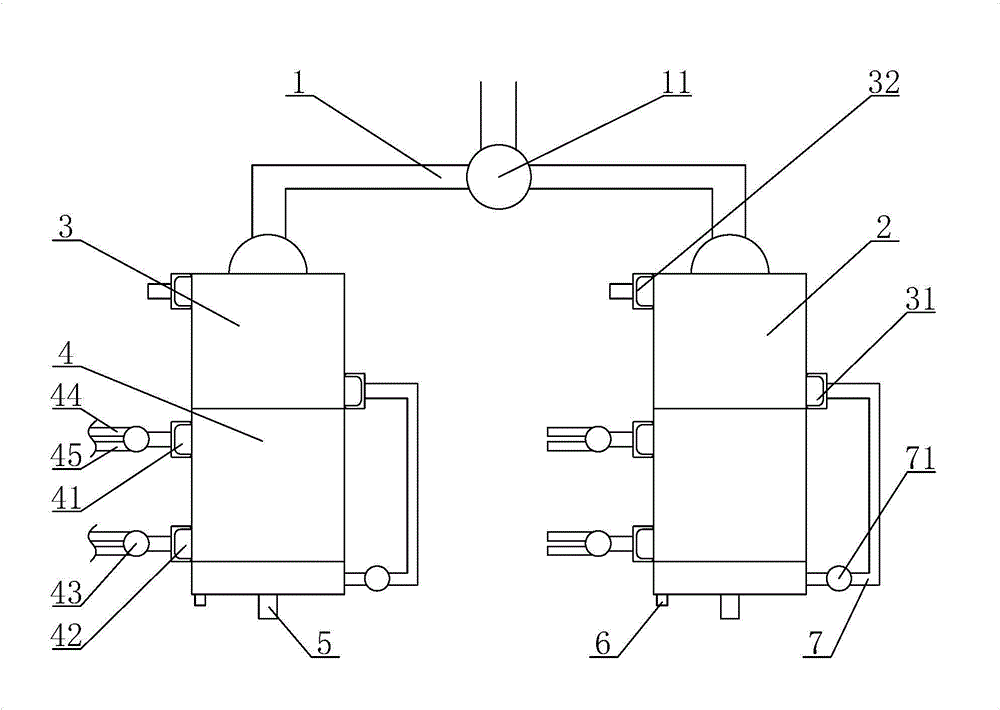

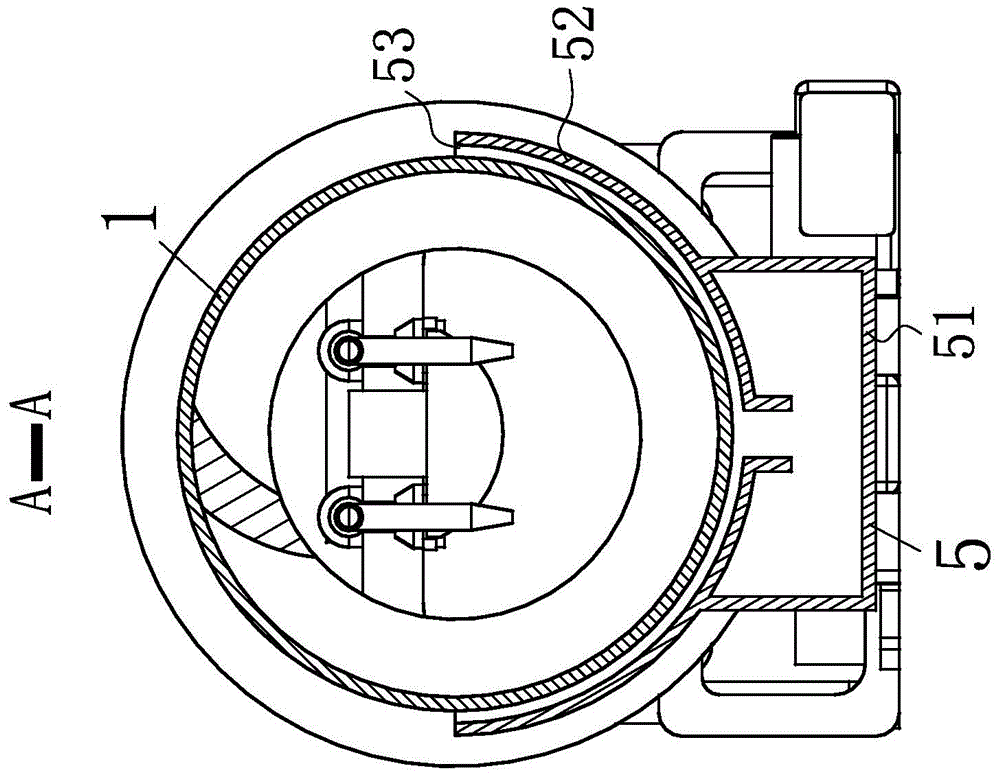

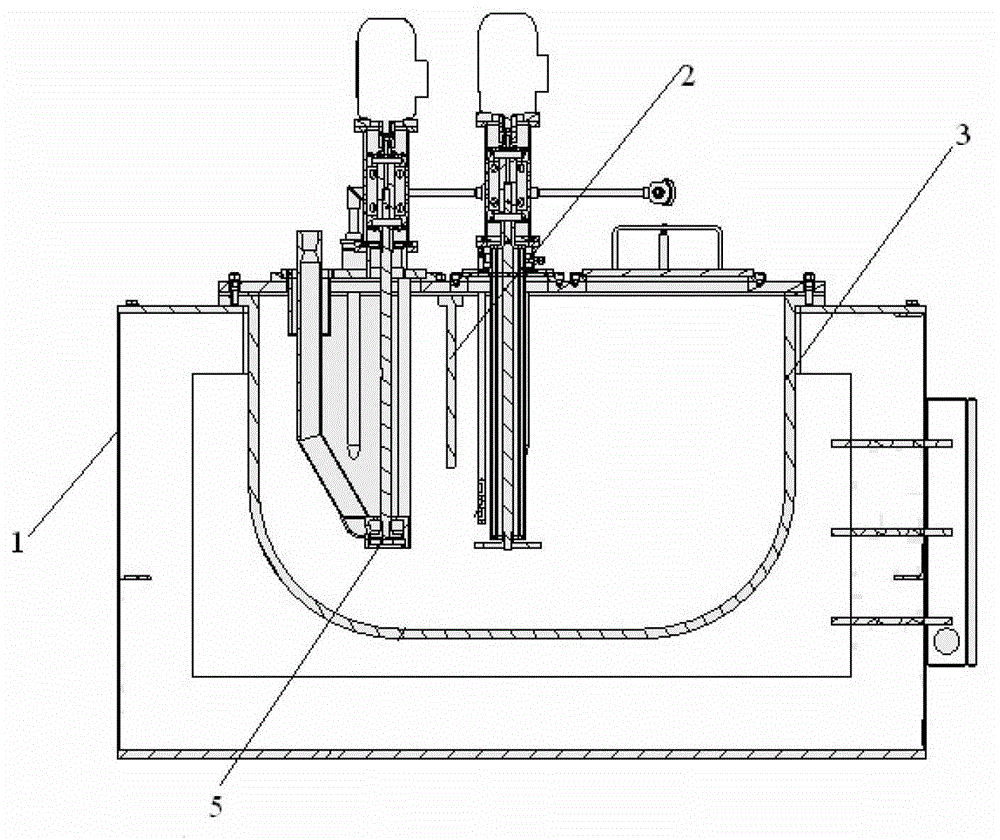

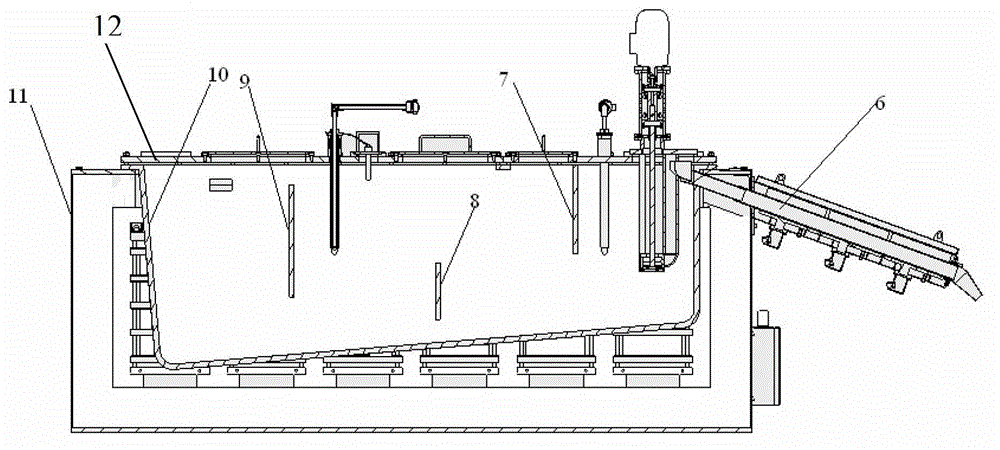

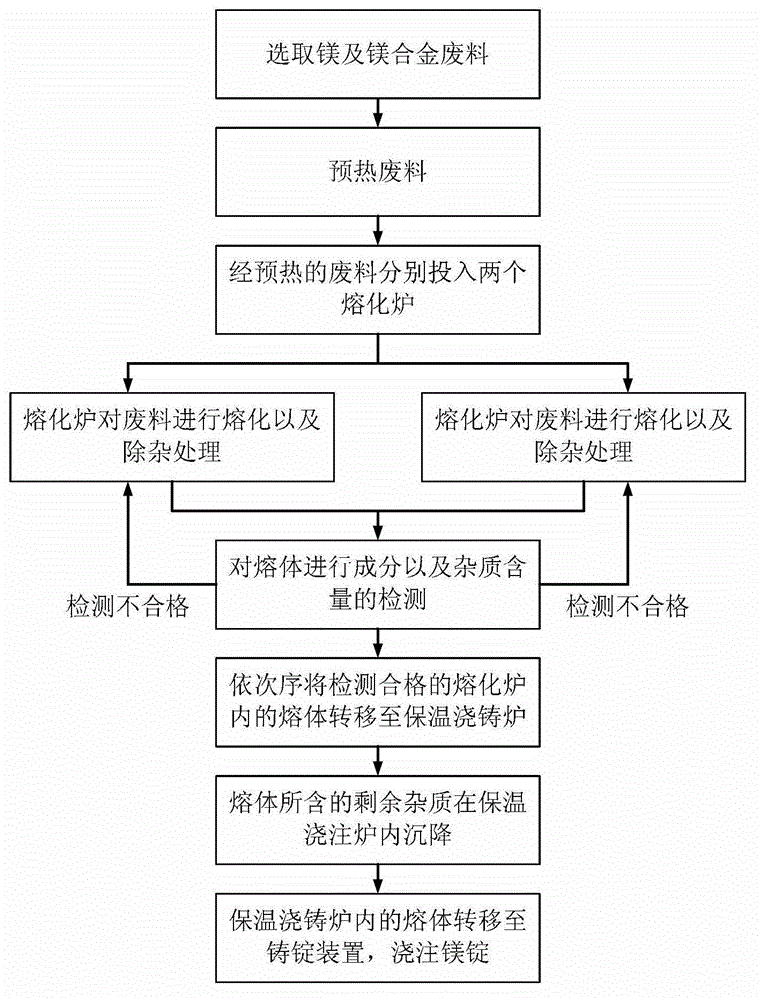

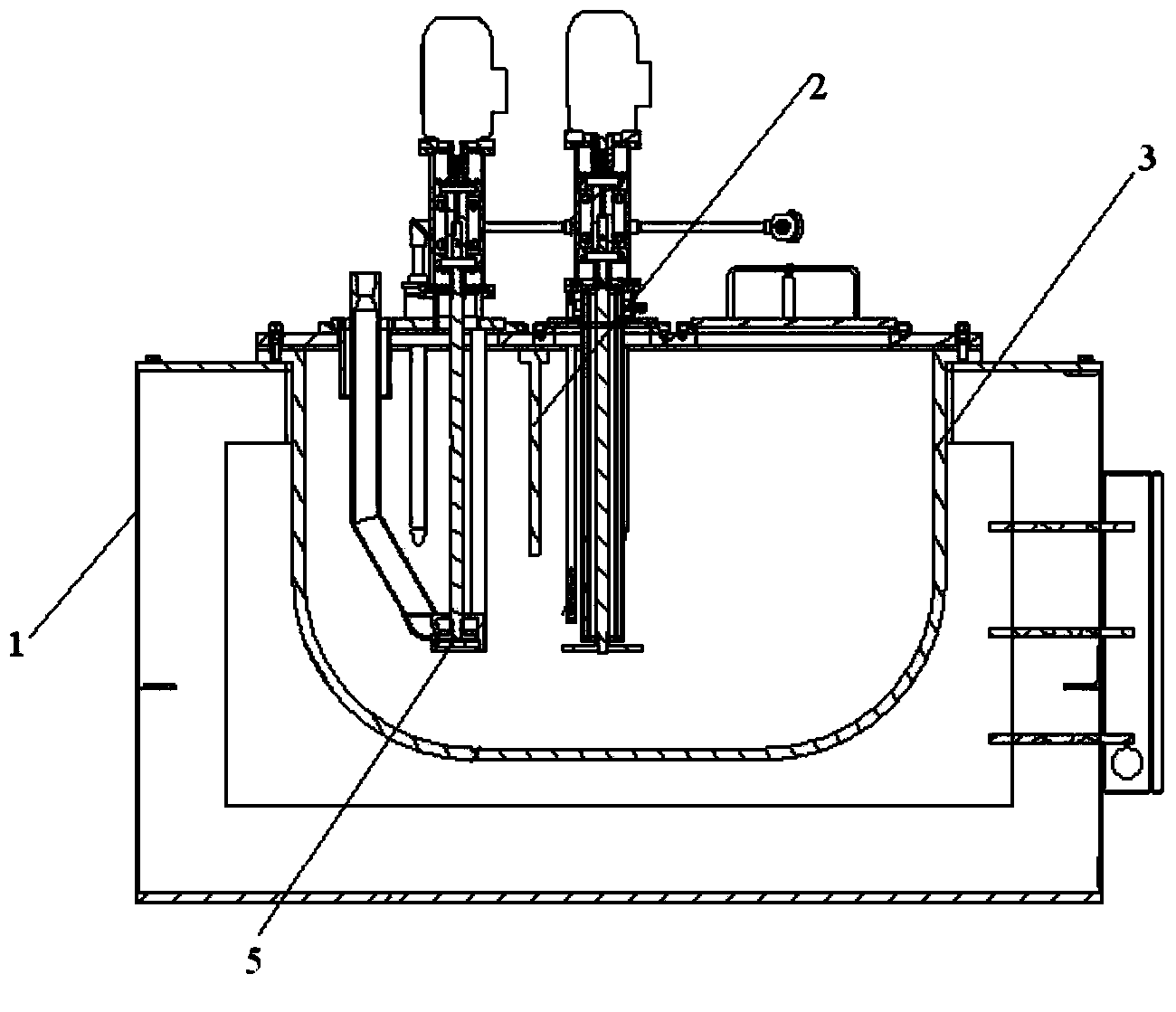

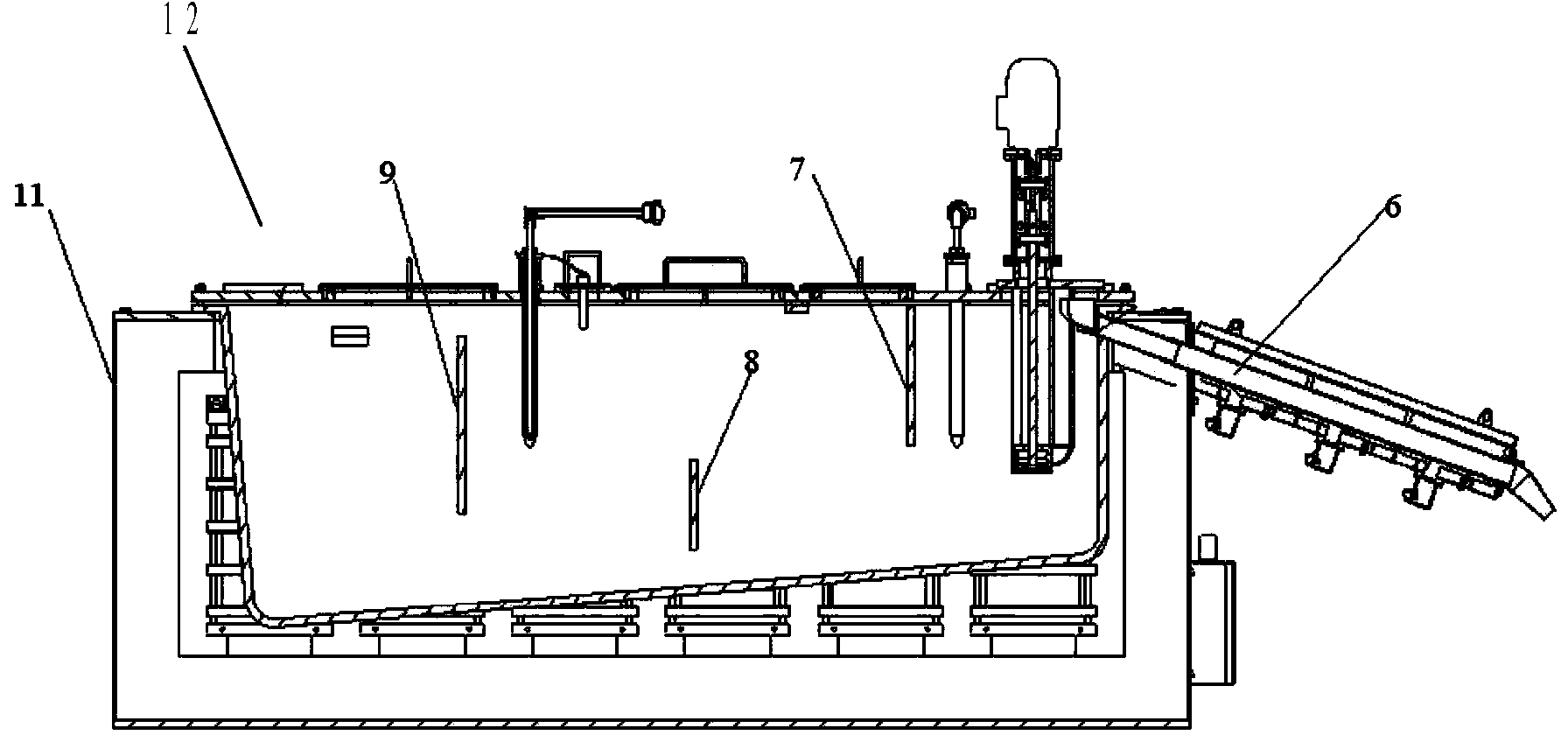

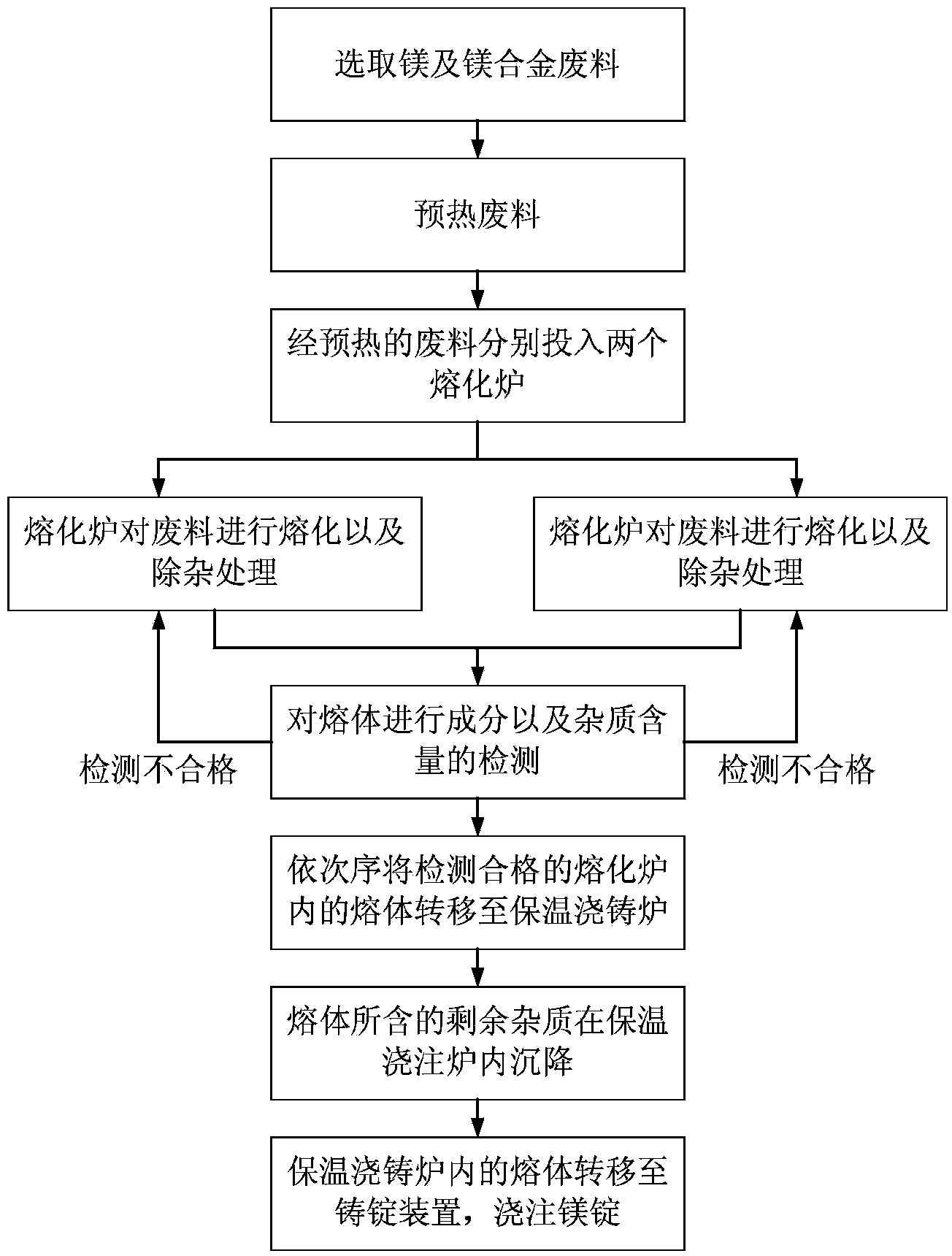

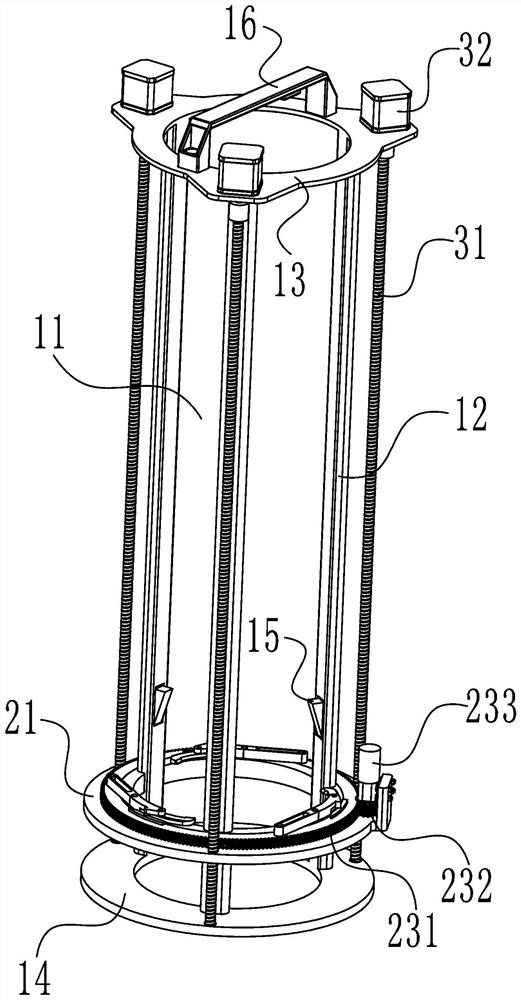

System and method for recycling magnesium and magnesium alloy waste

InactiveCN102912156AGuaranteed supplyContinuous recyclingIngot casting plantsProcess efficiency improvementCrucibleThermal insulation

The invention discloses a system and method for recycling magnesium and magnesium alloy waste. The system comprises at least one melting furnace, wherein an air intake device is communicated to the bottom of a first crucible, inert gas is blown in from the bottom of a melt, and bubbles carry impurities in the melt to a liquid level; when a melting furnace inputs the melt into a thermal insulation casting furnace, and a first liquid outlet pipe is communicated to the part, close to the bottom, of the first crucible so as to ensure that the melt can not carry over the impurities; and a small amount of impurities are still contained in the melt after the impurities are removed, and the impurities are settled at a position, close to a feeding hole, inside the thermal insulation casting furnace, so as to ensure that the impurities settled at the bottom of a second crucible can not be carried over when the melt is transferred toward an ingot casting device, so that the impurity removing effect and efficiency are guaranteed. When the thermal insulation casting furnace transfers the melt toward the ingot casting device, at least one melting furnace completes impurity removing treatment, the melt is transferred toward the thermal insulation casting furnace, feeding to the ingot casting device is guaranteed, a continuous recycling process is realized, and the production efficiency is improved.

Owner:天津镁特威科技有限公司

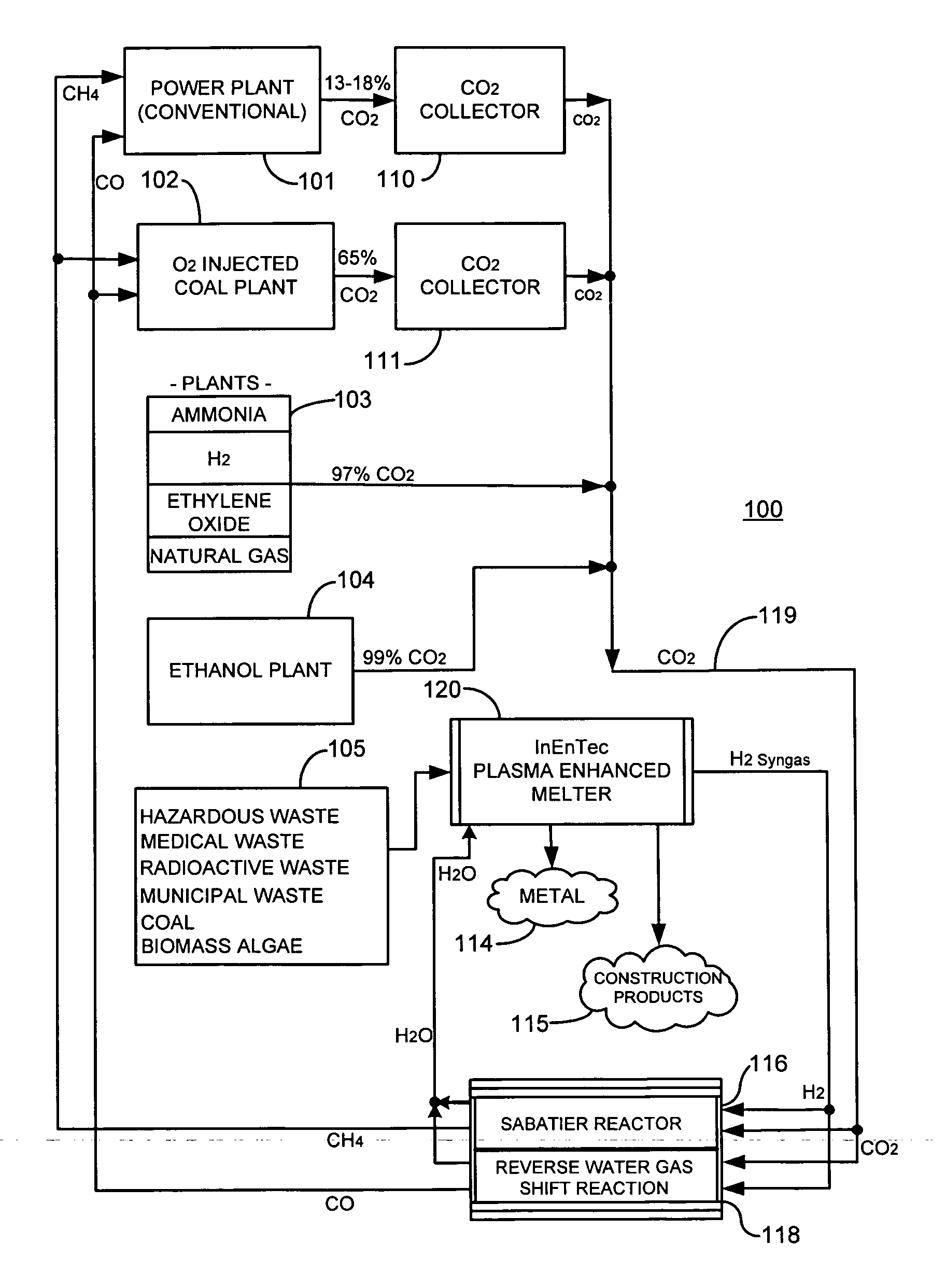

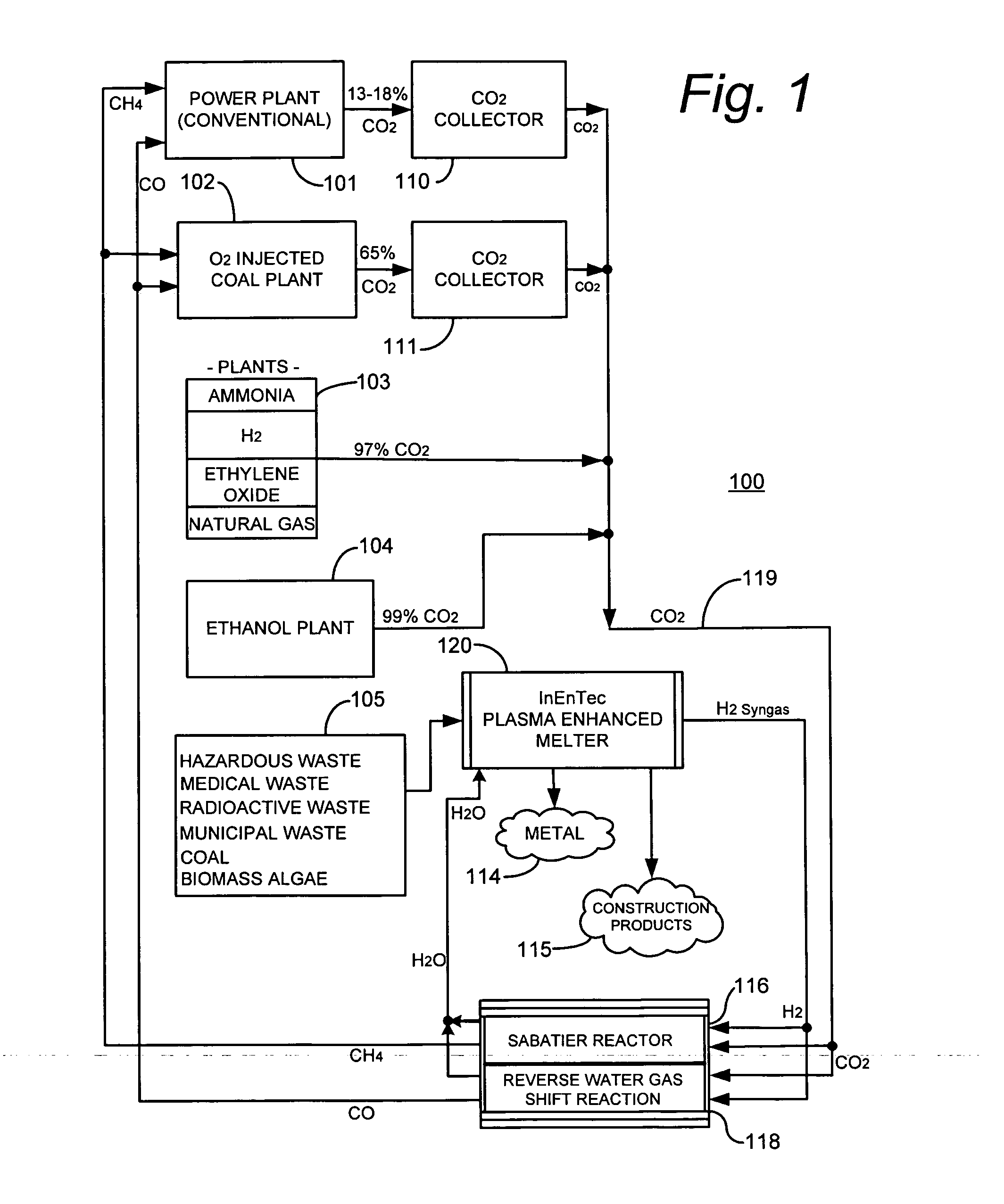

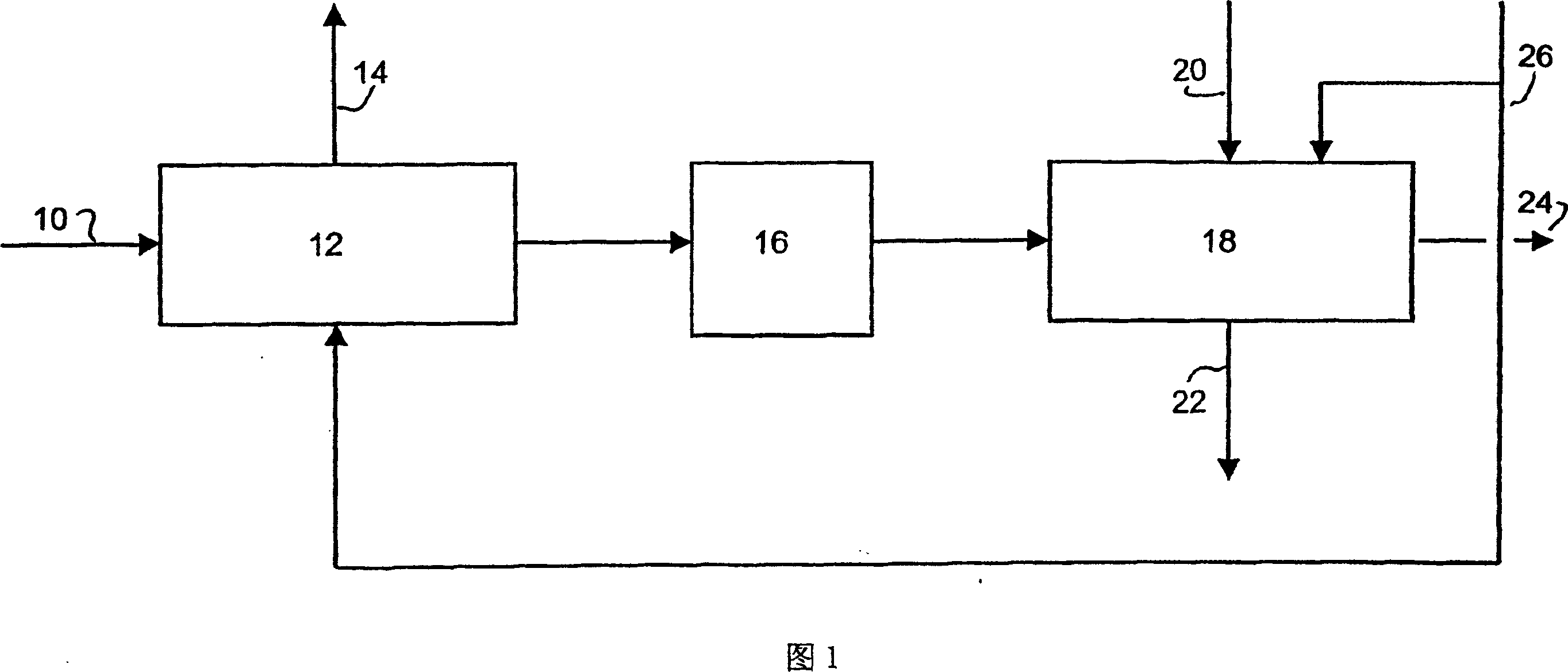

Recyling and reburning carbon dioxide in an energy efficient way

InactiveUS20110250100A1High conversion rate of methaneEasy to disassembleProductsReagentsSyngasCarbon footprint

A system for converting carbon dioxide into a fuel to be re-burned in an industrial process. The preferred feed stocks are taken from large volume carbon dioxide producers, and municipal waste. The reaction and processes reclaim lost energy in municipal waste, and industrial exhaust gas. The system is provided with a plasma melter having a feedstock input for receiving a feed fuel, and a syngas output for producing a syngas having an H2 component. Additionally, a Sabatier reactor is provided having a hydrogen input for receiving at least a portion of the H2 component produced by the plasma melter, and a methane output for producing CH4. The process has a large negative carbon footprint.

Owner:JURANITCH JAMES CHARLES

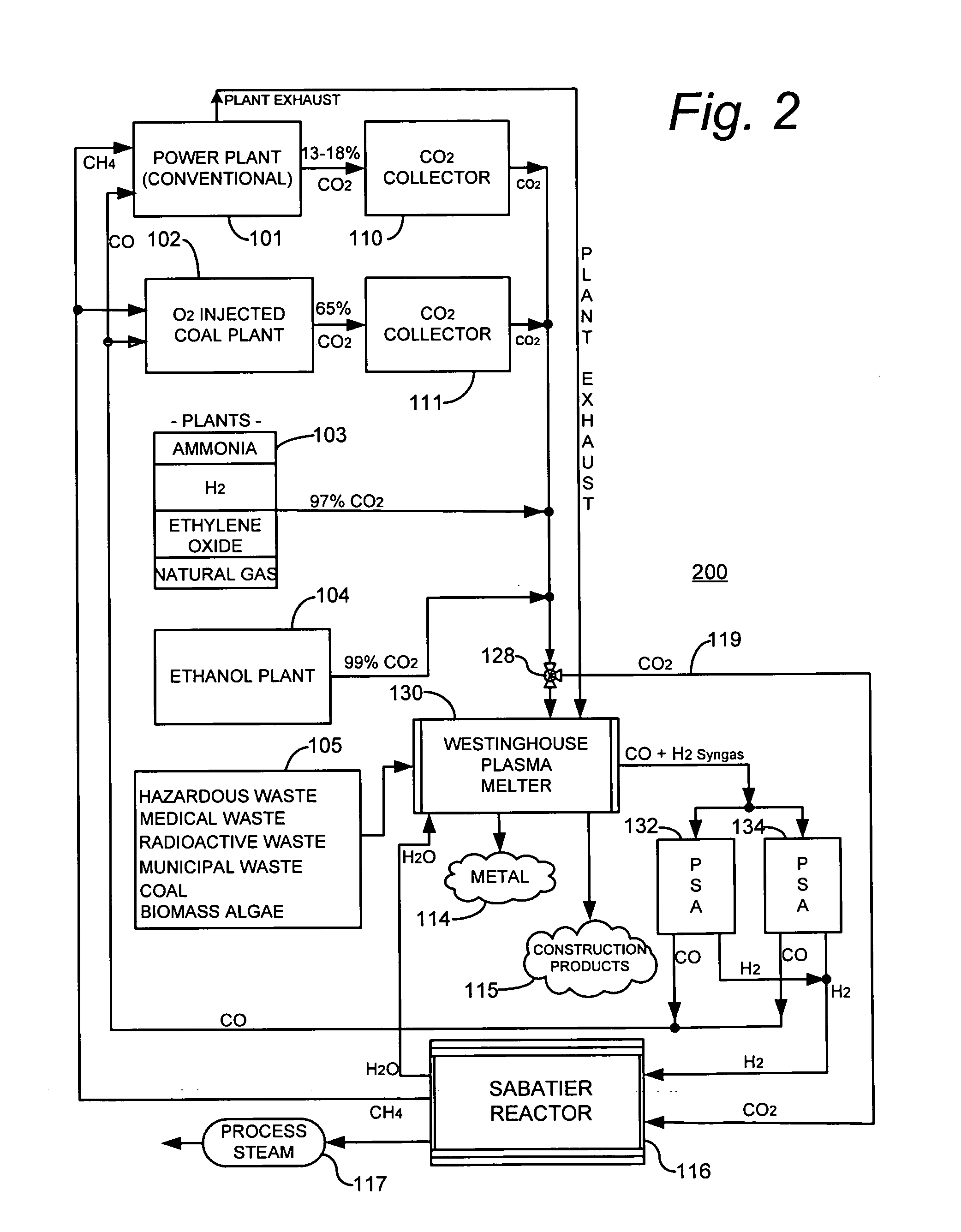

Mulching film recycling device

The invention relates to a mulching film recycling device, and belongs to the technical field of agricultural machinery. The mulching film recycling device is composed of a rack, a residual film conveying tooth rake, and a film collecting box; a film raking roller and the film collecting box are arranged on the rack; an auxiliary film collecting roller is arranged on the rack at the front end of the film raking roller; and the residual film conveying tooth rake is arranged on the rack above the auxiliary film collecting roller. The mulching film recycling device can recycle mulching films into the film collecting box. In the mulching film recycling process, the films are raked through elastic teeth of the film raking roller, the flaky mulching films are picked up one by one, and therefore the mulching films are recycled and are not prone to being missed, and the recycling rate can be effectively increased. In the rotating process, the elastic teeth clean an elastic tooth shaft and a main shaft, so that the mulching films are not prone to being attached to and wound around the elastic teeth, then the mulching films can be continuously recycled, the problems that an existing plastic film residue recycling machine is prone to winding and hanging the mulching films, cannot work continuously and is low in recycling rate are solved, and the device is particularly suitable for recycling the mulching films.

Owner:YANGTZE UNIVERSITY

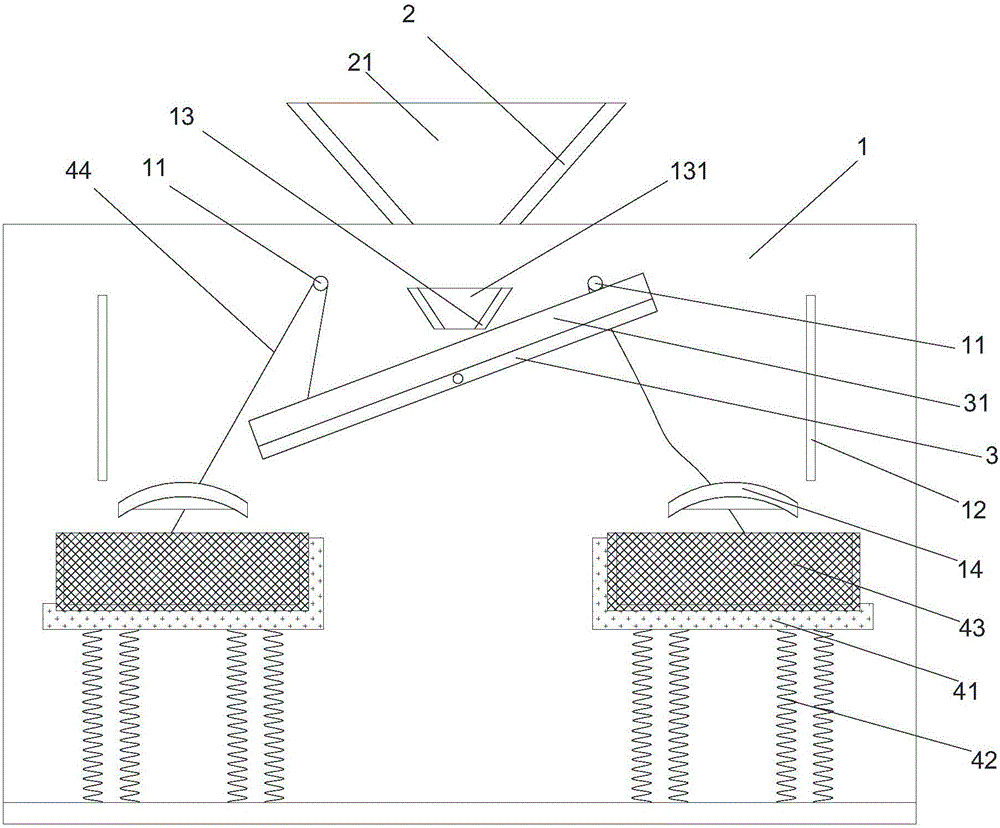

Novel loach egg recovery device

ActiveCN105918181AImplement extractionContinuous recyclingClimate change adaptationPisciculture and aquariaEngineeringElectrical and Electronics engineering

The invention provides a novel loach egg recovery device. The device comprises a rack, a liquid collection frame, a flow guide frame and two egg storage mechanisms, wherein the liquid collection frame is mounted on the rack; a liquid guide through hole is vertically formed in the liquid collection frame; a flow guide groove is formed in the upper part of the flow guide frame, and two flow guide frame rotation limiting rollers are mounted on the rack; each egg storage mechanism comprises a carrier, a reset part, an egg storage box and a traction rope, the carrier is movably mounted on the rack and moves in the vertical direction, the reset part is connected with the carrier and the rack, a holding groove is formed in the upper part of the carrier, the egg storage box is arranged on the carrier and corresponds to the holding groove, multiple water drainage holes are formed in the egg storage box, the diameter of each water drainage hole is not larger than 0.7 mm, and the first end of the traction rope is connected with the carrier; two liquid baffles are arranged on the rack and mounted above the two egg storage boxes. The novel loach egg recovery device is simple in structure and can be used for efficient recovery of loach eggs.

Owner:SUSONG FUMIN AQUATIC PROD CULTURE CO LTD

Process and adsorbent for the recovery of krypton and xenon from a gas or liquid stream

Xenon and / or krypton are recovered from oxygen containing gas, typically derived from liquid oxygen bottoms in a cryogenic air separation plant, by selective adsorption on a Li and Ag exchange zeolite containing 5 to 40% Ag exchange capacity on an equivalents basis, with periodic thermal regeneration of the adsorbent.

Owner:AIR PROD & CHEM INC

Water-washable masking coating solution for post-processing shoe sole and method for using coating solution

InactiveUS20170112239A1Improve productivityEasy to disassembleShoemaking devicesInsolesLaser etchingEngineering

The present invention is to develop a wet masking coating solution which is used to protect a shoe sole from contaminants and dust generated during a post-processing treatment of the shoe sole, such as laser etching or hot knife. The present invention proposes a water-washable masking coating solution for post-processing a shoe sole which can be perfectly removed just when the masking coating solution dried after post-processing treatment of the shoe sole is washed with water, thereby making consecutive work and mass production possible. Moreover, the present invention proposes a method for using the water-washable masking coating solution.

Owner:PARK HEEDAE

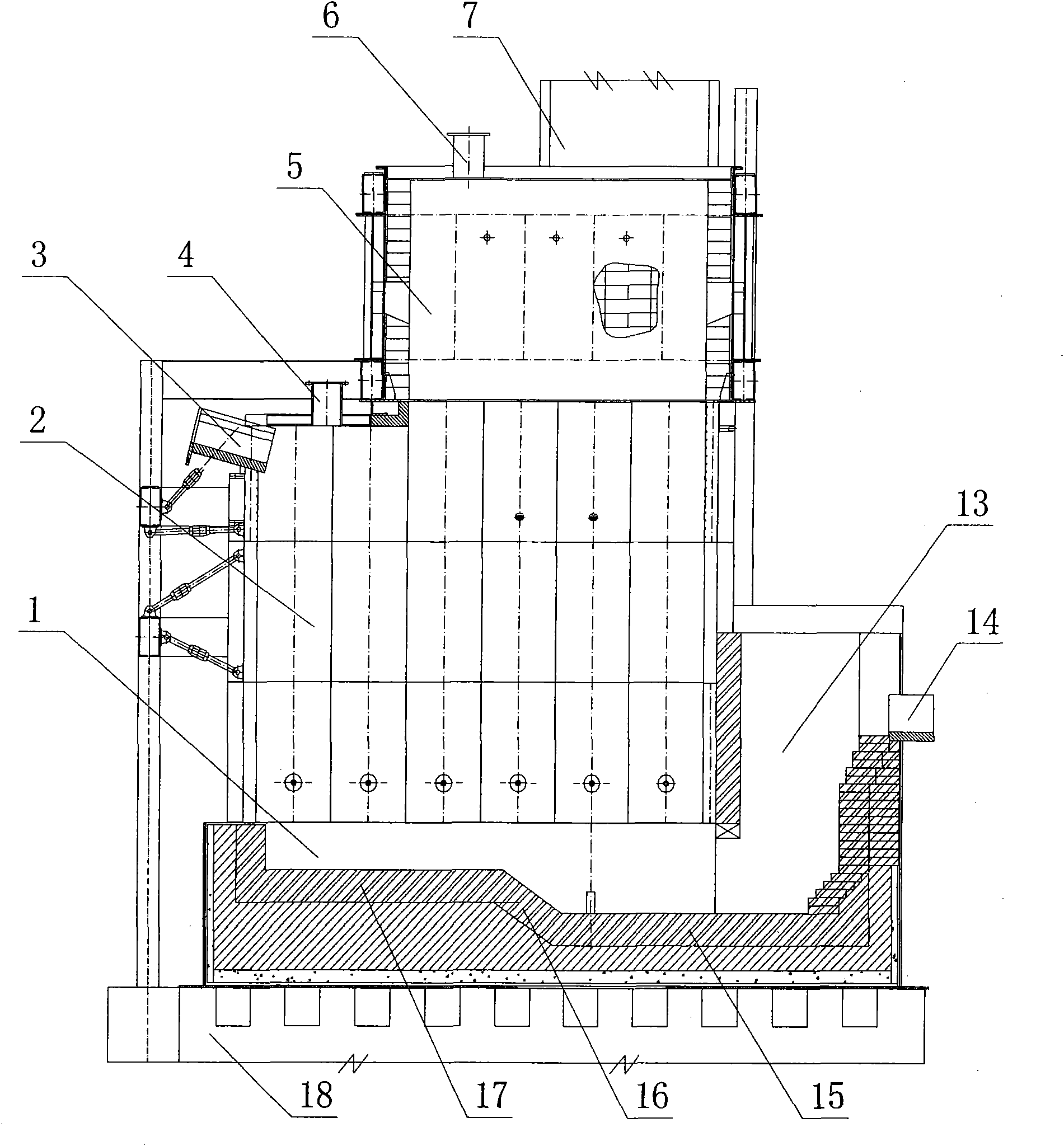

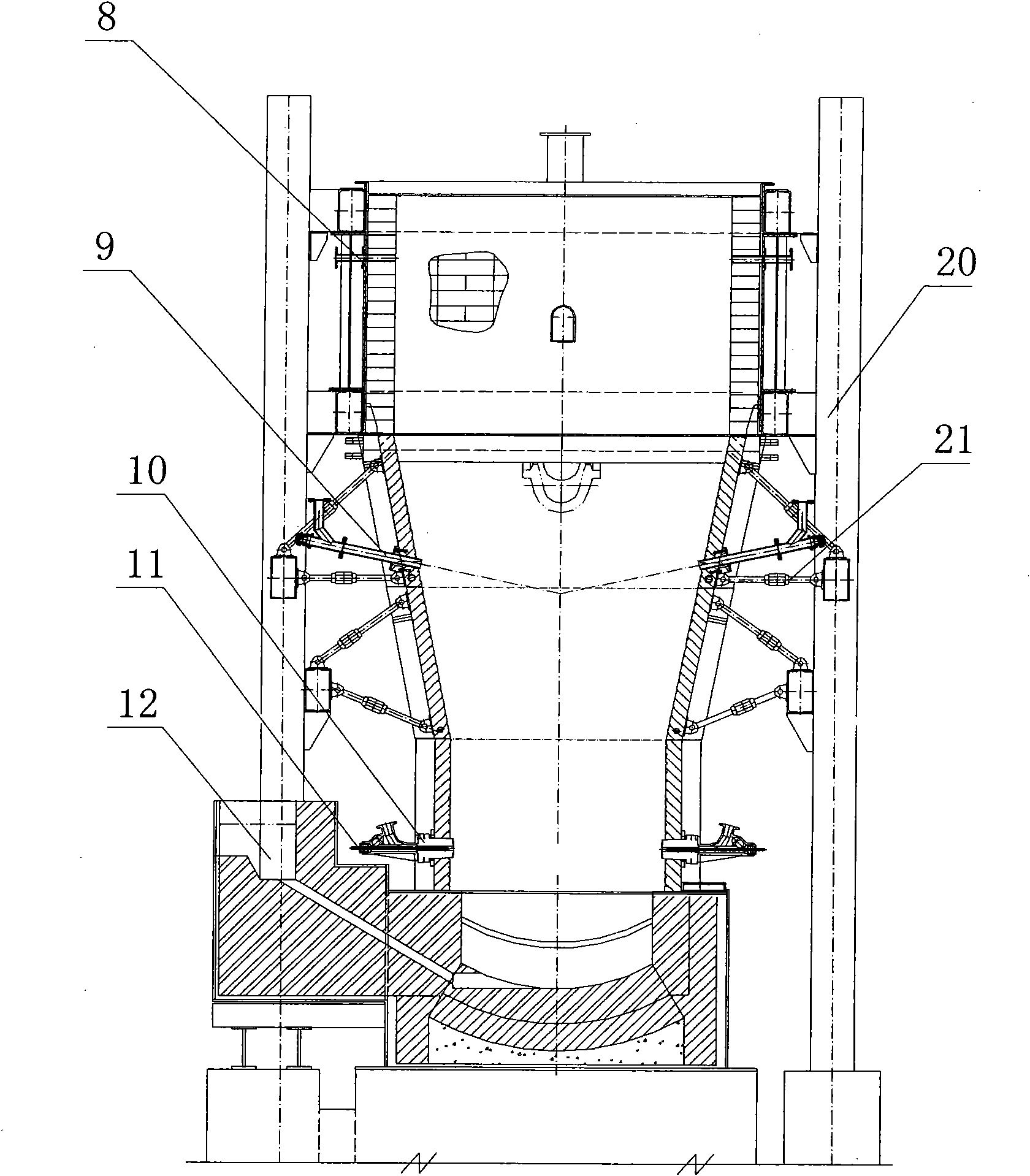

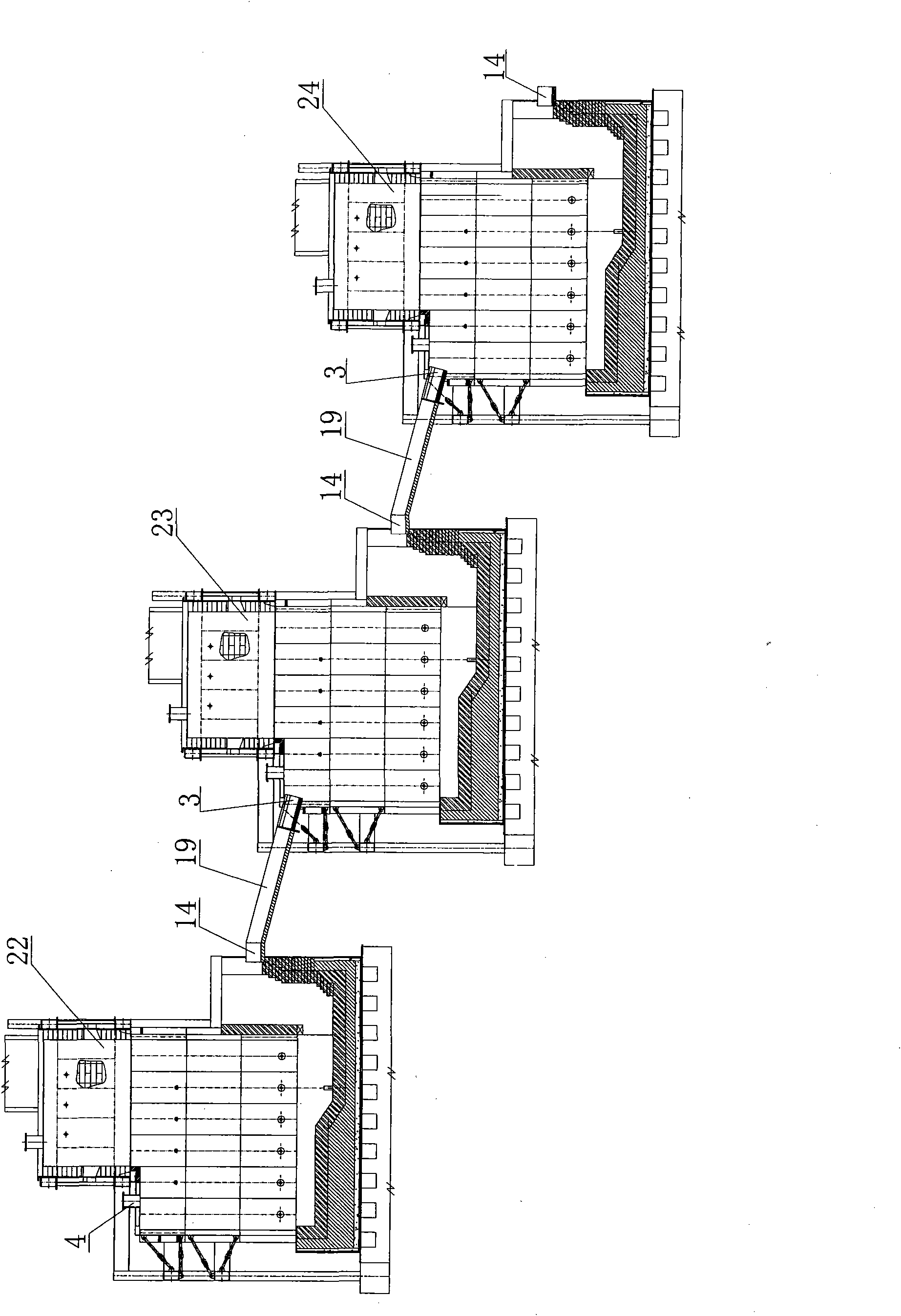

Direct lead-smelting comprehensive metallurgical device and smelting process

The invention relates to an energy-saving high-efficient direct lead-smelting comprehensive metallurgical device, which is formed by serially joining three melting bath smelting furnaces: a first furnace, a second furnace and a third furnace; and the second furnace consists of a furnace cylinder and a furnace body which is arranged on the furnace cylinder. The top part of the upper furnace body is provided with a smoke exhaust port and a standby feeding port; a charge feeding port and a slag feeding port are arranged above the lower furnace body; and the bottom part of the lower furnace body is provided with a slag siphonic water-collecting well. The furnace body is provided with three rows of supply-air outlets. The bottom part of the furnace cylinder is provided with a metal siphonic outlet. Due to the adoption of the direct lead-smelting comprehensive metallurgical device, the heat loss is small, the heat utilization rate is high, sulfuric dioxide smoke with high concentration can be produced, and the requirement for producing the acid can be more favorably satisfied; and molten high-lead thermal slag which is produced through oxidation and smelting directly flows into a reducing furnace, so the heat of the thermal molten slag can be adequately utilized. The land occupied area is small, the investment can be saved, the heat loss is less, the heat utilization rate is high, the heat energy can be adequately utilized, a great amount of energy consumption can be saved, output of smoke is small, the content of harmful ingredients in smoke is low, and the environmental pollution problem can be more effectively solved.

Owner:JIYUAN WANYANG SMELTING GROUP +2

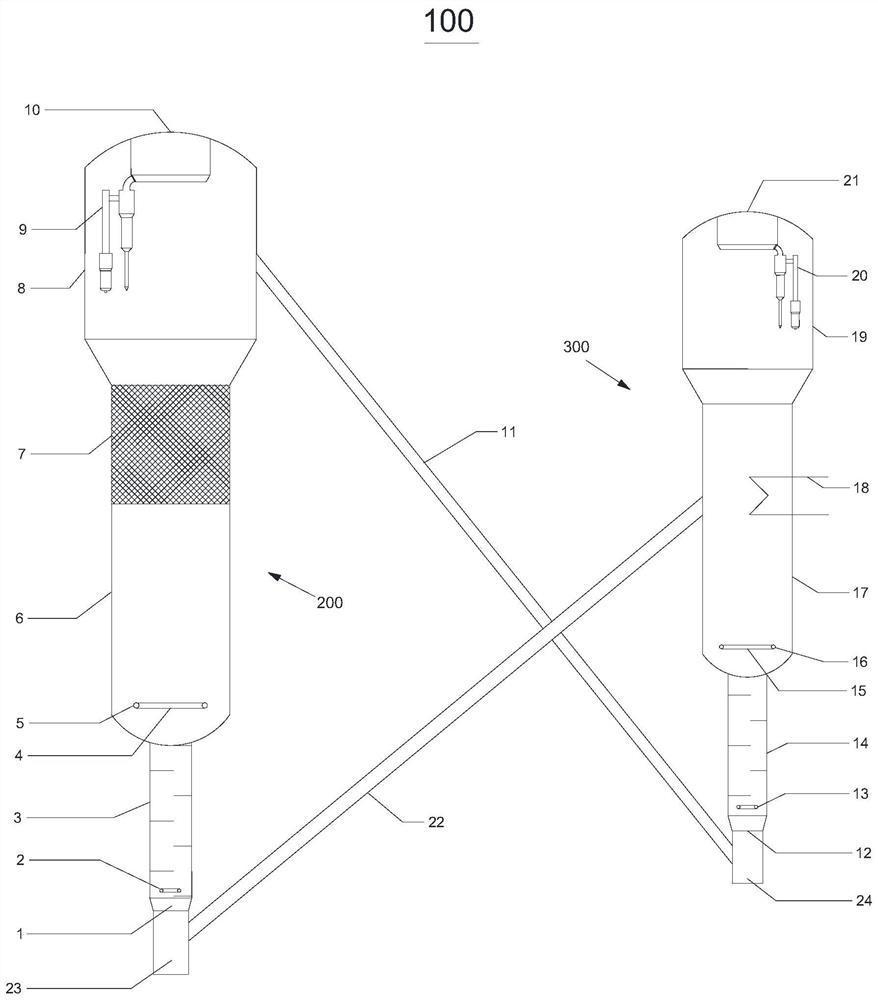

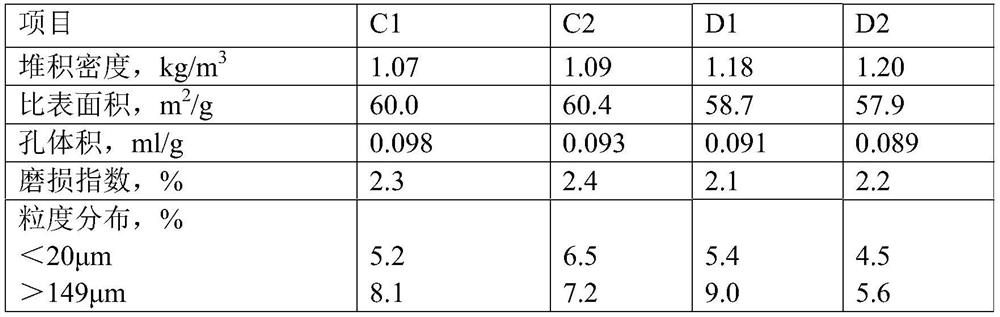

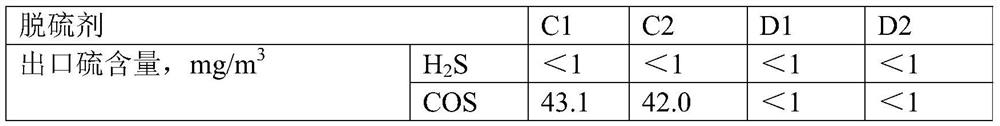

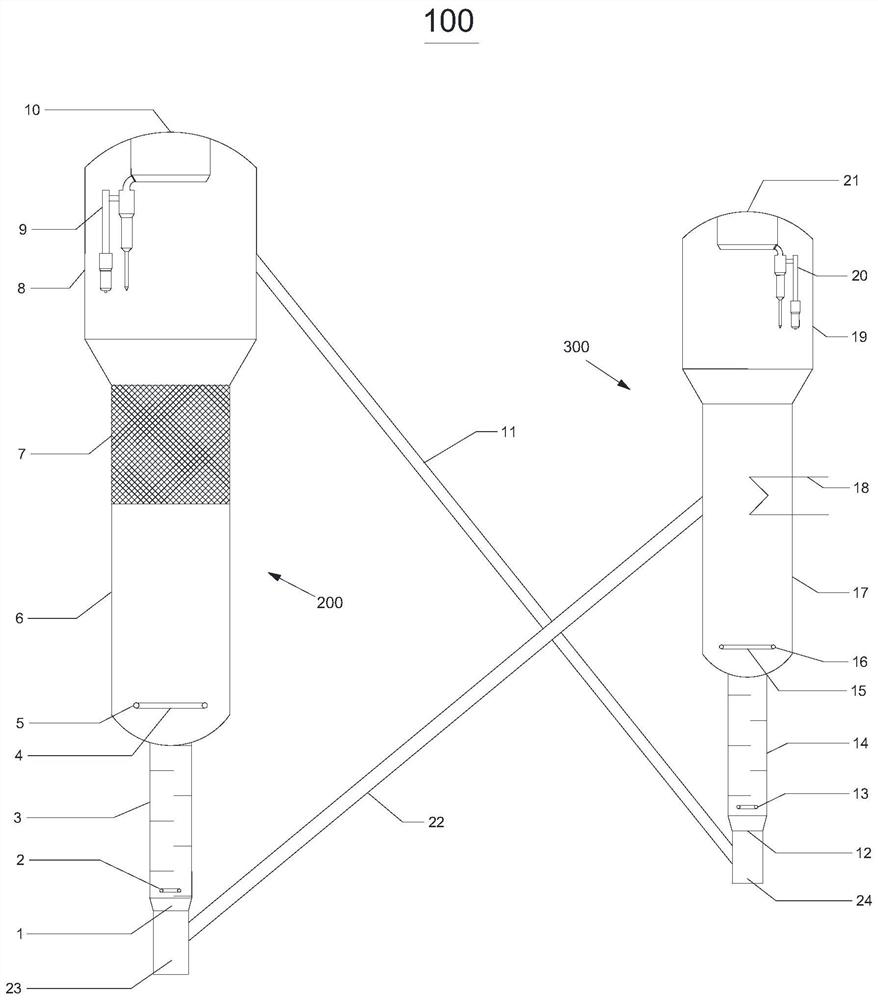

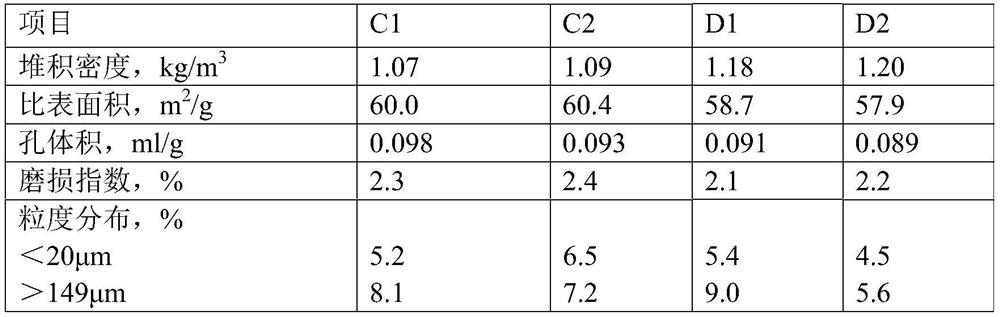

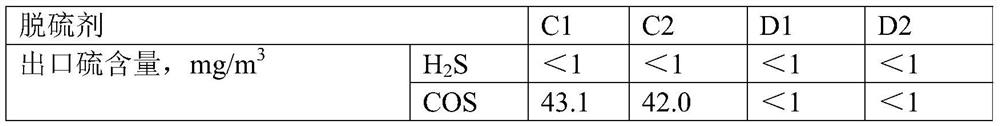

Coal gasification synthesis gas desulfurization device and method

ActiveCN111849562BEfficient removalComplete desulfurizationGas contaminants removalChemical/physical processesSyngasFluidized bed

Embodiments of the present invention provide a coal gasification-to-synthesis gas desulfurization device and method, which relate to the technical field of gas desulfurization. A method for desulfurization from coal gasification to syngas, comprising: reacting coal gasification to syngas with a desulfurizer to remove sulfides in the syngas to obtain desulfurized syngas and a deactivated desulfurizer, wherein the desulfurizer is modified with phosphorus or boron. Desulfurizing agent, its effective components include zinc oxide and hydrogenation active components; the deactivated desulfurization agent is reacted with oxygen to generate zinc oxide, and the hydrogenation active components are oxidized to obtain an oxidative desulfurization agent; the oxidative desulfurization agent is contacted with desulfurized synthesis gas The hydrogen in the desulfurized synthesis gas is reduced by the oxidized hydrogenation active components to obtain a desulfurizing agent that restores the activity. The coal gasification to syngas desulfurization device includes: a fluidized bed desulfurization reactor, a fluidized bed reduction reactor and a fluidized bed oxidation reactor. The above-mentioned device and method can ensure sufficient desulfurization, and the desulfurization agent can be recycled and used in the desulfurization process, and the desulfurization precision and sulfur capacity can be basically unchanged.

Owner:CHINA PETROLEUM & CHEM CORP +1

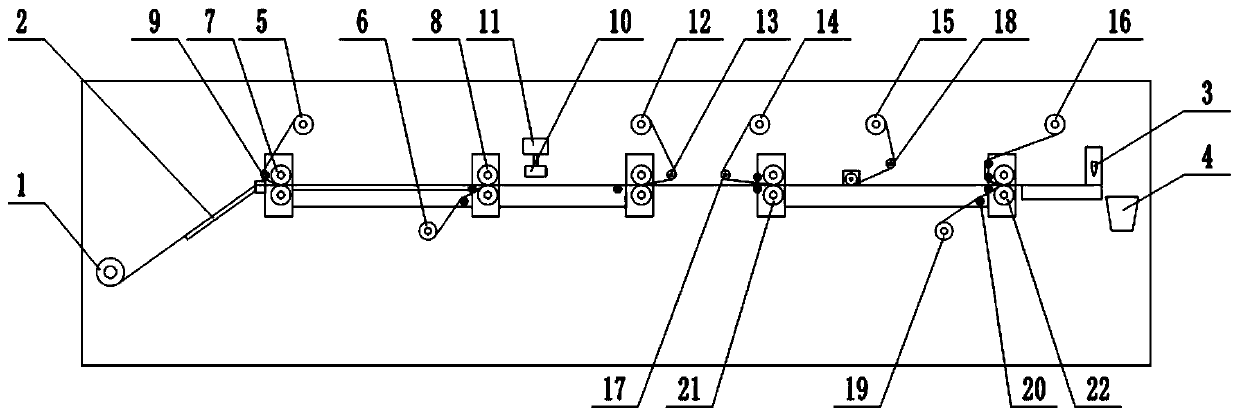

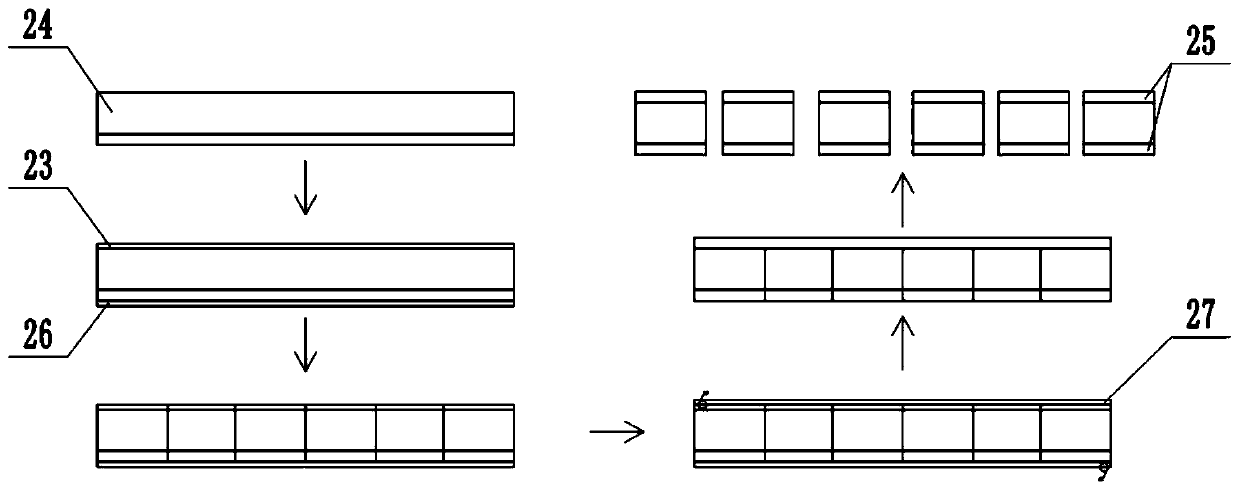

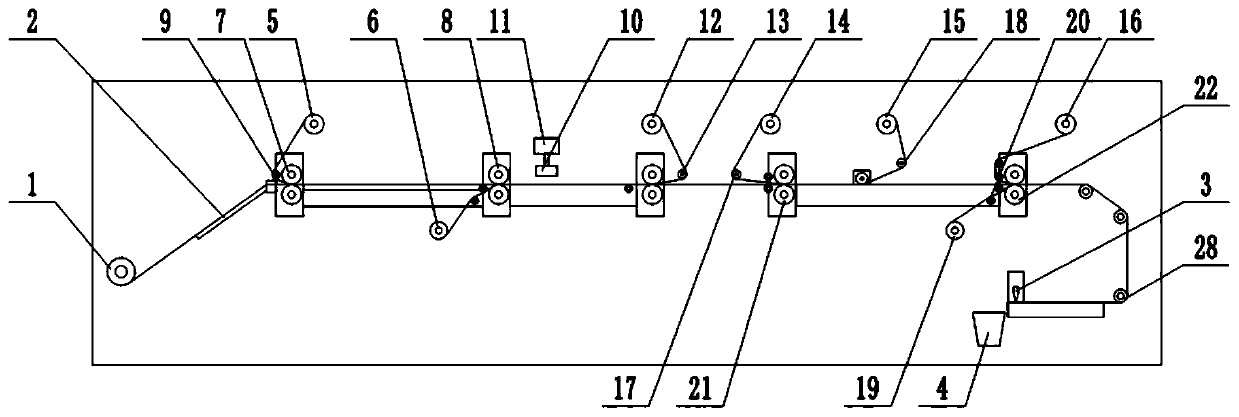

Double-sided adhesive die-cutting manufacturing process

InactiveCN110077894AEasy die-cuttingImprove work efficiencyArticle deliveryWebs handlingAdhesiveEngineering

The invention relates to the technical field of double-sided adhesive die-cutting, and discloses a double-sided adhesive die-cutting manufacturing process. The double-sided adhesive die-cutting manufacturing process comprises the following steps that (1), a double-sided adhesive tape pasted a bottom tape on the lower surface is discharged; (2), a first adhesive tape is pasted on the upper surfaceof the double-sided adhesive tape, then a second tape is pasted on the lower surface of the double-sided adhesive tape, so that the double-sided adhesive tape comprising the first adhesive tape, the double-sided adhesive tape, the bottom tape and the second adhesive tape from top to bottom in sequence is formed; (3) the double-sided adhesive tape is subjected to die-cutting, the die-cutting thickness is the sum of the thickness of the first adhesive tape, the double-sided adhesive tape and the bottom tape, and the second adhesive tape is not cut; (4) leftovers after die-cutting are recycled, and then the third adhesive tape is pasted on the upper surface of the double-sided adhesive tape; (5) the third adhesive tape and the first adhesive tape are recycled, the bottom tape is pasted on theupper surface of the double-sided adhesive tape, and then the second adhesive tape is recycled; and (6) the double-sided adhesive tape is cut to obtain a single double-sided adhesive tape product. According to the double-sided adhesive die-cutting manufacturing process, the problems of double-sided adhesive accumulation and low working efficiency existing in the existing double-sided adhesive die-cutting manufacturing process are solved.

Owner:重庆安洁电子有限公司

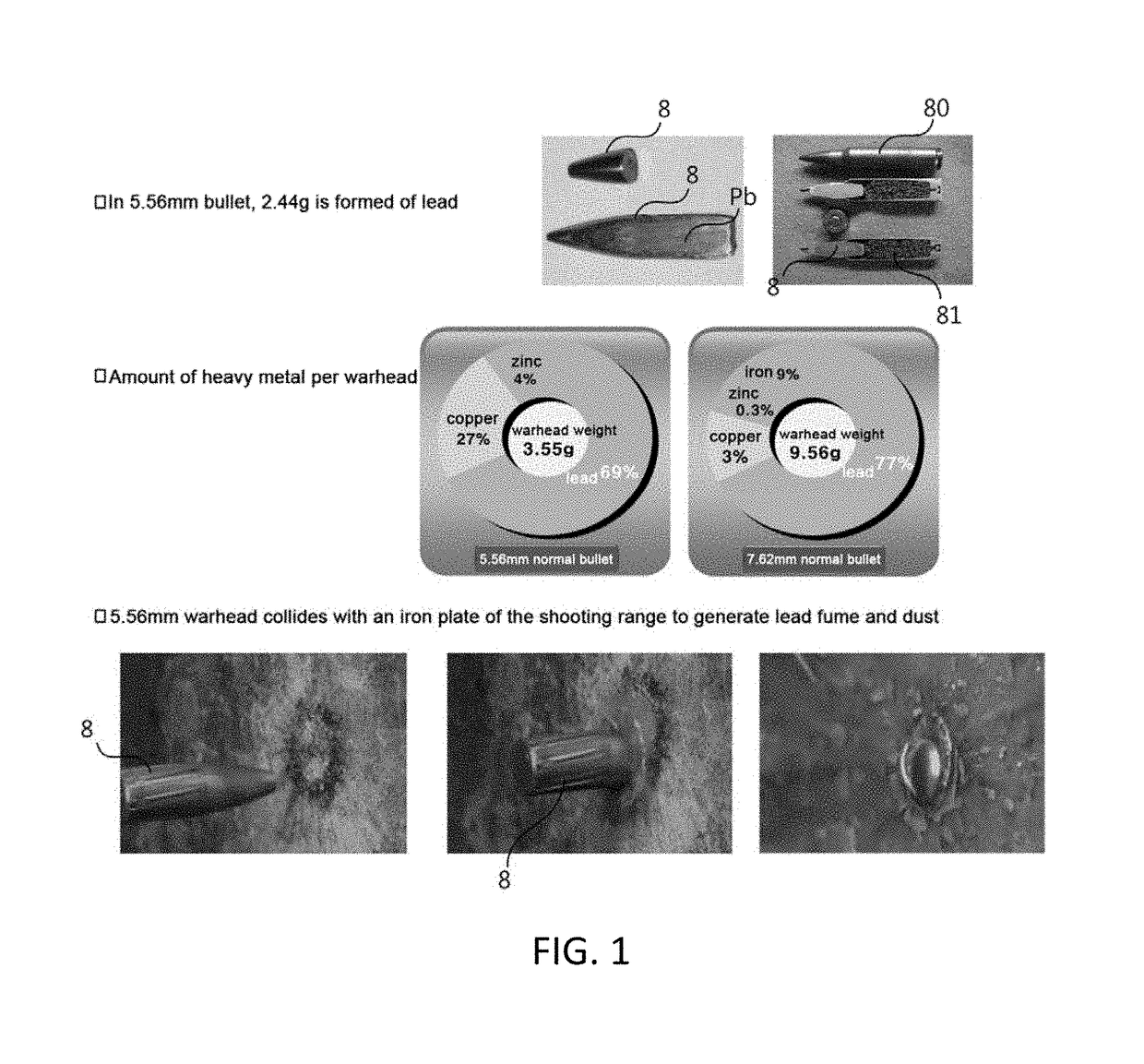

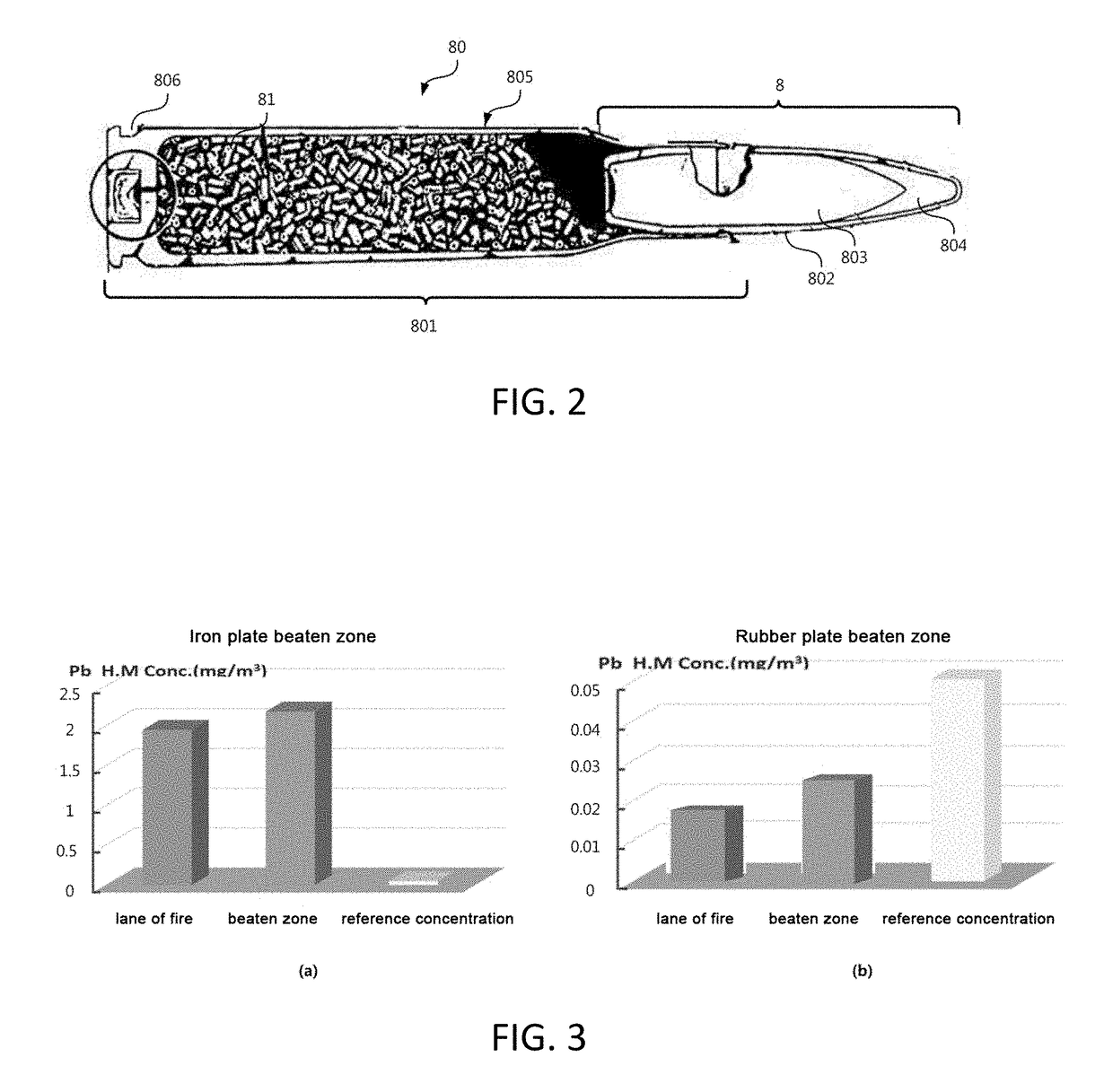

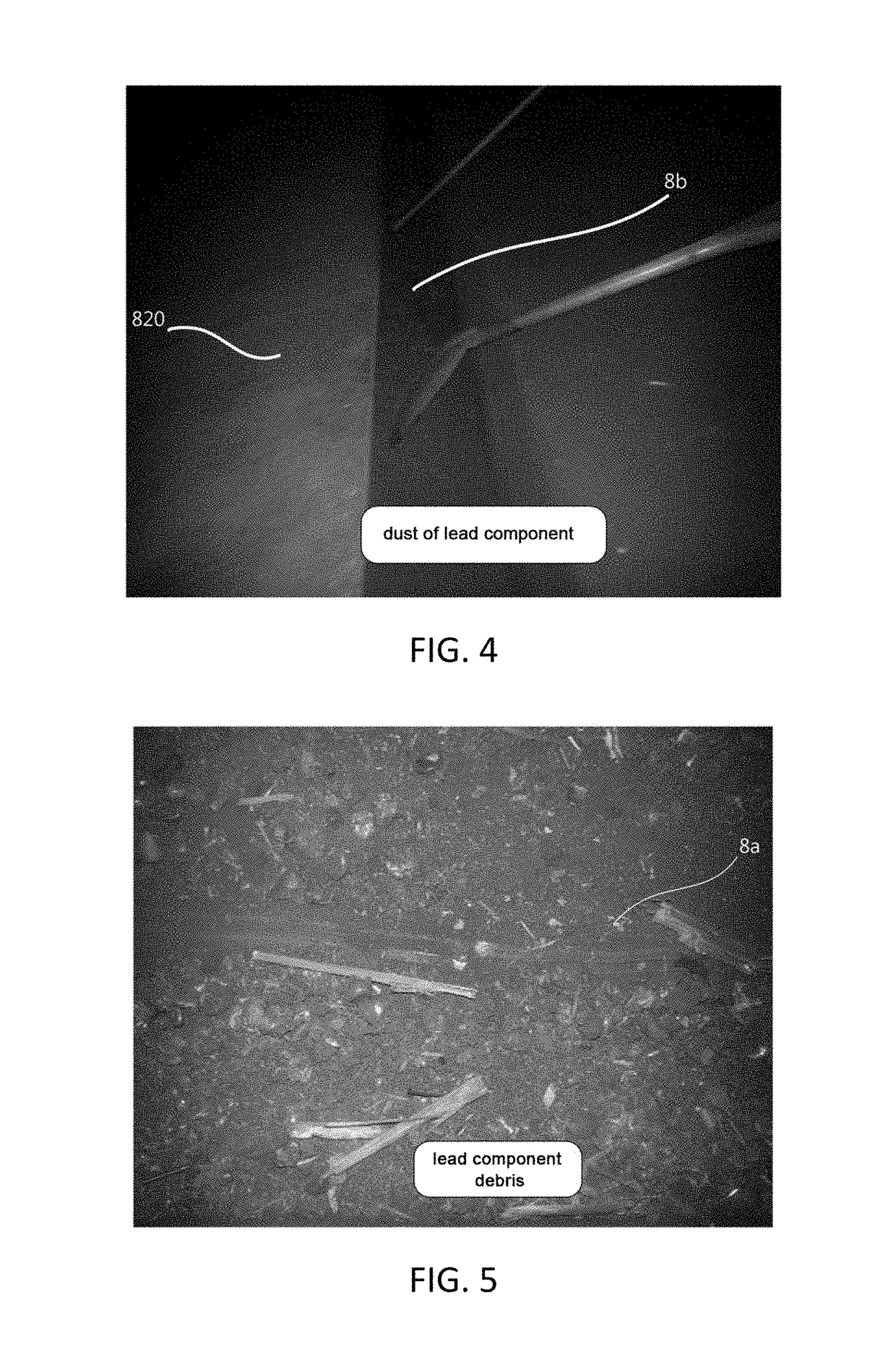

Bullet collecting box capable of stacking and installing, and bullet collecting system for preventing occurrence of lead fume in indoor shooting range using the bullet collecting box

InactiveUS10190855B2Easy to installReduce management costsTarget rangesBullet catchersFilling materialsEngineering

The present invention provides a bullet collecting box which is installed with a plurality of rubber plates in the bullet collecting box having a rectangular parallelepiped shape and filled with rubber powder filling materials having a particle size of 0.1 to 3 mm therein, thereby collecting the bullets fired in the indoor shooting range without damage, and a bullet collecting system which can be used by installing the bullet collecting box in the indoor shooting range. Also, the present invention provides a bullet collecting system for preventing occurrence of lead fume in the indoor shooting range, in which the beaten zone of the indoor shooting range is newly improved from an existing system of using an iron plate to a system of using powder filling materials, thereby preventing the leakage of lead fume, and contributing to an early normalization of the shooting range and a creative national defense.

Owner:KIM HEE JOUNG +3

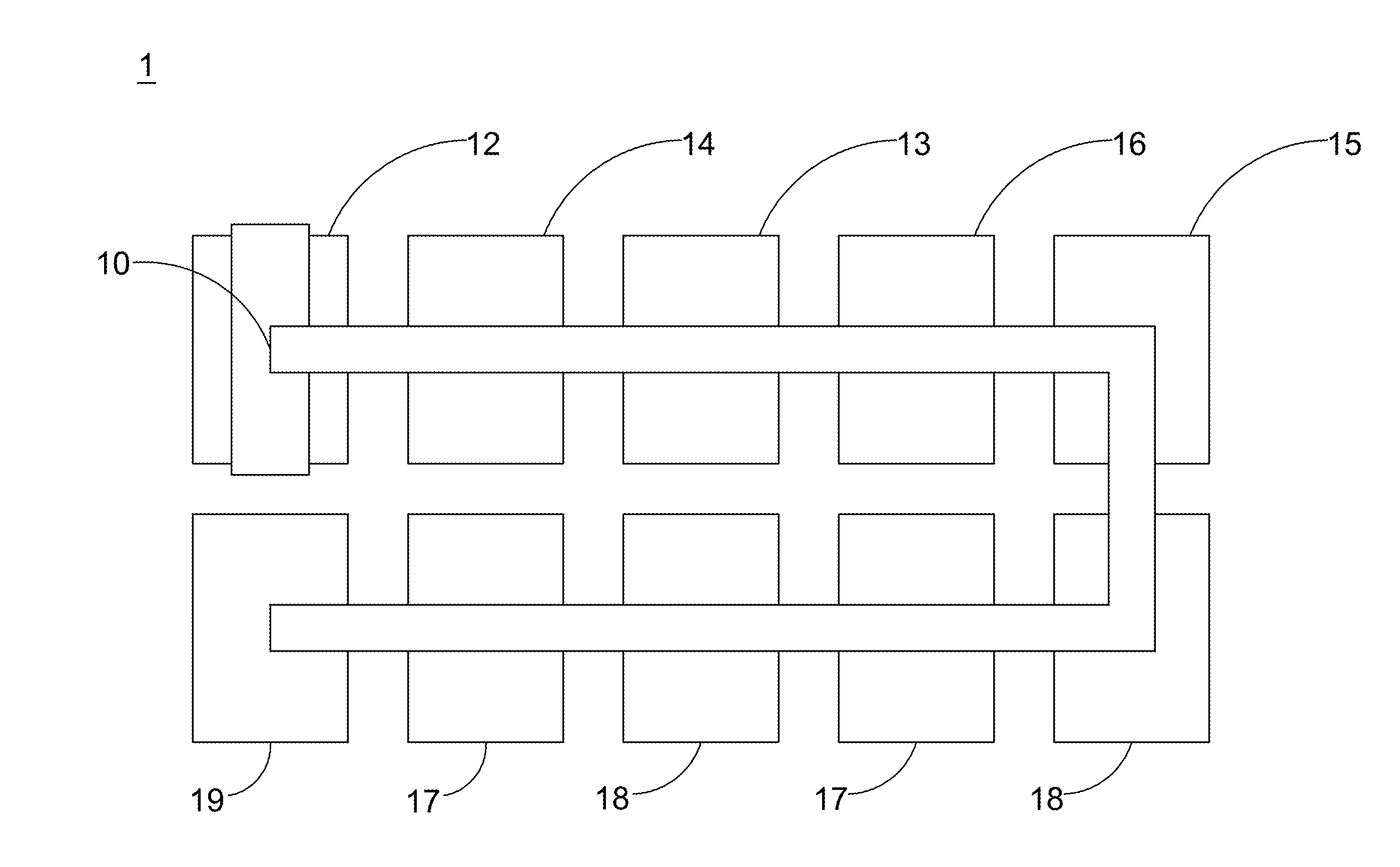

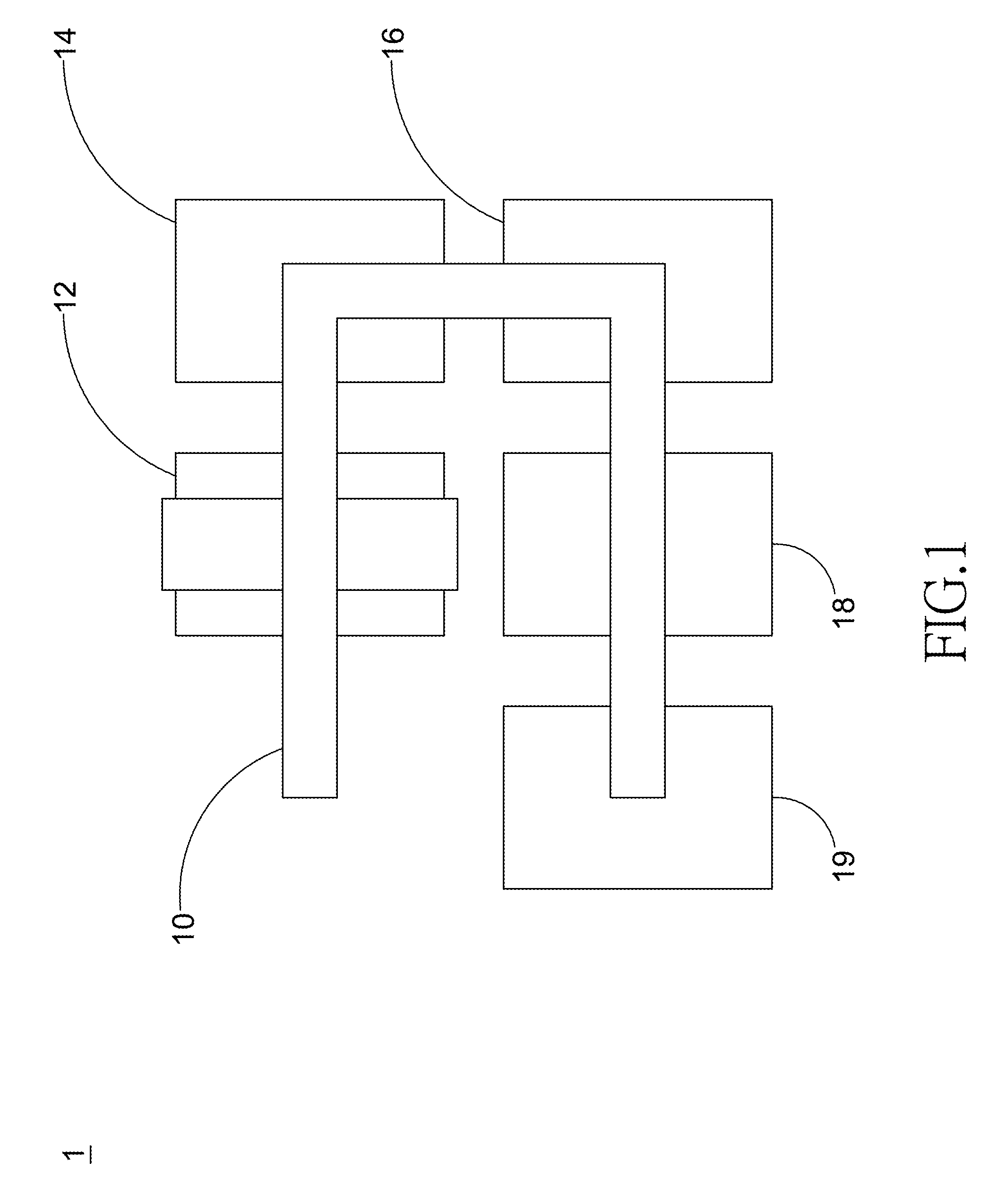

Apparatus for Recycling Noble Metals

InactiveUS20100252078A1Speed up recyclingIncrease volumeSolid sorbent liquid separationLiquid displacementUser needsDissolution

The present invention provides an apparatus for recycling noble metals, which comprises one or more conveyers, one or more carriers, an immersion device, one or more dissolution devices, and one or more rinse devices. The carriers, the immersion device, the dissolution devices, and the rinse devices are arranged in U-shape. Thereby, adding an object containing noble metals or pouring the object containing noble metals can be performed on the same side of the apparatus for recycling noble metals. Hence, a user needs not to operate on both sides of the apparatus for recycling noble metals, enhancing ease of operation. The carriers carry objects containing noble metals. The conveyer is used for conveying the carriers to the immersion device, the dissolution devices, and the rinse devices sequentially for recycling noble metals from the objects containing noble metals. The apparatus according to the present invention can recycle noble metals continuously. Thereby, the speed of recycling is enhanced, and the amount of recycled noble metals is increased as well.

Owner:SINGWEI TECH CO LTD

Drying and washing device for bearing

InactiveCN107552471AQuality assuranceNo dead endsDrying gas arrangementsCleaning using liquidsLiquid storage tankWater circulation

The invention relates to the technical field of cleaning equipment, in particular to a drying device for bearings, including a drum, two support seats, a material receiving box, a waste residue storage box, a cleaning liquid storage box, a clean water circulation box, a drying device, The spraying device and the power device, the drum is located on two support seats, and the right side of the drum is provided with a receiving box; Below, the drying device for drying is located inside the right side of the drum; the water spray device passes through the inside of the drum; the power device includes a large friction wheel, a small friction wheel, a reducer, a coupling And the motor, the large friction wheel is fixed on the drum, and the power unit is used to drive the drum to rotate. The invention can remove impurities, clean and dry the bearing, can solve the problem of equipment failure caused by scrap iron chips mixed in the cleaning liquid, can work continuously, can save a lot of labor and reduce production costs.

Owner:如皋市明德包装有限公司

Volatile organic product preparation method

InactiveCN102899358AStrong concentrationIncrease concentrationSemi-permeable membranesBiofuelsFiltrationUltrafiltration

The present invention provides a method for continuous fermentation and purification of a volatile organic product, and particularly relates to a method for production, separation, concentration and purification of a volatile organic product from a fermentation broth through a membrane separation process, wherein the membrane separation process is a combination comprising one or a plurality of processes selected from pervaporation, vapor penetration, micro-filtration, ultra-filtration and nano-filtration. With the method, concentration of a target organic product can be maintained to a low level during a fermentation process so as to avoid inhibition on the fermentation process; and after the oleophilic pervaporation membrane separation is performed, concentration of the target product in the penetrant is increased so as to reduce subsequent product concentration and purification energy consumption. The method further has an advantage that: the product concentration is controlled to a non-inhibitory concentration level during the fermentation process, such that the whole process can be subjected to a continuous operation.

Owner:ACS农化系统有限公司 +1

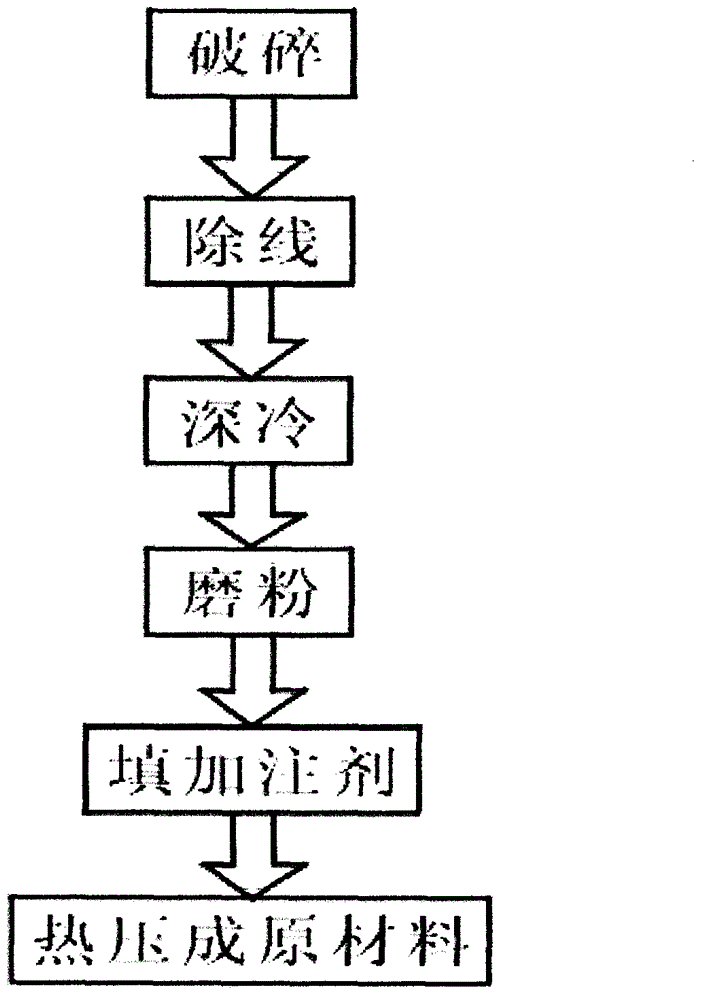

Method for processing hot melt adhesive waste products into raw material

The invention relates to a method for processing hot melt adhesive waste products into raw material. The method comprises the following steps of: 1) crushing: crushing the recycled hot melt adhesive waste products to below 20cm; 2) removing lines: separating the lines of the hot melt adhesive waste products crushed to below 20cm from hot melt adhesive; 3) performing deep cooling: performing the deep cooling on the separated hot melt adhesive to below minus 145 DEG C; 4) milling: milling the hot melt adhesive after deep cooling to powder particles in the size of 30 meshes to 60 meshes; 5) adding an injection agent: adding zinc stearate onto the powder particles of the hot melt adhesive; and 6) performing hot-pressing to form the raw material: performing the hot-pressing on the powder particles of the hot melt adhesive with the added zinc stearate to form a hot melt adhesive plate. The hot melt adhesive is further milled to the powder particles after deep cooling, so that the hot melt adhesive can become crisp to facilitate the milling, and the purpose of preventing a milling machine from being damaged is also achieved; furthermore, the molecular structure of the hot melt adhesive can be prevented from being damaged; and simultaneously, the production of toxic gas can be avoided, air pollution can be further avoided, and the hot melt adhesive waste products can be continuously recycled.

Owner:DONGGUAN FANGYAN PLASTIC TECH

Coal gasification synthesis gas desulfurization device and method

ActiveCN111849562AEfficient removalComplete desulfurizationGas contaminants removalChemical/physical processesSyngasFluidized bed

The embodiment of the invention provides a coal gasification synthesis gas desulfurization device and method, and relates to the technical field of gas desulfurization. The desulfurization method comprises the following steps: reacting the synthetic gas prepared by coal gasification with a desulfurizing agent to remove sulfide in the synthetic gas so as to obtain desulfurized synthetic gas and aninactivated desulfurizing agent, wherein the desulfurizing agent is a desulfurizing agent modified by phosphorus or boron, and the effective components of the desulfurizing agent comprise zinc oxide and a hydrogenation active component, reacting the deactivated desulfurizer with oxygen to generate zinc oxide, oxidizing the hydrogenation active component to obtain an oxidative desulfurizer, and contacting the oxidative desulfurizing agent with the desulfurized synthetic gas to reduce the oxidized hydrogenation active component by hydrogen in the desulfurized synthetic gas to obtain the desulfurizing agent with recovered activity. The desulfurization device comprises a fluidized bed desulfurization reactor, a fluidized bed reduction reactor and a fluidized bed oxidation reactor. According tothe device and the method, sufficient desulfurization can be guaranteed, the desulfurizing agent can be recycled in the desulfurization process, and the desulfurization precision and the sulfur capacity can be basically unchanged.

Owner:CHINA PETROLEUM & CHEM CORP +1

System and method for deep cleaning water ionizers

InactiveUS20150258587A1Continuous recyclingSpecific water treatment objectivesHollow article cleaningTitaniumEnvironmental engineering

A device, system and method of cleaning water ionizers. Allowing for regular end user fluid stream deep cleaning of water Ionizer internal components. Particularly metal surface known as Ionization plates or mesh plates. Water ionization plates typically accumulate water scale from prolonged contact with water passing over the plate surface during the ionization process.The present invention facilitates a pressurized streaming method of dissolving water scale buildup accumulated over time on internal parts of water Ionizer systems. Specifically, the ionization plates, typically some form of metal. i.e., medical grade titanium and or mesh plates materials found in water ionizers.

Owner:ALLEYNE CLEVELAND W

Chemical waste gas treatment device for olefin separation device

ActiveCN111632477AHave a relaxing effectEasy to clean upChemical industryDispersed particle separationChemical wasteAlkene

The invention provides a chemical waste gas treatment device for an olefin separation device. The chemical waste gas treatment device comprises a treatment structure; the treatment structure and the purification structure are in an independent state, and the treatment structure and the purification structure are communicated through a pipeline at the top end; and the purification structure and thetreatment structure are fixed through a clamping structure, a filtering structure is arranged at the tail end of the purification structure, waste gas entering a box body can directly pass through aspiral fan, when the waste gas passes through the spiral fan, the spiral fan is directly driven to rotate through the wind power, and the spiral fan is integrally mounted on a base, and is positionedin a heating box, so the waste gas can generate a rotating effect from the bottom end of the heating box, waste gas can be fully heated in the heating box to react, and a part of harmful substances are treated; and the heating box is integrally installed in a hinged mode, so the heating box can be integrally and directly unfolded, and the interior of the heating box can be conveniently cleaned.

Owner:CHINA CATALYST HUABANG (DONGYING) CO LTD

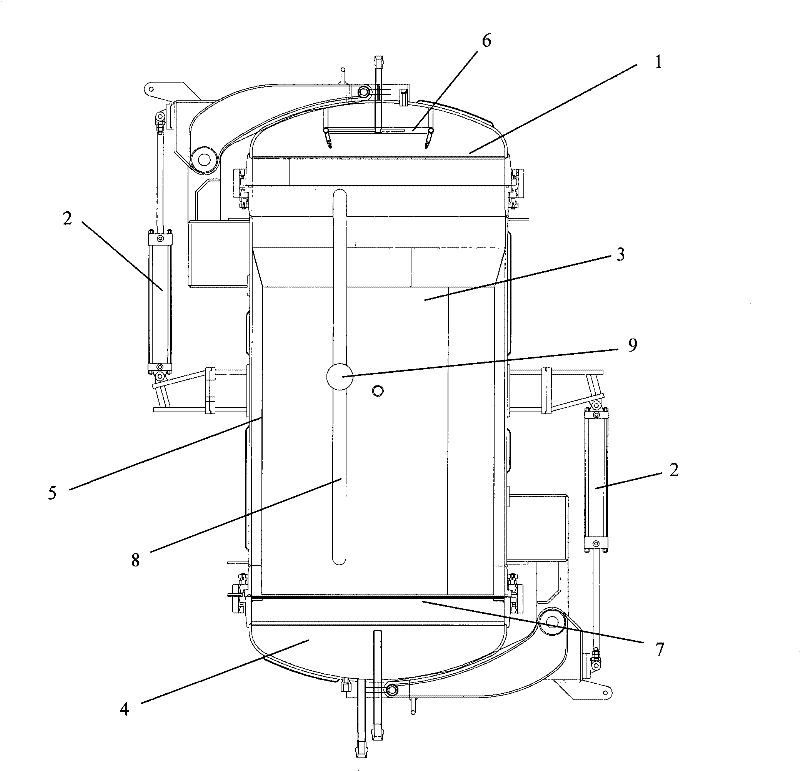

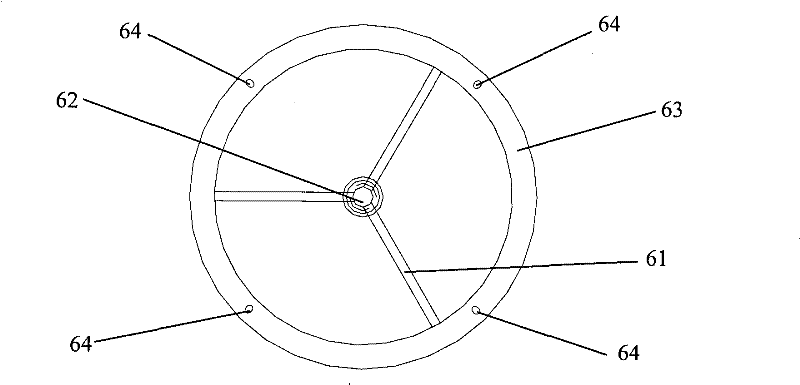

Tobacco shred immersion method and device

ActiveCN101744359BHigh energy consumptionReduce energy consumptionTobacco preparationLiquid stateAgricultural engineering

The invention relates to a tobacco shred immersion method and a device; the method comprises: (1) the tobacco shred is arranged in a pre-heating immersion device and then vacuumizing is carried out; (2) swelling agent with liquid state is sprayed on the tobacco shred; (3) swelling agent with gas state is filled in the immersion device; (4) immersion is carried out. The immersion device provided by the invention comprises a tank body, an upper tank cover, a lower tank cover and a hydraulic pressure opening device, a spraying device is arranged in the upper tank cover, wherein the tank body is provided with two layers of sleeves, a screen cloth is formed on the inner wall of the inner layer sleeve, and the pore diameter of the screen cloth is 1.5mm. The invention has simple structure and convenient operation, can achieve good immersion effect to the tobacco shred and can realize continuous immersion of the tobacco shred.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

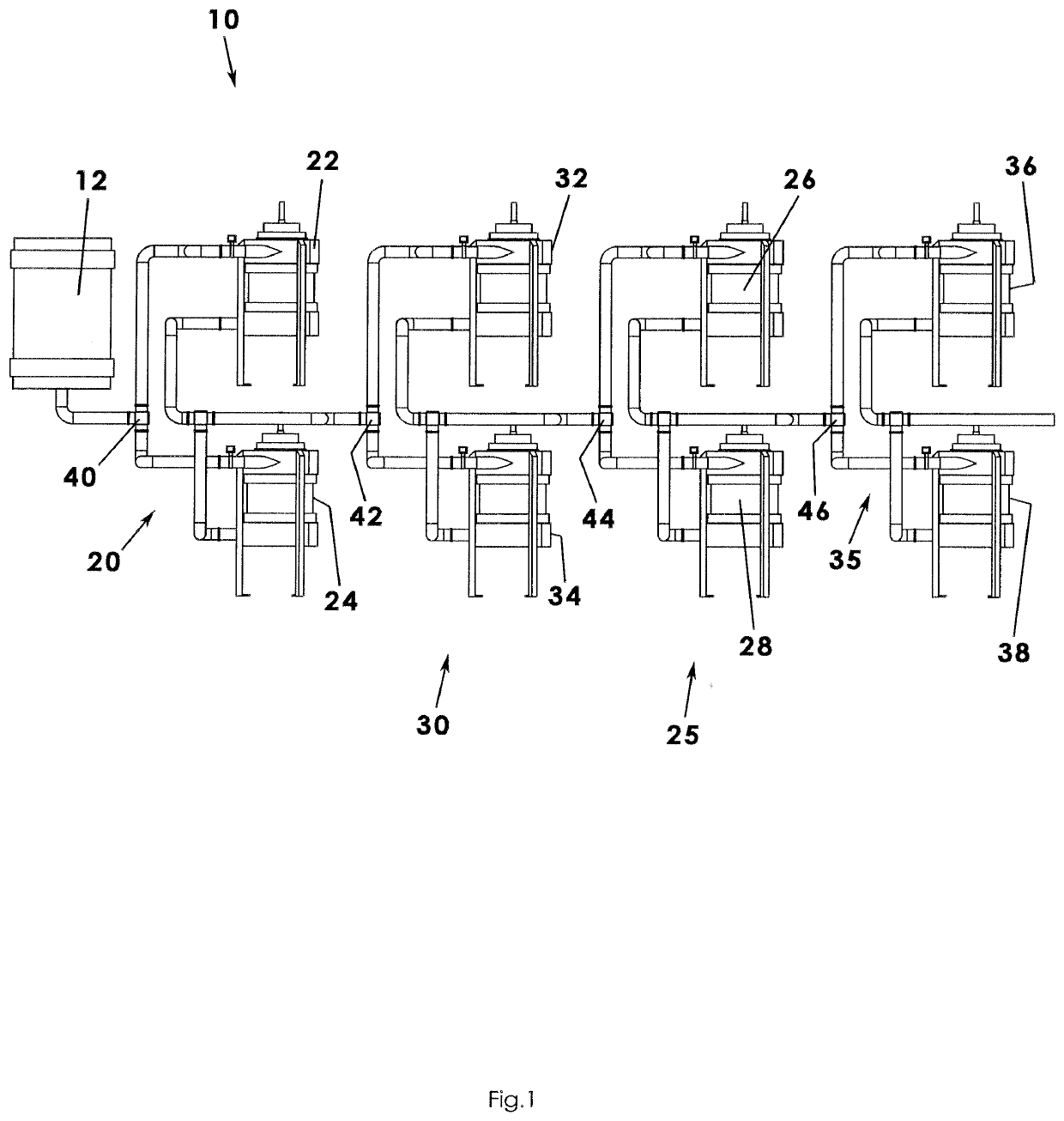

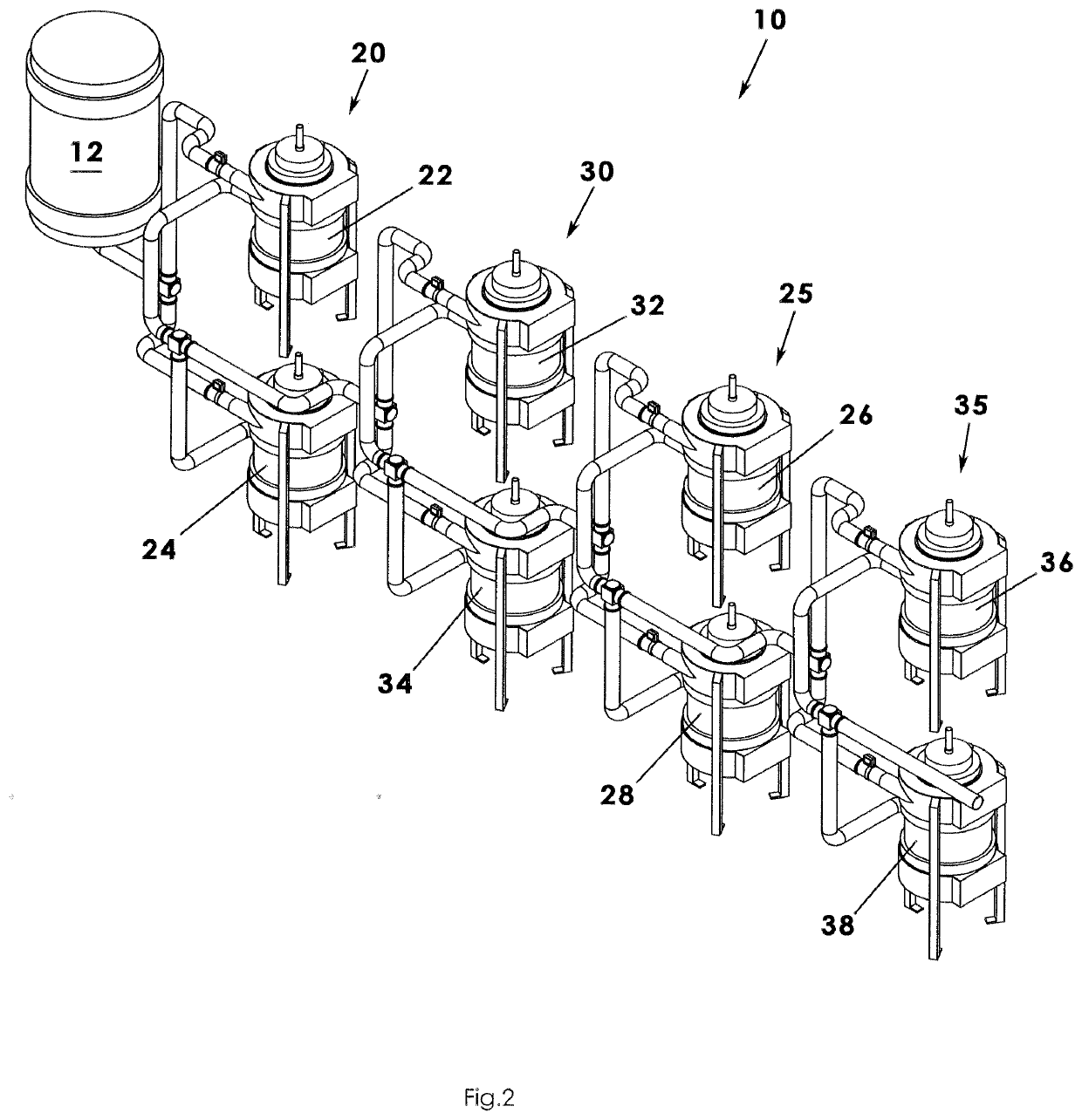

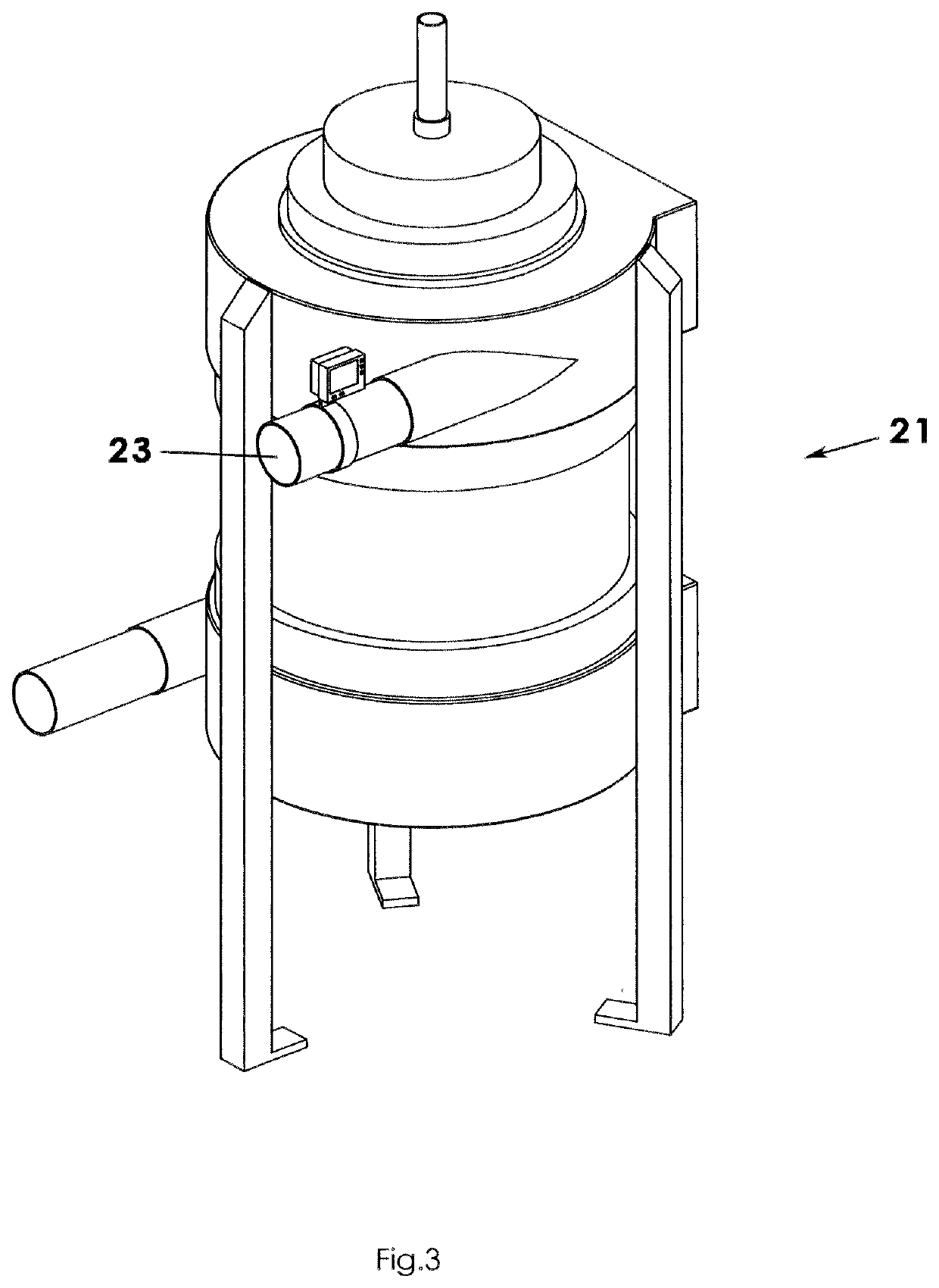

Multi-Column Continuous Resin Regeneration System

ActiveUS20210008539A1Continuous recyclingImprove efficiencyCation exchanger materialsIon-exchanger regenerationOrganic chemistryMaterials science

A continuous resin regeneration system includes a process by which resin in need of being recharged is continuously recharged and cleaned with a plurality of two-set filtration columns so that resin regeneration and the flow of influent is continuous and interrupted. Downstream filtration columns also undergo this cycling but at slower and related rates as the first column with the dirtiest water will naturally degrade resin faster than the downstream columns. Contaminated influent is cleaned by the continuously recharged resin in multiple column sets. The degree of cleaning of earlier filtration columns affects the resin flow rate of later filtration columns.

Owner:VANIER JAY +1

System and method for recycling magnesium and magnesium alloy waste

InactiveCN102912156BGuaranteed supplyContinuous recyclingIngot casting plantsProcess efficiency improvementThermal insulationIngot casting

The invention discloses a system and method for recycling magnesium and magnesium alloy waste. The system comprises at least one melting furnace, wherein an air intake device is communicated to the bottom of a first crucible, inert gas is blown in from the bottom of a melt, and bubbles carry impurities in the melt to a liquid level; when a melting furnace inputs the melt into a thermal insulation casting furnace, and a first liquid outlet pipe is communicated to the part, close to the bottom, of the first crucible so as to ensure that the melt can not carry over the impurities; and a small amount of impurities are still contained in the melt after the impurities are removed, and the impurities are settled at a position, close to a feeding hole, inside the thermal insulation casting furnace, so as to ensure that the impurities settled at the bottom of a second crucible can not be carried over when the melt is transferred toward an ingot casting device, so that the impurity removing effect and efficiency are guaranteed. When the thermal insulation casting furnace transfers the melt toward the ingot casting device, at least one melting furnace completes impurity removing treatment, the melt is transferred toward the thermal insulation casting furnace, feeding to the ingot casting device is guaranteed, a continuous recycling process is realized, and the production efficiency is improved.

Owner:天津镁特威科技有限公司

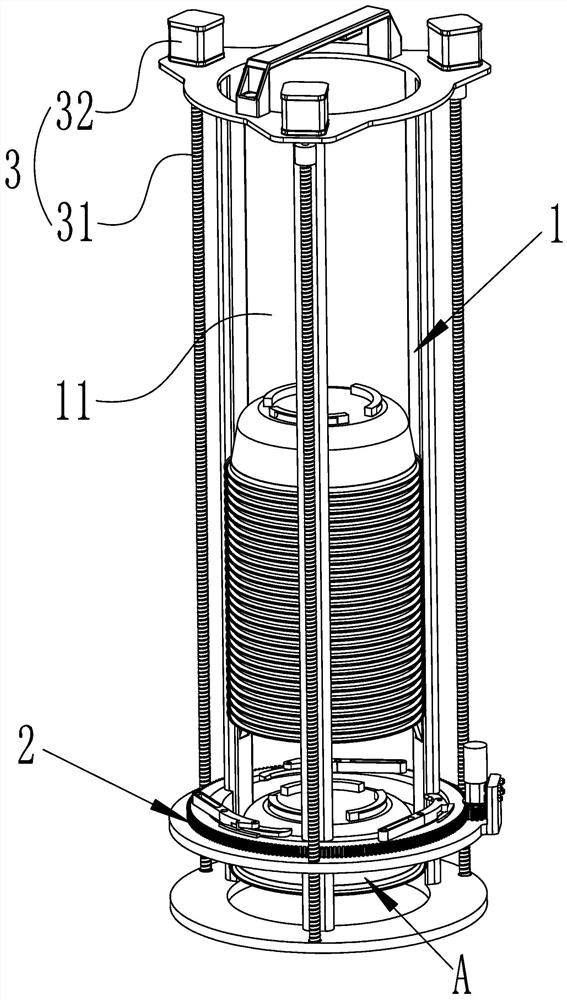

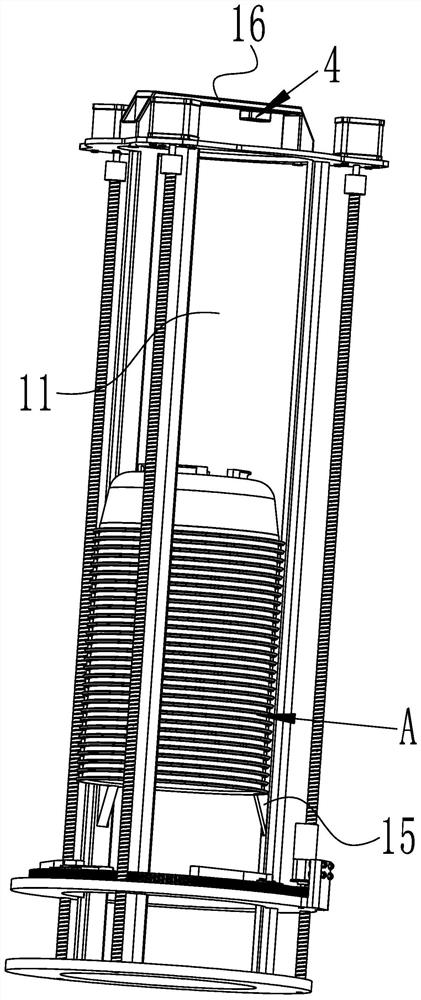

Apparatus for recovering seedling gaiwan

ActiveCN109287349BNovel structureIngenious designPlant protective coveringsAgricultural engineeringStructural engineering

The invention discloses a device for recovering a seedling covering bowl. The device comprises a covering bowl storage cylinder, a covering bowl grabbing mechanism and a lifting driving mechanism; thecovering bowl can be stored in the covering bowl storage cylinder, the covering bowl grasping mechanism is slidably mounted on the covering bowl storage cylinder and used for grasping the covering bowl into the covering bowl containing cavity, and the lifting driving mechanism is mounted on the covering bowl storage cylinder and used for driving the covering bowl grabbing mechanism to ascend anddescend. The provided device for recovering the seedling covering bowl is adopted and is novel in structure, ingenious in design, easy to obtain, high in automation degree and capable of quickly, continuously and efficiently recovering the covering bowl, so that the labor intensity of farmers in the process of recovering the covering bowl is greatly reduced.

Owner:GUIZHOU TOBACCO SCI RES INST

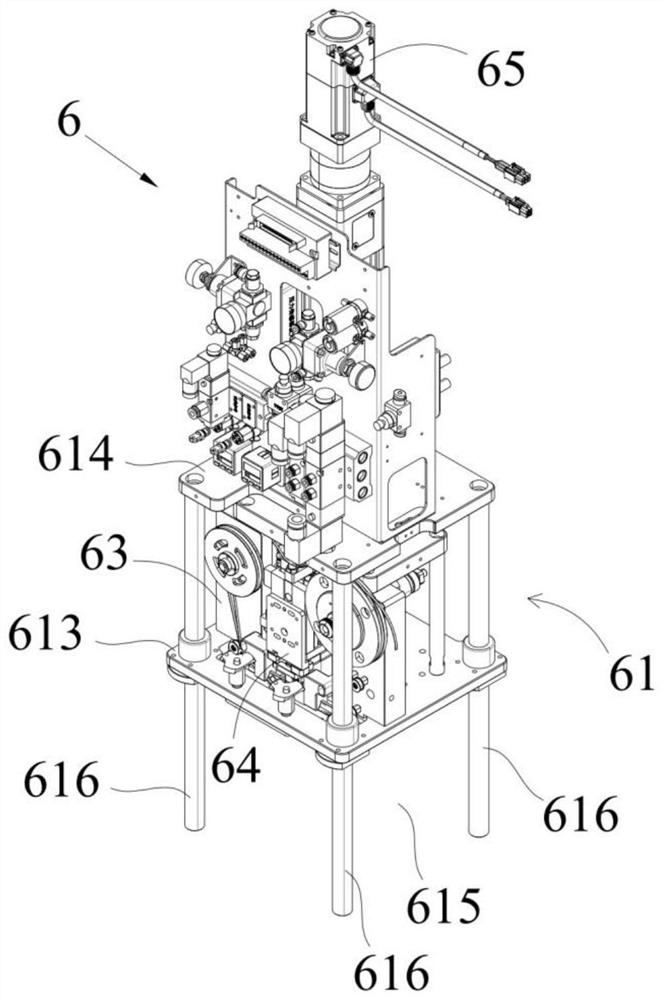

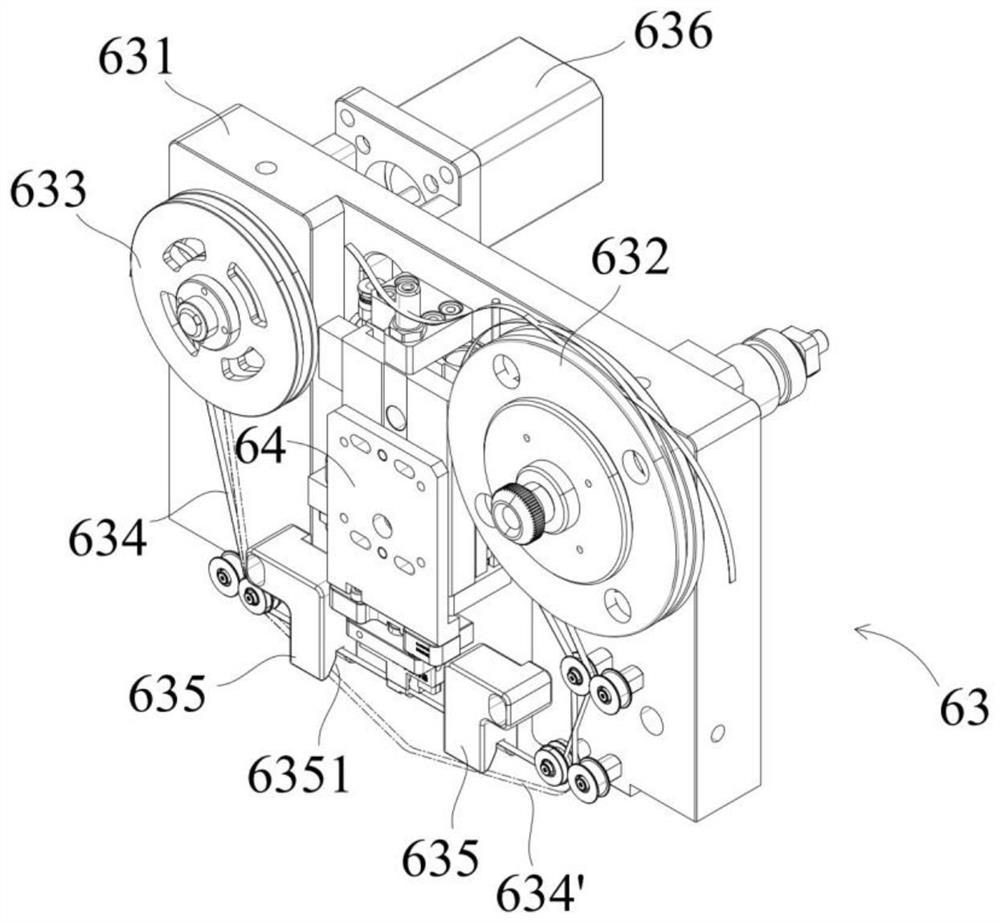

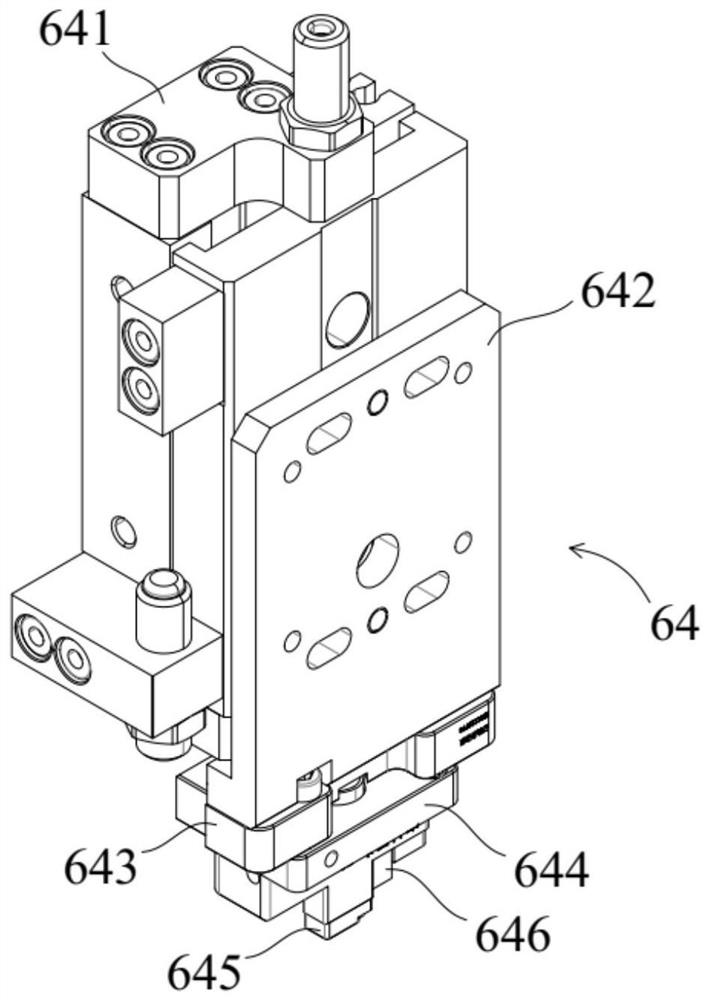

Downward pressing type sealing device

ActiveCN113401712AContinuous recyclingHigh degree of automationFluid-tightness measurementArticle deliveryEngineeringStructural engineering

The invention discloses a downward pressing type sealing device. The device comprises an installation support which comprises at least three lifting guide columns arranged in a non-collinear mode, a downward pressing installation plate movably connected to the lifting guide columns in a sleeving mode and a fixed installation plate fixedly connected to the lifting guide columns. The downward pressing installation plate is located below the fixed installation plate, the downward pressing installation plate and the fixed installation plate are arranged in a spaced mode to form a mounting space located between the downward pressing installation plate and the fixed installation plate, and a workpiece positioning space is formed under the downward pressing installation plate; a laminating module is installed on the downward pressing installation plate and located in the installation space, and a downward pressing type sealing mechanism is fixedly mounted in the laminating module; the lifting driver is installed on the fixed installation plate, and the power output end of the lifting driver is in transmission connection with the laminating module. According to the invention, the sealing film can be continuously released and the pressing sealing operation can be carried out on the sealing film transmission path, and the used sealing film can be continuously and automatically recovered.

Owner:SUZHOU RS TECH

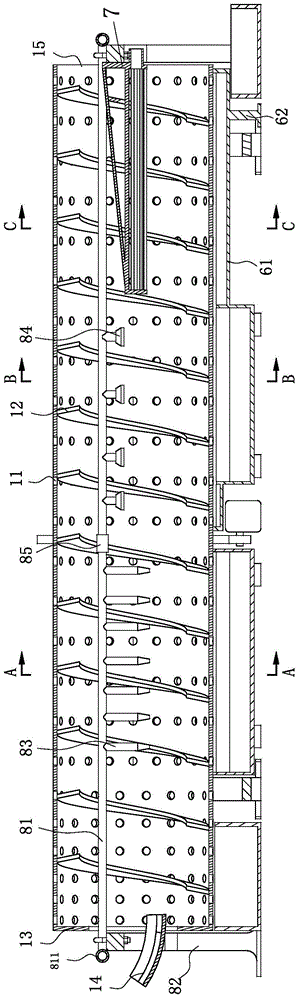

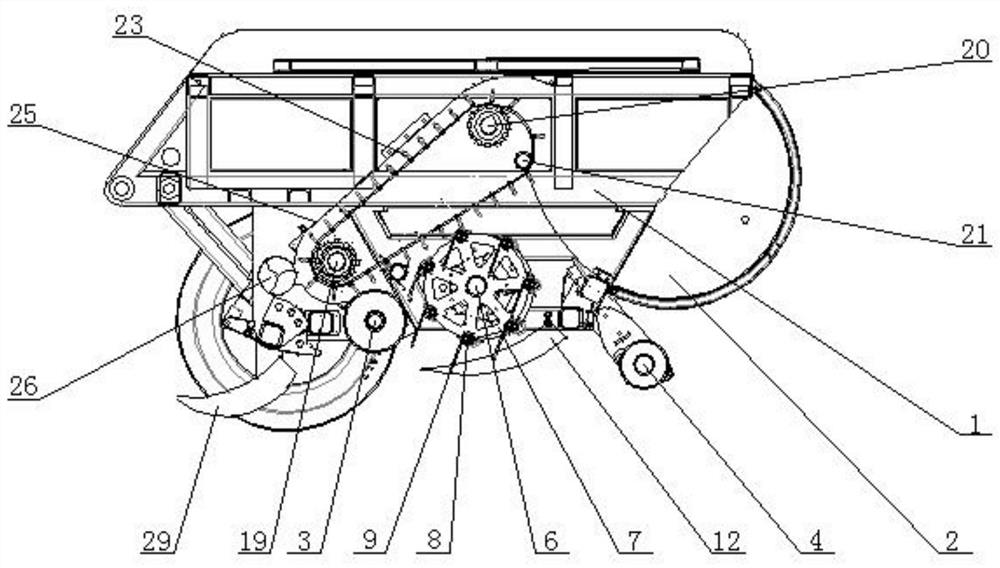

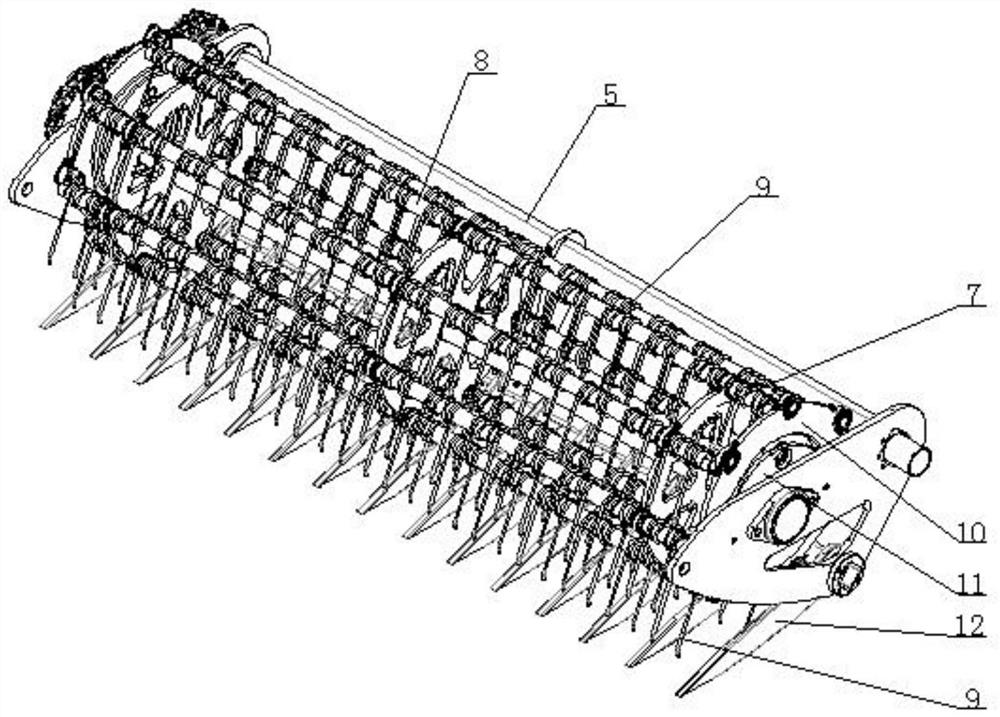

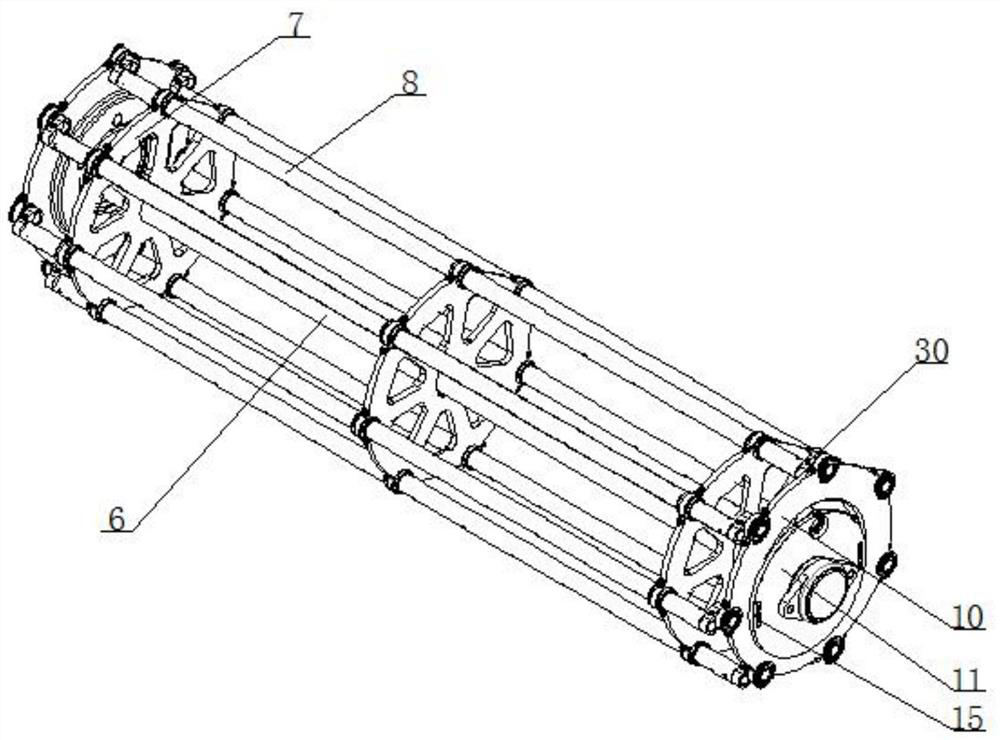

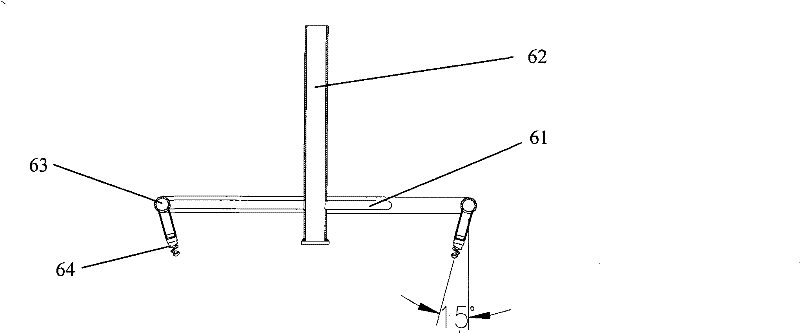

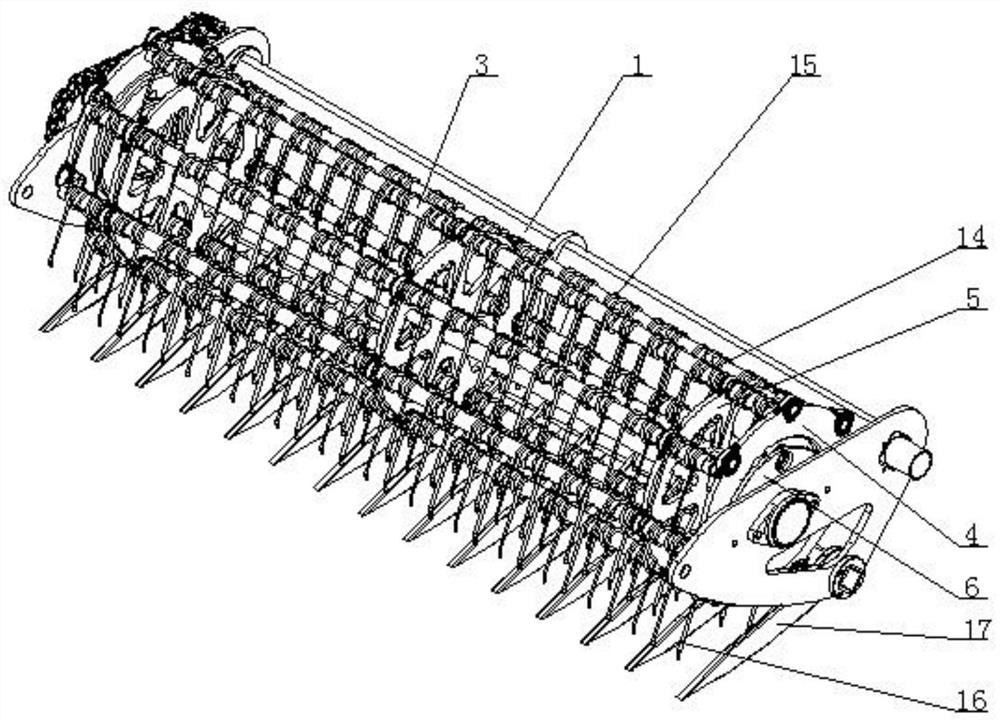

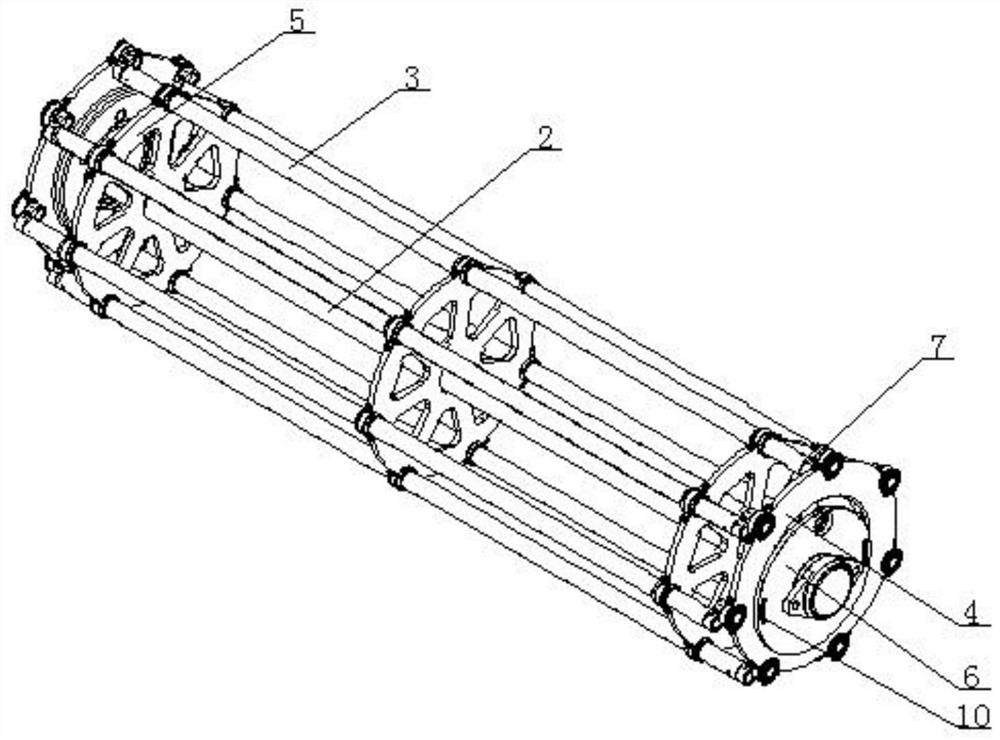

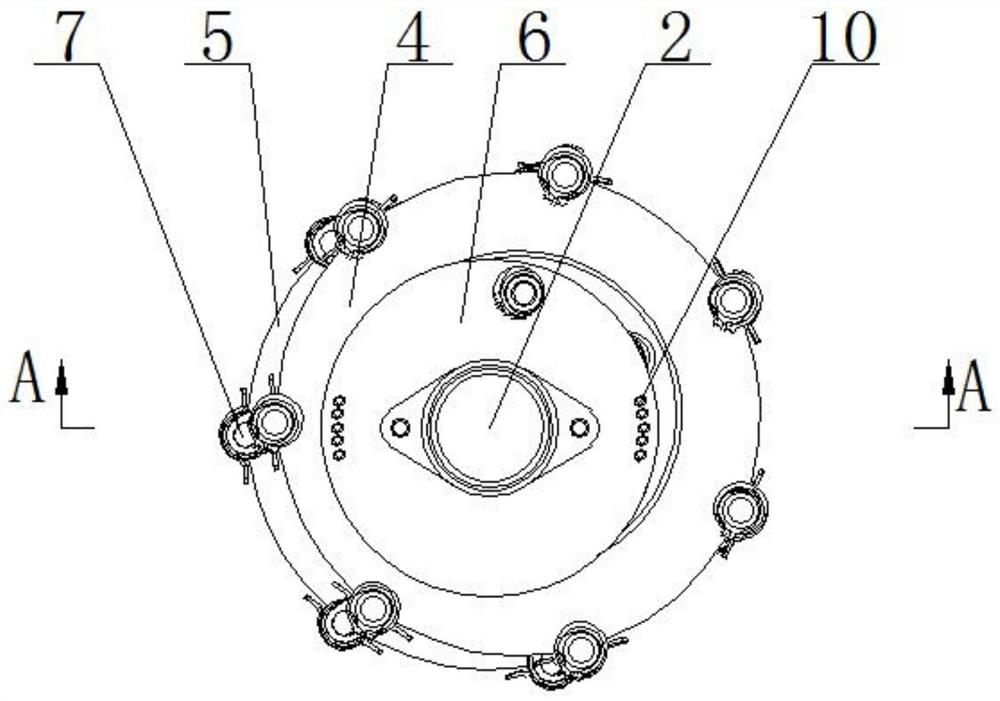

Directional eccentric elastic tooth film raking roller for mulching film recycling machine

ActiveCN112913349ANot easy to missNot easy to attachPlastic recyclingGatherer machinesAgricultural engineeringPlastic mulch

The invention relates to a directional eccentric elastic tooth film raking roller for a mulching film recycling machine, and belongs to the technical field of agricultural machinery. The film raking roller is composed of an assembling frame, a main shaft, an elastic tooth shaft and elastic teeth; a driving disc is installed on the assembling frame through the main shaft; the elastic teeth are installed on the circumference of the driving disc through the elastic tooth shaft; follow-up discs are respectively arranged at two ends of the main shaft on the outer side of the driving disc through eccentric discs; and the follow-up discs are connected with the elastic tooth shaft through crank throws 7. According to the directional eccentric elastic tooth film raking roller for the mulching film recycling machine, in the mulching film recycling process, film raking is conducted through the elastic teeth of the directional eccentric elastic tooth film raking roller, flaky mulching films are picked up one by one, and therefore the mulching films are recycled, the mulching films are not prone to being missed, and the recycling rate can be effectively increased; and in the rotating process of the elastic teeth, the elastic teeth clean the elastic tooth shaft and the main shaft, and the mulching films are not prone to being attached to or wound around the elastic teeth through an auxiliary film removing roller, so that continuous recycling can be achieved, the problems that an existing plastic film residue recycling machine is prone to winding and hanging mulching films, cannot work continuously and is low in recycling rate are solved, and the film raking roller is particularly suitable for recycling the mulching films.

Owner:YANGTZE UNIVERSITY

Sealing film laminating method

Owner:SUZHOU RS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com