Double-sided adhesive die-cutting manufacturing process

A production process and double-sided adhesive technology, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve problems such as low work efficiency and double-sided adhesive accumulation, and achieve high work efficiency and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

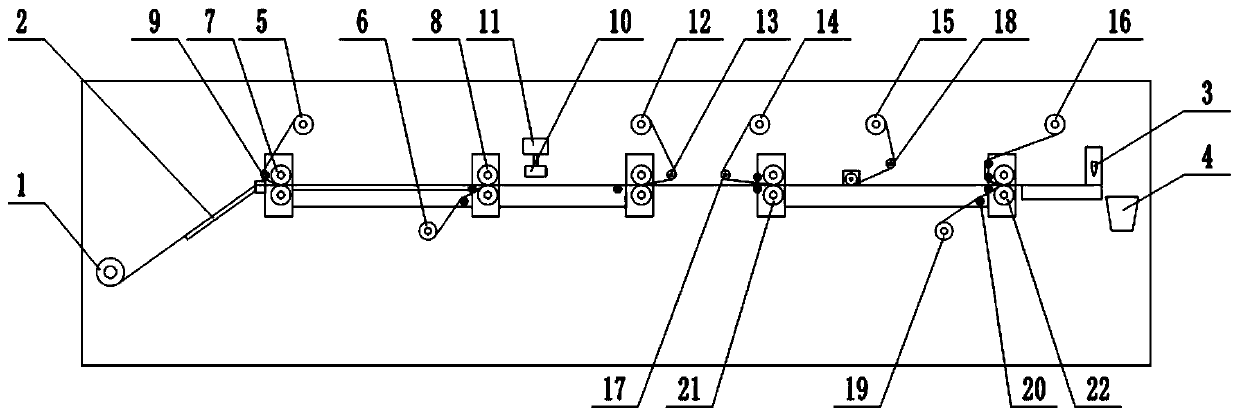

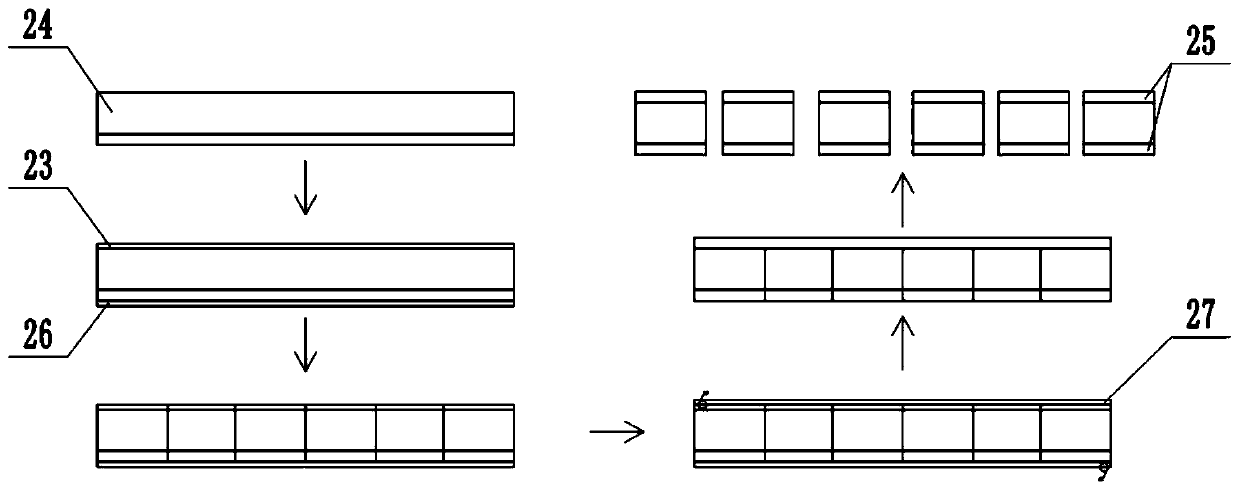

[0034] Embodiment one is basically as attached figure 1 , figure 2 Shown:

[0035] The double-sided adhesive die-cutting production process requires the use of a double-sided adhesive die-cutting production equipment. The equipment includes a frame. There are five sets of rollers for transmitting double-sided adhesive tapes; the feeding end is provided with a discharging unit for releasing double-sided adhesive tapes, and the discharging unit includes discharging rollers 1 that are rotatably connected The frame between the unit and the first pair of rollers 7 is connected with a material guide plate 2 inclined to the discharge roller 1 by bolts, and a number of parallel guide rollers are connected to the material guide plate 2 in rotation; A die-cutting unit is provided, and the die-cutting unit includes a die-cutting knife 3 vertically slidably connected to the frame. A recovery mechanism is provided at the discharge end. In this embodiment, the recovery mechanism is a co...

Embodiment 2

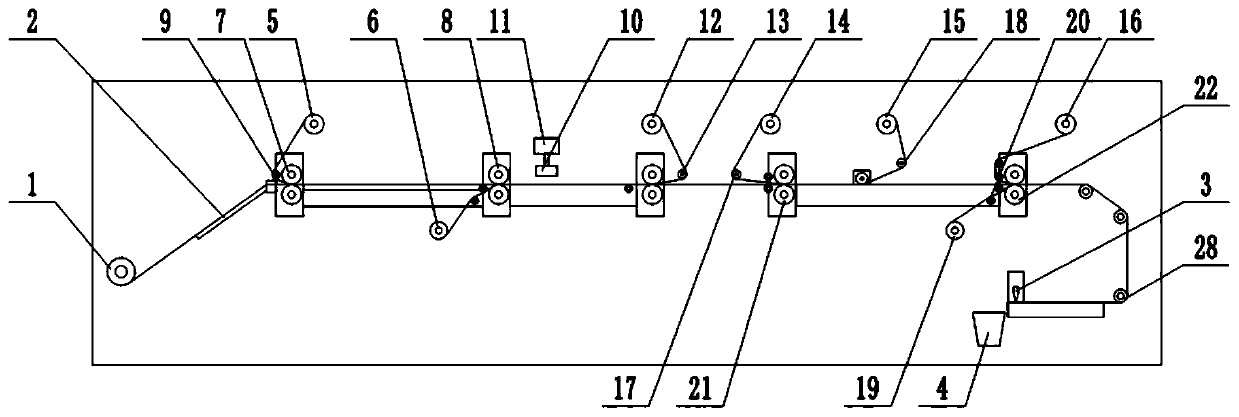

[0047] Embodiment two is basically as attached image 3 Shown:

[0048] The difference between this embodiment and Embodiment 1 is that the double-sided adhesive die-cutting production equipment used is different. On the basis of the double-sided adhesive die-cutting production equipment used in Embodiment 1, a turning mechanism is added, specifically: : between the double-sided adhesive tape lower surface treatment mechanism and the die-cutting unit, there is an overturning mechanism for exchanging the upper and lower surfaces of the double-sided adhesive tape. The overturning mechanism includes at least two guide rollers 28 that are rotatably connected to the frame. In the embodiment, there are three guide rollers 28, the guide rollers 28 are in contact with the lower surface of the double-sided tape and are located on the same side of the double-sided tape, and the guide rollers 28 transmit the double-sided tape to the die-cutting unit.

[0049] When implementing this proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com