Graphitization process of artificial graphite heat dissipation film

A technology of artificial graphite and graphitization, applied in the direction of inorganic chemistry, carbon compounds, heat exchange materials, etc., can solve the problems of short heating time, low maximum temperature, poor bending resistance and thermal conductivity of artificial graphite heat dissipation film, etc. Achieve the effect of improving bending resistance and thermal conductivity, and prolonging the heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

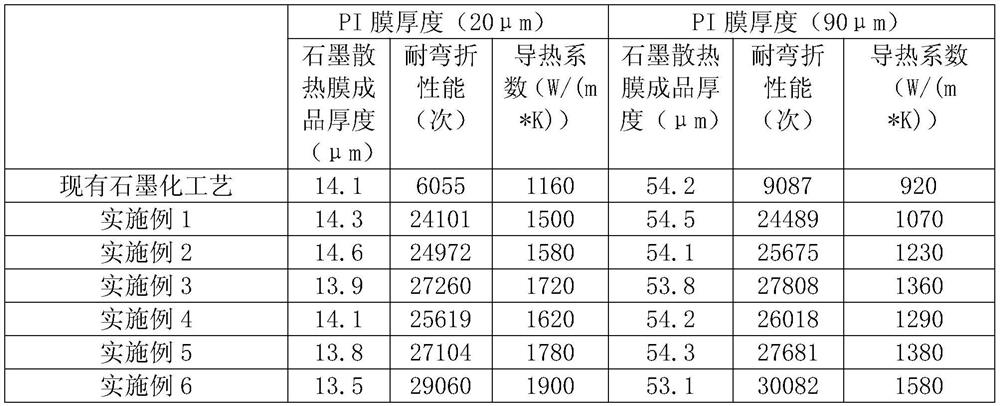

Examples

Embodiment 1

[0026] Embodiment 1 discloses a kind of artificial graphite heat dissipation film graphitization process, comprises the following steps:

[0027] Step 1: Obtain a carbonized film, send the PI film into a carbonization furnace through a boat for carbonization, and obtain a carbonized film;

[0028] Step 2: Install the furnace, send the carbonized film into the graphite furnace through the boat, and then close the furnace door;

[0029] Step 3: evacuate, and evacuate the inner cavity of the graphite furnace to a vacuum state;

[0030] Step 4: Fill inert protective gas, fill inert protective gas into the inner cavity of the graphite furnace after being evacuated, the inert protective gas is argon, the purity of argon is greater than 99.999%, during the filling process, when the air pressure in the graphite furnace When the pressure is 2-4kPa higher than the atmospheric pressure, keep the flow rate of the inert protective gas at 8-12L / min;

[0031] Step 5: First-stage temperatur...

Embodiment 2

[0037] Embodiment 2 discloses a kind of artificial graphite heat dissipation film graphitization process, comprises the following steps:

[0038] Step 1: Obtain a carbonized film, send the PI film into a carbonization furnace through a boat for carbonization, and obtain a carbonized film;

[0039] Step 2: Install the furnace, send the carbonized film into the graphite furnace through the boat, and then close the furnace door;

[0040] Step 3: evacuate, and evacuate the inner cavity of the graphite furnace to a vacuum state;

[0041] Step 4: Fill inert protective gas, fill inert protective gas into the inner cavity of the graphite furnace after being evacuated, the inert protective gas is argon, the purity of argon is greater than 99.999%, during the filling process, when the air pressure in the graphite furnace When the pressure is 2-4kPa higher than the atmospheric pressure, keep the flow rate of the inert protective gas at 8-12L / min;

[0042] Step 5: First-stage temperatur...

Embodiment 3

[0048] Embodiment 3 discloses a kind of artificial graphite heat dissipation film graphitization process, comprises the following steps:

[0049] Step 1: Obtain a carbonized film, send the PI film into a carbonization furnace through a boat for carbonization, and obtain a carbonized film;

[0050] Step 2: Install the furnace, send the carbonized film into the graphite furnace through the boat, and then close the furnace door;

[0051] Step 3: evacuate, and evacuate the inner cavity of the graphite furnace to a vacuum state;

[0052] Step 4: Fill inert protective gas, fill inert protective gas into the inner cavity of the graphite furnace after being evacuated, the inert protective gas is argon, the purity of argon is greater than 99.999%, during the filling process, when the air pressure in the graphite furnace When the pressure is 2-4kPa higher than the atmospheric pressure, keep the flow rate of the inert protective gas at 8-12L / min;

[0053] Step 5: First-stage temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com